Introduction: Navigating the Global Market for upholstery material for cars

In today’s competitive automotive landscape, sourcing high-quality upholstery material for cars poses a significant challenge for international B2B buyers. From the plush comforts desired in luxury vehicles to the robust durability required for commercial fleets, the right upholstery can transform a vehicle’s interior and enhance user experience. This comprehensive guide delves into the myriad types of upholstery materials available, their specific applications, and essential factors for supplier vetting.

Buyers will explore a range of options, including leather, vinyl, and innovative synthetic fabrics, each offering distinct advantages depending on usage scenarios and budget constraints. Cost considerations are also covered, ensuring that businesses can balance quality with affordability. By empowering B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—this guide provides actionable insights to make informed purchasing decisions.

Whether you are looking to upgrade existing vehicle interiors or source materials for manufacturing, understanding the global market dynamics and material characteristics is crucial. This resource equips buyers with the knowledge necessary to navigate the complexities of upholstery material sourcing, ensuring that your investment leads to lasting satisfaction and enhanced vehicle value.

Table Of Contents

- Top 8 Upholstery Material For Cars Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for upholstery material for cars

- Understanding upholstery material for cars Types and Variations

- Key Industrial Applications of upholstery material for cars

- 3 Common User Pain Points for ‘upholstery material for cars’ & Their Solutions

- Strategic Material Selection Guide for upholstery material for cars

- In-depth Look: Manufacturing Processes and Quality Assurance for upholstery material for cars

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘upholstery material for cars’

- Comprehensive Cost and Pricing Analysis for upholstery material for cars Sourcing

- Alternatives Analysis: Comparing upholstery material for cars With Other Solutions

- Essential Technical Properties and Trade Terminology for upholstery material for cars

- Navigating Market Dynamics and Sourcing Trends in the upholstery material for cars Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of upholstery material for cars

- Strategic Sourcing Conclusion and Outlook for upholstery material for cars

- Important Disclaimer & Terms of Use

Understanding upholstery material for cars Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Upholstery | Luxurious feel, high durability, easy maintenance | Luxury vehicles, high-end restorations | Pros: Elegant, long-lasting, easy to clean. Cons: Expensive, requires maintenance, temperature sensitivity. |

| Vinyl Upholstery | Cost-effective, stain-resistant, versatile colors | Fleet vehicles, commercial use | Pros: Affordable, easy to clean, durable. Cons: Less breathable, can feel sticky in heat. |

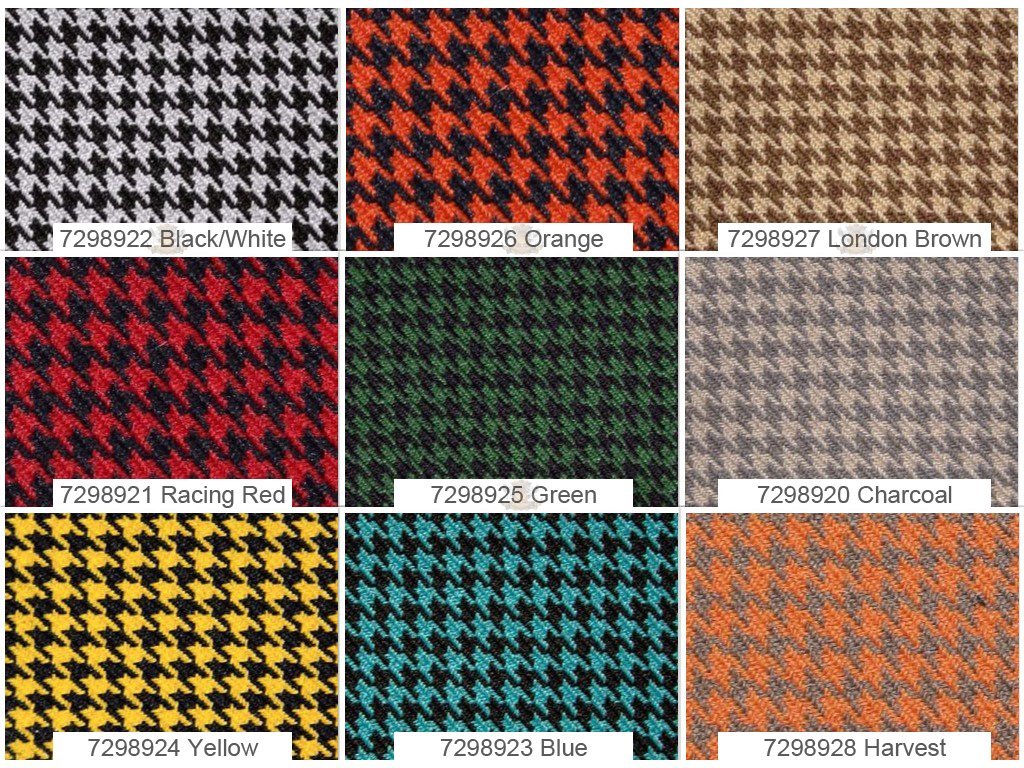

| Fabric Upholstery | Soft, breathable, available in numerous patterns | Family cars, custom designs | Pros: Comfortable, customizable, breathable. Cons: Prone to staining, may wear out faster. |

| Synthetic Fabrics | Soft feel, stain-resistant, budget-friendly options | Mid-range vehicles, rental fleets | Pros: Affordable, easy to maintain, durable. Cons: Less luxurious, can show wear over time. |

| Eco-Friendly Fabrics | Made from recycled or natural materials | Sustainable vehicles, eco-conscious brands | Pros: Environmentally friendly, durable. Cons: May be more expensive, limited availability. |

What are the Characteristics and Suitability of Leather Upholstery for Cars?

Leather upholstery is renowned for its luxurious aesthetic and durability, making it a popular choice for high-end vehicles and restorations. Its key features include resistance to wear and easy maintenance, which appeal to businesses focusing on longevity and elegance. For B2B buyers, investing in leather can enhance vehicle value, but considerations include the higher initial cost and the need for regular upkeep, especially in varying climates.

How Does Vinyl Upholstery Serve B2B Applications?

Vinyl upholstery stands out for its cost-effectiveness and versatility, making it ideal for fleet vehicles and commercial applications. Its resistance to stains and ease of cleaning are crucial for businesses that require durability without sacrificing aesthetics. While vinyl is budget-friendly, buyers should be aware of its lower breathability compared to other materials, which may affect comfort in hot climates.

What Makes Fabric Upholstery a Good Choice for Family Cars?

Fabric upholstery offers a soft, breathable option that can be customized in various colors and patterns, appealing to family car manufacturers and custom vehicle designers. Its comfort level is a significant advantage, particularly for long journeys. However, B2B buyers must consider the potential for staining and the need for more frequent maintenance compared to leather and vinyl, which could impact long-term costs.

Why Consider Synthetic Fabrics for Mid-Range Vehicles?

Synthetic fabrics, such as microfiber and polyester, provide a balance of comfort and durability at a budget-friendly price point, making them suitable for mid-range vehicles and rental fleets. Their stain-resistant properties and ease of maintenance align with the demands of high-usage environments. While they may lack the luxury feel of leather, their affordability and resilience make them an appealing option for B2B buyers focused on value.

What are the Benefits of Eco-Friendly Upholstery Materials?

Eco-friendly fabrics, crafted from recycled or natural materials, cater to the growing demand for sustainable options in the automotive industry. These materials not only reduce environmental impact but also offer durability suitable for various applications. However, B2B buyers should consider the potential for higher costs and limited availability, balancing sustainability with budget constraints.

Key Industrial Applications of upholstery material for cars

| Industry/Sector | Specific Application of upholstery material for cars | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Seat covers for passenger and commercial vehicles | Enhances vehicle appeal, increases resale value | Durability, compliance with safety standards, cost-effectiveness |

| Automotive Aftermarket | Custom upholstery for vehicle restoration | Provides unique customization, improves customer satisfaction | Variety of materials, availability, and design flexibility |

| Ride-Hailing Services | Upholstery for fleet vehicles | Increases comfort for passengers, enhances brand image | Stain resistance, ease of maintenance, cost-efficiency |

| Luxury Vehicle Customization | High-end leather and synthetic upholstery | Elevates luxury perception, attracts affluent clientele | Quality of materials, sourcing of sustainable options, aesthetics |

| Commercial Vehicle Upfitting | Durable upholstery for trucks and vans | Ensures longevity under heavy use, reduces maintenance costs | Heavy-duty materials, resistance to wear and tear, pricing |

How is Upholstery Material Used in Automotive Manufacturing?

In automotive manufacturing, upholstery materials are critical for creating seat covers in both passenger and commercial vehicles. These materials not only enhance the aesthetic appeal of the vehicle but also contribute to its overall comfort and safety. Manufacturers prioritize durability and compliance with safety standards, ensuring that the upholstery can withstand daily wear and tear. For international buyers, especially from regions like Africa and the Middle East, sourcing materials that are cost-effective while meeting high-quality standards is essential for maintaining competitive pricing in the market.

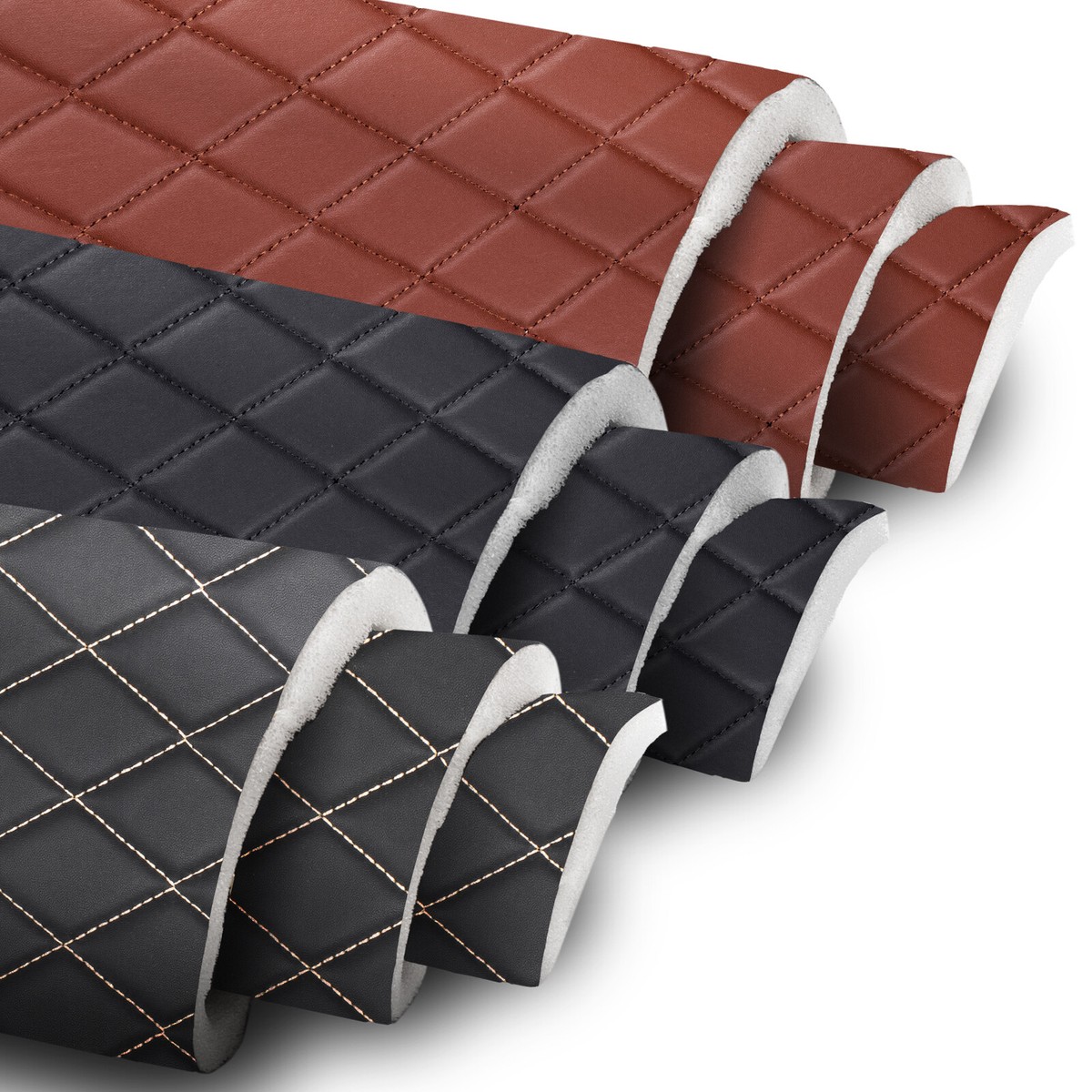

Illustrative image related to upholstery material for cars

What Role Does Upholstery Material Play in the Automotive Aftermarket?

The automotive aftermarket relies heavily on custom upholstery for vehicle restoration projects. This application allows businesses to offer personalized solutions that cater to specific customer preferences, enhancing satisfaction and loyalty. Buyers in this sector often seek a variety of materials, including leather and synthetic options, that provide both aesthetic appeal and functionality. Availability of diverse designs and colors is crucial, particularly for international buyers looking to cater to local tastes in regions such as South America and Europe.

How is Upholstery Material Beneficial for Ride-Hailing Services?

For ride-hailing services, upholstery materials are vital in outfitting fleet vehicles to ensure passenger comfort and satisfaction. High-quality, stain-resistant materials are preferred to maintain a clean and inviting environment for riders. Moreover, the choice of upholstery can enhance the brand image of the service, making it more appealing to potential customers. Buyers in this sector must consider cost-efficiency and ease of maintenance, especially in markets like Nigeria and Saudi Arabia, where operational costs are closely monitored.

Why is Upholstery Material Important for Luxury Vehicle Customization?

In the luxury vehicle customization sector, high-end upholstery materials such as premium leather and innovative synthetic fabrics are used to elevate the overall perception of the vehicle. This application appeals to affluent clientele who prioritize comfort, style, and exclusivity. Sourcing quality materials that also align with sustainability trends is increasingly important for businesses looking to attract eco-conscious consumers. For international buyers, understanding the local market’s luxury preferences can drive successful sourcing strategies.

How Does Upholstery Material Impact Commercial Vehicle Upfitting?

Commercial vehicle upfitting heavily utilizes durable upholstery materials to withstand the rigors of heavy use in trucks and vans. These materials must be resistant to wear and tear, ensuring longevity and reducing maintenance costs for businesses. Buyers should focus on sourcing heavy-duty options that offer both functionality and comfort, particularly for logistics and transportation companies. In regions like Africa and South America, where commercial transportation plays a significant role in the economy, finding cost-effective yet robust upholstery solutions is critical for operational success.

3 Common User Pain Points for ‘upholstery material for cars’ & Their Solutions

Scenario 1: Managing Durability Concerns in Upholstery Materials

The Problem: B2B buyers often face the challenge of selecting upholstery materials that will withstand the rigors of daily use, especially in environments where vehicles are subject to heavy wear and tear. This is particularly relevant for fleet managers or automotive manufacturers looking to maintain a cost-effective yet high-quality interior. Buyers may find themselves uncertain about which materials offer the best durability, leading to frequent replacements and increased maintenance costs.

The Solution: To address durability concerns, buyers should conduct thorough research on the performance characteristics of various upholstery materials. Prioritize options such as high-quality synthetic fabrics like polyester or nylon, which are known for their resistance to abrasions and stains. When sourcing these materials, look for suppliers that provide detailed specifications and performance ratings, including UV resistance and colorfastness. Additionally, consider implementing a testing phase where samples of the selected materials are subjected to real-world conditions before committing to large orders. This proactive approach not only ensures the longevity of the upholstery but also enhances customer satisfaction and reduces total cost of ownership.

Scenario 2: Balancing Aesthetics and Functionality

The Problem: Buyers often struggle to find upholstery materials that strike the right balance between aesthetics and functionality. For automotive businesses aiming to create a visually appealing interior while ensuring comfort and ease of maintenance, this can be a significant pain point. The challenge intensifies when targeting diverse markets, such as those in Africa or South America, where consumer preferences may vary greatly.

The Solution: To achieve a harmonious blend of aesthetics and functionality, buyers should engage in market research to understand regional preferences and trends. This insight will guide the selection of colors, textures, and styles that resonate with target consumers. When sourcing upholstery materials, consider options like leather for a luxurious look or innovative synthetic blends that offer vibrant colors and patterns while being easy to clean. Collaborate with suppliers who specialize in custom designs and can provide samples that showcase the material’s look and feel. This tailored approach ensures that the final product not only meets visual expectations but also supports practical needs such as stain resistance and easy maintenance.

Scenario 3: Understanding Eco-Friendly Upholstery Options

The Problem: As sustainability becomes a priority for many businesses, B2B buyers are increasingly pressured to source eco-friendly upholstery materials. However, the lack of clear information regarding the availability, performance, and cost implications of sustainable options can create confusion and hesitation in decision-making.

The Solution: To effectively navigate the eco-friendly upholstery landscape, buyers should start by identifying reputable suppliers who specialize in sustainable materials. Look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which ensure that the materials are produced under environmentally friendly practices. Additionally, engage suppliers who can provide comprehensive data on the lifecycle and recyclability of their products. For instance, consider materials made from recycled plastics or organic cotton that not only reduce environmental impact but also offer durability and comfort. By prioritizing partnerships with suppliers committed to sustainability, buyers can confidently offer eco-friendly upholstery solutions that align with their business values and appeal to environmentally conscious consumers.

Strategic Material Selection Guide for upholstery material for cars

When selecting upholstery materials for automotive applications, it is essential to understand the properties, advantages, and limitations of each option. This analysis focuses on four common materials: leather, vinyl, fabric (cloth), and synthetic fabrics, providing insights tailored for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Leather Upholstery?

Leather is renowned for its luxurious feel and durability. It typically has a temperature tolerance ranging from -30°C to 60°C, making it suitable for various climates. Leather also exhibits excellent abrasion resistance and is less prone to tearing compared to other materials. However, it requires regular maintenance to prevent drying and cracking.

Pros and Cons of Leather Upholstery

– Pros: Offers a high-end aesthetic, excellent durability, and easy cleaning. It ages well, developing a unique patina over time.

– Cons: Higher initial cost, requires maintenance, and can be uncomfortable in extreme temperatures without proper climate control.

Impact on Application

Leather is often preferred in luxury vehicles and high-end models due to its sophisticated appearance. Buyers in regions with hot climates, such as Saudi Arabia, should consider ventilation options to enhance comfort.

How Does Vinyl Upholstery Compare in Performance?

Vinyl upholstery provides a cost-effective alternative to leather while mimicking its appearance. It is resistant to moisture and stains, making it suitable for family vehicles and commercial applications. Vinyl can withstand temperatures from -20°C to 50°C but may become sticky in extreme heat.

Illustrative image related to upholstery material for cars

Pros and Cons of Vinyl Upholstery

– Pros: Affordable, easy to clean, and available in various colors and textures.

– Cons: Less breathable than leather, can degrade with prolonged sun exposure, and may not provide the same luxurious feel.

Impact on Application

Vinyl is commonly used in budget-friendly vehicles and commercial fleets. In regions like Nigeria, where cost-effectiveness is crucial, vinyl upholstery is a popular choice.

What Are the Advantages of Fabric Upholstery?

Fabric upholstery, typically made from natural fibers or blends, is soft and breathable. It can handle a temperature range of -10°C to 40°C, making it suitable for moderate climates. Modern treatments can enhance its stain resistance and durability.

Pros and Cons of Fabric Upholstery

– Pros: Comfortable, customizable in design, and generally lower in cost.

– Cons: More prone to staining, may wear out faster than leather or vinyl, and requires more frequent cleaning.

Illustrative image related to upholstery material for cars

Impact on Application

Fabric upholstery is ideal for family vehicles and those seeking a cozy interior. Buyers in cooler climates may prefer fabric for its warmth, while those in humid regions should consider moisture-resistant options.

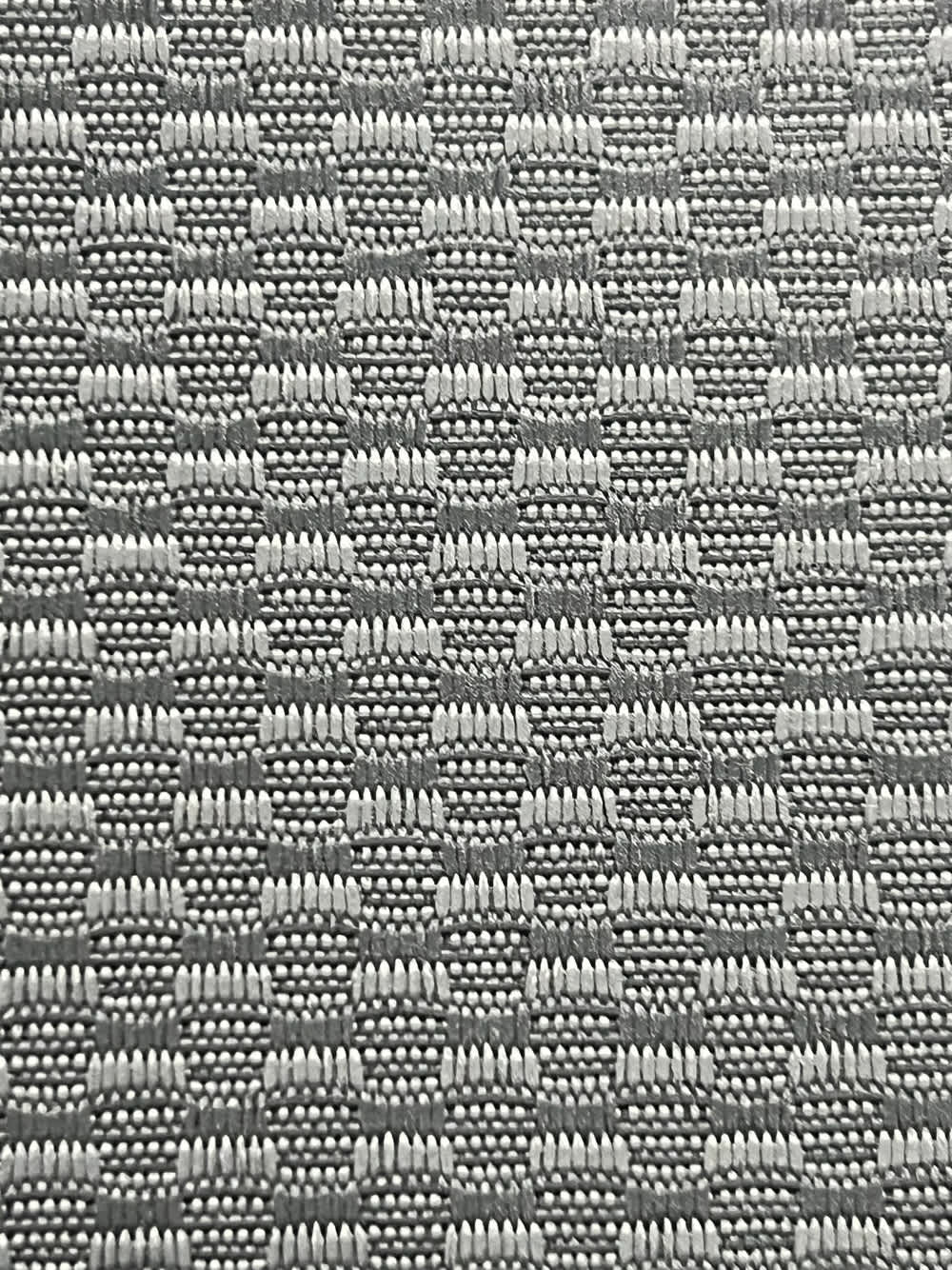

What Makes Synthetic Fabrics a Viable Option?

Synthetic fabrics, such as microfiber and polyester, combine the comfort of fabric with enhanced durability. They typically resist stains and can endure temperatures from -20°C to 50°C. These materials are often designed for easy maintenance and long-lasting performance.

Pros and Cons of Synthetic Fabrics

– Pros: Soft, stain-resistant, budget-friendly, and easy to clean.

– Cons: May lack the luxurious feel of leather, and some synthetic options can show wear over time.

Impact on Application

Synthetic fabrics are increasingly popular in various markets due to their affordability and versatility. In regions like South America, where the automotive market is price-sensitive, synthetic options provide a balance between quality and cost.

Summary Table of Upholstery Materials for Cars

| Material | Typical Use Case for upholstery material for cars | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Luxury vehicles and high-end models | High durability and aesthetic appeal | Higher cost and maintenance needs | Alta |

| Vinilo | Budget-friendly vehicles and commercial fleets | Affordable and easy to clean | Less breathable and may degrade | Low |

| Fabric (Cloth) | Family vehicles and customizable interiors | Comfortable and customizable | Prone to staining and wear | Medium |

| Synthetic Fabrics | Versatile applications in various markets | Stain-resistant and budget-friendly | May lack luxury feel | Medium |

This comprehensive analysis of upholstery materials provides B2B buyers with critical insights into their options, helping them make informed decisions tailored to their specific market needs and regional preferences.

Illustrative image related to upholstery material for cars

In-depth Look: Manufacturing Processes and Quality Assurance for upholstery material for cars

What Are the Main Stages of Manufacturing Upholstery Material for Cars?

The manufacturing process of upholstery materials for vehicles involves several key stages, each designed to ensure the final product meets high standards of quality and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing materials for automotive upholstery.

How Is Material Prepared for Upholstery Production?

The first stage in the manufacturing process is material preparation. This involves selecting raw materials, which may include natural fibers like cotton and wool, synthetic fibers such as polyester and nylon, or leather. Each material type has distinct properties that can impact the final product’s performance and aesthetics.

Once the materials are selected, they undergo various treatments to enhance their qualities. For example, fabrics may be dyed to achieve specific colors or treated with water-repellent or stain-resistant finishes. Leather may be tanned and conditioned to ensure it is supple and durable. This stage is critical as it sets the foundation for the quality of the upholstery material.

What Techniques Are Used in Forming Upholstery Materials?

After material preparation, the next stage involves forming the upholstery materials into usable formats. This typically includes weaving, knitting, or bonding materials together, depending on the type of upholstery being produced.

-

Weaving and Knitting: For fabrics, weaving or knitting techniques are used to create textiles that provide the necessary strength and flexibility. Different weave patterns can affect the fabric’s texture, durability, and appearance.

-

Bonding: For synthetic materials, bonding techniques may be employed, where layers of fabric are adhered together using adhesives or heat. This process can enhance the material’s durability and create multi-layered fabrics that offer additional benefits like insulation or sound dampening.

How Is Upholstery Material Assembled and Finished?

The assembly and finishing stages involve cutting, sewing, and finalizing the upholstery materials into the desired forms for vehicle interiors. This includes creating seat covers, door panels, and headliners.

Illustrative image related to upholstery material for cars

-

Cutting: Precision cutting is essential to ensure that pieces fit together seamlessly. This often involves using computer-aided design (CAD) software to create patterns that can be replicated accurately.

-

Sewing: Skilled operators sew the cut pieces together, ensuring strong seams that can withstand wear and tear. This process may also include adding decorative elements like stitching patterns or piping for aesthetic appeal.

-

Finishing: Finally, finishing touches are applied, which may include quality checks, final treatments (e.g., additional water repellency), and packaging for shipment. This stage is vital for ensuring that the upholstery material meets the expected quality standards before it reaches the customer.

What Are the Quality Control Measures for Upholstery Materials?

Quality assurance (QA) in the manufacturing of upholstery materials is critical to ensuring that the final products meet international standards and customer expectations. A robust QA process includes several checkpoints and testing methods.

Which International Standards Should Buyers Be Aware Of?

International standards play a significant role in the quality assurance of upholstery materials. One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has effective processes in place for ensuring product quality.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API standards (for products used in petroleum and natural gas industries) may also apply. Buyers should inquire about these certifications to ensure that the materials they are sourcing meet necessary regulations.

What Are the Key Quality Control Checkpoints?

Quality control in the upholstery manufacturing process typically includes several checkpoints:

-

Incoming Quality Control (IQC): This is the initial stage where raw materials are inspected upon arrival. This step ensures that all incoming materials meet predefined quality criteria before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor the production quality. This may include checking for defects during weaving, sewing, and finishing.

-

Final Quality Control (FQC): Before the finished products are packaged and shipped, a final quality check is performed. This ensures that the upholstery materials meet all specifications and standards, providing confidence in the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure that suppliers maintain high-quality standards:

-

Conduct Audits: Regular audits of suppliers can provide insights into their quality control processes. Buyers should consider on-site visits to assess manufacturing capabilities and quality assurance practices.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control procedures, including inspection reports and certifications. Reviewing these reports can help buyers understand the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct tests and evaluations to ensure that the products meet specified standards.

What Nuances Should International B2B Buyers Consider in Quality Control?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing upholstery materials.

Illustrative image related to upholstery material for cars

-

Cultural and Regulatory Differences: Different regions may have varying standards and regulations regarding materials and safety. It is essential for buyers to familiarize themselves with local regulations and ensure that suppliers comply.

-

Logistical Considerations: Shipping and handling can impact product quality, especially for sensitive materials like leather. Buyers should consider the entire supply chain, including transportation conditions, to ensure that products arrive in optimal condition.

-

Communication Barriers: Language differences may lead to misunderstandings about quality expectations. Establishing clear communication channels and ensuring that specifications are well-documented can mitigate these risks.

By understanding the manufacturing processes and quality assurance practices involved in upholstery materials for cars, B2B buyers can make more informed purchasing decisions, ensuring they select suppliers that meet their quality expectations and requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘upholstery material for cars’

To successfully procure upholstery materials for cars, it is essential to follow a systematic approach. This guide provides a clear checklist for B2B buyers to ensure they make informed and strategic decisions, ultimately leading to a successful sourcing experience.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the first step in the sourcing process. Identify the type of upholstery material required based on the vehicle’s intended use, whether for luxury cars, commercial vehicles, or family vehicles.

– Consider factors such as durability, comfort, and aesthetics to ensure the selected materials meet industry standards and customer expectations.

Step 2: Research Material Options

Familiarize yourself with various upholstery materials available in the market. This includes leather, vinyl, fabric, and synthetic options, each with distinct advantages and disadvantages.

– Evaluate factors such as cost, maintenance requirements, and lifespan to determine which materials align best with your project goals and target market preferences.

Illustrative image related to upholstery material for cars

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions.

– Assess their production capabilities, quality control measures, and past performance to ensure they can meet your specific needs and timelines.

Step 4: Request Samples and Prototypes

Obtaining samples of the materials you are considering is vital. This allows you to evaluate the quality, texture, and color in person.

– Test the samples for durability and maintenance ease to ensure they can withstand the intended use and meet your quality expectations.

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. A clear understanding of costs helps avoid surprises and ensures that the project remains within budget.

– Seek to establish long-term partnerships by negotiating favorable terms that could benefit both parties in future transactions.

Step 6: Verify Compliance with Regulations

Ensure that the materials sourced comply with local and international regulations, especially concerning safety and environmental standards.

– Check certifications and documentation that confirm the materials meet industry guidelines, which is particularly crucial for automotive applications where safety is paramount.

Illustrative image related to upholstery material for cars

Step 7: Plan for Logistics and Delivery

Finally, develop a robust logistics plan to manage the delivery of the upholstery materials. Consider factors such as shipping methods, timelines, and potential customs regulations, especially for international shipments.

– Establish clear communication channels with your supplier to monitor the delivery process and address any issues that may arise promptly.

By following this checklist, B2B buyers can streamline their procurement process for automotive upholstery materials, ensuring that they select the best options that meet both quality standards and market demands.

Comprehensive Cost and Pricing Analysis for upholstery material for cars Sourcing

What Are the Key Cost Components in Upholstery Material Sourcing for Cars?

When considering upholstery material for cars, a thorough understanding of the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of upholstery material significantly impacts costs. Leather tends to be the most expensive due to its durability and luxury appeal, while synthetic fabrics like vinyl and microfiber offer budget-friendly alternatives. Eco-friendly options may incur additional costs but can attract a growing segment of environmentally conscious consumers.

-

Labor: Labor costs vary based on the complexity of the upholstery work. Custom designs and intricate stitching require skilled labor, which can drive up costs. Conversely, mass production of standard designs can reduce labor expenses.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: Initial tooling costs for specialized machinery or molds can be significant, especially for custom upholstery solutions. However, these costs can be amortized over large production runs, making them more manageable for high-volume orders.

-

Quality Control (QC): Ensuring that materials meet specific standards is vital. QC processes may add to the overall cost but are essential for maintaining product quality and customer satisfaction.

-

Logistics: Shipping and handling costs can fluctuate based on the supplier’s location and the destination market. Buyers should account for freight costs, customs duties, and potential tariffs, especially when sourcing internationally.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary widely based on the supplier’s market position, product quality, and service offerings.

What Factors Influence Pricing for Upholstery Material?

Several factors can influence the pricing of upholstery materials, making it essential for buyers to conduct thorough market research.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Buyers should assess their needs and negotiate based on expected volume to secure favorable rates.

-

Specifications and Customization: Custom materials or unique specifications can lead to higher prices. Buyers should clearly outline their requirements to avoid unexpected costs.

-

Quality and Certifications: Higher-quality materials often come with certifications that ensure durability and safety. While these may increase upfront costs, they can lead to long-term savings by reducing the need for replacements or repairs.

-

Supplier Factors: Supplier reputation, location, and service capabilities can impact pricing. Established suppliers may command higher prices due to reliability and service quality, while newer suppliers might offer competitive rates to gain market share.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost. Understanding whether costs include insurance, freight, and customs duties is crucial for accurate budgeting.

How Can Buyers Negotiate Better Prices for Upholstery Materials?

Negotiating effectively can lead to significant savings for B2B buyers sourcing upholstery materials. Here are some tips:

Illustrative image related to upholstery material for cars

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and service. Long-term relationships often result in more favorable terms.

-

Leverage Volume: As mentioned, larger orders typically yield better pricing. Buyers should consider consolidating orders or collaborating with other businesses to increase volume.

-

Total Cost of Ownership (TCO): Assessing TCO rather than just initial costs can provide a clearer picture of value. Consider factors such as durability, maintenance, and potential for resale to inform purchasing decisions.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing strategies. For international buyers, currency fluctuations and local economic conditions in markets like Nigeria or Saudi Arabia may affect pricing.

-

Request Samples: Before committing to a large order, requesting samples can help assess quality and suitability, potentially leading to better-informed negotiations.

Disclaimer on Indicative Prices

Pricing for upholstery materials can fluctuate based on market conditions, supplier negotiations, and material availability. The information provided serves as a general guide and may not reflect current market prices. B2B buyers are encouraged to conduct thorough research and consult multiple suppliers to ensure competitive pricing and quality.

Alternatives Analysis: Comparing upholstery material for cars With Other Solutions

Exploring Alternatives to Upholstery Material for Cars

In the automotive industry, selecting the right upholstery material is crucial for enhancing vehicle aesthetics and comfort. However, various alternatives exist that can serve similar purposes, each with unique advantages and drawbacks. This analysis compares traditional upholstery materials with alternative solutions, providing B2B buyers with actionable insights for informed decision-making.

| Comparison Aspect | Upholstery Material For Cars | Alternative 1: Vinyl Wrap | Alternative 2: Seat Covers |

|---|---|---|---|

| Performance | High durability and comfort; offers luxury feel | Good durability; can mimic leather appearance | Varies widely; some offer decent protection, others less so |

| Cost | Medium to high; depends on material choice | Generally lower; cost-effective option for aesthetics | Low to medium; affordable but may require frequent replacement |

| Ease of Implementation | Requires professional installation for best results | DIY or professional; relatively simple to apply | Easy to apply; often designed for user-friendly installation |

| Maintenance | Moderate; requires specific care for longevity | Low; easy to clean and maintain | Varies; some are machine washable, while others may be less durable |

| Best Use Case | Ideal for long-term vehicle upgrades or restorations | Suitable for aesthetic updates or temporary solutions | Great for protecting existing upholstery or quick style changes |

Alternative 1: Vinyl Wrap

Vinyl wraps are an increasingly popular alternative to traditional upholstery materials. They provide a cost-effective way to enhance a vehicle’s appearance without the investment required for reupholstering. Vinyl is durable and can replicate the look of leather, making it an attractive choice for those looking to improve aesthetics.

Pros: Vinyl wraps are generally easier to apply and maintain than upholstery. They can be a DIY project for those with a knack for detail. Furthermore, they are resistant to stains and can be cleaned easily.

Cons: While they offer a visually appealing finish, vinyl wraps may not provide the same level of comfort or luxury as high-quality upholstery. Additionally, they can peel or fade over time, especially if exposed to harsh conditions.

Illustrative image related to upholstery material for cars

Alternative 2: Seat Covers

Seat covers are a versatile and budget-friendly solution for protecting and enhancing vehicle interiors. They come in various materials, including fabric and synthetic options, allowing buyers to choose based on their needs and preferences. Seat covers can be easily installed and removed, making them an ideal choice for temporary changes or protection.

Pros: Seat covers are often machine washable and can be replaced easily, making them a practical option for families or frequent drivers. They also offer a wide range of designs and colors to suit individual tastes.

Cons: The quality of seat covers can vary significantly, with cheaper options providing less durability and comfort. They may not fit as snugly as professionally installed upholstery, leading to potential wear and discomfort over time.

Making the Right Choice for Your Automotive Upholstery Needs

When selecting between upholstery materials and alternatives like vinyl wraps or seat covers, B2B buyers should consider their specific needs and the intended use of the vehicle. Factors such as budget, desired aesthetics, and long-term usage should guide the decision-making process. For those seeking a luxurious, durable solution, traditional upholstery remains the top choice. Conversely, if cost-effectiveness and ease of installation are priorities, vinyl wraps or seat covers may be more suitable. By evaluating these options carefully, buyers can ensure they choose a solution that aligns with their business goals and enhances their vehicle offerings.

Illustrative image related to upholstery material for cars

Essential Technical Properties and Trade Terminology for upholstery material for cars

What are the Key Technical Properties of Upholstery Materials for Cars?

When sourcing upholstery materials for automotive applications, understanding specific technical properties is essential for making informed decisions. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the quality and classification of the upholstery fabric. Higher grades often indicate better durability, resistance to wear, and overall performance. For B2B buyers, selecting the appropriate material grade ensures that the upholstery can withstand daily use and maintain its appearance over time, which is crucial for customer satisfaction and brand reputation.

2. Abrasion Resistance

Abrasion resistance measures how well a material can withstand wear from friction and rubbing. This property is typically quantified using the Martindale test, which indicates how many rubs a fabric can endure before showing signs of wear. For automotive upholstery, high abrasion resistance is vital, especially in high-traffic areas, to prolong the life of the material and reduce replacement costs.

3. Colorfastness

Colorfastness assesses a material’s ability to retain its color when exposed to various environmental factors, such as sunlight, washing, and rubbing. This specification is particularly important for upholstery that will face direct sunlight and frequent use. Ensuring high colorfastness helps prevent fading, which can negatively affect the vehicle’s interior aesthetics and resale value.

4. Flame Resistance

Flame resistance indicates a material’s ability to resist ignition and slow the spread of fire. Many automotive upholstery materials must meet specific regulatory standards for safety. B2B buyers should prioritize flame-resistant fabrics to enhance passenger safety and comply with industry regulations, particularly in regions with stringent safety standards.

5. Water Resistance

Water resistance refers to a material’s ability to repel water and resist damage from moisture. This property is essential for vehicles that may encounter spills or wet conditions. Choosing upholstery with good water resistance helps maintain hygiene and comfort, while also extending the lifespan of the upholstery.

6. Stretch and Recovery

Stretch and recovery describe how a fabric behaves when subjected to tension. Good stretch and recovery ensure that upholstery maintains its shape and does not sag over time. This property is critical for maintaining the visual appeal and comfort of automotive interiors.

What Are Common Trade Terms Used in the Upholstery Industry?

Understanding industry terminology can streamline communication and negotiations in the upholstery market. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or materials that are used in the manufacturing of vehicles. In the upholstery context, OEM materials are those that meet the original specifications set by the vehicle manufacturer. B2B buyers often seek OEM products for guaranteed quality and compatibility with specific vehicle models.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and purchasing strategies. Understanding MOQ helps businesses plan their orders effectively to avoid excess stock or insufficient supplies.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is vital for B2B transactions, allowing buyers to compare prices and terms from different suppliers, ensuring they secure the best deal for upholstery materials.

4. Incoterms

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers, as they clarify who is responsible for shipping costs, insurance, and risk during transportation of upholstery materials.

5. Lead Time

Lead time refers to the time required from placing an order to the delivery of the product. In the upholstery industry, understanding lead times is essential for project planning and inventory management. B2B buyers should factor in lead times to ensure timely delivery of materials for manufacturing or reupholstering projects.

Illustrative image related to upholstery material for cars

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make better purchasing decisions that align with their needs and expectations, ultimately improving their operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the upholstery material for cars Sector

What Are the Current Market Dynamics and Key Trends in Upholstery Material for Cars?

The automotive upholstery market is experiencing transformative growth driven by several global factors. Firstly, the increasing demand for vehicle personalization is encouraging manufacturers to offer a wider range of upholstery materials, from luxurious leather to eco-friendly fabrics. This trend is particularly pronounced in emerging markets in Africa and South America, where consumers are eager to customize their vehicles to reflect personal style and local culture. Additionally, advancements in technology are reshaping sourcing strategies, with digital platforms enabling B2B buyers to connect with suppliers directly, facilitating easier access to diverse materials.

Another key trend is the rise of synthetic materials, which are gaining popularity due to their durability and ease of maintenance. Buyers in regions such as the Middle East and Europe are increasingly leaning towards synthetic options that mimic the appearance and feel of traditional materials while offering better resistance to wear and tear. Moreover, the automotive industry is adapting to changing consumer preferences regarding comfort and aesthetics, leading to innovations in upholstery technology. For instance, the introduction of moisture-resistant and stain-proof fabrics is appealing to families and individuals who require functional yet stylish interiors.

How Is Sustainability Influencing Sourcing Trends for Upholstery Materials in the Automotive Industry?

Sustainability is becoming a crucial consideration for B2B buyers in the upholstery material sector. The environmental impact of traditional sourcing practices has prompted companies to seek ethical supply chains that prioritize eco-friendly materials. This shift is particularly relevant for international buyers from regions like Africa and Europe, where regulatory pressures and consumer awareness regarding sustainability are rising.

Illustrative image related to upholstery material for cars

Buyers are increasingly looking for upholstery materials that are certified as sustainable, such as those made from organic cotton, recycled polyester, or other eco-friendly textiles. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® provide assurances that materials are produced without harmful chemicals and under fair labor practices. Additionally, the adoption of circular economy principles in sourcing practices is gaining momentum, promoting the reuse and recycling of materials to minimize waste. By prioritizing sustainability, B2B buyers not only meet regulatory requirements but also enhance their brand reputation among environmentally conscious consumers.

What Is the Evolution of Upholstery Materials in the Automotive Sector?

The evolution of upholstery materials in the automotive sector has been marked by significant technological and consumer-driven changes. Historically, leather was the dominant choice for vehicle interiors, prized for its luxury and durability. However, as car ownership expanded globally, particularly in emerging markets, the demand for more affordable and practical materials grew.

In the late 20th century, advancements in synthetic materials transformed the landscape, offering alternatives that combined durability with aesthetic appeal. This evolution continued with the introduction of high-performance fabrics that provide additional benefits, such as moisture resistance and ease of cleaning. Today, the upholstery market reflects a diverse array of materials that cater to various consumer preferences, from luxury to eco-conscious choices, indicating a shift towards greater customization and sustainability in automotive interiors.

In summary, the upholstery material for cars sector is rapidly evolving, driven by market dynamics that prioritize personalization, sustainability, and technological advancements. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with both consumer expectations and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of upholstery material for cars

-

How do I choose the right upholstery material for my automotive business?

Selecting the ideal upholstery material involves evaluating several factors, including durability, aesthetics, functionality, and cost. Consider the specific needs of your clientele—families may prioritize stain resistance, while luxury vehicle owners might seek high-end leather. It’s also essential to assess the climate in your target market, as materials can perform differently in various environmental conditions. Finally, sample materials to evaluate their feel and appearance before making bulk purchases. -

What is the best upholstery fabric for high-traffic vehicles?

For high-traffic vehicles, such as taxis or family cars, synthetic fabrics like polyester or microfiber are often the best choices. These materials are not only durable and stain-resistant but also easy to clean, making them ideal for frequent use. Additionally, vinyl upholstery offers a budget-friendly option with a similar durability profile. Always consider the specific wear and tear expected in the vehicle’s daily use to make an informed decision. -

Can I customize upholstery materials for my specific needs?

Yes, many suppliers offer customization options for upholstery materials. You can request specific colors, patterns, and finishes to match your branding or to meet customer preferences. Discussing your requirements with potential suppliers can lead to bespoke solutions that enhance your product offerings. Just ensure that the supplier can accommodate your customization needs within your desired timeline. -

What are the minimum order quantities (MOQ) for upholstery materials?

Minimum order quantities can vary significantly by supplier and material type. While some manufacturers may allow orders as small as 10 yards, others may have higher MOQs, especially for custom fabrics. It’s crucial to clarify these details upfront when negotiating with suppliers to avoid unexpected costs or delays in your supply chain. -

What payment terms should I expect when sourcing upholstery materials internationally?

Payment terms can differ based on the supplier and the nature of the transaction. Common arrangements include payment in advance, letters of credit, or payment upon delivery. Establishing clear terms during the negotiation process is essential to avoid misunderstandings. Be sure to discuss the possibility of bulk discounts, as larger orders may qualify for more favorable terms. -

How can I vet suppliers for quality upholstery materials?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their reputation through customer reviews and industry references. Request samples to evaluate the material quality firsthand. Additionally, inquire about their production processes, certifications, and quality assurance protocols. Establishing a good line of communication can also provide insights into their reliability and customer service. -

What logistics considerations should I keep in mind when importing upholstery materials?

When importing upholstery materials, consider shipping times, customs regulations, and import duties specific to your country. It’s essential to choose a reliable shipping partner who understands the intricacies of international trade. Additionally, ensure that the supplier provides the necessary documentation for customs clearance to avoid delays. Planning your logistics effectively can help streamline your supply chain and reduce potential costs. -

What quality assurance measures should I implement when sourcing upholstery materials?

Implementing quality assurance measures is vital to maintain product standards. Consider establishing a clear set of quality metrics that the materials must meet before accepting delivery. Conduct inspections upon receipt and maintain a good relationship with your supplier to address any issues promptly. Regular audits and feedback can also enhance the quality of future orders and ensure consistency in your upholstery materials.

Top 8 Upholstery Material For Cars Manufacturers & Suppliers List

1. Midwest Fabrics – Fast Delivery & Easy Returns

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: This company, Midwest Fabrics – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies including Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-Grain, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland, Perforated Palma, Plain Rosette, Morbern, Volkswagen, Woven, Futura Xt…

3. Fabric Wholesale Direct – Automotive Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Automotive Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: Largest selection of classic auto interiors including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1956 Ford Fairlane Sunliner, 1968 Dodge Polara Convertible, 1970 Chevrolet Malibu Sport Coupe, a…

5. A·1 Foam & Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Car Interior Fabrics available at A·1 Foam & Fabrics include various collections such as Velvets, Suedes, and Tweeds suitable for automotive, RV, and trucking applications. Key products include: 1. 555 Portfolio Tweed Collection – Abrasion resistance: 50,000+ DR #10 Cotton Duck, Flame Retardancy: California T.B. 117 Section E-Class 1 (Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pass),…

6. Keyston Bros – Automotive Fabric Collections

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Automotive Fabric product categories include: Automotive Vinyl (Autosoft Vinyl Collection, Softside Automotive Collection, Partners Vinyl, Automotive Quilt, Perforated Vinyl), Automotive Leather (Podium Premium Collection, Autosoft Leather Collection, Partners Leather, Vezzano Leather, Perforated Leather), Auto Cloth & Fabrics (Alcantara, Byrne Tweed, Crossway Collection, Lucido Collection, Street…

7. Original Auto Fabric – Vintage & New Upholstery Materials

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: Original Auto Fabric offers a wide selection of vintage and new auto upholstery materials, including specialty car cloths, marine and automotive vinyls, custom carpets, floor mats, and vinyl tops. They provide over 230 licensed logos for floor mats, molded carpet to OEM specifications, and specialize in vinyl tops such as Stayfast Top Fabric for brands like Buick, Cadillac, Dodge, and Ford. Their …

8. Kovi Fabrics – Automotive Upholstery

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Automotive Upholstery: Durable, Affordable Car Interior Fabric. High Performance Fabric that is waterproof, spill proof, stain proof, and weatherproof. Select fabrics have anti-microbial properties. Available in various styles including prints, patterns, and solids. Vinyl options include matte, glossy, distressed, animal hide, and reptile replications. Premium selection backed by a lifetime warran…

Strategic Sourcing Conclusion and Outlook for upholstery material for cars

As we conclude our exploration of automotive upholstery materials, it is evident that strategic sourcing plays a pivotal role in enhancing the quality and value of vehicle interiors. By prioritizing durability, aesthetics, and functionality, B2B buyers can make informed decisions that align with their market demands and customer preferences.

Investing in high-quality upholstery not only elevates the driving experience but also significantly impacts vehicle resale value. The selection of materials—be it luxurious leather, practical vinyl, or innovative synthetic fabrics—should be guided by a thorough understanding of their respective benefits and limitations. This nuanced approach ensures that buyers can cater to diverse clientele across various regions, including Africa, South America, the Middle East, and Europe.

Looking ahead, the upholstery market is poised for growth, driven by evolving consumer trends and technological advancements in materials. As you navigate this dynamic landscape, consider forging partnerships with reliable suppliers who can offer a range of sustainable, customizable options. Embrace the opportunity to elevate your offerings and meet the demands of the modern automotive market. Engage with us today to explore how you can optimize your sourcing strategies and stay ahead in this competitive industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.