Introduction: Navigating the Global Market for vinyl leatherette fabric

In the dynamic landscape of global commerce, sourcing high-quality vinyl leatherette fabric poses a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek durable and aesthetically pleasing materials for diverse applications—ranging from furniture upholstery to automotive interiors—understanding the nuances of vinyl leatherette becomes paramount. This guide delves into the myriad types of vinyl leatherette fabrics available, their various applications, and essential considerations for supplier vetting.

B2B buyers will find valuable insights on cost structures, performance features, and sustainability considerations that influence purchasing decisions. With the growing demand for eco-friendly materials and innovative design, knowing how to identify reliable suppliers and navigate pricing models is critical for success. This comprehensive resource empowers decision-makers to make informed selections that align with their project requirements, ensuring they achieve both quality and value.

By addressing key questions about the types of vinyl leatherette, their performance characteristics, and optimal sourcing strategies, this guide serves as an indispensable tool for businesses aiming to thrive in competitive markets. Whether you’re in Brazil, Nigeria, or anywhere in between, understanding the global market for vinyl leatherette fabric will enhance your procurement strategies and drive your business forward.

Table Of Contents

- Top 7 Vinyl Leatherette Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vinyl leatherette fabric

- Understanding vinyl leatherette fabric Types and Variations

- Key Industrial Applications of vinyl leatherette fabric

- 3 Common User Pain Points for ‘vinyl leatherette fabric’ & Their Solutions

- Strategic Material Selection Guide for vinyl leatherette fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for vinyl leatherette fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vinyl leatherette fabric’

- Comprehensive Cost and Pricing Analysis for vinyl leatherette fabric Sourcing

- Alternatives Analysis: Comparing vinyl leatherette fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for vinyl leatherette fabric

- Navigating Market Dynamics and Sourcing Trends in the vinyl leatherette fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vinyl leatherette fabric

- Strategic Sourcing Conclusion and Outlook for vinyl leatherette fabric

- Important Disclaimer & Terms of Use

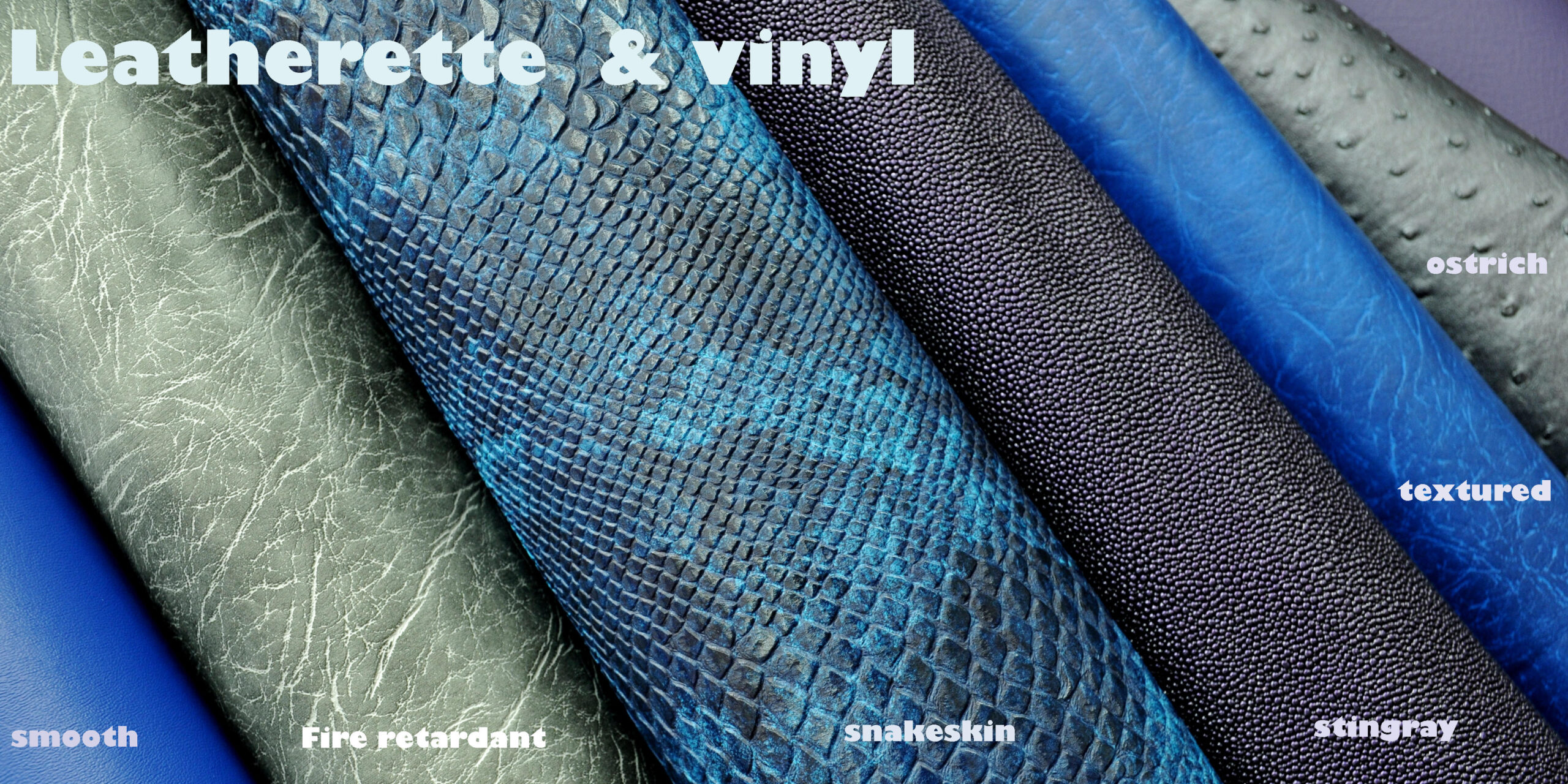

Understanding vinyl leatherette fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cuero PU | Soft, supple texture; resembles genuine leather closely | Furniture upholstery, automotive interiors, apparel | Pros: Cost-effective, easy to clean; Cons: May not be as durable as PVC in heavy-use scenarios. |

| PVC Vinyl | Stiffer feel; highly water-resistant; durable | Marine upholstery, outdoor furniture, commercial settings | Pros: Excellent durability, low maintenance; Cons: Less breathable, can feel less luxurious. |

| Eco-friendly Vinyl | Made from recycled materials; lower environmental impact | Sustainable furniture lines, eco-conscious brands | Pros: Sustainable choice; Cons: May have limited color options compared to traditional vinyl. |

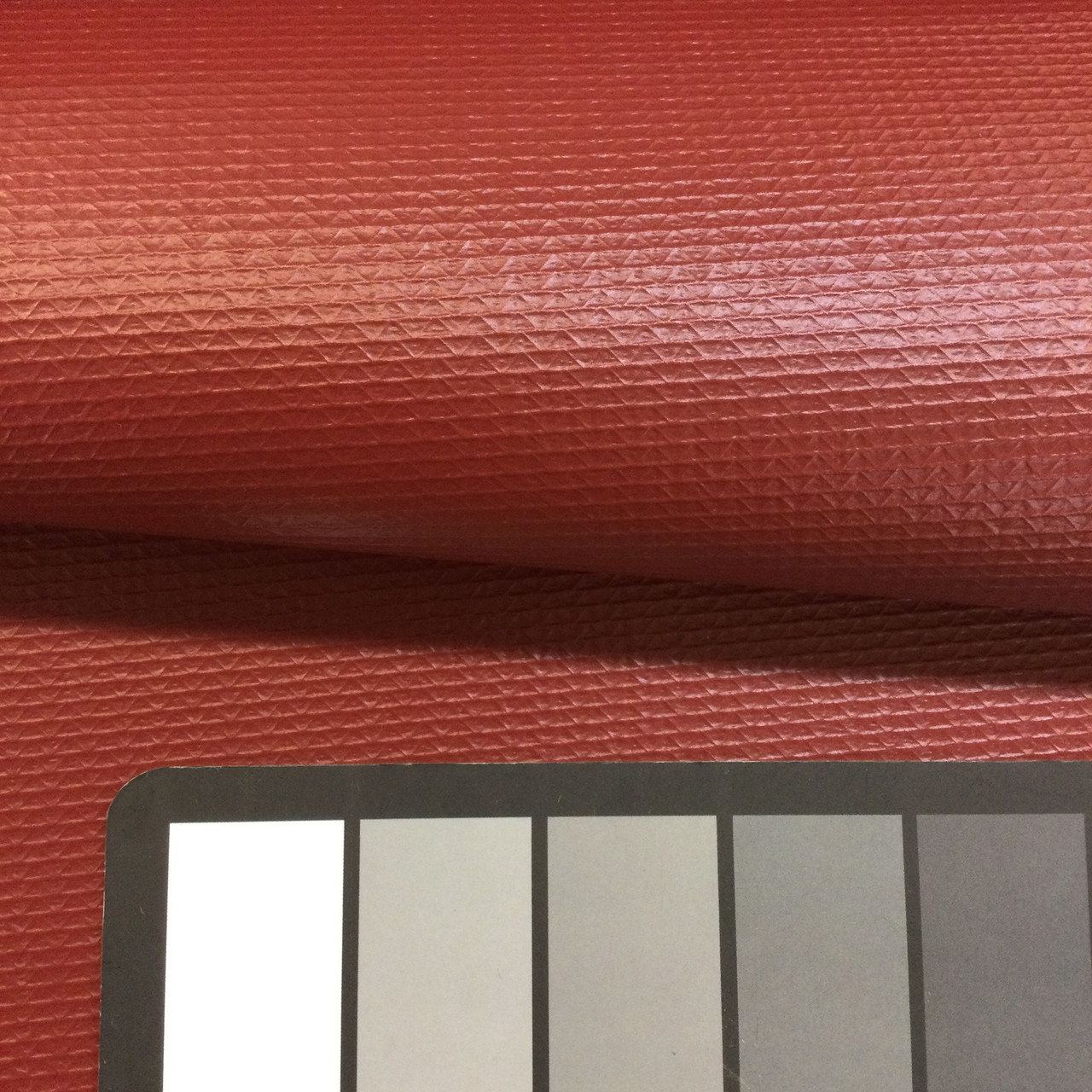

| Textured Vinyl | Embossed patterns for aesthetic appeal | High-end furniture, fashion accessories | Pros: Enhances visual appeal; Cons: Can be more expensive than standard vinyl. |

| Stretch Vinyl | 4-way stretch capabilities; flexible | Automotive seats, sports gear, fitted furniture | Pros: Great for form-fitting applications; Cons: May require specialized sewing techniques. |

What are the Characteristics of PU Leather?

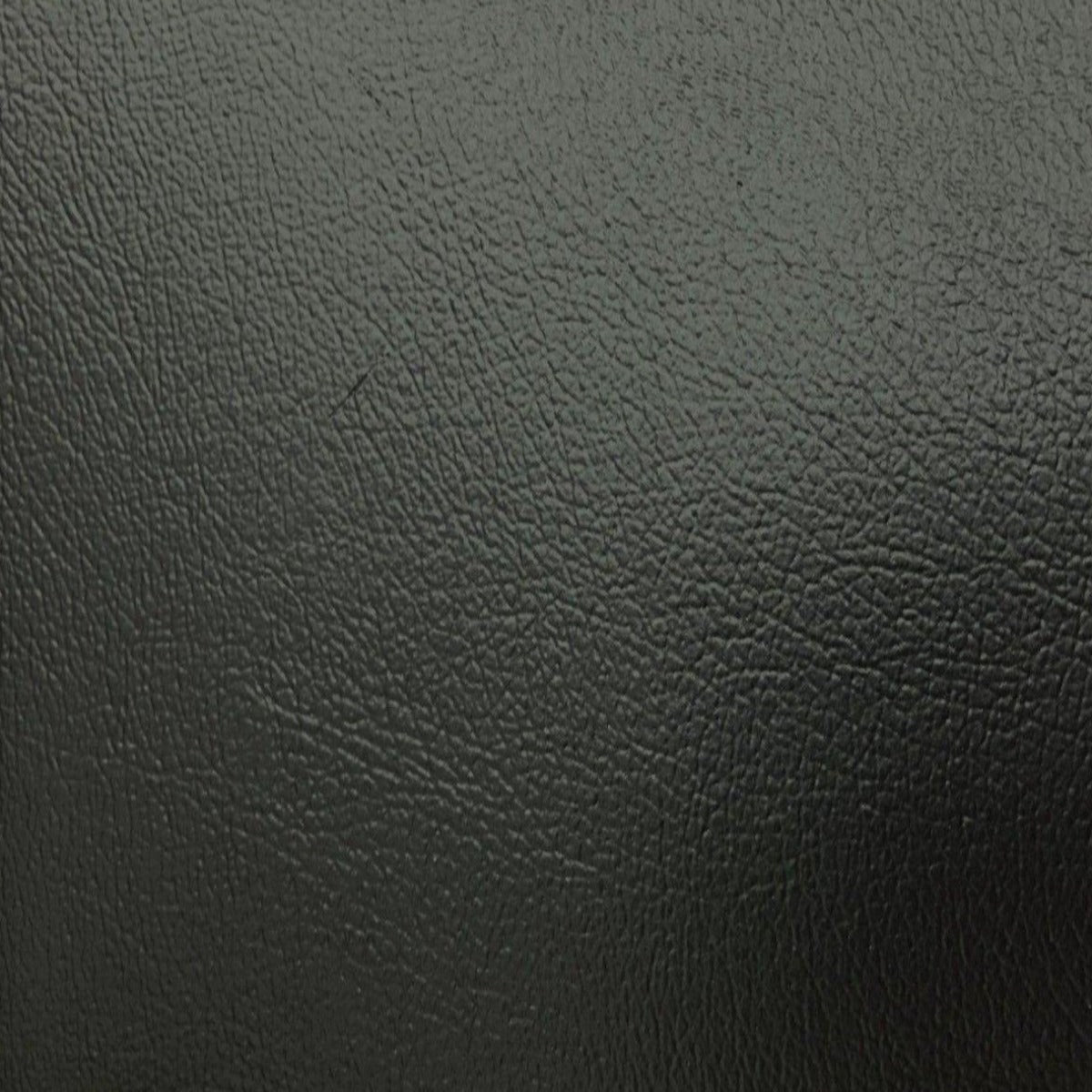

Polyurethane leather, or PU leather, is a synthetic alternative that closely mimics the texture and appearance of real leather. It is known for its softness and flexibility, making it suitable for a wide range of applications including furniture upholstery and automotive interiors. When considering PU leather for B2B purchases, buyers should focus on its cleaning ease and affordability, as it can be significantly less expensive than genuine leather. However, it may not withstand heavy use as effectively as other options like PVC.

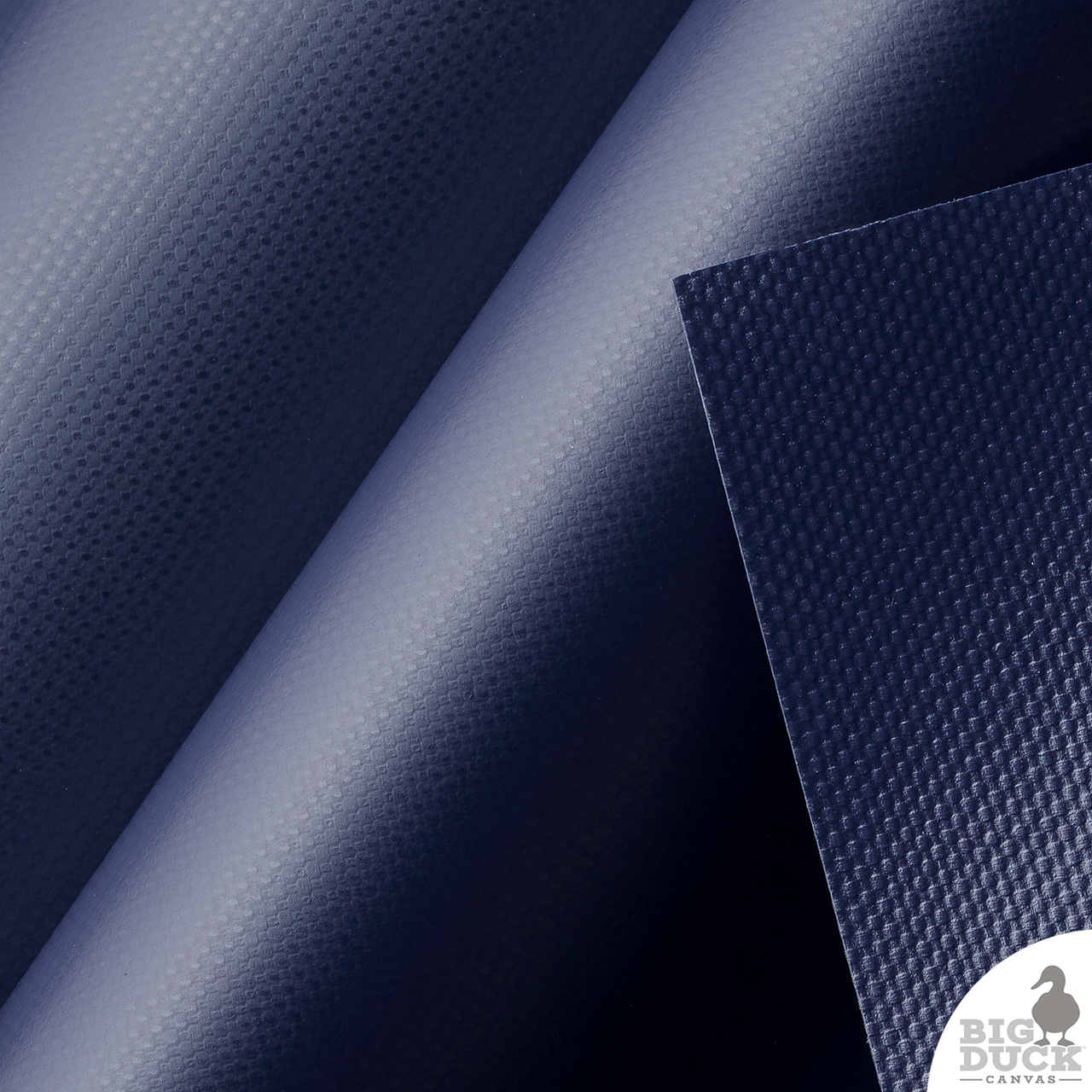

How Does PVC Vinyl Stand Out?

Polyvinyl chloride (PVC) vinyl is distinguished by its durability and water resistance, making it ideal for environments exposed to moisture, such as marine and outdoor furniture applications. Its stiffer texture offers a robust solution for commercial settings, where longevity is crucial. B2B buyers should weigh its low maintenance requirements against its less luxurious feel, which may not appeal to all consumer segments.

What Makes Eco-friendly Vinyl a Smart Choice?

Eco-friendly vinyl is crafted from recycled materials, appealing to brands focusing on sustainability. This type of vinyl can serve well in environmentally conscious furniture lines and other applications where brand image is tied to eco-friendliness. While it presents a sustainable option, B2B buyers must consider potential limitations in color variety compared to traditional vinyl.

Why Choose Textured Vinyl for Aesthetic Appeal?

Textured vinyl features embossed patterns that add visual interest, making it suitable for high-end furniture and fashion accessories. This variation can elevate the perceived quality of products, appealing to a market segment that values aesthetics. However, B2B buyers should be prepared for a higher price point, which may not align with budget constraints for all projects.

When is Stretch Vinyl the Best Option?

Stretch vinyl offers 4-way stretch capabilities, making it an excellent choice for applications requiring flexibility, such as automotive seats or fitted furniture. Its adaptability allows for creative designs and comfort, particularly in sports gear. Buyers should consider the need for specialized sewing techniques when selecting this option, as it may require additional investment in training or equipment.

Key Industrial Applications of vinyl leatherette fabric

| Industry/Sector | Specific Application of vinyl leatherette fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for residential and commercial furniture | Durable, easy-to-clean surfaces that enhance aesthetics | Ensure availability of a variety of colors and textures |

| Automotive Industry | Interior seating and trim materials | Cost-effective alternative to genuine leather | Compliance with safety and durability standards |

| Marine Industry | Upholstery for boat interiors and exterior cushions | Water-resistant and mildew-resistant options | Consider UV resistance and ease of maintenance |

| Hospitality and Healthcare | Upholstery for chairs and booths in restaurants and clinics | Long-lasting, hygienic surfaces that are easy to clean | Look for antimicrobial treatments and heavy-duty options |

| Outdoor Furniture and Equipment | Upholstery for patio and poolside furniture | Weather-resistant and easy to maintain | Assess colorfastness and resistance to fading and cracking |

How is Vinyl Leatherette Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, vinyl leatherette fabric is extensively utilized for both residential and commercial upholstery. This material provides a durable and aesthetically pleasing surface that is easy to clean, addressing common issues related to wear and tear, especially in high-traffic areas. International buyers from regions like Africa and South America should prioritize sourcing options that offer a diverse palette of colors and textures to meet varying design preferences while ensuring the fabric can withstand the rigors of daily use.

What Role Does Vinyl Leatherette Play in the Automotive Industry?

The automotive industry uses vinyl leatherette fabric for interior seating and trim, offering a cost-effective alternative to genuine leather without compromising on style or durability. This material is particularly advantageous for manufacturers looking to reduce costs while maintaining high-quality interiors. Buyers should consider sourcing fabrics that comply with safety and durability standards, ensuring they meet the demands of both local regulations and customer expectations in diverse markets like the Middle East and Europe.

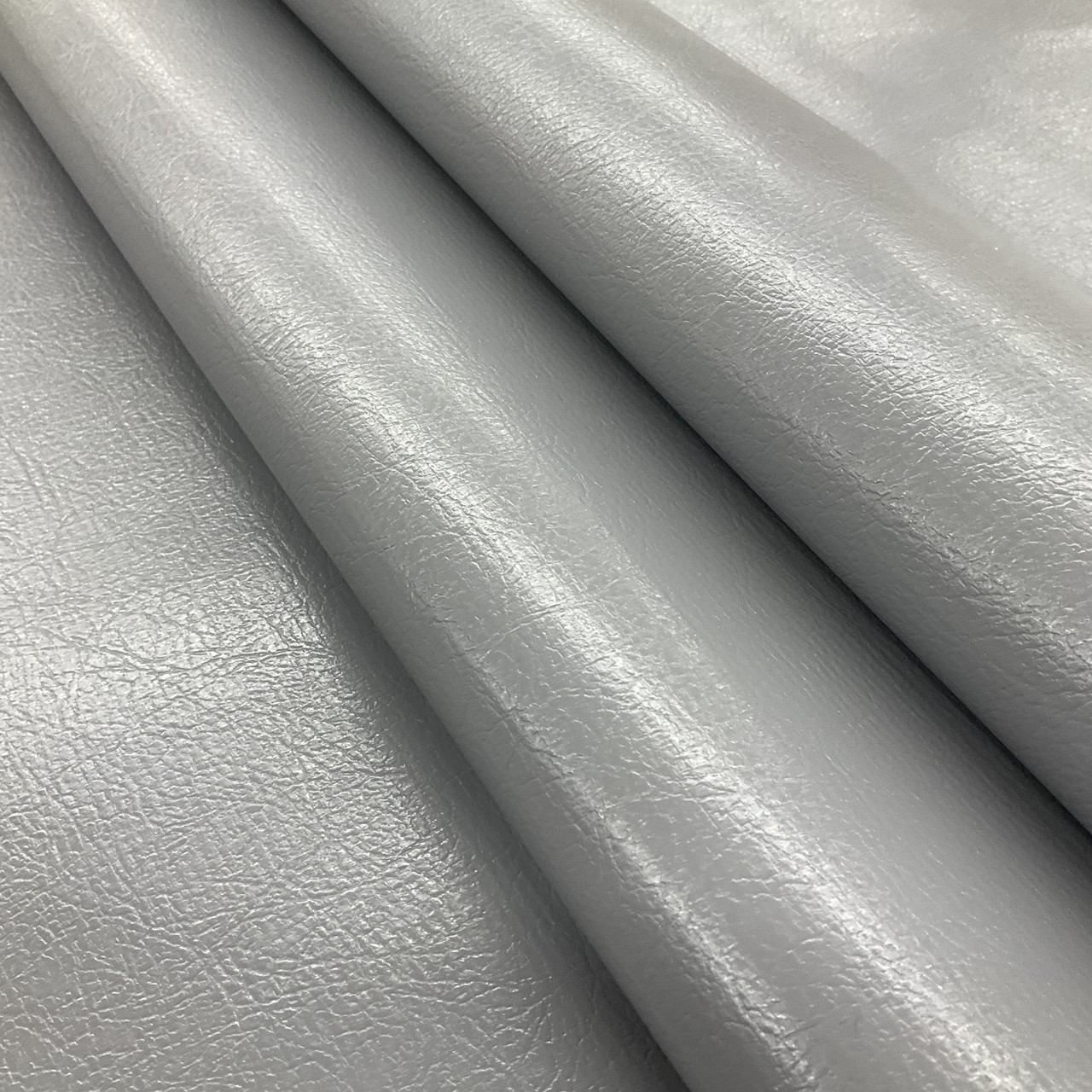

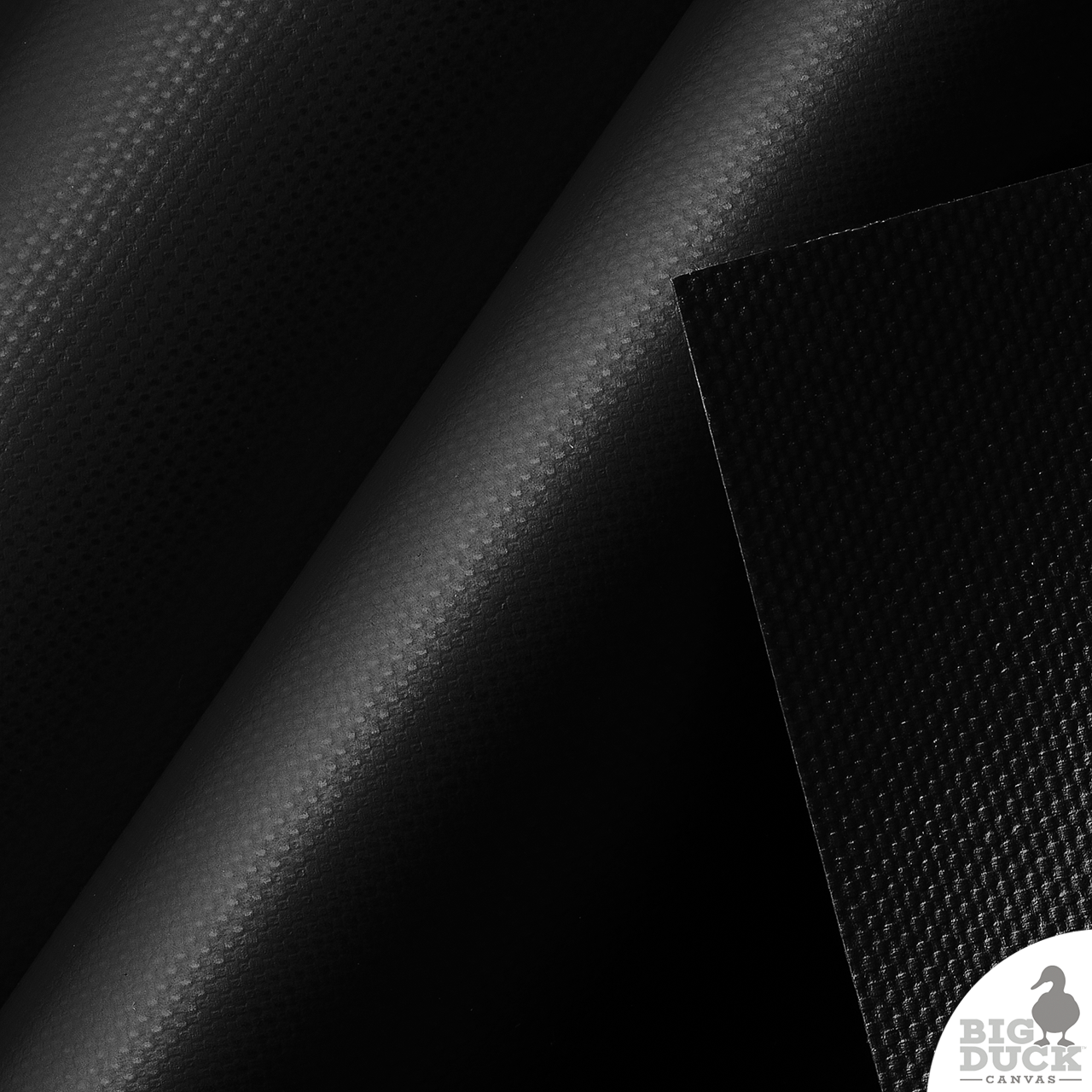

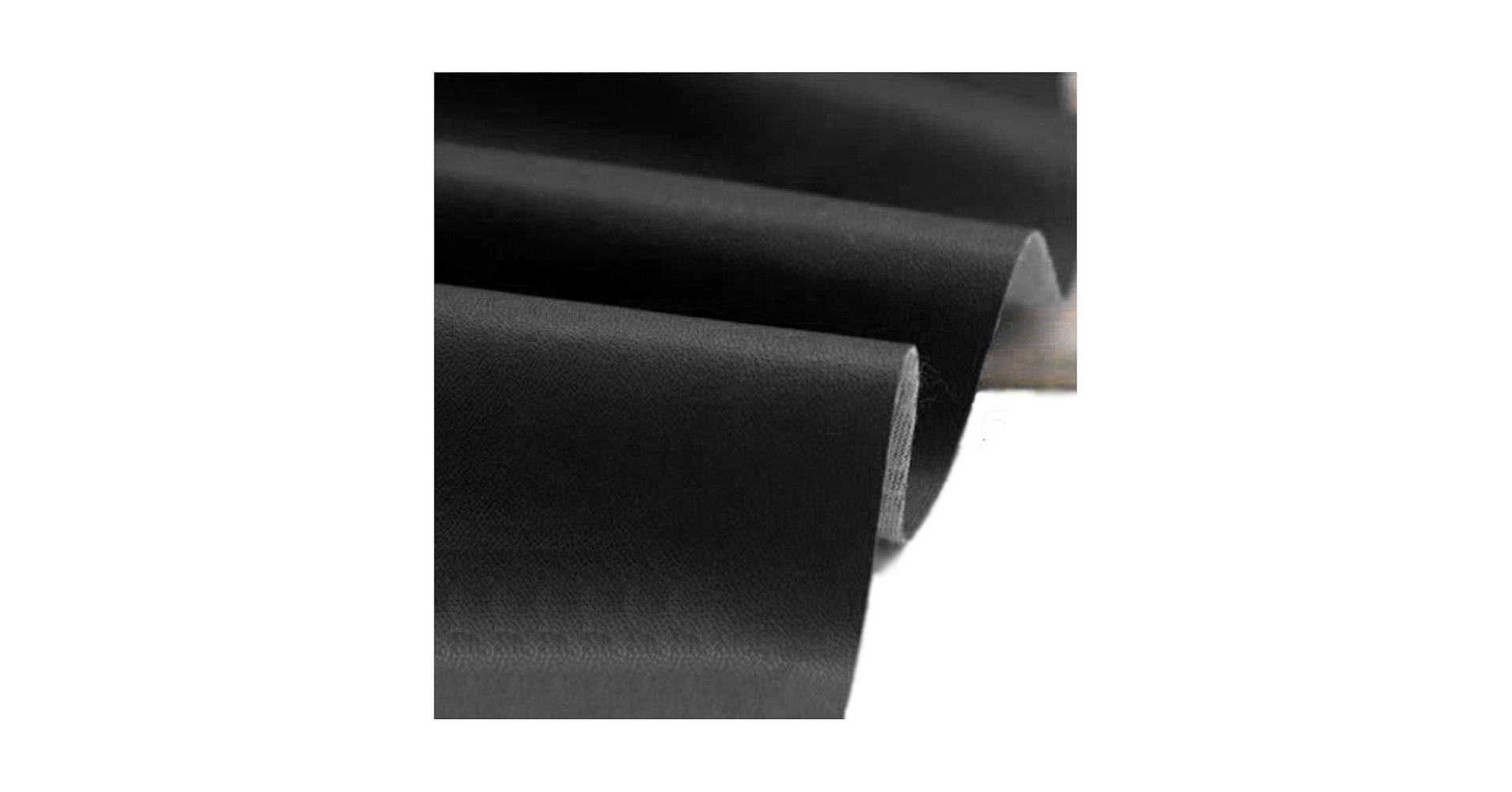

Illustrative image related to vinyl leatherette fabric

Why is Vinyl Leatherette Important for the Marine Industry?

In the marine industry, vinyl leatherette fabric is favored for its water-resistant and mildew-resistant properties, making it ideal for boat interiors and exterior cushions. This material not only enhances the aesthetic appeal of marine vessels but also solves the problem of moisture-related damage, which is crucial for longevity in marine environments. Buyers should evaluate options that provide UV resistance and ease of maintenance to ensure that the upholstery remains functional and visually appealing over time.

How is Vinyl Leatherette Used in Hospitality and Healthcare?

In the hospitality and healthcare sectors, vinyl leatherette fabric is employed for upholstery on chairs and booths, providing long-lasting surfaces that are easy to clean and maintain. This is particularly important in environments that require high hygiene standards, such as hospitals and restaurants. Buyers should look for fabrics that come with antimicrobial treatments and heavy-duty options, ensuring they can withstand frequent cleaning without compromising their appearance or integrity.

What Benefits Does Vinyl Leatherette Offer for Outdoor Furniture?

For outdoor furniture and equipment, vinyl leatherette fabric serves as an excellent upholstery option due to its weather-resistant properties. This material is designed to withstand exposure to the elements, making it suitable for patio and poolside furniture. When sourcing vinyl leatherette for outdoor applications, it is essential to assess the fabric’s colorfastness and resistance to fading and cracking, ensuring that the investment remains visually appealing and functional over time.

3 Common User Pain Points for ‘vinyl leatherette fabric’ & Their Solutions

Scenario 1: Navigating Quality Discrepancies in Vinyl Leatherette Fabric

The Problem: B2B buyers often face challenges in ensuring the quality of vinyl leatherette fabric from suppliers, especially when sourcing from international markets. Variability in material quality can lead to inconsistencies in product performance, such as durability and appearance. This is particularly frustrating for businesses that rely on a consistent aesthetic and functional performance for their upholstery projects. Poor quality fabric can lead to increased returns, unhappy customers, and wasted resources.

The Solution: To mitigate quality discrepancies, buyers should implement a robust vetting process for suppliers. This includes requesting samples before committing to large orders to evaluate the fabric’s texture, color consistency, and performance features like stain resistance or water repellency. Additionally, seeking out suppliers who provide detailed product specifications and certifications can help ensure the fabric meets industry standards. Establishing long-term relationships with reputable suppliers can also provide a more reliable source of quality materials over time. Engaging in regular quality checks and maintaining open lines of communication with suppliers will further safeguard against discrepancies.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: International B2B buyers frequently encounter inventory management issues due to unpredictable supply chain disruptions. Fluctuations in demand, shipping delays, and customs regulations can lead to either excess inventory or stockouts, impacting project timelines and customer satisfaction. Such challenges are particularly pronounced in regions with less stable logistics networks.

The Solution: To effectively manage inventory, buyers should adopt a just-in-time (JIT) inventory approach, which allows for the procurement of materials closer to the time they are needed. This minimizes excess stock and reduces storage costs. Collaborating with multiple suppliers can also provide a safety net against supply chain disruptions. Implementing inventory management software can help track stock levels in real time, forecast demand, and automate reordering processes. Establishing strong relationships with logistics providers can also enhance the reliability of shipping timelines, ensuring that materials arrive as needed.

Illustrative image related to vinyl leatherette fabric

Scenario 3: Understanding the Environmental Impact of Vinyl Leatherette Fabric

The Problem: As sustainability becomes a priority for many businesses, B2B buyers are increasingly concerned about the environmental impact of the materials they source, including vinyl leatherette fabric. The production processes and the materials used can raise questions about sustainability and eco-friendliness, which can affect a company’s brand reputation and compliance with regulations.

The Solution: Buyers should prioritize sourcing vinyl leatherette fabrics that are labeled as eco-friendly or sustainable. This includes materials made from recycled plastics or those that use environmentally safe manufacturing processes. Engaging with suppliers who are transparent about their sourcing and production practices can help buyers make informed decisions. Furthermore, conducting research on certifications such as OEKO-TEX or GRS (Global Recycled Standard) can ensure that the materials meet sustainability criteria. Buyers can also consider implementing a lifecycle analysis to evaluate the environmental impact of their fabric choices, which can help align their sourcing strategies with their sustainability goals.

Strategic Material Selection Guide for vinyl leatherette fabric

What Are the Key Materials Used in Vinyl Leatherette Fabric?

When selecting vinyl leatherette fabric for various applications, understanding the properties and characteristics of the materials involved is crucial. Below, we analyze four common materials used in the production of vinyl leatherette fabric, focusing on their performance, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to vinyl leatherette fabric

1. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used polymer known for its durability and resistance to moisture and chemicals. It can withstand a temperature range of -10°C to 60°C, making it suitable for various environments. Its inherent resistance to corrosion makes it ideal for applications exposed to harsh conditions.

Pros & Cons:

PVC is cost-effective and readily available, making it an attractive option for bulk purchases. However, it can be less flexible than other materials, which may limit its use in applications requiring a more supple fabric. Additionally, while PVC is durable, it may not have the same aesthetic appeal as higher-end alternatives.

Impact on Application:

PVC is commonly used in commercial upholstery, automotive interiors, and marine applications due to its water-resistant properties. However, it may not be suitable for high-end residential furniture where aesthetics are a priority.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local regulations regarding PVC usage, as some countries have restrictions due to environmental concerns. Familiarity with ASTM standards for PVC can be beneficial.

Illustrative image related to vinyl leatherette fabric

2. Polyurethane (PU)

Key Properties:

PU leather, a type of synthetic leather, offers a soft texture and flexibility that closely mimics genuine leather. It has excellent abrasion resistance and can endure temperatures from -30°C to 80°C, making it versatile for various applications.

Pros & Cons:

The primary advantage of PU is its leather-like appearance and feel, which enhances product appeal. It is also more environmentally friendly than PVC. However, PU can be more expensive and may require specific cleaning and maintenance to preserve its appearance over time.

Impact on Application:

PU is ideal for high-end furniture, fashion accessories, and automotive interiors where aesthetics and comfort are paramount. Its water resistance also makes it suitable for outdoor applications.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards for PU across different regions. Compliance with international standards such as JIS or DIN can help ensure product quality and performance.

3. Polyester

Key Properties:

Polyester is known for its strength and resistance to stretching and shrinking. It can withstand temperatures up to 100°C and is often blended with other materials to enhance durability and texture.

Illustrative image related to vinyl leatherette fabric

Pros & Cons:

Polyester is relatively inexpensive and offers good color retention, making it a popular choice for a wide range of applications. However, it may not provide the same level of water resistance as PVC or PU, which could be a drawback in specific environments.

Impact on Application:

This material is commonly used in upholstery for residential furniture and commercial settings. Its ability to hold vibrant colors makes it suitable for fashion applications as well.

Considerations for International Buyers:

When sourcing polyester-based vinyl leatherette, buyers should check for compliance with local textile standards. Understanding the regional preferences for fabric texture and durability can also influence purchasing decisions.

Illustrative image related to vinyl leatherette fabric

4. Nylon

Key Properties:

Nylon is a synthetic polymer known for its exceptional strength and elasticity. It can handle high temperatures (up to 120°C) and is resistant to abrasion, making it suitable for demanding applications.

Pros & Cons:

The primary advantage of nylon is its durability, which makes it ideal for high-traffic areas. However, it can be more expensive than other materials, and its moisture absorption can lead to issues in humid environments.

Impact on Application:

Nylon is often used in commercial upholstery and automotive applications where durability is critical. Its strength makes it suitable for outdoor furniture as well.

Considerations for International Buyers:

Buyers should be aware of the specific standards applicable to nylon in their regions, especially in Europe, where stringent regulations may apply. Understanding the local market demand for durability and performance can guide material selection.

Summary Table

| Material | Typical Use Case for vinyl leatherette fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Commercial upholstery, automotive interiors | Cost-effective and widely available | Less flexible, aesthetic limitations | Low |

| PU | High-end furniture, fashion accessories | Leather-like appearance and feel | More expensive, requires maintenance | Alta |

| Polyester | Residential and commercial upholstery | Good color retention | Lower water resistance | Medium |

| Nylon | Commercial upholstery, outdoor furniture | Exceptional durability | Higher cost, moisture absorption issues | Alta |

This guide equips international B2B buyers with essential insights into the materials used in vinyl leatherette fabric, enabling informed purchasing decisions that align with their specific application needs and regional compliance standards.

Illustrative image related to vinyl leatherette fabric

In-depth Look: Manufacturing Processes and Quality Assurance for vinyl leatherette fabric

What Are the Key Stages in the Manufacturing Process of Vinyl Leatherette Fabric?

The manufacturing of vinyl leatherette fabric involves several critical stages, each contributing to the final quality and performance of the material. Understanding these stages is essential for B2B buyers looking to procure high-quality upholstery materials.

Material Preparation: What Goes Into Making Vinyl Leatherette?

The first stage of manufacturing vinyl leatherette begins with material preparation. This involves sourcing high-quality substrates, typically a base fabric made from polyester or cotton, which will provide the necessary strength and durability. The fabric is then coated with a polymer, usually polyvinyl chloride (PVC) or polyurethane (PU), which gives vinyl its leather-like appearance and properties.

In this phase, additives are often included to enhance characteristics such as flexibility, water resistance, and UV stability. These additives can also help in achieving specific textures and colors, allowing for a wide range of design options. Quality control starts here, as the choice of raw materials can significantly affect the final product.

How Is Vinyl Leatherette Formed and Assembled?

The next phase is forming, where the prepared substrate is coated with the polymer. This is typically done through techniques such as calendering or coating. Calendering involves passing the substrate through rollers to ensure a uniform coating. This technique allows for the creation of various textures, mimicking the grain of real leather.

Once the coating is applied, the material is cured to ensure that the polymer adheres properly to the fabric. This curing process can involve heat or chemical treatments, which solidify the polymer and enhance its durability. After curing, the fabric may undergo a finishing stage, where additional treatments are applied for aesthetics, such as embossing or printing designs onto the surface.

Illustrative image related to vinyl leatherette fabric

What Finishing Techniques Are Commonly Used in Vinyl Leatherette Production?

Finishing techniques play a crucial role in determining the look and feel of vinyl leatherette. Common methods include:

- Embossing: This technique creates a three-dimensional texture that simulates the appearance of real leather.

- Printing: Digital or screen printing can be used to apply patterns or colors, allowing for customization based on client requirements.

- Lamination: A protective top layer can be added to enhance water resistance and durability.

These finishing processes not only affect aesthetics but also influence the fabric’s performance characteristics, such as stain resistance and ease of cleaning.

How Is Quality Assurance Implemented in Vinyl Leatherette Manufacturing?

Quality assurance is paramount in the manufacturing of vinyl leatherette to ensure that the final product meets international standards and customer expectations. Various quality control measures are implemented throughout the production process.

Illustrative image related to vinyl leatherette fabric

Which International Standards Are Relevant for Vinyl Leatherette Fabric?

B2B buyers should be aware of several international standards that govern the quality of vinyl leatherette fabric. ISO 9001 is a widely recognized quality management standard that ensures consistent quality in manufacturing processes. Compliance with this standard indicates that a supplier has effective quality management systems in place.

Additionally, for products intended for specific markets, certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for industrial applications may be relevant. These certifications ensure that the product meets safety and performance requirements specific to its application.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are essential for maintaining high standards throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This stage assesses the quality of raw materials upon arrival. Suppliers must provide certificates of compliance or testing results for materials used.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues early. This includes checking the thickness of coatings, adherence levels, and the integrity of the substrate.

- Final Quality Control (FQC): This final inspection assesses the finished product for defects, ensuring that it meets design specifications and performance criteria.

B2B buyers should inquire about the specific QC processes implemented by suppliers to ensure they are sourcing from reliable manufacturers.

Illustrative image related to vinyl leatherette fabric

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are some actionable steps to consider:

What Are Effective Ways to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers can perform on-site audits to evaluate the manufacturing environment, machinery, and adherence to quality standards. This provides firsthand insight into the supplier’s capabilities and commitment to quality.

How Can Buyers Utilize Reports and Third-Party Inspections?

Requesting quality control reports from suppliers can help buyers understand the consistency of the product quality over time. These reports should detail IQC, IPQC, and FQC results. Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices, offering further assurance before placing large orders.

Illustrative image related to vinyl leatherette fabric

What Are the Nuances of Quality Control for International Buyers?

For international buyers, understanding the nuances of quality control is essential. Different regions may have varying standards and expectations. For example, buyers in Europe may prioritize compliance with CE standards, while those in Africa might focus more on cost-effectiveness and durability due to different market conditions.

It’s also important for buyers to be aware of potential language barriers and cultural differences that may affect communication with suppliers. Establishing clear expectations and maintaining open lines of communication can help mitigate these challenges.

By thoroughly understanding the manufacturing processes and quality assurance practices associated with vinyl leatherette fabric, B2B buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vinyl leatherette fabric’

To assist B2B buyers in sourcing vinyl leatherette fabric effectively, this step-by-step checklist serves as a comprehensive guide. It will help you navigate the complexities of selecting the right materials for your projects while ensuring quality and compliance with industry standards.

Step 1: Define Your Technical Specifications

Understanding your project’s requirements is crucial before initiating the sourcing process. Define the intended use of the vinyl leatherette, whether for upholstery, automotive interiors, or marine applications. Consider technical specifications such as thickness, durability, stain resistance, and color options, which will influence the final product’s performance.

- Performance Criteria: Identify specific performance features you need, such as water resistance or UV stability.

- Compliance Requirements: Ensure your specifications meet any relevant regulations or standards applicable in your region.

Step 2: Research Potential Suppliers

A thorough supplier search is essential for successful procurement. Look for manufacturers and distributors specializing in vinyl leatherette fabric. Investigate their market reputation, product range, and customer service record to gauge reliability.

- Supplier Directories: Utilize online platforms and trade directories to compile a list of potential suppliers.

- Industry Reviews: Check reviews and testimonials from other B2B buyers to assess quality and service levels.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, it’s crucial to verify their certifications and compliance with industry standards. Certifications can indicate the quality of materials and ethical sourcing practices.

- ISO Certifications: Look for suppliers with ISO certifications that demonstrate adherence to international quality standards.

- Sustainability Certifications: If sustainability is a priority, check for eco-friendly certifications that align with your company’s values.

Step 4: Request Samples

Obtaining samples is a vital step in assessing the quality of the vinyl leatherette fabric. Samples allow you to evaluate color accuracy, texture, and durability firsthand.

- Limitations on Samples: Be aware of any limitations on the number of samples you can request and ensure they represent the final product accurately.

- Testing for Performance: Conduct tests on the samples to ensure they meet your specifications, such as stain resistance and flexibility.

Step 5: Negotiate Pricing and Terms

Once you’ve selected potential suppliers, initiate negotiations on pricing and terms. Understanding the pricing structure is essential for budgeting and forecasting.

- Bulk Purchase Discounts: Inquire about discounts for larger orders, as many suppliers offer better rates for volume purchases.

- Payment Terms: Discuss payment options and terms to align with your cash flow requirements.

Step 6: Finalize Orders and Confirm Delivery Timelines

After agreeing on terms, finalize your order while confirming delivery timelines. Clear communication regarding expected lead times is vital to ensure your project stays on schedule.

Illustrative image related to vinyl leatherette fabric

- Written Agreements: Ensure all terms, including pricing, delivery dates, and product specifications, are documented in a written agreement.

- Tracking and Communication: Establish a communication plan for tracking your order and addressing any potential issues during transit.

Step 7: Conduct Quality Checks Upon Arrival

Upon receipt of the vinyl leatherette fabric, conduct thorough quality checks to ensure it meets your specifications and expectations.

- Inspect for Defects: Look for any defects or discrepancies in color, texture, and overall quality.

- Documentation: Keep records of the inspection results and any communications with the supplier regarding quality concerns.

By following these steps, B2B buyers can streamline their sourcing process for vinyl leatherette fabric, ensuring they make informed decisions that align with their project needs and business goals.

Comprehensive Cost and Pricing Analysis for vinyl leatherette fabric Sourcing

What Are the Key Cost Components in Vinyl Leatherette Fabric Sourcing?

When sourcing vinyl leatherette fabric, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The base material for vinyl leatherette typically includes polyurethane (PU) or polyvinyl chloride (PVC). The choice of material significantly influences the price, with PU often being more costly due to its enhanced softness and durability.

- Labor: Labor costs can vary depending on the manufacturing region. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality does not suffer as a result.

- Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities and factory maintenance. These costs are generally fixed but can vary based on the efficiency of the manufacturing process.

- Tooling: Custom molds or equipment required for specific designs can add to the initial costs. Buyers should consider the tooling costs when requesting custom patterns or textures.

- Quality Control (QC): QC is vital to ensure product consistency and adherence to specifications. Higher QC standards may lead to increased costs but result in fewer defects and returns.

- Logistics: Shipping and handling expenses can vary significantly based on distance and shipping methods. International buyers must account for customs duties and taxes, which can affect the overall cost.

- Margin: Suppliers typically include a profit margin that can vary based on competition, demand, and the perceived value of the product.

How Do Price Influencers Affect Vinyl Leatherette Fabric Pricing?

Several factors can influence the pricing of vinyl leatherette fabric, particularly for B2B transactions.

Illustrative image related to vinyl leatherette fabric

- Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing structures. Larger orders typically secure better per-unit pricing due to economies of scale.

- Specifications and Customization: Custom orders may incur additional costs for tooling and setup. Buyers should weigh the benefits of customization against these potential costs.

- Material Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly or fire-retardant) can drive up prices. However, these features can also enhance the value proposition for end-users.

- Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may command higher prices but can also offer more consistent service.

- Incoterms: Understanding the Incoterms agreed upon in the contract can clarify who bears the responsibility for shipping costs and risks, impacting the total landed cost of the fabric.

What Are Effective Buyer Tips for Negotiating Vinyl Leatherette Fabric Prices?

International B2B buyers should adopt strategic approaches to secure favorable pricing for vinyl leatherette fabric.

- Negotiation Strategies: Establish clear objectives and be prepared to negotiate on volume, payment terms, and delivery schedules. Building a rapport with suppliers can also facilitate better deals.

- Focus on Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, shipping, handling, and potential returns. This holistic view can help in making more informed purchasing decisions.

- Understand Pricing Nuances: Be aware of regional pricing differences, particularly in markets like Africa, South America, and the Middle East. Local economic conditions, currency fluctuations, and import tariffs can all affect the final price.

- Consider Long-term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Loyalty can often translate to discounts and priority service.

- Stay Informed: Regularly review market trends and pricing benchmarks to ensure that you are getting competitive rates. Subscribing to industry reports or trade publications can provide valuable insights.

Disclaimer on Indicative Prices

Pricing for vinyl leatherette fabric can fluctuate based on various factors, including market demand, supplier pricing strategies, and material availability. As such, the prices referenced in this analysis are indicative and should be confirmed with suppliers during the procurement process.

Alternatives Analysis: Comparing vinyl leatherette fabric With Other Solutions

Understanding Alternatives to Vinyl Leatherette Fabric

When considering upholstery materials, vinyl leatherette fabric stands out for its durability and aesthetic appeal. However, various alternatives exist that may better suit specific needs or preferences. This analysis compares vinyl leatherette against two viable alternatives: Polyurethane (PU) leather and genuine leather. Each of these options has unique attributes, making them suitable for different applications in the B2B sector.

| Comparison Aspect | Vinilo Polipiel | Polyurethane (PU) Leather | Genuine Leather |

|---|---|---|---|

| Performance | Highly durable, water and stain-resistant | Soft, leather-like feel, durable | Excellent durability, breathability |

| Cost | Cost-effective, up to 75% less than genuine leather | Moderately priced, generally higher than vinyl | Premium cost, can be significantly higher |

| Ease of Implementation | Simple to cut and sew, widely available | Requires careful handling, may need specialized tools | Requires skilled labor for proper installation |

| Maintenance | Low maintenance, easy to clean with mild soap | Moderate maintenance, usually easy to clean | High maintenance, requires conditioning and special care |

| Best Use Case | Residential and commercial upholstery, marine applications | Fashion items, automotive interiors | High-end furniture, luxury automotive |

In-Depth Look at Alternatives

What are the Advantages and Disadvantages of Polyurethane (PU) Leather?

Polyurethane leather is often chosen for its soft texture and leather-like appearance, making it a popular choice in fashion and automotive industries. It offers a compromise between the affordability of vinyl and the luxurious feel of genuine leather. However, while PU leather is more supple, it may not be as robust as vinyl leatherette in high-traffic environments. It requires moderate maintenance and careful handling during installation, which can increase labor costs.

Illustrative image related to vinyl leatherette fabric

What Makes Genuine Leather a Popular Choice Despite Its Cost?

Genuine leather is prized for its durability and breathability, making it ideal for high-end furniture and luxury vehicles. Its longevity can justify the higher initial investment for many businesses. However, genuine leather requires significant maintenance, including regular conditioning to prevent cracking and drying. Additionally, the procurement process can be more complex and costly, which may not align with budget constraints for many B2B buyers.

How to Choose the Right Upholstery Material for Your Needs

Selecting the right upholstery material involves evaluating several factors, including performance requirements, budget constraints, and maintenance capabilities. Vinyl leatherette fabric is an excellent choice for those seeking a cost-effective, low-maintenance solution, particularly in high-use environments like restaurants or public transport. In contrast, PU leather may be ideal for applications where a softer, more luxurious appearance is desired, such as in fashion or premium automotive interiors. Genuine leather, while the most expensive option, is best suited for high-end applications where durability and aesthetics are paramount.

Ultimately, the choice depends on the specific needs of the project, the target market, and the desired balance between cost and quality. By assessing these factors, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for vinyl leatherette fabric

What Are the Key Technical Properties of Vinyl Leatherette Fabric?

Understanding the essential technical properties of vinyl leatherette fabric is crucial for B2B buyers aiming to make informed purchasing decisions. Here are some of the most significant specifications to consider:

Illustrative image related to vinyl leatherette fabric

1. Material Composition

Vinyl leatherette, often made from polyvinyl chloride (PVC) or polyurethane (PU), offers a synthetic alternative to genuine leather. The choice between PVC and PU affects the fabric’s flexibility, softness, and durability. PU is generally regarded as higher quality due to its softer feel and greater resistance to wear and tear. For manufacturers, knowing the material composition helps in selecting the right fabric for specific applications, such as upholstery for furniture or automotive interiors.

2. Thickness and Weight

The thickness of vinyl leatherette typically ranges from 0.6 mm to 2.0 mm, while the weight can vary between 300 to 800 grams per linear meter. Thicker materials tend to be more durable, making them suitable for high-traffic areas, while lighter weights are ideal for applications where flexibility is paramount. Buyers should consider these factors when determining the fabric’s suitability for their intended use, ensuring it meets durability and aesthetic requirements.

3. Abrasion Resistance

Abrasion resistance is a critical property that indicates how well the fabric can withstand wear from friction. It is often measured using the Martindale test, where higher values (typically 20,000 cycles or more) indicate better durability. For B2B buyers, understanding abrasion resistance is vital, especially for applications in commercial settings such as hotels and restaurants, where fabrics are subjected to frequent use.

Illustrative image related to vinyl leatherette fabric

4. Fire Retardancy

Many industries require materials to meet specific fire safety standards. Vinyl leatherette can be treated to be fire retardant, ensuring compliance with regulations in sectors like hospitality and transportation. Buyers must inquire about fire ratings and certifications to ensure the material meets local and international safety codes.

5. Stain and Water Resistance

Vinyl leatherette is generally easy to clean and maintain due to its inherent stain and water resistance. Fabrics treated with additional coatings can enhance these properties, making them suitable for environments where spills are likely. This feature is particularly attractive to buyers in the food service and healthcare industries, where hygiene is paramount.

What Are Common Trade Terms Related to Vinyl Leatherette Fabric?

In the B2B landscape, understanding industry terminology is essential for effective communication and negotiation. Here are some commonly used terms in the vinyl leatherette fabric market:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vinyl leatherette, an OEM might produce fabric for furniture manufacturers or automotive suppliers. Understanding OEM relationships can help buyers identify reliable sources for their material needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For vinyl leatherette fabric, MOQs can vary significantly based on the supplier and the specific material. Buyers should be aware of MOQs to ensure they can meet their project requirements without overcommitting resources.

Illustrative image related to vinyl leatherette fabric

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the vinyl leatherette market, issuing an RFQ can help buyers compare options from multiple suppliers, ensuring they get the best deal based on quality and price.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which outline the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is crucial for international buyers to understand shipping costs, risk management, and insurance responsibilities related to vinyl leatherette fabric transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For vinyl leatherette fabric, lead times can vary based on production schedules and shipping methods. Buyers should factor in lead times when planning projects to avoid delays in production or delivery.

By understanding these technical properties and trade terms, B2B buyers can navigate the vinyl leatherette fabric market more effectively, making informed decisions that align with their project needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the vinyl leatherette fabric Sector

What Are the Current Market Dynamics and Key Trends in the Vinyl Leatherette Fabric Sector?

The vinyl leatherette fabric market is experiencing robust growth, driven by increasing demand across various industries, including automotive, furniture, and fashion. Factors such as affordability, durability, and versatility make vinyl leatherette an attractive option for manufacturers and designers. International buyers, particularly from Africa, South America, the Middle East, and Europe, are capitalizing on these advantages. Countries like Brazil and Nigeria are witnessing a surge in demand due to rising disposable incomes and a growing middle class, which is shifting preferences toward synthetic materials that offer a leather-like aesthetic without the associated costs.

Emerging trends in B2B sourcing include a shift towards online procurement platforms that enhance accessibility and streamline the purchasing process. Buyers are increasingly leveraging technology to compare product specifications, prices, and supplier ratings, which facilitates informed decision-making. Additionally, there is a growing emphasis on customization, with suppliers offering tailored solutions to meet specific project needs, including unique colors, textures, and performance features such as stain resistance and water repellency.

Another significant trend is the integration of smart textiles in vinyl leatherette products, enhancing their functionality and appeal. Innovations such as antimicrobial finishes and enhanced UV resistance are becoming commonplace, catering to consumers’ demands for high-performance materials. As market dynamics evolve, international buyers must stay abreast of these trends to optimize their sourcing strategies effectively.

How Is Sustainability and Ethical Sourcing Reshaping the Vinyl Leatherette Fabric Market?

Sustainability is increasingly becoming a focal point in the vinyl leatherette fabric sector. The environmental impact of traditional leather production has prompted a shift towards more sustainable alternatives. Vinyl leatherette, often produced using less resource-intensive methods, presents an eco-friendlier option. International B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of eco-friendly materials and production processes.

Ethical sourcing is paramount, particularly as consumers become more aware of the implications of their purchases. Buyers are encouraged to seek out suppliers that adhere to ethical labor practices and maintain transparency throughout their supply chains. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can serve as indicators of a supplier’s commitment to sustainability and ethical standards.

Illustrative image related to vinyl leatherette fabric

Moreover, the trend towards sustainable sourcing is influencing product development in the vinyl leatherette market. Manufacturers are exploring biodegradable options and innovations in recycling technologies to minimize waste and reduce their carbon footprint. By prioritizing sustainability, B2B buyers can not only align with global environmental standards but also cater to a growing segment of eco-conscious consumers.

What Is the Historical Context of Vinyl Leatherette Fabric in B2B Markets?

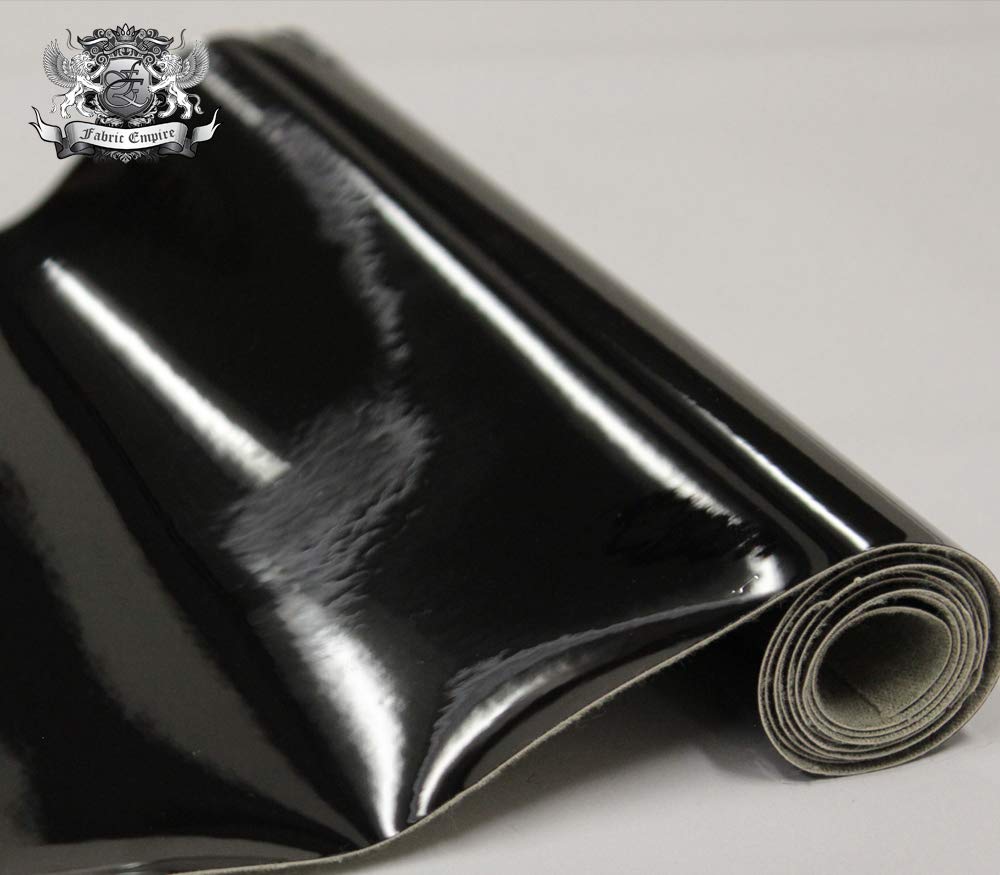

Vinyl leatherette, often referred to as faux leather or synthetic leather, has evolved significantly since its inception. First introduced in the early 20th century, the material gained popularity as a cost-effective alternative to genuine leather. Initially, its use was limited to specific applications, but advancements in manufacturing processes and material technology have broadened its scope.

The introduction of polyurethane (PU) leather in the 1960s marked a significant milestone in the evolution of synthetic leather. PU leather offered enhanced durability and a more genuine feel, making it a preferred choice for various applications, including upholstery and automotive interiors. As manufacturing techniques improved, vinyl leatherette began to dominate markets due to its affordability and versatility.

Today, vinyl leatherette fabric is ubiquitous, with applications spanning residential and commercial furniture, automotive interiors, and even fashion accessories. As the market continues to evolve, international B2B buyers are poised to benefit from the rich history and ongoing innovations within the vinyl leatherette sector. This historical context underscores the material’s resilience and adaptability in meeting changing consumer demands and market conditions.

Illustrative image related to vinyl leatherette fabric

Frequently Asked Questions (FAQs) for B2B Buyers of vinyl leatherette fabric

-

How do I choose the right vinyl leatherette fabric for my project?

Selecting the right vinyl leatherette fabric begins with understanding your project requirements. Consider factors such as the intended use (e.g., upholstery, automotive, marine), desired aesthetic, and performance features like stain resistance and durability. Evaluate the fabric’s texture, color options, and thickness, which can impact both appearance and functionality. Request samples from suppliers to assess quality firsthand and ensure the fabric meets your specifications. Additionally, inquire about certifications to confirm compliance with industry standards, especially if the fabric will be used in commercial applications. -

What are the advantages of using vinyl leatherette over genuine leather?

Vinyl leatherette offers several advantages compared to genuine leather, particularly in cost and maintenance. It is often up to 75% cheaper, making it a budget-friendly option for large-scale projects. Vinyl is also water-resistant, stain-resistant, and easier to clean, requiring only a damp cloth for maintenance. Furthermore, it is available in a wider variety of colors and patterns, allowing for more design flexibility. This synthetic material is also animal-friendly, appealing to businesses focused on sustainability and ethical sourcing. -

What is the typical minimum order quantity (MOQ) for vinyl leatherette fabric?

Minimum order quantities for vinyl leatherette fabric can vary significantly by supplier and region. Generally, MOQs range from 50 to 500 yards, depending on the manufacturer and the specific fabric type. When sourcing internationally, consider the supplier’s production capabilities and whether they can accommodate smaller orders or offer bulk pricing for larger quantities. It’s advisable to communicate your needs clearly to suppliers and negotiate MOQs that fit your business model, especially if you are a startup or a small business. -

How do I vet suppliers of vinyl leatherette fabric for international trade?

Vetting suppliers involves thorough research and due diligence. Start by checking their business credentials, including registration, certifications, and industry reputation. Request references from previous clients and assess their track record for timely deliveries and quality assurance. Utilize platforms like Alibaba or global trade directories to find reviews and ratings. Additionally, consider visiting the supplier’s facility if feasible, or arrange for third-party inspections to verify the quality of products before placing bulk orders. Ensure they comply with international trade regulations and can meet your specific needs. -

What payment terms should I expect when sourcing vinyl leatherette fabric?

Payment terms can vary based on the supplier’s policies and your negotiation. Common options include a deposit upfront (usually 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer letter of credit (LC) options, providing added security for both parties. Be sure to clarify payment methods accepted (bank transfer, PayPal, etc.) and inquire about any early payment discounts or financing options. It’s essential to establish clear payment terms in your contract to avoid disputes later in the transaction process. -

How can I customize vinyl leatherette fabric for my specific needs?

Customization options for vinyl leatherette fabric often include color, texture, and pattern variations. Many manufacturers offer the ability to create bespoke designs or finishes tailored to your branding or project requirements. To initiate customization, provide detailed specifications to your supplier, including desired samples or design concepts. Be aware that custom orders may have higher MOQs and longer lead times. Discuss costs associated with customization upfront to ensure the project remains within budget and meets your timeline. -

What quality assurance processes should I expect from suppliers?

Quality assurance processes may vary, but reputable suppliers typically implement several measures to ensure product quality. Expect to see testing for durability, colorfastness, and compliance with safety regulations. Some suppliers may provide certifications or test reports for their materials. It’s advisable to request a quality control plan, detailing the steps taken during production and post-production inspections. Discuss the possibility of receiving samples before bulk production to assess quality firsthand, and ensure that the supplier offers a return or replacement policy for defective goods. -

What logistics considerations should I be aware of when importing vinyl leatherette fabric?

When importing vinyl leatherette fabric, logistics considerations include shipping methods, customs duties, and delivery timelines. Choose between air or sea freight based on your budget and urgency. Confirm the supplier’s shipping capabilities and whether they can handle customs clearance. Be aware of import regulations specific to your country, including tariffs and taxes that may apply. Collaborate with a reliable freight forwarder to streamline the shipping process and ensure compliance with international trade laws. Establish clear communication with your supplier to coordinate shipping schedules effectively.

Top 7 Vinyl Leatherette Fabric Manufacturers & Suppliers List

1. Folio Fabrics – Vinyl & Faux Leather Upholstery

Domain: foliofabrics.com

Registered: 2013 (12 years)

Introduction: Shop Vinyl & Faux Leather For Upholstery By The Yard – Folio Fabrics. Key features include: 4-Way Stretch, Ink Resistant, Bacteria & Mildew Resistant, Performance, Breathable, Pet Friendly, Eco-Friendly, Stain Resistant, Fade Resistant, Weather Resistant. Applications include Upholstery, Home Contract, Outdoor, Marine, Auto, Healthcare. Patterns available: Exotics, Distressed, Pebbled, Metallic, L…

2. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric. Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders. Available in various colors: Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, Gold. Uses include Furniture, Automotive, Marine. Brands include Naugahyde, Omnova Boltaflex, Nassimi, Spradling. Types include Vinyl (PVC), Uretha…

3. Fabric Warehouse – Indoor Upholstery Vinyl Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Indoor Upholstery Vinyl Fabric By The Yard, FOLDED FABRICS, SHIPS FREE OVER $100, Returns & Shipping Policy, Non-Marine Upholstery Vinyl, Discount options: 20% OFF (1), 30% OFF (2), 40% OFF (59), 60% OFF (1), Standard Shipping (84), Color Themes: Beige (5), Black (1), Blue (12), Brown (36), Gray (5), Green (5), Orange (2), Pink (1), Purple (1), Red (4), Remnants Vs Yards: By the Yard (24), Remnant…

4. Big Z Fabric – Faux Leather Vinyl

Domain: bigzfabric.com

Registered: 2010 (15 years)

Introduction: Faux Leather Vinyl Fabric – Durable & Stylish for Upholstery. Huge selection of prints and patterns available. Sold by the yard. Regular updates on new arrivals and special pricing through the blog. Featured products include Storm Shield Marine Vinyl, Alligator Embossed Vinyl, DuroLast® Marine Vinyl, AquaGuard® Crocodile Marine Vinyl, and various embossed and patterned faux leather options. Catego…

5. Online Fabric Store – Vinyl and Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Vinyl and Leather fabrics are available in various types and characteristics, including options that are flame retardant, water repellent, and extra wide. They come in a range of colors such as black, white, ivory, natural, tan, gold, yellow, orange, brown, green, pink, red, blue, purple, and gray. The fabrics are suitable for various applications including upholstery, fashion, and décor. They are…

6. Ottertex® – Stretch Vegan Leather Vinyl Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Ottertex® Stretch Vegan Leather Vinyl Fabric

7. BuyFabrics – Faux Leather and Vinyl Collection

Domain: buyfabrics.com

Registered: 2001 (24 years)

Introduction: Faux Leather and Vinyl collection includes various fabrics suitable for home decor, upholstery, and apparel. Key features include:

– Free shipping for contiguous U.S. orders over $99 (exclusions apply)

– Products sorted by color, fiber content, categories, and suitability for different uses (e.g., activewear, costumes, crafts)

– Price range for fabrics, with some on sale (e.g., Rich Olive Green Fa…

Strategic Sourcing Conclusion and Outlook for vinyl leatherette fabric

In the evolving landscape of upholstery solutions, vinyl leatherette fabric stands out as a versatile and cost-effective alternative to genuine leather. Its durability, ease of maintenance, and extensive customization options make it a preferred choice for a wide array of applications, from residential furniture to commercial transportation seating. For international B2B buyers, particularly in emerging markets such as Africa and South America, strategic sourcing of high-quality vinyl leatherette can lead to significant cost savings and enhanced product offerings.

Leveraging the benefits of vinyl leatherette not only allows businesses to meet diverse consumer demands but also positions them competitively in the global market. The ongoing advancements in manufacturing techniques have made it possible to produce eco-friendly and performance-enhanced vinyl options, aligning with the growing demand for sustainable materials. As you consider your sourcing strategies, focus on suppliers who provide comprehensive product ranges, competitive pricing, and reliable quality assurance.

Looking ahead, the market for vinyl leatherette fabric is poised for growth, driven by innovation and increasing consumer awareness of its benefits. Seize the opportunity to explore new supplier partnerships and product lines that can elevate your business offerings and cater to the evolving needs of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to vinyl leatherette fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.