Introduction: Navigating the Global Market for cracked leather

In the competitive landscape of B2B procurement, sourcing high-quality cracked leather can present significant challenges, particularly for businesses looking to maintain their reputation for excellence. Cracked leather, often a byproduct of environmental exposure and inadequate care, can undermine the aesthetic appeal of leather goods and diminish their market value. This guide serves as a comprehensive resource for international B2B buyers, detailing everything from the types of cracked leather available to their various applications across industries, supplier vetting best practices, and cost considerations.

Understanding the nuances of cracked leather is essential for making informed purchasing decisions. Buyers from regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Brazil, will find valuable insights into selecting reliable suppliers, assessing the quality of leather products, and implementing effective maintenance strategies. With a focus on actionable information, this guide empowers businesses to navigate the complexities of the cracked leather market, ensuring that they can source materials that meet their quality standards while also addressing the needs of their customers. By leveraging this knowledge, B2B buyers can enhance their product offerings and secure a competitive edge in the global marketplace.

Table Of Contents

- Top 6 Cracked Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cracked leather

- Understanding cracked leather Types and Variations

- Key Industrial Applications of cracked leather

- 3 Common User Pain Points for ‘cracked leather’ & Their Solutions

- Strategic Material Selection Guide for cracked leather

- In-depth Look: Manufacturing Processes and Quality Assurance for cracked leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cracked leather’

- Comprehensive Cost and Pricing Analysis for cracked leather Sourcing

- Alternatives Analysis: Comparing cracked leather With Other Solutions

- Essential Technical Properties and Trade Terminology for cracked leather

- Navigating Market Dynamics and Sourcing Trends in the cracked leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cracked leather

- Strategic Sourcing Conclusion and Outlook for cracked leather

- Important Disclaimer & Terms of Use

Understanding cracked leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Cracked Leather | Shallow cracks mostly on the surface | Fashion accessories, upholstery | Pros: Easier to repair, less costly. Cons: May require frequent maintenance. |

| Deep Cracked Leather | Significant fissures penetrating deeper into the material | High-end furniture, automotive interiors | Pros: Durable if repaired, unique aesthetic. Cons: More expensive to restore, potential for structural weakness. |

| Weathered Leather | Aged appearance with cracks due to environmental exposure | Vintage-style products, luxury goods | Pros: Character and charm, strong market appeal. Cons: Repair can be challenging, may deter some buyers. |

| Faux Cracked Leather | Synthetic material mimicking natural leather with cracks | Budget-friendly products, fashion | Pros: Cost-effective, low maintenance. Cons: Less durable, may not appeal to luxury markets. |

| Embossed Cracked Leather | Textured surface with intentional crack patterns | Specialty items, fashion accessories | Pros: Unique design, high visual appeal. Cons: Difficult to repair without damaging the pattern. |

What Are the Characteristics of Surface Cracked Leather?

Surface cracked leather is characterized by shallow, superficial cracks that typically occur due to dryness or lack of proper care. This type is commonly found in fashion accessories and upholstery, making it a popular choice for businesses seeking cost-effective leather products. Buyers should consider the ease of repair and maintenance, as surface cracks can often be treated with conditioners or creams, making it a practical option for retailers looking to maintain product quality without significant investment.

How Does Deep Cracked Leather Differ from Other Types?

Deep cracked leather features significant fissures that penetrate the material, often resulting from prolonged neglect or harsh environmental conditions. This type is prevalent in high-end furniture and automotive interiors, where durability is crucial. Buyers should be aware that while deep cracks can be restored, the process is more complex and costly. The aesthetic appeal of deep cracked leather can be unique, attracting niche markets, but businesses must weigh the potential for structural weaknesses against the investment in restoration.

What Makes Weathered Leather Attractive for B2B Buyers?

Weathered leather exhibits an aged appearance with natural cracks, often sought after for its vintage charm. This type is particularly appealing in the luxury goods market and for vintage-style products. B2B buyers should consider the character and unique appeal of weathered leather, which can enhance product desirability. However, the repair process can be challenging, and some buyers may be deterred by the visible signs of wear, making it essential to balance aesthetics with potential maintenance issues.

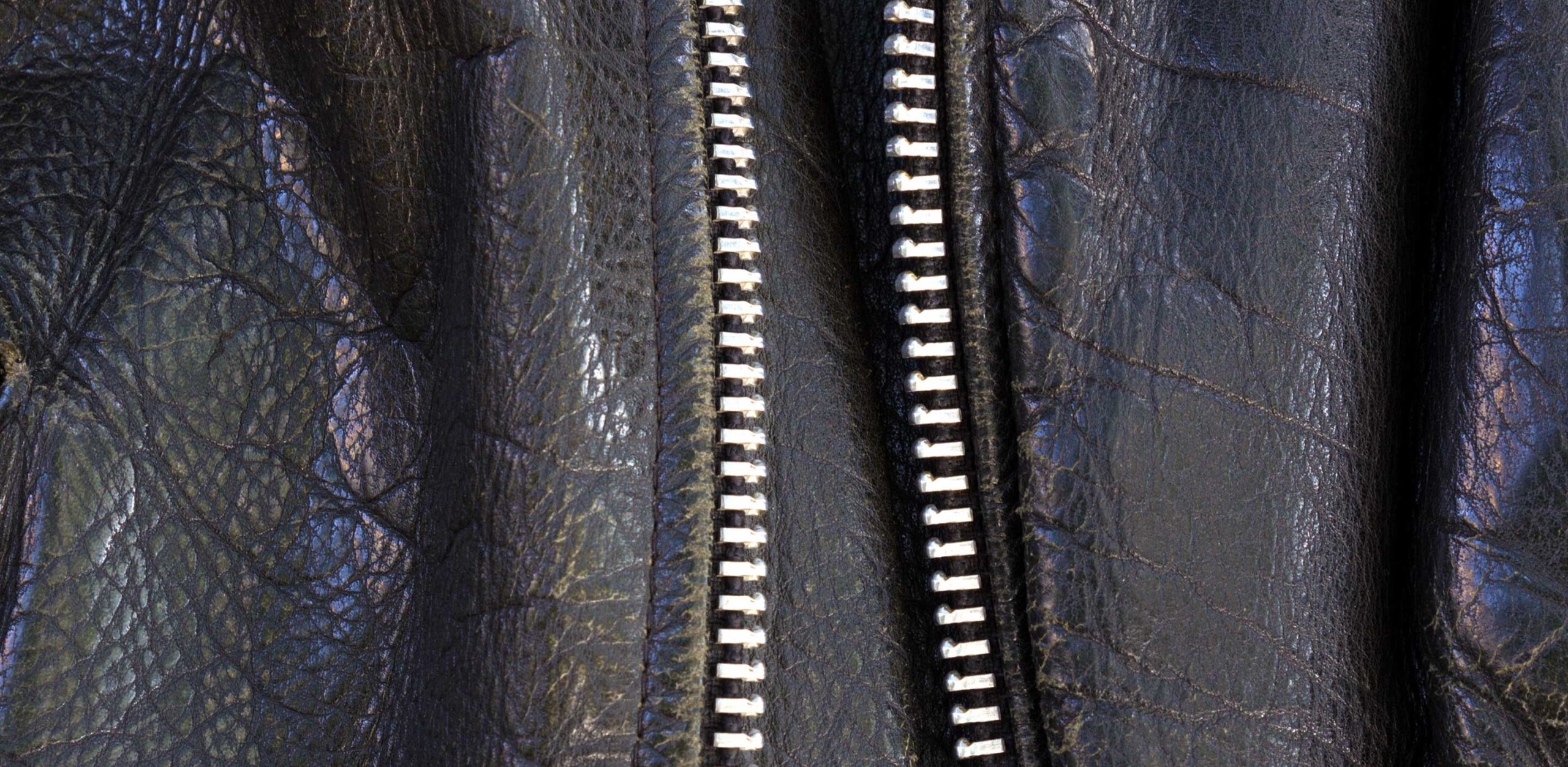

Illustrative image related to cracked leather

What Are the Benefits of Faux Cracked Leather?

Faux cracked leather is a synthetic alternative designed to mimic the look of natural leather while incorporating cracks into its texture. This type is commonly used in budget-friendly products and fashion items. For B2B buyers, the primary advantages include cost-effectiveness and low maintenance requirements. However, it may lack the durability and luxury appeal of genuine leather, which could limit its marketability in high-end sectors. Businesses should assess their target audience’s preferences when considering faux options.

How Does Embossed Cracked Leather Stand Out?

Embossed cracked leather features intentional crack patterns that create a distinctive texture, making it popular in specialty items and fashion accessories. This type offers unique design opportunities, appealing to consumers looking for standout products. B2B buyers should note that while embossed leather can enhance visual appeal, repairing it can be complex, as any restoration efforts must not compromise the embossed pattern. This consideration is vital for businesses aiming to maintain product integrity while addressing customer concerns about wear and tear.

Key Industrial Applications of cracked leather

| Industry/Sector | Specific Application of cracked leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Production of distressed leather garments | Unique aesthetic appeal that attracts consumers | Ensure sustainable sourcing and quality control for durability |

| Automotive | Upholstery for vintage or classic vehicles | Cost-effective restoration of high-value vehicles | Look for compatibility with existing materials and repairability |

| Furniture Manufacturing | Upholstery for rustic-style furniture | Enhanced character and market differentiation | Assess long-term durability and ease of maintenance |

| Accessories | Handbags and wallets with a vintage look | Appeals to niche markets seeking unique products | Ensure color consistency and texture matching for branding |

| Craft and DIY | Upcycling projects for creative artisans | Promotes sustainability and innovation in design | Source from reputable suppliers who provide detailed specifications |

How is Cracked Leather Used in Fashion and Apparel?

In the fashion and apparel industry, cracked leather is often intentionally used to create distressed garments, such as jackets and bags, which are in high demand for their unique aesthetic appeal. This application solves the problem of uniformity in leather products, offering consumers a product that tells a story and stands out in a crowded market. B2B buyers in this sector, particularly from regions like Europe and South America, should prioritize sourcing from suppliers who emphasize sustainable practices and can guarantee the quality and durability of their products.

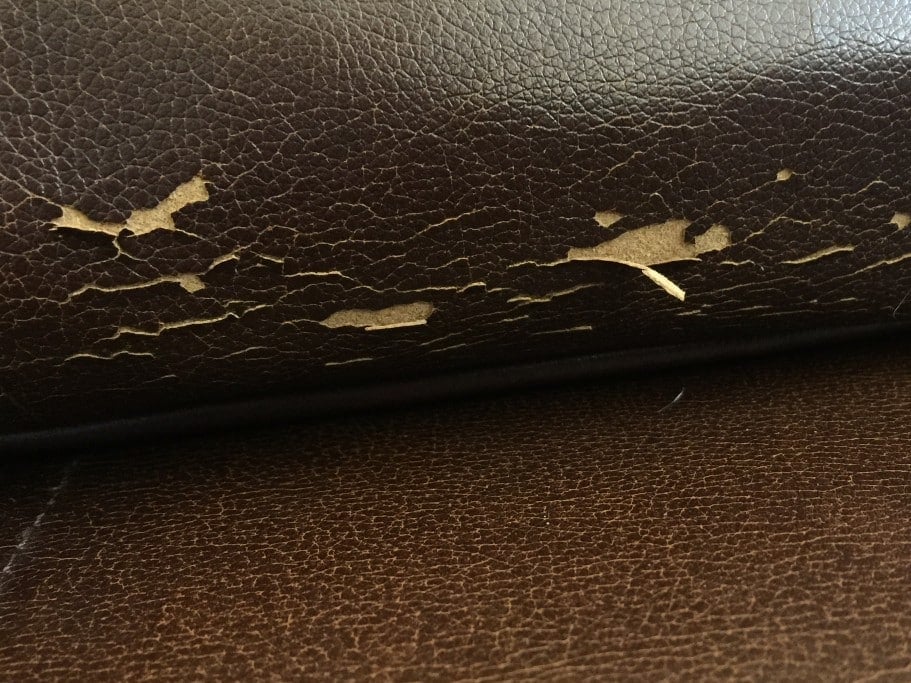

Illustrative image related to cracked leather

What Role Does Cracked Leather Play in Automotive Upholstery?

Cracked leather finds significant utility in the automotive sector, particularly for upholstery in vintage or classic vehicles. This application allows for a cost-effective restoration option that helps maintain the vehicle’s authenticity and value. Buyers should focus on sourcing materials that not only match the original specifications but also ensure compatibility with other materials used in the vehicle’s interior. Additionally, they should consider the repairability of cracked leather to facilitate future maintenance.

How is Cracked Leather Used in Furniture Manufacturing?

In furniture manufacturing, cracked leather is often utilized for rustic-style upholstery, providing a distinctive character to sofas and chairs. This use enhances the aesthetic appeal and allows manufacturers to differentiate their products in a competitive marketplace. Buyers should evaluate the long-term durability of cracked leather, as well as ease of maintenance, to ensure customer satisfaction and repeat business. Sourcing from suppliers who can provide consistent quality and detailed specifications is crucial for success.

What Are the Benefits of Cracked Leather in Accessories?

Cracked leather is increasingly popular in the accessories market, particularly for handbags and wallets that aim for a vintage or artisanal look. This application appeals to niche markets seeking unique and authentic products. For international buyers, especially from Africa and the Middle East, it is essential to ensure color consistency and texture matching to maintain brand integrity. Sourcing from reliable suppliers who can meet these aesthetic requirements is vital for capturing and retaining consumer interest.

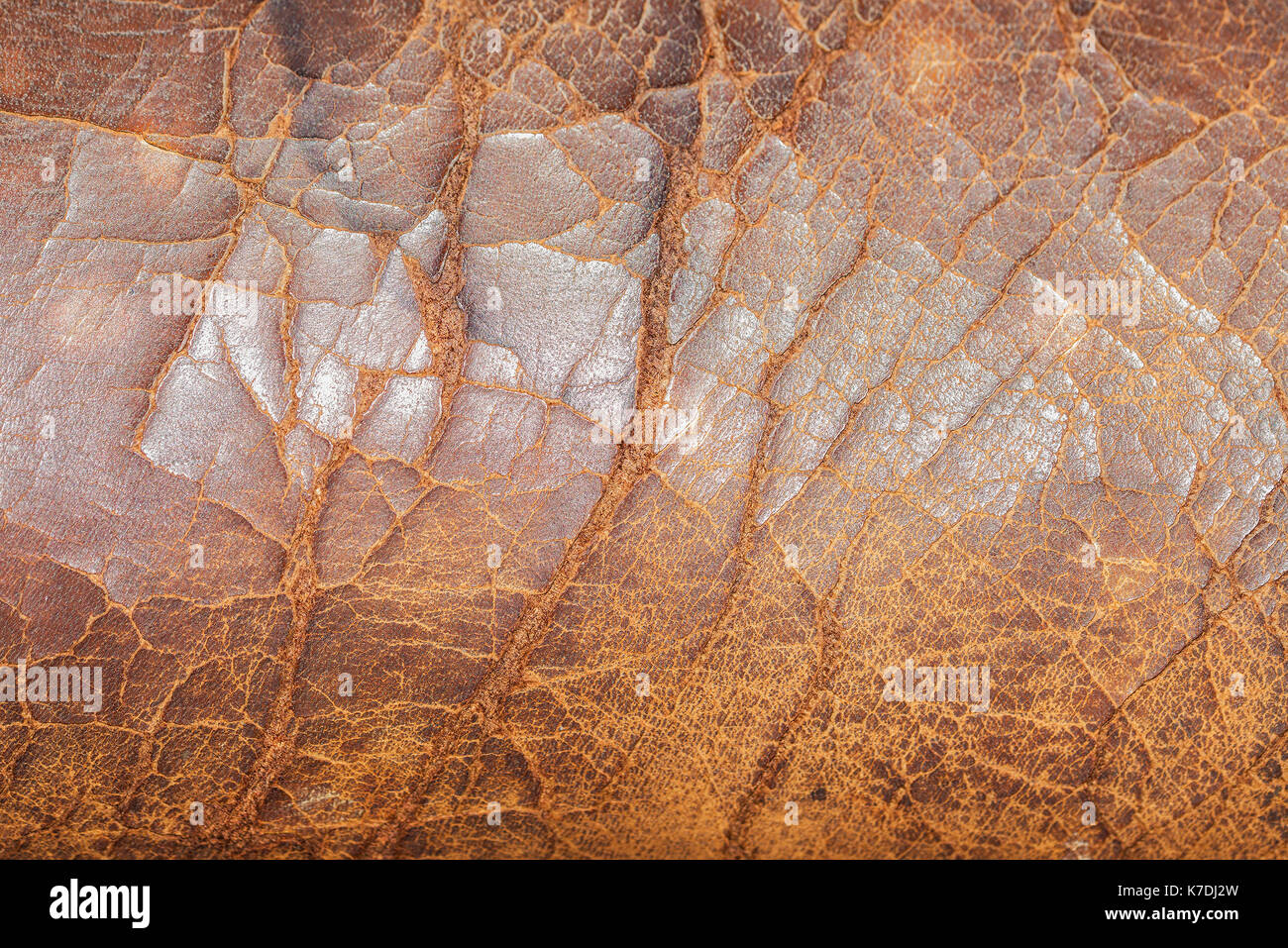

Illustrative image related to cracked leather

How is Cracked Leather Used in Craft and DIY Projects?

In the craft and DIY sector, cracked leather is often repurposed by artisans for various creative projects, promoting sustainability and innovation in design. This application allows for the transformation of damaged leather into unique items, reducing waste and encouraging environmentally friendly practices. Buyers in this sector should look for reputable suppliers who provide detailed specifications about the leather’s properties, ensuring that it meets the creative needs of their projects while maintaining quality.

3 Common User Pain Points for ‘cracked leather’ & Their Solutions

Scenario 1: The Cost of Quality Goods Diminished by Cracked Leather

The Problem: B2B buyers, particularly in the luxury goods and fashion sectors, often face significant challenges when sourcing high-quality leather products. Over time, leather items such as handbags, wallets, and furniture can develop cracks, which not only affect their aesthetic appeal but also diminish their perceived value. This is particularly concerning for businesses that rely on brand reputation and customer satisfaction. Buyers may struggle with maintaining inventory that reflects their brand’s commitment to quality, leading to potential losses in sales and customer trust.

The Solution: To mitigate the risk of acquiring cracked leather items, buyers should prioritize partnerships with reputable suppliers who offer detailed product care instructions and warranty options. When sourcing leather products, it’s essential to request samples to assess quality before bulk purchasing. Additionally, ensure that suppliers provide information on the tanning processes used, as vegetable-tanned leathers generally have better longevity and resistance to cracking. Invest in training for your staff on proper leather care and maintenance, which includes regular conditioning using high-quality leather creams to prevent cracks from developing in the first place. By adopting these proactive measures, businesses can maintain their inventory’s quality and protect their brand’s reputation.

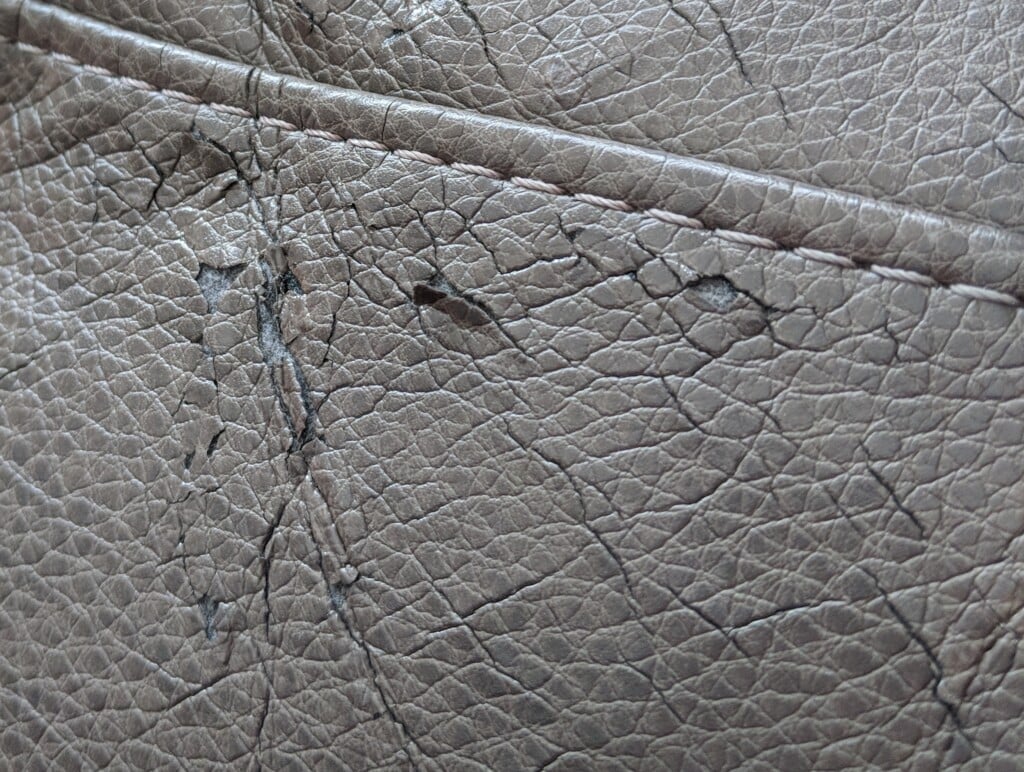

Scenario 2: Customer Returns Due to Cracking

The Problem: A frequent issue faced by B2B buyers in retail or wholesale is managing customer returns due to cracked leather products. This situation can lead to increased operational costs and damage to customer relationships, especially if the returns are perceived as a reflection of poor product quality. Buyers may feel overwhelmed by the logistics of returns and the impact this has on their bottom line, leading to frustration and a potential loss of repeat customers.

Illustrative image related to cracked leather

The Solution: To address this issue, buyers should implement a robust quality control process for incoming leather goods. This can include a thorough inspection for signs of cracking or dryness before products are added to inventory. Establish a clear return policy that emphasizes quality standards, allowing customers to feel confident in their purchases. Additionally, consider offering a leather care kit as part of the purchase, educating customers on maintenance practices that can prolong the life of their leather items. By actively engaging customers in the upkeep of their products, businesses can reduce return rates and foster long-term loyalty.

Scenario 3: Repairing Cracked Leather Products for Resale

The Problem: For businesses that deal in second-hand leather goods or refurbished products, cracked leather poses a unique challenge. Buyers may struggle to find effective methods for restoring these items without incurring high costs. The inability to effectively repair cracked leather can result in unsellable inventory and lost revenue opportunities, causing significant stress for businesses that rely on this segment.

The Solution: Investing in training for staff on leather repair techniques can greatly enhance a business’s ability to restore cracked leather items. For minor cracks, using a high-quality leather conditioner can rejuvenate the material, while deeper cracks may require a leather filler and dye to achieve a seamless look. Establish partnerships with local leather artisans who specialize in repairs, allowing for a more cost-effective solution that also supports local businesses. Furthermore, documenting the repair process can create a transparent narrative for customers, emphasizing the effort taken to restore each piece. This not only adds value to the product but also enhances the brand’s story of sustainability and craftsmanship, appealing to eco-conscious consumers.

Strategic Material Selection Guide for cracked leather

What Are the Key Properties of Common Materials Used in Cracked Leather Repair?

When addressing cracked leather, selecting the right materials for repair is crucial for ensuring durability and aesthetic appeal. Here, we analyze four common materials used in the repair and restoration of cracked leather: leather fillers, conditioners, dyes, and sealers.

Illustrative image related to cracked leather

Leather Fillers: What Are Their Key Properties and Applications?

Leather fillers are designed to repair deep cracks and restore the structural integrity of leather. They typically possess good adhesion properties, flexibility, and the ability to mimic the texture of natural leather. A high-quality filler can withstand temperature fluctuations without losing its effectiveness, making it suitable for various environments.

Pros: Leather fillers provide a robust solution for deep cracks, offering a seamless finish that can blend with the original leather. They are relatively easy to apply and can be customized with dyes.

Cons: The manufacturing complexity can vary, and some fillers may require specific application techniques. Additionally, if not properly applied, they can appear unnatural or lead to further cracking.

Impact on Application: Leather fillers are particularly effective for items exposed to stress, such as bags or furniture. Their compatibility with different leather types is essential for ensuring a successful repair.

Conditioners: How Do They Contribute to Leather Longevity?

Conditioners are crucial for maintaining leather’s suppleness and preventing future cracks. They typically contain oils and waxes that penetrate the leather fibers, restoring moisture and flexibility. Conditioners can be used regularly to prolong the life of leather products.

Illustrative image related to cracked leather

Pros: They are relatively low-cost and easy to apply, making them accessible for regular maintenance. Conditioners also enhance the appearance of leather, giving it a rich, polished look.

Cons: Over-application can lead to a greasy finish, and not all conditioners are suitable for all leather types. Some may also require time to absorb fully, which can delay the repair process.

Impact on Application: For international buyers, the choice of conditioner may depend on local climate conditions. In humid regions, for instance, a lighter conditioner may be preferable to prevent excess moisture retention.

Dyes: What Role Do They Play in Repairing Cracked Leather?

Dyes are essential for blending repaired areas with the surrounding leather. They come in various formulations, including water-based and alcohol-based options, each with unique properties. Dyes should be color-fast and resistant to fading from exposure to light and moisture.

Illustrative image related to cracked leather

Pros: Dyes can effectively cover imperfections and are available in a wide range of colors, allowing for precise matching. They are also relatively inexpensive and easy to apply.

Cons: Dyes may require multiple applications for full coverage, increasing the time and effort involved. Additionally, some dyes may not adhere well to all leather types, necessitating a compatibility check.

Impact on Application: For buyers in regions with high UV exposure, selecting a UV-resistant dye is crucial to prevent fading and maintain the product’s appearance over time.

Illustrative image related to cracked leather

Sealers: Why Are They Important in Leather Repair?

Sealants are used to protect repaired areas and enhance the longevity of the leather. They create a barrier against moisture and dirt, preventing future damage. Sealers often come in spray or liquid form and should be compatible with the other materials used in the repair process.

Pros: Sealers provide excellent protection against stains and moisture, extending the life of leather products. They are typically easy to apply and dry quickly.

Cons: Some sealers may alter the texture or sheen of the leather, which could be undesirable for certain applications. Additionally, they may require reapplication over time to maintain effectiveness.

Impact on Application: Buyers should consider local environmental factors when selecting a sealer. In regions with high humidity, a breathable sealer may be necessary to prevent moisture buildup.

Illustrative image related to cracked leather

Summary Table of Material Selection for Cracked Leather Repair

| Material | Typical Use Case for cracked leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather Filler | Repairing deep cracks in leather items | Seamless finish that blends with original leather | Can appear unnatural if not applied correctly | Medium |

| Conditioner | Regular maintenance to prevent cracking | Restores moisture and enhances appearance | Over-application can lead to greasy finish | Low |

| Dye | Blending repaired areas with original leather | Wide color range for precise matching | May require multiple applications for full coverage | Low |

| Sealer | Protecting repaired areas from moisture and stains | Excellent protection against damage | May alter texture or sheen of leather | Medium |

This strategic material selection guide provides B2B buyers with actionable insights into the properties, advantages, and limitations of materials used in cracked leather repair. Understanding these factors is essential for making informed purchasing decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cracked leather

What Are the Key Stages in the Manufacturing Process of Cracked Leather?

The production of leather, particularly when addressing the needs of cracked leather, involves several critical stages: material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in the final quality of the leather products, ensuring that they meet the rigorous standards expected by B2B buyers.

How Is Material Prepared for Leather Production?

The initial stage of leather manufacturing begins with sourcing high-quality animal hides. The selection process is paramount; hides that exhibit natural flaws or imperfections may be more susceptible to cracking in the future. Once sourced, hides undergo a cleaning and preservation process that includes salting or drying to prevent decay.

After preservation, the hides are subjected to tanning, which is essential for converting raw animal skins into durable leather. Various tanning methods exist, including vegetable tanning and chrome tanning. Vegetable tanning, favored for its eco-friendliness, utilizes natural tannins from plant sources, while chrome tanning is more common due to its efficiency and ability to produce softer leather.

What Techniques Are Used in Forming and Assembling Leather Products?

During the forming stage, the leather is cut into specific patterns based on the intended product, whether it’s bags, shoes, or upholstery. Precision cutting is critical to ensure that the final product maintains structural integrity and minimizes waste.

Illustrative image related to cracked leather

The assembly process involves stitching or bonding the cut pieces together. High-quality stitching techniques, such as double-stitched seams, enhance durability and reduce the likelihood of cracks forming at stress points. Additionally, adhesives may be used in some applications, particularly where flexibility and comfort are paramount.

How Is the Finishing Process Executed to Prevent Cracking?

The finishing stage is where leather products receive their final touch. This includes dyeing, conditioning, and applying protective coatings. For cracked leather, it is crucial to incorporate moisturizers or oils during this stage to help maintain flexibility and prevent future cracking.

Finishing techniques may also involve the application of topcoats that provide water and stain resistance, further enhancing the leather’s durability. Quality manufacturers often conduct a thorough inspection during this stage to ensure that the product meets aesthetic and functional standards.

What Quality Assurance Measures Are In Place for Leather Manufacturing?

Quality assurance (QA) is essential in the leather industry, particularly when dealing with cracked leather. International standards such as ISO 9001 provide a framework for ensuring consistent quality across manufacturing processes. Adhering to these standards helps manufacturers establish robust QA protocols.

Illustrative image related to cracked leather

Which International Standards Should Buyers Be Aware Of?

B2B buyers should be familiar with various international standards and certifications relevant to leather products. In addition to ISO 9001, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the end-use of the leather goods. These standards ensure that products are safe, reliable, and of high quality.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control in leather manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. It ensures that the hides meet specified quality standards before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed at various stages to identify any deviations from quality standards. This may include assessments of dye uniformity, stitching quality, and overall craftsmanship.

-

Final Quality Control (FQC): Once the products are completed, a final inspection is conducted to verify that they meet all specifications and quality benchmarks. This step is critical for identifying any defects or inconsistencies before products are shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Here are some effective strategies for conducting due diligence:

What Auditing Methods Are Effective for Quality Verification?

-

Supplier Audits: Conducting on-site audits can provide invaluable insights into a manufacturer’s processes, equipment, and quality control measures. This allows buyers to assess compliance with international standards and internal quality benchmarks.

-

Requesting Quality Reports: B2B buyers should request detailed quality reports from suppliers, including data on defect rates, customer feedback, and corrective actions taken. This documentation can help establish a supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct pre-shipment inspections to ensure that products meet specified quality standards before they leave the factory.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, understanding the nuances of quality control is crucial. Differences in regulations, market expectations, and cultural attitudes toward quality can affect the manufacturing and inspection processes. Buyers should be aware of the following:

-

Cultural Sensitivity: Different regions may have varying expectations regarding quality and aesthetics in leather products. Understanding these cultural nuances can help buyers set realistic expectations and foster better communication with suppliers.

-

Regulatory Compliance: Ensuring that products comply with both local and international regulations is essential for avoiding legal issues. Buyers should familiarize themselves with the relevant laws in their respective markets, especially regarding safety and environmental standards.

-

Adaptability: Buyers should remain flexible and adaptable, ready to negotiate or adjust quality expectations based on the supplier’s capabilities and the specific market demands.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing cracked leather products, ensuring they acquire high-quality materials that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cracked leather’

Introducción

When sourcing cracked leather, it is essential to approach the process with a structured strategy. This guide provides B2B buyers with actionable steps to ensure they acquire high-quality materials that meet their specific needs, whether for manufacturing, repair, or resale. By following this checklist, you can minimize risks and enhance the overall quality of your leather products.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the cracked leather you require is critical. Consider factors such as the type of leather (e.g., vegetable-tanned, chrome-tanned), thickness, texture, and intended use. Document these specifications to communicate effectively with potential suppliers, ensuring they understand your precise needs.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in cracked leather. Utilize online platforms, industry directories, and trade shows to find reputable vendors. Create a shortlist based on their experience, product range, and customer reviews to streamline your selection process.

Illustrative image related to cracked leather

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. Certifications such as ISO or environmental compliance indicate a supplier’s commitment to quality and sustainability. This step is crucial to ensure that the leather you source is ethically produced and meets the necessary regulations in your target market.

Step 4: Request Samples for Quality Assessment

Always request samples from shortlisted suppliers to assess the quality of the cracked leather. Examine the samples for factors such as texture, flexibility, and the extent of cracking. This hands-on evaluation will help you determine whether the leather meets your quality standards before making a larger commitment.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms with your selected suppliers. Understanding the cost implications, including potential bulk discounts or shipping fees, is vital for budgeting. Ensure the payment terms are favorable, allowing for flexibility while safeguarding your interests.

Illustrative image related to cracked leather

Step 6: Inquire About Repair Options and Support

When sourcing cracked leather, it’s beneficial to inquire whether suppliers offer repair products or support services. Some suppliers may provide leather conditioners, fillers, or restoration kits that can help maintain the quality of the leather over time. This added value can enhance your product offering and customer satisfaction.

Step 7: Establish Clear Communication Channels

Effective communication with your supplier is key to a successful partnership. Set up regular updates and feedback mechanisms to ensure alignment on orders, quality control, and delivery schedules. Establishing these channels will help you address any issues promptly and foster a long-term relationship with your supplier.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for cracked leather, ensuring they secure quality materials that align with their business objectives.

Illustrative image related to cracked leather

Comprehensive Cost and Pricing Analysis for cracked leather Sourcing

What Are the Key Cost Components in Cracked Leather Sourcing?

When sourcing cracked leather, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of leather used significantly impacts costs. Cracked leather can be sourced from various types, such as vegetable-tanned or chrome-tanned leather, each with different price points due to the quality and treatment processes involved.

-

Labor: Skilled labor is essential for both the production and repair of cracked leather. The complexity of the repair processes—whether it involves simple conditioning or extensive restoration—will influence labor costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. The location of the manufacturing facility can also affect these costs, especially if it’s situated in regions with higher operational costs.

-

Tooling: Specific tools and equipment are required for both the production and repair of leather. This includes machinery for cutting, stitching, and finishing, which can add to the overall cost.

-

Quality Control (QC): Ensuring that the leather meets quality standards involves additional costs related to inspections and testing. Certifications for leather quality can further influence the pricing structure.

-

Logistics: Shipping costs vary based on the origin and destination, especially for international shipments. Factors such as shipping method, weight, and packaging will affect logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit margins. This can vary significantly based on market demand and the supplier’s positioning.

How Do Price Influencers Impact Cracked Leather Sourcing?

Several factors can influence the pricing of cracked leather, making it essential for buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Understanding the supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized orders, such as specific finishes or treatments, can increase costs. Standardized products may offer more competitive pricing.

-

Material Quality and Certifications: High-quality leather or certified materials often come at a premium. Buyers should assess whether the additional cost aligns with their needs for durability and appearance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Well-established suppliers may charge more due to their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: The terms of trade (Incoterms) dictate the responsibilities of buyers and sellers in shipping, impacting overall costs. Understanding these terms can help buyers manage risk and control expenses.

What Are Effective Buyer Tips for Cost-Efficiency in Cracked Leather Sourcing?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, adopting strategic approaches can yield significant cost savings:

-

Negotiation: Always engage in negotiations. Suppliers often have room for flexibility in pricing, especially if you can demonstrate long-term potential or larger order volumes.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost of the leather, including maintenance and potential repair costs. Investing in high-quality leather may reduce long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect total costs. Familiarizing yourself with local market conditions can provide leverage during negotiations.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to new products or technologies.

Disclaimer on Indicative Prices

While the information provided offers a comprehensive overview of cost components and pricing influencers for cracked leather sourcing, actual prices may vary significantly based on current market conditions, regional differences, and specific supplier agreements. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing cracked leather With Other Solutions

Exploring Alternatives to Cracked Leather

When considering the impact of cracked leather on product quality and longevity, it is essential to explore viable alternatives that may suit your business needs. Cracked leather, while luxurious and aesthetically appealing, can present challenges in maintenance and longevity. Below, we compare cracked leather with other popular materials—synthetic leather and canvas—providing insights into their performance, cost, and overall suitability for various applications.

| Comparison Aspect | Cracked Leather | Piel sintética | Canvas |

|---|---|---|---|

| Performance | High durability, but prone to cracking if not maintained | Good durability; resistant to wear and tear | Moderate durability; can wear out faster in harsh conditions |

| Cost | Generally high due to sourcing and processing | Usually lower; varies by quality and brand | Affordable; costs vary based on treatment and weight |

| Ease of Implementation | Requires specific care and maintenance | Easy to clean and maintain | Simple to use; can be treated for water resistance |

| Maintenance | High; requires regular conditioning and care | Low; occasional cleaning needed | Moderate; requires treatment for longevity |

| Best Use Case | Luxury products like bags, jackets, and furniture | Everyday items like bags, upholstery, and clothing | Casual items like backpacks, tents, and outdoor gear |

What Are the Pros and Cons of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, provides a cost-effective alternative to genuine leather. One of its main advantages is its resistance to wear and tear, making it suitable for high-traffic items. Additionally, synthetic leather is easier to clean and maintain, requiring only occasional wiping down to keep it looking fresh. However, it lacks the prestige and luxury appeal of genuine leather, which may be a drawback for businesses focused on high-end markets. Moreover, synthetic options may not breathe as well as leather, potentially leading to discomfort in specific applications.

How Does Canvas Compare to Cracked Leather?

Canvas is a versatile fabric made from cotton, linen, or synthetic fibers, known for its durability and strength. It’s an affordable option for businesses looking for lightweight solutions that can withstand wear. The best use cases for canvas include outdoor gear, such as tents and backpacks, due to its water-resistant capabilities when treated appropriately. However, canvas may not offer the same level of luxury or aesthetic appeal as cracked leather, which can be a consideration for businesses in the fashion or luxury sectors. While it requires moderate maintenance, canvas does not need the same level of conditioning as leather, making it a practical choice for casual items.

How to Choose the Right Solution for Your Business Needs

Selecting the right material depends on various factors including target market, intended use, and budget. If your business emphasizes luxury and high-quality products, investing in cracked leather may be worthwhile, provided you are prepared for the maintenance it requires. Conversely, if you are targeting a more budget-conscious market or require items that can withstand harsh conditions, synthetic leather or canvas may be more suitable. Ultimately, understanding your customer base and the specific requirements of your products will guide you in making the best choice for your business.

Essential Technical Properties and Trade Terminology for cracked leather

What Are the Key Technical Properties of Cracked Leather?

When sourcing cracked leather for manufacturing or resale, understanding the essential technical properties is crucial for ensuring quality and longevity. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality classification of leather based on its source and treatment. Higher grades are typically more durable and less prone to cracking. For B2B buyers, selecting a suitable material grade ensures that products not only meet customer expectations but also withstand wear and tear, reducing return rates and enhancing customer satisfaction.

Illustrative image related to cracked leather

2. Moisture Content

Moisture content indicates the amount of water present in the leather. Proper moisture levels are vital to maintaining the flexibility and durability of the material. For international buyers, understanding moisture content helps in assessing how well the leather can adapt to different climates, particularly in regions with extreme humidity or dryness, thus impacting product quality during transit and storage.

3. Tensile Strength

Tensile strength measures the leather’s ability to withstand tension without breaking. This property is particularly important for items like bags and footwear, which experience significant stress. Buyers should prioritize suppliers who can provide tensile strength specifications to ensure that the leather can endure the demands of its intended use, thereby minimizing potential losses from product failures.

4. Flexibilidad

Flexibility refers to the leather’s ability to bend and stretch without cracking. This property is essential for ensuring that leather goods maintain their shape and usability over time. In B2B transactions, flexibility is a key selling point, especially for products that require intricate designs or frequent movement, such as automotive upholstery or fashion accessories.

5. Surface Finish

The surface finish of leather affects its appearance and durability. Different treatments (e.g., aniline, semi-aniline, or pigmented) can enhance or detract from the leather’s resistance to cracking. Buyers should understand the implications of various finishes, as they can influence customer perceptions and the overall marketability of the final product.

6. Color Fastness

Color fastness measures how well the dye adheres to the leather and resists fading or bleeding. This property is particularly important for items exposed to sunlight or frequent handling. Buyers need to ensure that the leather meets industry standards for color fastness to avoid quality issues that could lead to customer dissatisfaction.

Illustrative image related to cracked leather

Which Common Trade Terms Should B2B Buyers Know When Dealing with Cracked Leather?

Understanding industry jargon is essential for effective negotiation and sourcing. Here are some common trade terms relevant to cracked leather:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the leather industry, this could involve sourcing cracked leather from an OEM that specializes in producing leather for specific applications. Knowing this term helps buyers identify reliable suppliers who can meet their production needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and financial planning. Understanding MOQs can help businesses negotiate better terms and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For buyers of cracked leather, issuing an RFQ can streamline the procurement process and ensure that all potential suppliers provide comparable information, aiding in decision-making.

Illustrative image related to cracked leather

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Knowing these terms is essential for B2B transactions involving cracked leather, as they dictate shipping responsibilities, risk, and costs. Understanding Incoterms helps buyers avoid unexpected charges and delays.

5. Lead Time

Lead time is the duration from order placement to delivery. This term is vital for B2B buyers who need to manage timelines effectively, especially when dealing with cracked leather that may require specific handling or treatment before use.

6. Certification Standards

Certification standards refer to industry benchmarks that leather products must meet, such as environmental sustainability or quality control. Familiarity with these standards can help buyers ensure that their products align with regulatory requirements and market expectations, particularly in regions with stringent import regulations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their procurement of cracked leather meets both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the cracked leather Sector

What Are the Current Market Dynamics and Key Trends in the Cracked Leather Sector?

The cracked leather sector is experiencing notable shifts driven by evolving consumer preferences and market demands. Globally, the luxury leather goods market is expanding, with an increasing focus on high-quality, durable products. Key drivers include a rising middle class in emerging markets such as Nigeria and Brazil, where consumers are seeking premium leather goods that combine aesthetics with longevity. Additionally, the growth of e-commerce platforms has facilitated access to a broader range of suppliers, allowing international buyers to source cracked leather products from various regions.

Illustrative image related to cracked leather

Emerging trends in B2B sourcing for cracked leather include the adoption of advanced technology in manufacturing processes. Innovations such as automated tanning and dyeing techniques enhance production efficiency and quality, making it easier for buyers to find consistent and reliable products. Furthermore, there is a growing emphasis on customization, with businesses offering tailored solutions to meet specific buyer requirements. This shift is particularly relevant in regions like the Middle East and Europe, where personalized leather goods are gaining traction.

International buyers should also be aware of the competitive landscape, which is seeing an influx of new entrants, particularly from Asia and Latin America. This diversification presents opportunities for cost-effective sourcing but also necessitates a thorough evaluation of quality and sustainability practices among suppliers.

How Is Sustainability and Ethical Sourcing Shaping the Cracked Leather Market?

Sustainability is becoming a cornerstone of the cracked leather sector, with increasing scrutiny on environmental impacts and ethical sourcing practices. Buyers are now more informed and concerned about the origins of the leather they purchase, prompting a shift towards suppliers who prioritize sustainable practices. This includes the use of vegetable tanning methods, which are less harmful to the environment compared to traditional chemical tanning processes.

Ethical supply chains are also gaining prominence, as consumers demand transparency regarding labor practices and animal welfare. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers seeking to establish credibility in the market. These certifications not only assure buyers of responsible sourcing but also enhance brand reputation and consumer trust.

Illustrative image related to cracked leather

As international buyers from regions such as Africa and South America navigate this landscape, it is crucial to partner with suppliers who demonstrate a commitment to sustainability. This approach not only aligns with global consumer trends but also mitigates risks associated with regulatory compliance and reputational damage.

What Is the Historical Context of Cracked Leather in B2B Markets?

The evolution of cracked leather as a significant product in B2B markets can be traced back to the increasing demand for durable and aesthetically pleasing leather goods. Historically, leather has been valued for its strength and longevity, but the awareness of its maintenance needs has evolved over time. In the early 20th century, leather was primarily viewed as a luxury item, often associated with high-end fashion and bespoke products.

As industrialization progressed, the production of leather became more widespread, leading to advancements in tanning techniques that improved the durability and finish of leather goods. However, the understanding of the importance of leather care, particularly in preventing cracking and damage, has only recently gained traction. This shift reflects a broader trend in consumer awareness regarding product longevity and sustainability, making it a pivotal aspect for B2B buyers in today’s market.

In conclusion, as the cracked leather sector continues to develop, international buyers must stay informed about market dynamics, sustainability practices, and historical influences to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of cracked leather

-

How do I solve the issue of cracked leather in my products?

To address cracked leather, start by assessing the severity of the damage. For light cracks, applying a high-quality leather conditioner can significantly improve the appearance and restore flexibility. For deeper cracks, consider using a leather crack filler followed by dye to blend the repair with the surrounding material. Regular maintenance with conditioners can also prevent future cracking. It’s essential to educate your team on proper care techniques to extend the life of leather products. -

What is the best method for repairing deep cracks in leather?

The most effective method for repairing deep cracks involves a two-step process: first, use a leather crack filler to fill in the cracks, allowing it to dry completely. Then, apply a matching leather dye to blend the repair seamlessly with the surrounding area. This approach not only restores the leather’s appearance but also reinforces its structure. Ensure you follow up with a leather sealer to protect against future damage. -

What should I consider when sourcing cracked leather from international suppliers?

When sourcing cracked leather, prioritize suppliers who demonstrate expertise in leather quality and repair techniques. Look for certifications and customer testimonials to validate their reliability. It’s crucial to inquire about the sourcing of their leather, including whether it meets your region’s import regulations. Consider potential shipping times and logistics, especially if you’re importing from regions like Europe or South America, which may have varying standards and practices. -

How can I verify the quality of cracked leather before purchasing?

To verify quality, request samples from potential suppliers and conduct a thorough examination. Assess the leather’s texture, flexibility, and the depth of cracks. A reliable supplier should provide detailed information about their tanning processes and the type of leather used. Additionally, consider third-party inspections or certifications that can attest to the quality of the leather, ensuring it meets your business standards. -

What are the minimum order quantities (MOQ) for cracked leather?

Minimum order quantities can vary widely among suppliers. Typically, MOQs for cracked leather range from 50 to 500 square feet, depending on the supplier’s production capabilities and the leather type. Always clarify MOQs during negotiations, as some suppliers may offer flexibility for first-time buyers or for bulk orders. Understanding the MOQ will help you manage inventory and budget effectively. -

What payment terms are commonly offered by suppliers of cracked leather?

Payment terms can differ significantly between suppliers. Common arrangements include 30% upfront payment with the balance due upon delivery, or net 30-day terms after receipt of goods. It’s advisable to negotiate terms that align with your cash flow needs. Additionally, consider using letters of credit for larger transactions to mitigate risk and ensure payment security, especially in international dealings. -

How can I ensure quality assurance (QA) when sourcing cracked leather?

Implementing a robust quality assurance process is vital. Define clear quality standards and expectations in your contracts with suppliers. Request samples for inspection before full-scale orders and consider establishing a QA checklist that includes criteria for crack depth, color consistency, and overall texture. Regular audits and third-party inspections can further enhance quality assurance, especially for bulk orders. -

What logistics considerations should I keep in mind when importing cracked leather?

When importing cracked leather, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Engage with experienced logistics partners who can navigate international shipping complexities. Ensure that your supplier provides all necessary documentation to facilitate customs clearance. Additionally, plan for potential delays by allowing extra time in your supply chain to avoid disruptions in production.

Top 6 Cracked Leather Manufacturers & Suppliers List

1. Carl Friedrik – Leather Cream

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Carl Friedrik Leather Cream: A luxurious blend of oils, wax emulsions, and softeners designed to nourish and soften leather. Key ingredients include carnauba wax for shine and lanolin for moisture retention. Recommended for use in repairing light leather cracks.

2. Buffalo Jackson – Cracked Leather Repair

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Cracked Leather Repair involves three main steps: 1. Clean the leather surface with a soft brush or cloth, and apply leather cleaner or saddle soap to the cracks. 2. Smooth the cracks using mink oil or neatsfoot oil, applying with gentle pressure and a cloth or spoon. 3. Treat the leather by applying a leather conditioner to the treated area and surrounding leather, continuing monthly applications…

3. Facebook – Leather Furniture Restoration

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Furniture Repair & Restoration for a leather piece

4. Leatherworker – Ecoflow Pro Dye

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 8oz leather, Ecoflow dye, alcohol-based Pro Dye, rifle case for a saddle, 1.5″ strap

5. RubnRestore – Soft Filler for Leather and Vinyl Repair

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Repair products for leather and vinyl include Soft Filler for cracks, burns, tears, cuts, and holes. The filler is water-based and requires a warm surface (120º – 145º F) for proper curing. For extensive sun-damaged vinyl, Liquid Rubber® is recommended for resurfacing. Instructions for subpatching cuts, tears, or holes are provided, including cleaning with alcohol, applying a patch, and using Soft…

6. The Fedora Lounge – Jacket Repair Guide

Domain: thefedoralounge.com

Registered: 2003 (22 years)

Introduction: This company, The Fedora Lounge – Jacket Repair Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cracked leather

The strategic sourcing of cracked leather presents significant opportunities for international buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the intricacies of leather maintenance and repair is crucial for preserving the value of leather goods, which are often seen as luxury items. By sourcing high-quality leather and investing in effective repair solutions, businesses can enhance customer satisfaction and reduce costs associated with product turnover.

Leveraging proper leather conditioning and repair techniques not only extends the lifespan of products but also mitigates the environmental impact associated with leather waste. Buyers should prioritize suppliers who offer comprehensive care solutions and sustainable practices, ensuring that their sourcing aligns with market demands for quality and durability.

As the global market for leather continues to evolve, staying ahead means fostering strong relationships with suppliers who understand the nuances of leather maintenance. Embrace innovation and invest in strategic partnerships that can elevate your product offerings. The future is bright for those who act decisively—source wisely, invest in quality, and position your business for sustained growth in the competitive leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.