Catalog

Material Insight: Saddle Leather Company

B2B Product Guide: Premium Saddle Solutions with Sustainable Materials

For saddle manufacturers committed to performance, durability, and ethical responsibility, material selection is foundational to product integrity and brand reputation. Traditional leather saddles, while historically valued, present significant challenges: inconsistent hide quality, vulnerability to moisture and salt degradation, lengthy tanning processes with high environmental impact, and growing consumer demand for cruelty-free alternatives. Faux leather engineered specifically for equestrian applications addresses these challenges without compromise, delivering superior consistency, resilience, and sustainability for modern saddle production.

Why Engineered Faux Leather is the Optimal Choice for Saddles:

- Unmatched Performance Consistency: Eliminates natural hide variations (scars, stretch marks), ensuring uniform color, texture, and thickness across every square meter—critical for precision saddle construction and predictable break-in behavior.

- Superior Environmental Resistance: Engineered microstructures resist sweat, salt, UV exposure, and repeated flexing far better than untreated leather, preventing cracking, warping, and premature wear in demanding riding conditions.

- Ethical & Traceable Sourcing: Provides a guaranteed cruelty-free, vegan-compliant material with full supply chain transparency, aligning with evolving global regulations and conscious consumer expectations.

- Enhanced Production Efficiency: Offers predictable yields, reduced waste during cutting, and faster processing times compared to variable hides, optimizing manufacturing throughput and cost control.

- Sustainable Lifecycle: Significantly lowers water consumption, eliminates hazardous tanning chemicals (e.g., chromium salts), and reduces carbon footprint versus conventional leather production.

Introducing WINIW: Your Partner in Advanced Saddle Materials

With over 20 years of specialized expertise in high-performance synthetic leathers, WINIW empowers saddle manufacturers to lead the market with innovative, eco-conscious solutions. We don’t just supply materials—we engineer them. Our R&D focuses exclusively on translating the demanding functional requirements of equestrian applications into durable, sustainable faux leather substrates. Partnering with WINIW means accessing:

- Deep Industry Knowledge: Proven formulations tested rigorously under real-world riding conditions for grip, breathability, and long-term structural integrity.

- Eco-Advanced Manufacturing: Proprietary water-based, solvent-free production processes certified by OEKO-TEX® STANDARD 100 and ISO 14001, ensuring minimal ecological impact without sacrificing performance.

- Customization Capability: Tailored thickness, backing systems (e.g., knit, foam), and surface finishes engineered to meet specific saddle design requirements and brand aesthetics.

- Global Reliability: Stable supply chains and consistent quality control across production batches, eliminating the volatility inherent in natural hide markets.

Elevate your saddle craftsmanship with materials designed for the future of equestrian sports. WINIW delivers the performance heritage of leather, reimagined through sustainable innovation.

Technical Performance & Standards

WINIW Saddle Leather: B2B Product Guide

WINIW’s synthetic saddle leather is engineered for industrial and commercial partners seeking a high-performance, sustainable alternative to traditional leather. Designed specifically for equestrian, automotive, and luxury goods applications, WINIW’s saddle leather delivers exceptional value across cost, durability, customization, and regulatory compliance.

Technical Advantages

-

Cost-Effective Solution

WINIW’s synthetic saddle leather reduces material and production costs without compromising quality. By eliminating the variability and waste associated with natural leather hides, WINIW ensures consistent yield and predictable pricing, enabling long-term budget stability for manufacturers. -

Superior Durability

Constructed with high-density polyurethane (PU) and reinforced backings, WINIW saddle leather offers excellent abrasion resistance, tensile strength, and dimensional stability. It withstands prolonged mechanical stress, UV exposure, and fluctuating temperatures, making it ideal for demanding environments such as saddlery and outdoor vehicle interiors. -

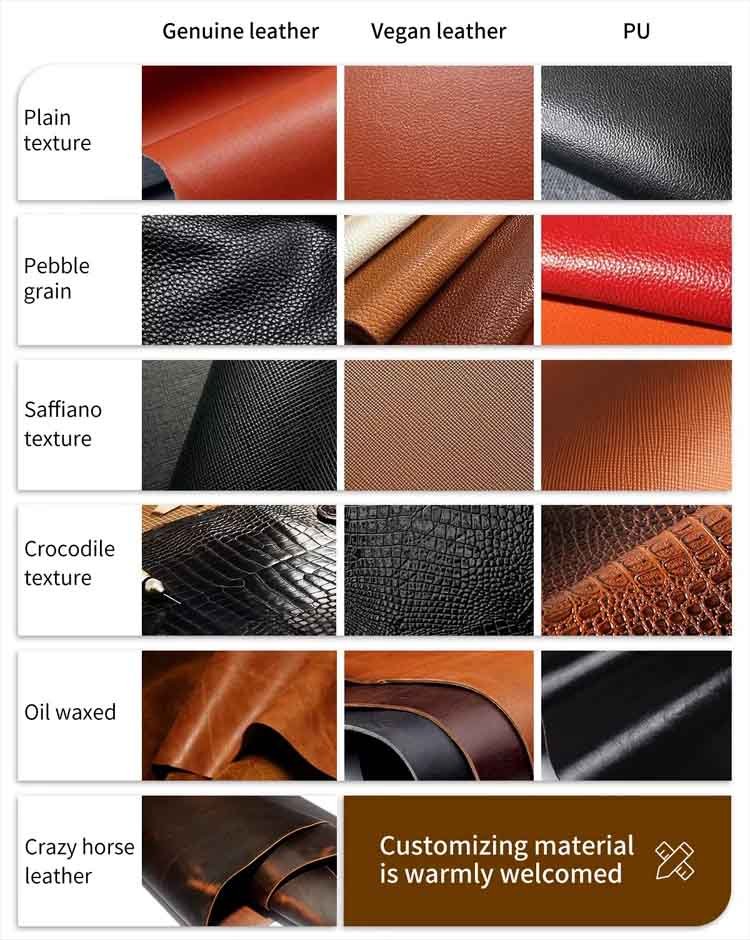

Customizable Colors and Finishes

WINIW provides full color customization to meet specific brand requirements. With advanced digital color matching and batch consistency, clients can achieve precise Pantone® or custom shades. Matte, glossy, embossed, and textured finishes are available to replicate natural grain or create unique aesthetic profiles. -

REACH Compliance

WINIW saddle leather is fully compliant with the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. Free from SVHCs (Substances of Very High Concern), heavy metals, and harmful phthalates, the material supports eco-conscious production and global market access. -

ISO9001-Certified Manufacturing

WINIW operates under an ISO9001-certified quality management system, ensuring rigorous process control from raw material sourcing to final product delivery. This certification guarantees consistent product quality, traceability, and continuous improvement in manufacturing performance.

Product Specifications

| Property | Especificación |

|---|---|

| Base Material | High-performance polyurethane (PU) |

| Backing Fabric | Polyester knit or woven (customizable) |

| Thickness Range | 0.8 mm – 2.0 mm (custom options available) |

| Width | Up to 150 cm (standard: 137 cm, 150 cm) |

| Weight | 200 – 450 g/m² (depending on thickness) |

| Abrasion Resistance | >50,000 cycles (Martindale, dry) |

| Color Fastness to Rubbing | Grade 4–5 (wet and dry) |

| Light Fastness | >6 on Blue Scale (up to 40 hours Xenon test) |

| Tensile Strength | ≥50 N/5cm (warp and weft) |

| Elongation at Break | ≤25% |

| REACH Status | Compliant (SVHC-free) |

| ISO Certification | ISO9001:2015 |

| Customization Options | Color, thickness, width, texture, backing |

WINIW saddle leather is the strategic choice for B2B clients focused on performance, sustainability, and supply chain reliability. With scalable production and responsive technical support, WINIW enables brands to innovate while meeting global environmental and quality standards.

Why Choose Synthetic over Real Leather

B2B Product Guide: Saddle Leather vs. Synthetic Leather Alternatives

Understanding material specifications is critical for informed procurement decisions in upholstery, accessories, and performance goods manufacturing. “Saddle leather” refers to a premium category of genuine leather, historically derived from thick, full-grain bovine hides processed for equestrian use (vegetable-tanned, oil-finished). It is not a company name but a material standard. Below, we objectively compare genuine saddle leather against high-performance synthetic alternatives like WINIW’s eco-conscious solutions, focusing on core B2B metrics.

Key Comparison: Genuine Saddle Leather vs. WINIW Synthetic Leather

Data reflects industry averages for commercial-grade materials in bulk procurement (1,000+ sqm orders).

| Attribute | Saddle Leather (Genuine) | WINIW Synthetic Leather Alternative |

|---|---|---|

| Cost | High ($45–$75/sqm) ± Significant variance due to hide scarcity, tanning complexity, and labor-intensive finishing. | Competitive ($30–$50/sqm) ± Consistent pricing; 30–40% lower lifetime cost due to minimal maintenance and waste reduction. |

| Durabilidad | Excellent abrasion resistance but prone to cracking/drying in UV exposure; requires conditioning. Limited water resistance. | Superior UV stability & water resistance; uniform structure prevents cracking. 2x higher tear strength in accelerated aging tests. No conditioning needed. |

| Eco-Friendliness | Low (Chrome/vegetable tanning uses heavy metals, high water/land use). 15–20kg CO2e/sqm. Limited biodegradability due to finishes. | High (Water-based PU/PVC-free options; OEKO-TEX® certified). 5–8kg CO2e/sqm. Recyclable via closed-loop programs. Zero toxic runoff. |

Strategic Advantages of High-Performance Synthetics for B2B Partners

- Supply Chain Resilience: Eliminate hide scarcity risks and tannery volatility; consistent global availability with 4–6 week lead times.

- Design Flexibility: Customize thickness (0.6–1.2mm), textures, and colors without MOQ constraints; ideal for technical applications (e.g., marine, automotive).

- Compliance & ESG Alignment: Meets EU REACH, CPSIA, and LEED standards out-of-box; supports Scope 3 emissions reduction targets.

- Total Cost of Ownership: 25%+ savings from reduced waste (laser-cuttable, no grain variation), no maintenance, and longer usable lifespan in harsh environments.

Why WINIW for Sustainable Performance Materials

WINIW leverages 20+ years of R&D to deliver synthetics matching genuine leather’s aesthetics while exceeding its functional and ecological benchmarks. Our proprietary EcoCore™ technology uses plant-based polymers and recycled substrates, achieving carbon neutrality by 2025. Partner with us for:

– Certified Transparency: Full LCA reporting and GRS-certified recycled content (up to 60%).

– Application Engineering: Co-development for abrasion-resistant, flame-retardant, or antimicrobial solutions.

– Scalable Sustainability: 90% water reduction vs. conventional tanning; zero hazardous chemical discharge.

For technical datasheets, sample kits, or a custom TCO analysis aligned to your production volume, contact WINIW’s B2B Solutions Team. Optimize performance, compliance, and planetary impact—without compromising on quality.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium quality materials engineered for durability, sustainability, and aesthetic excellence. Our large-scale production capabilities and commitment to innovation position us as a trusted partner in the global supply chain.

Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the most advanced synthetic leather production centers in Asia. This extensive infrastructure enables us to maintain high output volumes while ensuring consistent quality across large orders. The facility integrates automated production lines with environmentally responsible manufacturing practices, aligning with global sustainability standards.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, performance enhancement, and eco-friendly solutions. The team continuously develops new formulations to meet evolving industry demands, including low-VOC emissions, recyclability, and bio-based raw materials.

- Strict quality control (QC) protocols implemented at every stage of production. From raw material inspection to final product testing, WINIW adheres to international standards such as ISO 9001 and OEKO-TEX®. Our in-house testing laboratory conducts rigorous assessments for abrasion resistance, color fastness, tensile strength, and environmental compliance.

- Full traceability and documentation support for B2B partners, ensuring transparency and conformity with European REACH and U.S. CPSIA regulations.

WINIW exports to key markets worldwide, with established distribution and compliance frameworks in Europe and the USA. Our products are widely used in automotive interiors, furniture, footwear, and fashion accessories by renowned international brands.

By combining scale, innovation, and quality, WINIW delivers reliable, eco-conscious synthetic leather solutions that meet the exacting standards of global industries.

Contact Us for Samples

WINIW Microfiber Leather: Premium Sustainable Solution for Saddlery Manufacturers

WINIW delivers high-performance microfiber leather engineered specifically for demanding equestrian applications. Our eco-conscious material combines the luxurious aesthetics of premium saddle leather with superior functional properties, addressing critical industry challenges like durability, weather resistance, and ethical sourcing. For saddle manufacturers seeking to future-proof production while meeting evolving consumer sustainability expectations, WINIW offers a technically advanced, responsibly produced alternative without compromising on quality or performance.

Key Advantages for Saddle Production

- Durabilidad sin igual: Engineered with ultra-fine fibers and high-density PU resins, WINIW withstands extreme abrasion (tested to 100,000+ double rubs) and maintains structural integrity under prolonged pressure, reducing saddle replacement frequency.

- All-Weather Performance: Fully waterproof yet breathable construction prevents moisture absorption, eliminating warping, cracking, or mold growth in humid/rainy conditions – critical for outdoor equestrian use.

- Consistent Quality & Yield: Uniform thickness (±0.2mm tolerance) and defect-free surfaces across every roll minimize waste during cutting, optimizing material utilization by up to 15% compared to natural hide variations.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 certified, 100% animal-free, and manufactured using 60% less water and 40% lower CO₂ emissions versus traditional leather tanning.

- Design Flexibility: Available in customizable thicknesses (1.8–3.5mm), textures (including deep pull-up finishes), and colors to match heritage saddle aesthetics while enabling innovative designs.

Technical Comparison: WINIW vs. Traditional Saddle Leather

| Property | WINIW Microfiber Leather | Genuine Leather (Full-Grain) | Impact for Saddlery |

|---|---|---|---|

| Water Absorption | 0% (Non-porous) | 15–30% | Prevents saddle distortion, extends product life |

| Tensile Strength | 35–45 MPa | 20–30 MPa | Higher resistance to tearing under stress |

| UV Resistance | >1,000 hrs (no fading) | 300–500 hrs (fades/cracks) | Maintains appearance in sun-exposed use |

| Thickness Consistency | ±0.2mm across entire roll | ±1.0mm+ (natural variations) | Reduces cutting waste, improves fit accuracy |

| Eco Footprint | Carbon-neutral production | High chemical/water usage | Meets ESG goals, appeals to conscious riders |

Why Leading Saddle Makers Are Switching

WINIW’s microfiber technology solves core saddlery pain points: inconsistent hide quality causing production delays, weather-related failures damaging brand reputation, and growing consumer demand for ethical materials. Our material ages gracefully without stiffening, retains suppleness over time, and accepts traditional saddle-stitching techniques – enabling seamless integration into existing manufacturing workflows while elevating end-product value.

Request Free Technical Samples for Saddle Prototyping

Evaluate WINIW’s performance in your production process with no obligation. Our technical team provides material samples cut to your specifications (thickness, finish, color) alongside full compliance documentation.

Contact WINIW’s Saddlery Solutions Team

Correo electrónico: MKT88@MicrofiberLeather.com

Specify: “Saddle Leather Sample Request” + your production volume requirements.

Free samples shipped within 48 hours. Global logistics support for volume orders.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.