Catalog

Material Insight: What Is Pleather Made Of

B2B Product Guide: Understanding Pleather and the Advantages of Faux Leather

What Is Pleather Made Of?

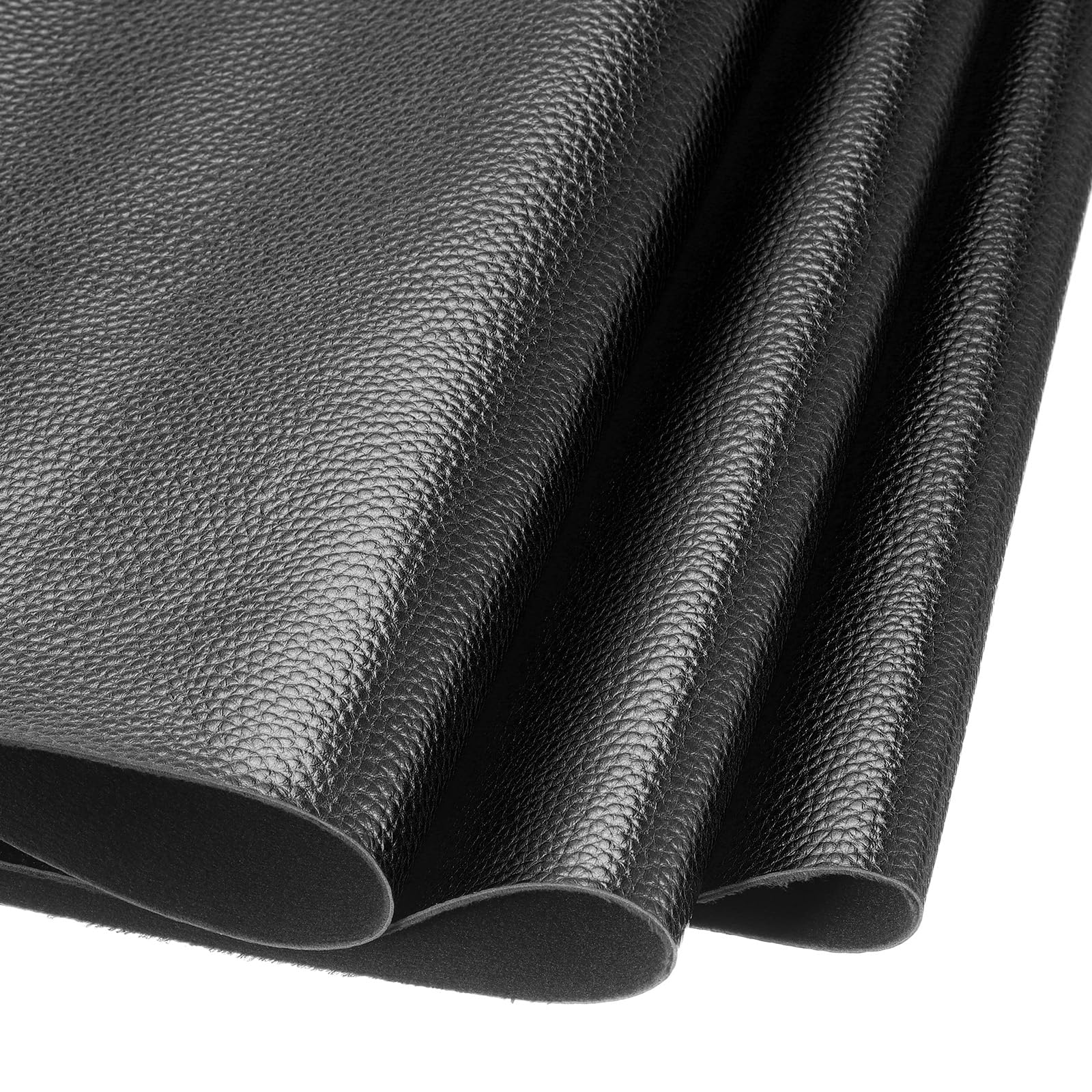

Pleather, commonly known as faux or synthetic leather, is a human-made material designed to replicate the look, feel, and durability of natural leather—without the environmental and ethical concerns associated with animal hide. At its core, pleather is typically composed of a textile backing, such as polyester or cotton, coated with a polymer layer. The most common polymers used are polyurethane (PU) and polyvinyl chloride (PVC).

- Polyurethane (PU) leather offers superior breathability, flexibility, and softness, making it ideal for high-end applications in fashion, furniture, and automotive interiors.

- PVC leather, while less breathable, provides excellent water resistance and durability, often used in outdoor and heavy-use environments.

Modern advancements have led to the development of eco-friendly variants, including water-based PU and recycled base fabrics, significantly reducing the environmental footprint of synthetic leather production.

Why Is Faux Leather the Best Choice for This Application?

Faux leather has emerged as the preferred material across industries due to its versatility, consistency, and sustainable advantages. Unlike genuine leather, which varies in quality and texture from hide to hide, faux leather delivers uniform performance and appearance—critical for large-scale manufacturing and branding consistency.

- Cost-Effective: Lower production and maintenance costs compared to animal leather.

- Ethical & Cruelty-Free: No animal byproducts involved, aligning with global sustainability and ethical sourcing standards.

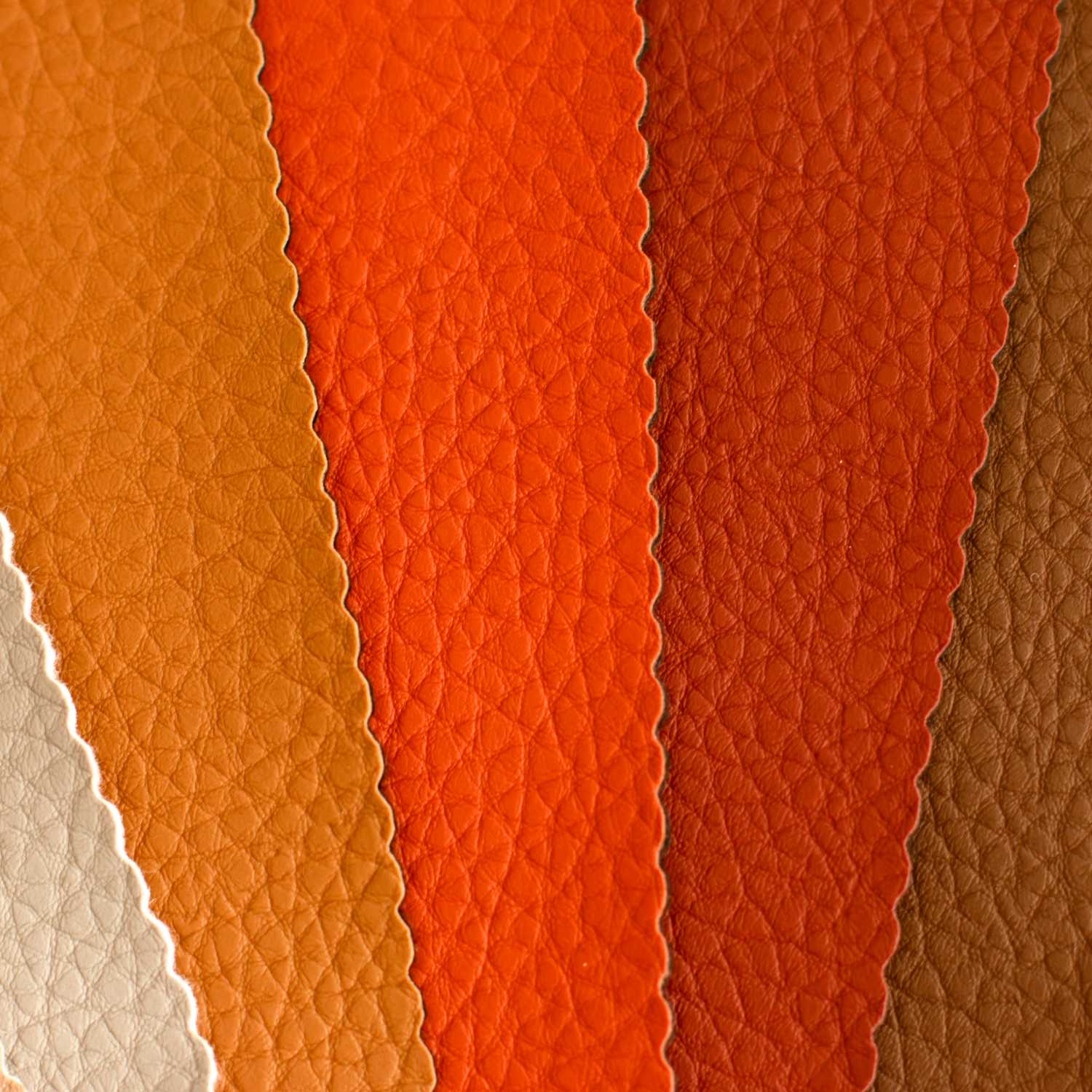

- Customizable: Available in a wide range of colors, textures, and finishes, including matte, glossy, embossed, and soft-touch.

- Durability: Resistant to fading, cracking, and staining—especially in high-performance PU formulations.

- Sustainability: Many modern faux leathers, including those from WINIW, utilize low-VOC, recyclable, and bio-based materials.

These attributes make faux leather the optimal choice for applications in upholstery, apparel, footwear, automotive interiors, and consumer electronics.

Introducing WINIW: Innovation in Synthetic Leather for Over 20 Years

WINIW has been a trusted leader in the synthetic leather industry for more than two decades, specializing in high-performance, eco-conscious faux leather solutions for global B2B clients. With a strong commitment to innovation, quality, and sustainability, WINIW serves industries ranging from automotive and furniture to fashion and sports equipment.

- 20+ years of R&D expertise in PU and eco-friendly synthetic leather technologies.

- ISO-certified manufacturing processes ensuring consistency, safety, and environmental compliance.

- Custom development capabilities—from texture and color to functional properties like abrasion resistance and UV stability.

- Partnerships with leading brands seeking durable, ethical, and scalable materials.

At WINIW, we don’t just manufacture synthetic leather—we engineer smarter, cleaner alternatives that meet the evolving demands of modern design and responsible production.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Product Guide

WINIW synthetic leather (commonly referred to as “pleather”) is engineered as a high-performance alternative to genuine leather and lower-grade synthetics. At its core, WINIW pleather is composed of a polyurethane (PU) resin base bonded to a textile substrate (typically polyester or nylon). This composition eliminates plasticizers like phthalates—common in PVC-based alternatives—ensuring inherent stability, longevity, and environmental safety. Below are the technical advantages driving adoption across furniture, automotive, and fashion supply chains.

Key Technical Advantages

- Cost-Effective Lifecycle Value: WINIW’s PU formulation requires no plasticizers, eliminating degradation risks (e.g., cracking, stickiness) seen in PVC. This extends product lifespan by 30–50% versus conventional synthetics, reducing replacement frequency and total cost of ownership.

- Enhanced Durability: Engineered with cross-linked PU polymers, WINIW leather achieves 100,000+ double-rub abrasion resistance (Martindale test) and 500+ kPa tensile strength. Resists UV fading, hydrolysis, and chemical exposure (e.g., oils, cleaners), critical for automotive and contract furniture.

- Precision Color Customization: Full integration of pigments into the PU matrix enables Pantone®-matched consistency across 5,000+ shades. Unlike surface-dyed alternatives, color remains uniform through wear, with ΔE <1.0 (industry standard: ΔE <2.0).

- REACH Compliance Guaranteed: All formulations exclude SVHCs (Substances of Very High Concern) per EU REACH Annex XIV/XVII. Independent lab reports verify <0.1 ppm heavy metals (Cd, Pb, Hg) and zero phthalates—ensuring seamless market access in EU/US/Asia.

- ISO 9001-Certified Consistency: Rigorous process control from resin synthesis to finishing guarantees batch-to-batch uniformity in thickness, color, and physical properties. Traceability systems meet automotive Tier-1 supplier requirements.

Technical Specifications Overview

| Parámetro | WINIW Standard Specification | Industry Benchmark | Significance |

|---|---|---|---|

| Material Base | 100% Plasticizer-Free PU | PVC/PU Blends | Eliminates degradation; eco-safe |

| Thickness Range | 0.6–2.0 mm | 0.8–1.5 mm | Enables lightweight yet robust designs |

| Abrasion Resistance | ≥100,000 double-rubs | 50,000–80,000 | 2x lifespan in high-traffic use |

| Color Fastness | ISO 105-B02: Grade 5 | Grade 3–4 | No fading under UV/chemical exposure |

| REACH Status | Fully Compliant (SVHC-free) | Often Non-Compliant | Avoids import barriers; brand safety |

| Tensile Strength | ≥500 kPa | 300–400 kPa | Resists tearing during fabrication |

| Certifications | ISO 9001, OEKO-TEX® Standard 100 | Varies | Ensures quality/reliability |

WINIW’s technical rigor transforms synthetic leather from a cost-driven substitute into a value-engineered material. By prioritizing molecular stability, regulatory alignment, and precision manufacturing, we deliver solutions that reduce environmental liability while meeting the most demanding performance criteria. Partner with WINIW to specify synthetic leather that performs—without compromise.

Why Choose Synthetic over Real Leather

B2B Product Guide: Pleather vs. Real Leather – Material Composition, Performance, and Sustainability

In the modern manufacturing and design landscape, selecting the right leather alternative or material is critical for product performance, cost-efficiency, and environmental responsibility. Two widely used materials—pleather and real leather—offer distinct advantages and trade-offs. Understanding their composition, along with comparative metrics in cost, durability, and eco-friendliness, enables brands to make informed, sustainable sourcing decisions.

Composition Overview

-

Pleather (Synthetic Leather)

Pleather is a man-made material primarily composed of a plastic base, typically polyurethane (PU) or polyvinyl chloride (PVC), coated onto a fabric backing such as polyester or cotton. At WINIW, we specialize in high-performance PU-based synthetic leathers engineered for breathability, softness, and long-term durability. Our formulations eliminate the use of PVC, reducing environmental impact while maintaining superior tactile and mechanical properties. -

Real Leather

Real leather is derived from animal hides, most commonly bovine, ovine, or porcine sources. The raw hide undergoes a tanning process—either chrome tanning (using chromium salts) or vegetable tanning (using natural tannins)—to preserve and stabilize the material. While valued for its natural grain and aging characteristics, real leather production involves significant resource inputs, including water, energy, and chemicals.

Comparative Analysis: Cost, Durability, and Eco-Friendliness

| Metric | Pleather (PU-based) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher cost due to raw material and processing |

| Durabilidad | High resistance to cracking and fading; lifespan of 3–5 years with proper care | Long lifespan (5–15+ years); develops patina but prone to drying and staining |

| Eco-Friendliness | PVC-free PU pleather is recyclable and lowers carbon footprint; water-based production reduces emissions | High environmental cost: land use, greenhouse gas emissions, and toxic runoff from tanneries |

Key Considerations for B2B Buyers

- Supply Chain Stability: Pleather offers consistent texture, color, and thickness across batches, enabling streamlined production. Real leather varies naturally, requiring additional sorting and quality control.

- Customization: Synthetic leathers like WINIW’s can be engineered for specific performance needs—water resistance, UV stability, softness—without compromising sustainability.

- Sustainability Goals: Brands committed to reducing animal-derived materials and minimizing environmental impact increasingly adopt advanced PU pleathers. WINIW’s eco-conscious production aligns with global standards, including REACH and OEKO-TEX® certifications.

- End-of-Life Impact: PVC-based pleather is not biodegradable and poses recycling challenges. WINIW’s PVC-free, water-based PU leather supports circular economy initiatives through safer disposal and recyclability.

Conclusion

While real leather remains valued for its traditional appeal and longevity, pleather—particularly high-grade PU synthetic leather—offers a cost-effective, customizable, and increasingly sustainable alternative. For forward-thinking B2B partners in fashion, furniture, automotive, and accessories, choosing advanced pleather solutions supports both performance objectives and environmental responsibility.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global Excellence

WINIW stands as a leader in high-performance synthetic leather manufacturing, delivering sustainable, premium materials trusted by global brands. Our vertically integrated operations combine cutting-edge innovation with rigorous quality assurance, ensuring products meet the exacting standards of international markets. Below, we detail the foundational strengths driving our reliability as your strategic B2B partner.

Unmatched Manufacturing Capacity & Infrastructure

Our state-of-the-art facility spans 100,000 square meters in Wenzhou, China, representing one of the largest dedicated synthetic leather production ecosystems in Asia. This scale enables agile, high-volume output without compromising on precision or sustainability. Key advantages include:

– Full control over the entire production chain, from resin formulation to finishing.

– Dedicated zones for eco-friendly water-based PU/PE/PVC processing, minimizing environmental impact.

– Advanced automation for consistent texture, color, and thickness across all batches.

– Strategic inventory management to ensure on-time delivery for large-scale orders.

Innovation-Driven R&D Excellence

WINIW’s competitive edge is powered by a 40+ member R&D team, including material scientists and chemical engineers with advanced degrees. We invest 8% of annual revenue into research, focusing on:

– Developing next-generation bio-based and recycled-content materials (e.g., 30%+ PCR content options).

– Enhancing performance properties: abrasion resistance, UV stability, and breathability for automotive, footwear, and upholstery.

– Accelerating time-to-market with rapid prototyping and client co-development programs.

– Achieving certifications like OEKO-TEX® STANDARD 100 and REACH compliance through rigorous material screening.

Zero-Compromise Quality Control System

Every meter of WINIW leather undergoes 17+ inspection stages, enforced by our ISO 9001-certified quality management system. Our QC protocol ensures:

– Real-time monitoring of critical parameters (thickness, tensile strength, color fastness) via AI-assisted inline sensors.

– Third-party lab validation for chemical safety (e.g., CPSIA, Prop 65) and physical performance.

– Traceability from raw material lot to finished roll through blockchain-enabled systems.

– <0.5% defect rate across all production lines, exceeding industry benchmarks.

Proven Global Market Access

WINIW exports to 50+ countries, with 65% of annual volume shipped to EU and USA clients. Our compliance infrastructure guarantees seamless market entry:

– Full adherence to EU REACH, US CPSIA, and California Prop 65 chemical restrictions.

– Dedicated regulatory team managing evolving standards (e.g., EU Green Deal, TSCA).

– Logistics partnerships enabling carbon-neutral shipping options for transoceanic orders.

– Long-term contracts with Tier-1 automotive and luxury fashion brands, validating our quality consistency.

By integrating massive-scale production with uncompromising eco-innovation and quality governance, WINIW delivers synthetic leather that meets both performance demands and sustainability commitments. Partner with us to secure a resilient, future-proof material supply chain. Contact our B2B solutions team to discuss custom specifications or request certified sample kits.

Contact Us for Samples

B2B Product Guide: Understanding Pleather – Sustainable Synthetic Leather Solutions by WINIW

WINIW specializes in high-performance, eco-conscious synthetic leather for global B2B clients across furniture, automotive, fashion, and interior design industries. Our pleather materials combine durability, aesthetic versatility, and environmental responsibility—engineered to meet the demands of modern manufacturing without compromising on quality.

Pleather, often used interchangeably with synthetic leather, refers to a category of materials designed to replicate the look and feel of genuine leather. At WINIW, our pleather is primarily crafted from premium microfiber and PU (polyurethane) polymers, offering a sustainable alternative to animal hides and traditional PVC-based leathers.

Key benefits of WINIW pleather:

– 100% animal-free and cruelty-free production

– Low environmental impact with reduced carbon footprint

– High resistance to abrasion, UV light, and staining

– Customizable textures, colors, and finishes

– Breathable, soft, and lightweight composition

– Compliant with global environmental standards (REACH, RoHS, OEKO-TEX®)

Our advanced manufacturing process ensures consistent roll-to-roll quality, making WINIW pleather ideal for high-volume production and precision applications.

What Is Pleather Made Of?

Pleather is typically composed of a fabric backing—often polyester or cotton—coated with a polymer layer. At WINIW, we use:

– Microfiber base: Made from ultra-fine synthetic fibers (typically 0.5–1.0 denier), providing strength, flexibility, and a leather-like drape.

– PU (Polyurethane) coating: A non-toxic, eco-friendly polymer that delivers softness, durability, and resistance to wear.

– Water-based finishing technologies: Reduce VOC emissions and support sustainable production.

Unlike outdated PVC leather, WINIW pleather avoids chlorine-based chemicals and offers superior breathability and biodegradability under industrial conditions.

| Feature | WINIW Pleather | Traditional PVC Leather |

|---|---|---|

| Base Material | Microfibra + PU | Plastic (PVC) + fabric |

| Environmental Impact | Low (water-based) | High (chlorine-based) |

| Breathability | Alta | Low |

| Durabilidad | Excellent | Moderate |

| Customization Options | Extensive | Limited |

WINIW is committed to innovation and sustainability in every square meter we produce. Our pleather solutions support eco-certified supply chains and align with ESG goals for forward-thinking brands.

Request Free Samples

Experience the quality and versatility of WINIW pleather firsthand. Free samples are available for qualified B2B partners.

For more information on what is pleather made of and how our materials can enhance your product line, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.