Catalog

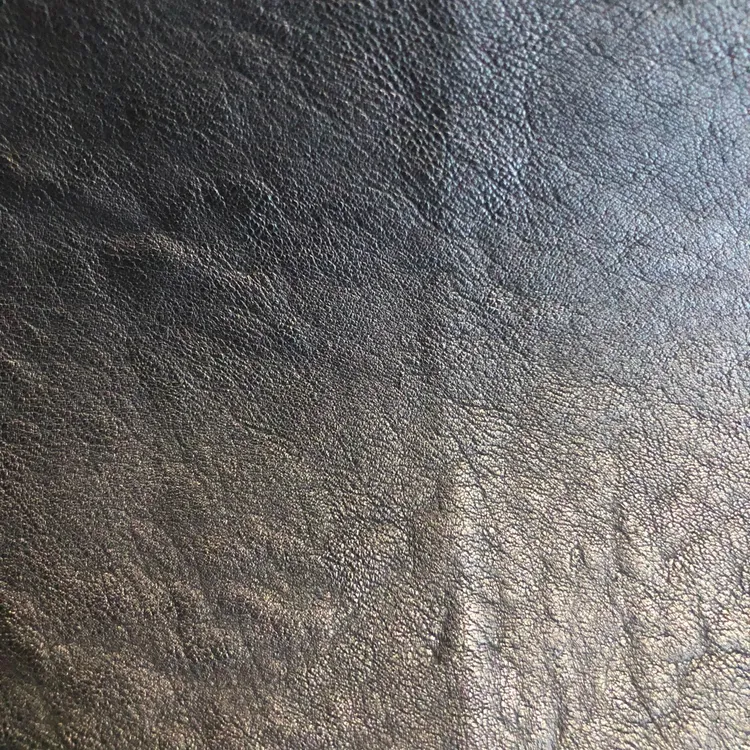

Material Insight: Real Leather Fabric

B2B Product Guide: Real Leather Fabric & the Superior Alternative

Real leather fabric, derived from tanned animal hides, has long been associated with luxury, durability, and timeless aesthetics in upholstery, automotive interiors, and high-end accessories. While it offers natural grain variation and a premium tactile feel, its application in modern B2B manufacturing presents significant challenges. Sourcing inconsistencies, ethical concerns regarding animal welfare, susceptibility to cracking and fading under UV exposure, and high maintenance requirements (including chemical treatments for water resistance) create operational inefficiencies and sustainability gaps for forward-thinking brands. Additionally, the resource-intensive tanning process—often involving heavy metals and high water consumption—conflicts with escalating corporate ESG mandates and consumer demand for transparent, low-impact materials.

Faux leather (synthetic leather) emerges as the optimal solution for contemporary B2B applications, directly addressing the limitations of real leather while aligning with market-driven priorities:

- Consistent Quality & Scalability: Engineered for uniform texture, color, and thickness, eliminating batch variations inherent in natural hides. This ensures reliable production yields and reduces waste.

- Enhanced Performance: Superior resistance to UV degradation, moisture, stains, and abrasion without requiring post-treatment. Ideal for high-traffic environments like public transport, healthcare, and contract furniture.

- Ethical & Traceable Sourcing: 100% animal-free, eliminating supply chain complexities tied to livestock agriculture and tannery labor practices.

- Sustainability by Design: Modern faux leathers leverage recycled content (e.g., PET bottles), water-based polyurethanes (PU), and solvent-free processes, drastically lowering carbon and water footprints versus traditional leather.

- Cost Efficiency: Reduced raw material volatility, lower maintenance costs, and extended product lifecycles deliver stronger total cost of ownership.

WINIW stands as the strategic partner for brands committed to redefining material excellence. With over 20 years of specialized expertise in synthetic leather innovation, we combine deep technical knowledge with an unwavering dedication to eco-conscious manufacturing. Our R&D-driven approach focuses on creating high-performance, responsibly sourced solutions—from ultra-soft microfiber textiles to abrasion-resistant PU leathers—that meet rigorous industry standards (e.g., automotive OEM, fire safety, REACH). By prioritizing water-based chemistry, recycled inputs, and closed-loop production systems, WINIW empowers B2B clients to achieve aesthetic ambition without compromising environmental integrity or operational resilience. Partner with us to future-proof your product lines with materials engineered for today’s conscious marketplace.

Technical Performance & Standards

B2B Product Guide: WINIW Real Leather Fabric

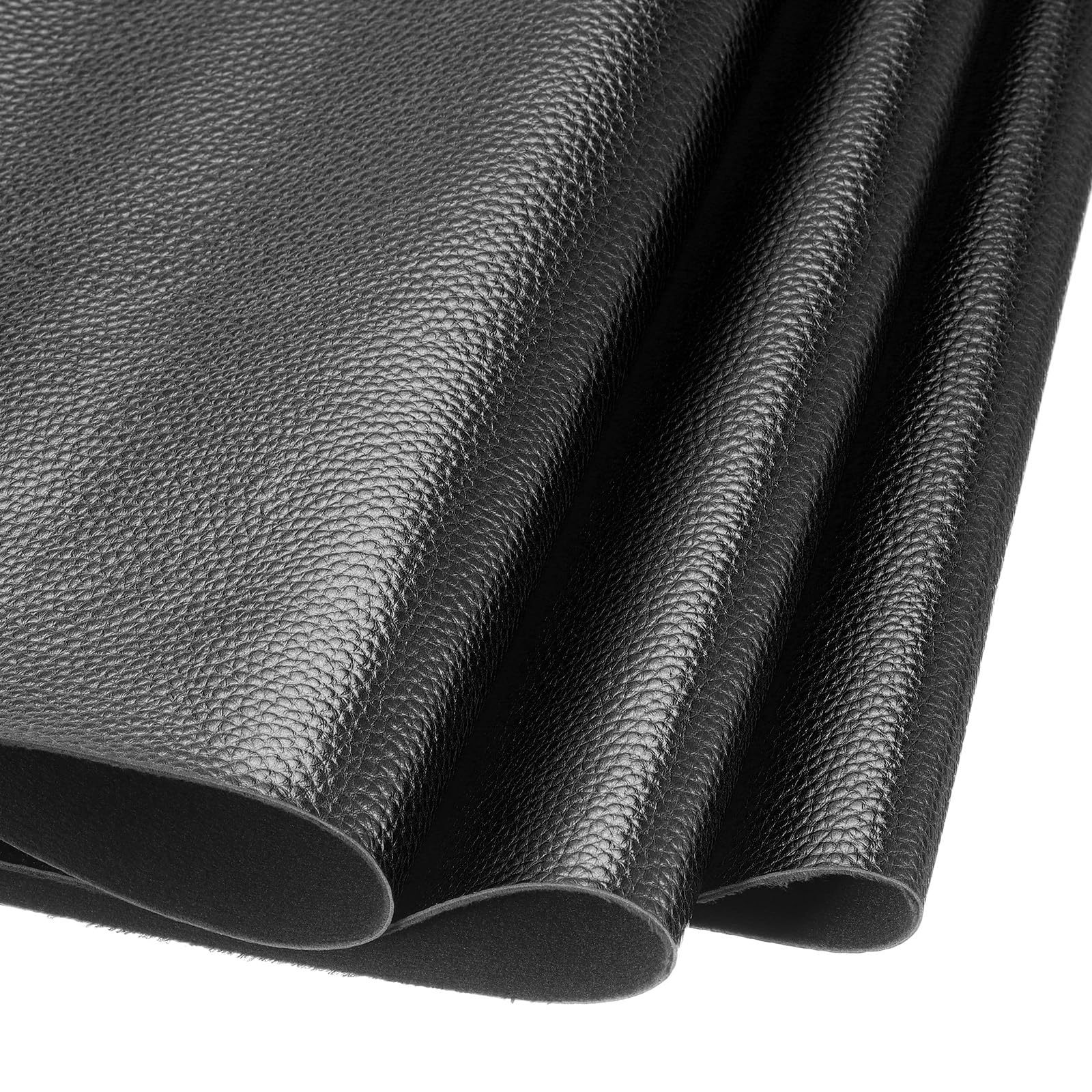

WINIW’s Real Leather Fabric is a premium synthetic leather solution engineered for industrial and commercial applications requiring durability, consistency, and environmental responsibility. Designed for B2B clients in furniture, automotive, footwear, and upholstery sectors, this material delivers the luxurious look and feel of genuine leather without the associated cost and sustainability challenges.

Engineered with advanced polyurethane (PU) and microfiber technology, WINIW’s Real Leather Fabric offers superior performance across key operational metrics. It is ideal for high-volume manufacturing environments where material consistency, compliance, and long-term value are critical.

Key Technical Advantages

- Cost-effective: Offers a lower total cost of ownership compared to genuine leather, with reduced waste during cutting and processing. No variability in hide quality eliminates sorting and grading costs.

- Duradero: High tensile strength, excellent abrasion resistance, and dimensional stability ensure long product life cycles, reducing replacement frequency and after-sales service demands.

- Customizable Colors: Full spectrum color matching available (Pantone, RAL, or custom references). Consistent dye batch performance supports brand standardization across global production sites.

- REACH Compliant: Formulated without SVHCs (Substances of Very High Concern), phthalates, heavy metals, or AZO dyes. Regular third-party testing ensures ongoing regulatory compliance for EU markets.

- ISO9001 Certified Production: Manufactured under a certified quality management system, ensuring consistent product specifications, traceability, and process control across all production batches.

Technical Specifications

| Property | Especificación |

|---|---|

| Base Material | High-density microfiber + PU coating |

| Thickness Range | 0.8 mm – 2.0 mm (customizable) |

| Weight | 280 – 450 g/m² |

| Tensile Strength | ≥ 80 N/5cm (warp), ≥ 70 N/5cm (weft) |

| Tear Strength | ≥ 30 N |

| Martindale Abrasion | ≥ 30,000 cycles (no break) |

| Color Fastness to Rubbing | Dry: 4–5, Wet: 3–4 (Grade) |

| Light Fastness | ≥ 4 (Blue Scale) |

| Cold Crack Resistance | Passes at -20°C |

| Heat Resistance | Stable up to 80°C (168 hrs) |

| REACH Status | Compliant (SVHC-free, updated annually) |

| ISO Certification | ISO9001:2015 (Quality Management) |

| Customization Options | Color, thickness, texture, roll width (1.37m standard) |

WINIW’s Real Leather Fabric supports sustainable manufacturing goals without compromising on performance or aesthetics. With scalable production capacity and global logistics support, it is the preferred choice for forward-thinking brands seeking reliable, eco-conscious materials.

Why Choose Synthetic over Real Leather

B2B Product Guide: Understanding Leather Material Terminology & Sustainable Alternatives

As a leading innovator in high-performance synthetic leather, WINIW clarifies common industry terminology to support informed procurement decisions. The term “real leather fabric” is frequently misused and causes significant confusion in B2B sourcing. True “Real Leather” is a natural material derived directly from animal hides (bovine, ovine, etc.), processed through tanning. There is no standardized product category called “real leather fabric” – this often refers to cuero sintético (like WINIW’s offerings) or bonded leather, neither of which are genuine leather. Below is a critical comparison for supply chain professionals prioritizing performance, cost, and sustainability.

Key Distinctions: Real Leather vs. Synthetic Leather (e.g., WINIW)

- Real Leather

- Sourced from animal hides; a natural byproduct of the meat industry.

- Requires resource-intensive tanning (water, chemicals, energy).

- Inherent variability in grain, thickness, and defects per hide.

-

Non-recyclable at end-of-life; landfill-bound or incinerated.

-

Synthetic Leather (WINIW’s Specialty)

- Engineered from plant-based or recycled polymers (e.g., PU, TPU, bio-PVDF).

- Consistent thickness, color, and performance across batches.

- Designed for circularity: Recyclable content (up to 60% recycled PET/plant-based) and end-of-life recyclability programs.

- Eliminates ethical concerns and volatile hide market dependencies.

Comparative Analysis: Real Leather vs. WINIW Synthetic Leather

| Criteria | Real Leather | WINIW Synthetic Leather |

|---|---|---|

| Cost | High volatility; subject to hide market fluctuations, tanning costs, and waste (up to 30% per hide unusable). Premium grades significantly increase expense. | Stable pricing; no raw material scarcity. Lower waste (<5%) in production. Predictable long-term costs for budget planning. |

| Durabilidad | Prone to scratches, fading, and moisture damage. Requires chemical conditioning. Lifespan: 5-10 years with meticulous care. | Superior abrasion/UV resistance. Stain, water, and mildew resistant. No conditioning needed. Lifespan: 10-15+ years in commercial settings (e.g., automotive, furniture). |

| Eco-Friendliness | High environmental burden: 15,000–20,000 L water per kg hide, toxic tanning chemicals (chromium), methane emissions from livestock. Non-biodegradable post-treatment. | 60-80% lower water usage. Zero chromium; solvent-free processes. Recycled content (e.g., 50% RPET) and recyclable end-products. Aligns with ESG goals and EU Green Deal standards. |

Strategic Advantages for B2B Partners

WINIW’s synthetic leather delivers measurable value for forward-thinking manufacturers:

– Supply Chain Resilience: Eliminate hide market volatility and ethical sourcing risks.

– Design Freedom: Custom thicknesses (0.6–1.2mm), textures, and colors without hide limitations.

– Sustainability Compliance: Meet corporate net-zero targets with traceable, low-impact materials (ISO 14001 certified production).

– Total Cost Efficiency: Reduce waste, maintenance, and replacement costs over product lifecycle.

For industries demanding reliability, ethical integrity, and environmental accountability – from automotive seating to luxury furniture – WINIW provides a technically superior, future-proof alternative to real leather. Our solutions support circular economy frameworks while exceeding performance benchmarks in commercial applications. Contact WINIW’s technical team for material samples and lifecycle assessment (LCA) data tailored to your specifications.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable, and durable materials. Our manufacturing excellence is backed by extensive infrastructure, technical expertise, and a commitment to quality and environmental responsibility.

Our state-of-the-art production facility spans 100,000 square meters, making it one of the largest synthetic leather manufacturing hubs in Asia. This expansive campus integrates advanced production lines with eco-conscious processes, enabling high-volume output without compromising on sustainability or precision.

Key strengths of the WINIW factory include:

-

Advanced R&D Team: A dedicated research and development department staffed with material scientists and engineers drives continuous innovation. Our team develops customized solutions for diverse industries, including automotive, furniture, fashion, and sports, focusing on performance, recyclability, and low environmental impact.

-

Strict Quality Control (QC): Every batch undergoes rigorous testing in our on-site laboratories. We adhere to international standards such as REACH, RoHS, and OEKO-TEX® to ensure product safety, durability, and consistency. Our QC protocols cover raw material inspection, in-process monitoring, and final product verification.

-

Sustainable Manufacturing: WINIW prioritizes eco-friendly practices, utilizing water-based, solvent-free, and bio-based technologies. Our production processes minimize waste and emissions, supporting our clients’ ESG goals.

-

Global Export Capability: WINIW exports to key markets worldwide, including Europe and the USA. Our logistics network ensures reliable, on-time delivery with full compliance with regional regulatory requirements.

The combination of scale, innovation, and quality makes WINIW a trusted partner for brands seeking high-performance synthetic leather with a responsible footprint.

Contact Us for Samples

WINIW Synthetic Leather Solutions: Premium Microfiber for Sustainable B2B Applications

WINIW delivers high-performance, eco-conscious synthetic leather engineered for discerning manufacturers across furniture, automotive, fashion, and technical textiles. Our microfiber leather replaces traditional animal hides without compromising on durability, aesthetics, or environmental responsibility. Backed by ISO 14001 certification and water-based PU technology, WINIW offers supply chain resilience and ethical compliance for global brands.

Why Partner with WINIW?

- Eco-Integrity: 100% animal-free production with OEKO-TEX® Standard 100 certification; zero heavy metals or phthalates.

- Performance Parity: Matches genuine leather in tear strength, abrasion resistance, and breathability (test data available upon request).

- Customization Flexibility: Tailor thickness (0.6mm–2.0mm), weight (200–800g/m²), textures (suede, pebble, exotic), and color fastness (ISO 105-B02 Level 4+).

- Supply Chain Stability: Mitigate volatility risks with consistent lead times and scalable production capacity (5M+ meters/month).

WINIW Core Product Specifications

| Product Line | Thickness Range | Key Applications | Sustainability Highlights |

|---|---|---|---|

| WINIW EcoLuxe™ | 0.8–1.5mm | Upholstery, Handbags | 30% recycled content; GRS-certified |

| WINIW AutoGrade™ | 1.2–2.0mm | Automotive Interiors | Low-VOC; FMVSS 302 compliant |

| WINIW TechWeave™ | 0.6–1.0mm | Technical Apparel, Footwear | Waterproof; 50k+ Martindale cycles |

Addressing Modern Manufacturing Challenges

- Regulatory Compliance: Meet EU REACH, California Prop 65, and China GB 18401 standards without reformulation delays.

- Circular Economy Integration: End-of-life recyclability support via our closed-loop partnership program.

- Cost Efficiency: Reduce waste with precision cutting yields up to 95% (vs. 70–80% for irregular hide grading).

Póngase en contacto con MKT88@MicrofiberLeather.com for ‘real leather fabric’ alternatives that exceed sustainability mandates and performance benchmarks. Free physical samples available to qualified B2B partners for material validation. Elevate your product line with traceable, premium synthetic leather—engineered for the future.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.