Catalog

Material Insight: Automobile Upholstery Fabric

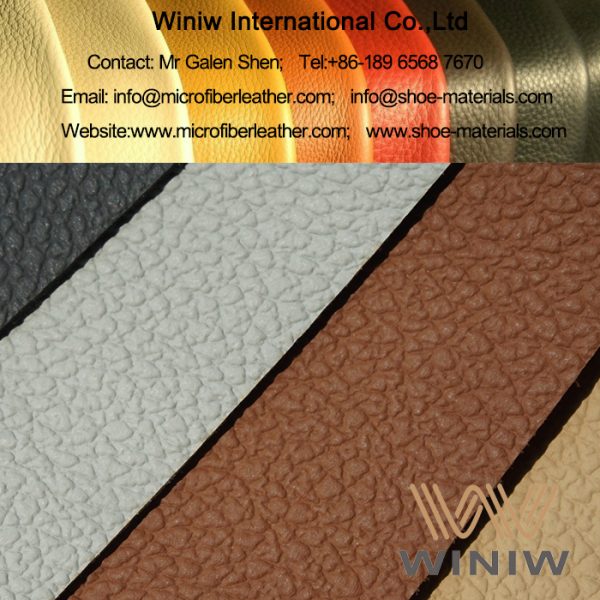

B2B Product Guide: Premium Synthetic Leather for Automobile Upholstery Fabric

Automotive upholstery demands materials that transcend basic aesthetics, requiring exceptional performance under rigorous daily use, stringent safety regulations, and evolving sustainability expectations. Unlike standard upholstery fabrics, automobile seating and interior surfaces face extreme challenges: constant friction, UV exposure, temperature fluctuations, chemical resistance needs, and uncompromising durability requirements. Selecting the right material is critical for OEMs and Tier-1 suppliers, directly impacting brand reputation, passenger satisfaction, and long-term vehicle value.

Why Premium Automotive-Grade Synthetic Leather is the Optimal Choice

– Superior Durability & Longevity: Engineered to withstand millions of abrasion cycles, intense UV radiation, and extreme temperatures (-30°C to +80°C), ensuring cabin interiors maintain integrity and appearance throughout the vehicle’s lifespan, reducing warranty claims.

– Enhanced Safety Compliance: Meets or exceeds global automotive flammability standards (FMVSS 302, ISO 3795) and low-emission requirements (VOC, fogging), critical for passenger safety and regulatory approval in all major markets.

– Consistent Quality & Design Flexibility: Offers uniform texture, color fastness, and seamless large-format production, eliminating natural leather’s inherent inconsistencies. Enables precise customization for brand-specific aesthetics, including texture, color, and embossing.

– Sustainability & Ethical Sourcing: Provides a traceable, cruelty-free alternative with significantly lower environmental impact versus conventional leather—reducing water consumption, chemical usage, and carbon footprint across the supply chain.

Introducing WINIW: Your Trusted Partner in Automotive Synthetic Leather Innovation

With over 20 years of specialized expertise in high-performance synthetic materials, WINIW has become a global leader in engineered solutions for the automotive industry. We partner exclusively with OEMs and Tier-1 suppliers to develop next-generation upholstery fabrics that meet the sector’s most demanding technical and ecological challenges. Our R&D-driven approach combines cutting-edge polymer science with deep manufacturing mastery, resulting in materials that deliver:

| Core WINIW Advantage | Impact for Automotive Partners |

|---|---|

| Advanced Eco-Technology | OEKO-TEX® STANDARD 100 certified, REACH/ELV compliant, and recyclable formulations supporting circular economy goals |

| Automotive-Grade Performance | Validated through OEM-specific testing protocols for abrasion, lightfastness, cold crack, and chemical resistance |

| End-to-End Supply Chain Control | Vertically integrated production ensuring consistent quality, traceability, and on-time delivery for JIT manufacturing |

WINIW’s commitment to sustainable innovation ensures your vehicle interiors achieve the perfect balance of luxury, resilience, and responsibility—elevating brand perception while meeting tomorrow’s regulatory landscape today. Partner with us to transform your upholstery vision into a competitive advantage.

Technical Performance & Standards

WINIW Automobile Upholstery Fabric – Technical Product Guide

WINIW’s premium automobile upholstery fabric is engineered for high-performance applications in automotive interiors, delivering a superior balance of durability, comfort, and environmental responsibility. Designed specifically for OEMs and Tier-1 suppliers, our synthetic leather solutions meet stringent global standards while supporting sustainable manufacturing goals.

The fabric is constructed using advanced polyurethane (PU) and microfiber technologies, enabling exceptional resilience under dynamic stress conditions typical in vehicle interiors. WINIW’s commitment to innovation ensures that each product batch exceeds industry benchmarks for abrasion resistance, UV stability, and chemical safety.

Key Technical Advantages:

-

Abrasion Resistant: WINIW’s upholstery fabric undergoes rigorous testing to ensure long-term durability. With a Martindale abrasion resistance rating exceeding 50,000 cycles, the material maintains surface integrity and appearance even after prolonged use, making it ideal for high-traffic seating and interior trims.

-

UV Resistant: The fabric is formulated with advanced UV stabilizers that prevent color fading, cracking, and surface degradation. It passes ISO 105-B02 and AATCC 16.3 tests for lightfastness, ensuring consistent aesthetics and performance under prolonged exposure to sunlight.

-

VOC Free: WINIW’s production process eliminates volatile organic compounds (VOCs), ensuring low emissions and improved cabin air quality. The material complies with automotive OEM requirements such as VDA 276 and ISO 12219-2, contributing to healthier interior environments.

-

REACH Compliant: The fabric is fully compliant with the EU REACH regulation (EC 1907/2006), including SVHC (Substances of Very High Concern) screening. No restricted substances are used in manufacturing, ensuring safety for end-users and alignment with global chemical regulations.

-

ISO 9001 Certified Production: WINIW’s quality management system is ISO 9001 certified, guaranteeing consistent product quality, traceability, and process control across all production stages. This ensures reliable performance and supply chain stability for B2B partners.

The following table summarizes key technical specifications of WINIW’s standard automobile upholstery fabric:

| Especificación | Test Method | Performance Value |

|---|---|---|

| Abrasion Resistance | ISO 12947-2 (Martindale) | ≥ 50,000 cycles (no break) |

| Color Fastness to Light | ISO 105-B02 | ≥ Grade 6 (after 400h Xenon exposure) |

| VOC Emissions | VDA 276 | < 10 µg/g (total VOC) |

| Hydrolysis Resistance | ISO 1419 (70°C, 95% RH) | No cracking after 500 hours |

| Tensile Strength | ISO 1421 | ≥ 80 N (warp and weft) |

| Tear Strength | ISO 13937-1 | ≥ 30 N |

| REACH SVHC Compliance | EC 1907/2006 | Fully compliant, no listed substances |

| Formaldehyde Content | EN 717-1 | < 0.01 ppm (non-detectable) |

| Density | ASTM D3776 | 380 g/m² ± 10% |

| Thickness | ISO 2589 | 1.2 mm ± 0.1 mm |

WINIW’s automobile upholstery fabric is suitable for passenger cars, commercial vehicles, and electric vehicles (EVs), where material performance and indoor air quality are critical. Our B2B solutions are customizable in texture, color, and backing structure to meet specific design and engineering requirements.

Partner with WINIW to integrate high-performance, eco-conscious synthetic leather into your next-generation vehicle interiors—engineered for excellence, verified by standards.

Why Choose Synthetic over Real Leather

B2B Product Guide: Automobile Upholstery Material Comparison

Selecting the right material for automotive interiors requires balancing performance, cost, sustainability, and brand positioning. This guide objectively compares premium synthetic leather (specifically engineered for automotive use, such as WINIW’s offerings) against traditional bovine leather for seat upholstery and trim applications.

Key Comparison: Premium Synthetic Leather vs. Bovine Leather

| Criteria | Premium Synthetic Leather (e.g., WINIW) | Bovine Leather |

|---|---|---|

| Cost | – 20-35% lower material cost vs. top-grade leather – Consistent pricing unaffected by hide scarcity or grade variation – Reduced waste during cutting (up to 15% higher yield) |

– High base cost (premium hides command 30-50% premium) – Significant price volatility due to livestock markets – 25-40% material waste due to hide irregularities |

| Durabilidad | – Superior resistance to scratches, UV fading, and abrasion (50,000+ double rubs) – Uniform thickness and performance across entire roll – Resists cracking in extreme temperatures (-30°C to 85°C) – Non-porous surface repels stains and spills |

– Prone to scratching, fading, and drying over time – Natural grain variations create weak spots – Susceptible to cracking in dry/cold climates – Requires frequent conditioning to maintain integrity |

| Eco-Friendliness | – 70% lower water consumption vs. tanning – Zero animal sourcing – WINIW options use 30-100% recycled content (PET, PU) – Greenguard Gold certified for low VOC emissions – Fully recyclable at end-of-life (closed-loop potential) |

– Tanning uses 15,000+ L water/finished hide + toxic chromium – High carbon footprint (livestock = 14.5% global GHG) – Chemical runoff contaminates waterways – Non-recyclable; landfill-bound at end-of-life |

Why Modern Synthetic Leather Aligns with Automotive Industry Shifts

- Supply Chain Resilience: Eliminates dependency on volatile hide markets and ethical concerns around livestock sourcing.

- Design Flexibility: Custom colors, textures, and thicknesses achievable without dye-lot inconsistencies.

- Regulatory Compliance: Meets stringent global VOC standards (e.g., ELV, REACH) without chemical treatments.

- Total Cost of Ownership: Lower maintenance costs (no conditioning), higher yield, and extended lifespan in high-usage vehicles (e.g., ride-sharing, fleets).

- Brand Sustainability: Directly supports ESG goals through traceable, circular material streams—critical for OEMs targeting carbon-neutral certifications.

WINIW’s premium synthetic leather delivers uncompromised luxury aesthetics while solving the ethical, environmental, and operational challenges inherent in bovine leather. For automotive partners prioritizing innovation, compliance, and lifecycle responsibility, it represents the strategic material choice for next-generation interiors. Request our technical datasheets for specific performance metrics (ASTM D4060, ISO 11640) tailored to your production requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative and sustainable materials for global B2B clients. With a strong foundation in research, production excellence, and environmental responsibility, WINIW serves markets across Europe, the USA, and beyond, delivering premium synthetic leather solutions that meet rigorous international standards.

- Operates a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry, enabling high-volume production with consistent quality and on-time delivery.

- Houses a dedicated R&D team of over 100 technical experts focused on material innovation, eco-friendly formulations, and application-specific development, ensuring cutting-edge performance and compliance with evolving global regulations.

- Implements a strict quality control (QC) system throughout the entire production cycle, from raw material inspection to finished product testing, adhering to ISO 9001 standards and undergoing regular third-party audits.

- Maintains full traceability and compliance with REACH, RoHS, and other environmental regulations, supporting sustainable supply chains for environmentally conscious brands.

- Exports to key international markets including Europe and the USA, where WINIW’s products are trusted by leading companies in automotive, furniture, apparel, and sports industries for their durability, aesthetics, and ecological profile.

WINIW’s integrated capabilities—from advanced R&D and large-scale manufacturing to rigorous quality assurance—position the company as a reliable, long-term partner for global businesses seeking high-quality, sustainable synthetic leather solutions.

Contact Us for Samples

WINIW Premium Synthetic Leather: Engineered for Automotive Excellence

WINIW delivers high-performance, sustainable microfiber leather solutions engineered specifically for demanding automobile upholstery applications. Our materials combine uncompromising durability with responsible manufacturing, meeting stringent global automotive standards while supporting your brand’s environmental commitments. Ideal for premium seating, door panels, dashboards, and steering wheels, WINIW provides the aesthetic refinement and technical reliability modern vehicles require.

Key Advantages for Automotive Manufacturers

- Superior Durability: Engineered to withstand 500,000+ double-rub cycles (Martindale test), ensuring long-term resilience against abrasion, tearing, and pilling in high-use seating areas.

- Eco-Conscious Composition: Contains up to 30% recycled polyester content; certified by OEKO-TEX® STANDARD 100 (Class I) and bluesign® for non-toxic, low-VOC emissions.

- Enhanced Comfort & Safety: Breathable structure regulates temperature, while meeting FMVSS 302 flammability standards and featuring anti-microbial treatment.

- Design Flexibility: 200+ color/microtexture options with consistent dye-lot repeatability; compatible with laser cutting, ultrasonic welding, and seamless bonding processes.

- Resource Efficiency: 40% lower water consumption and 35% reduced CO2 emissions versus conventional leather production (per ISO 14040 LCA).

Technical Specifications Comparison

| Property | WINIW Automotive Grade | Industry Standard | Test Method |

|---|---|---|---|

| Abrasion Resistance | 500,000+ cycles | 300,000 cycles | ISO 12947-2 |

| Colorfastness (Light) | Grade 7 (ISO 105-B02) | Grade 5 | ISO 105-B02 |

| Tensile Strength | ≥ 35 N/mm² | ≥ 25 N/mm² | ISO 1767 |

| VOC Emissions | < 10 µg/g | < 50 µg/g | VDA 276 |

| Recycled Content | 30% | 0–10% | GRS Certification |

Why Global Automotive Leaders Choose WINIW

- End-to-End Traceability: Blockchain-enabled supply chain transparency from raw material to finished roll.

- Regulatory Compliance: Pre-certified for EU REACH, U.S. TSCA, and China GB 18580-2017 indoor air quality standards.

- Waste Reduction: Precision-width rolls (1.37m, 1.57m) minimize cutting waste; offcuts recyclable into automotive insulation.

- Accelerated Development: Dedicated engineering support for custom formulations (e.g., enhanced UV resistance, thermoformed stability).

Request Physical Validation for Your Next Project

Experience WINIW’s precision and sustainability firsthand. We provide complimentary 30cm x 30cm samples for technical evaluation, including full compliance documentation and test reports. Contact our automotive materials team to specify requirements:

MKT88@MicrofiberLeather.com

Subject Line: “Automotive Upholstery Sample Request – [Your Company Name]”

WINIW: Where Innovation Meets Responsibility in Automotive Interiors.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.