Introduction: Navigating the Global Market for leather goods manufacturers

In the dynamic landscape of global commerce, sourcing high-quality leather goods manufacturers presents a unique challenge for international B2B buyers. With the rise of sustainable practices and evolving consumer preferences, it is crucial to identify suppliers who not only deliver exceptional craftsmanship but also align with ethical production standards. This guide serves as a comprehensive resource, addressing the complexities involved in selecting the right leather goods manufacturer. We will explore various types of leather products, applications across different industries, supplier vetting processes, and cost considerations, ensuring that your purchasing decisions are informed and strategic.

For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—this guide empowers you to navigate the intricate world of leather goods manufacturing. By providing actionable insights and expert recommendations, we aim to equip you with the knowledge needed to forge successful partnerships that drive your business forward. Whether you are seeking bespoke items or bulk orders, understanding the nuances of the leather goods market will enable you to make choices that enhance your brand’s reputation and meet your customers’ expectations.

Join us as we delve into the essential elements of sourcing and collaborating with leather goods manufacturers, ensuring that your investment yields quality products that stand the test of time.

Table Of Contents

- Top 5 Leather Goods Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather goods manufacturers

- Understanding leather goods manufacturers Types and Variations

- Key Industrial Applications of leather goods manufacturers

- 3 Common User Pain Points for ‘leather goods manufacturers’ & Their Solutions

- Strategic Material Selection Guide for leather goods manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturers’

- Comprehensive Cost and Pricing Analysis for leather goods manufacturers Sourcing

- Alternatives Analysis: Comparing leather goods manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for leather goods manufacturers

- Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturers

- Strategic Sourcing Conclusion and Outlook for leather goods manufacturers

- Important Disclaimer & Terms of Use

Understanding leather goods manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Luxury Leather Manufacturers | High-quality materials, artisanal craftsmanship, often bespoke designs | High-end retail, luxury brands | Pros: Unique products, strong brand reputation; Cons: Higher costs, longer lead times |

| Mass Production Leather Manufacturers | Large-scale production, standardized designs, cost-effective | Retail chains, e-commerce platforms | Pros: Competitive pricing, rapid fulfillment; Cons: Less customization, potential quality variability |

| Handmade Leather Goods Producers | Focus on craftsmanship, unique designs, often sustainable practices | Niche markets, artisanal shops | Pros: Distinctive products, emphasis on sustainability; Cons: Higher price points, limited scalability |

| Vegan Leather Manufacturers | Use of synthetic or plant-based materials, eco-friendly focus | Sustainable brands, fashion retailers | Pros: Appeal to eco-conscious consumers, innovative materials; Cons: Perceived lower quality compared to genuine leather |

| Specialized Leather Accessory Makers | Focus on specific products (e.g., wallets, bags), often customizable | Corporate gifts, promotional items | Pros: Tailored solutions, brandable products; Cons: Limited product range, may require minimum order quantities |

What are the Characteristics of Luxury Leather Manufacturers?

Luxury leather manufacturers are distinguished by their commitment to high-quality materials and meticulous craftsmanship. These producers often create bespoke designs that cater to high-end retail and luxury brands. When considering a partnership, B2B buyers should evaluate the manufacturer’s reputation, the traceability of materials, and the potential for unique product offerings. However, it’s essential to account for the higher costs and longer lead times associated with these manufacturers.

Illustrative image related to leather goods manufacturers

How Do Mass Production Leather Manufacturers Operate?

Mass production leather manufacturers focus on large-scale production with standardized designs, making them ideal for retail chains and e-commerce platforms. Their operations are streamlined for efficiency, allowing for competitive pricing and rapid fulfillment. B2B buyers should consider the trade-offs between cost and quality, as products may exhibit variability. Additionally, customization options may be limited, which could affect branding efforts.

Why Choose Handmade Leather Goods Producers?

Handmade leather goods producers emphasize craftsmanship and unique designs, often incorporating sustainable practices into their production processes. These manufacturers cater to niche markets and artisanal shops, appealing to consumers who value authenticity and sustainability. B2B buyers should weigh the benefits of distinctive products against the higher price points and limited scalability that these producers may present.

What Makes Vegan Leather Manufacturers Stand Out?

Vegan leather manufacturers focus on creating eco-friendly alternatives to traditional leather, using synthetic or plant-based materials. These products are increasingly popular among sustainable brands and fashion retailers looking to appeal to eco-conscious consumers. Buyers should assess the quality and durability of these materials, as well as their market acceptance. While vegan leather offers innovative solutions, it may be perceived as lower quality compared to genuine leather.

How Do Specialized Leather Accessory Makers Fit into the Market?

Specialized leather accessory makers concentrate on specific products, such as wallets or bags, and often offer customizable options for corporate gifts or promotional items. This specialization allows for tailored solutions that can enhance brand visibility. B2B buyers should consider the limited product range and possible minimum order quantities when engaging with these manufacturers, balancing the need for unique offerings against potential constraints.

Key Industrial Applications of leather goods manufacturers

| Industry/Sector | Specific Application of leather goods manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of luxury handbags and accessories | Enhances brand image and customer loyalty | Quality of leather, craftsmanship, and sustainability certifications |

| Automotive | Leather interiors for vehicles | Improves aesthetics and comfort for end-users | Durability, color options, and compliance with safety regulations |

| Hospitality & Tourism | Custom leather goods for hotels and resorts | Elevates guest experience and brand differentiation | Customization options, lead times, and bulk pricing |

| Sporting Goods | Leather equipment and accessories for sports | Increases product performance and consumer appeal | Material quality, functionality, and adherence to sports regulations |

| Home Décor | Leather upholstery and decorative items | Adds luxury and warmth to interior spaces | Availability of various textures, colors, and eco-friendly options |

How Are Leather Goods Manufacturers Used in Fashion & Apparel?

In the fashion and apparel sector, leather goods manufacturers produce luxury handbags and accessories that significantly enhance a brand’s image. High-quality leather and exceptional craftsmanship attract discerning customers, fostering brand loyalty. For international buyers, particularly in regions like Europe and the Middle East, sourcing involves ensuring that the leather meets sustainability standards, which can be crucial for brand positioning in eco-conscious markets.

What Role Do Leather Goods Manufacturers Play in the Automotive Industry?

Leather goods manufacturers are integral to the automotive industry, specializing in the production of leather interiors for vehicles. This application not only elevates the aesthetic appeal of cars but also enhances comfort for passengers. Buyers must consider factors such as durability, color options, and compliance with safety regulations when sourcing leather for automotive use, particularly in regions like South America and Africa where market expectations may vary.

How Do Leather Goods Manufacturers Enhance Hospitality & Tourism?

In the hospitality and tourism sector, leather goods manufacturers create custom items such as leather key holders, luggage tags, and promotional gifts for hotels and resorts. These products enhance the guest experience and help establish a unique brand identity. Buyers looking for these products should focus on customization options, lead times, and bulk pricing to ensure they meet their operational needs while providing a luxurious touch to their offerings.

What Is the Importance of Leather Goods Manufacturers in Sporting Goods?

Leather goods manufacturers supply high-quality leather equipment and accessories for various sports, enhancing performance and appeal. Whether it’s gloves, bags, or protective gear, the quality of leather can influence the usability and durability of the products. Buyers, especially in regions like Africa and South America, should prioritize material quality and functionality, ensuring compliance with relevant sports regulations to meet consumer expectations.

Illustrative image related to leather goods manufacturers

How Do Leather Goods Manufacturers Contribute to Home Décor?

In the home décor sector, leather goods manufacturers produce upholstered furniture and decorative leather items that add a touch of luxury and warmth to interiors. This application is essential for creating inviting spaces in residential and commercial properties. International buyers must consider the availability of various textures and colors, as well as eco-friendly options, to meet the growing demand for sustainable interior design solutions.

3 Common User Pain Points for ‘leather goods manufacturers’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather for Production

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets their specific standards for durability and aesthetics. Given the wide variety of leather types and sourcing locations, navigating the quality control process can be overwhelming. Buyers may find themselves receiving subpar materials that do not align with their brand’s luxury image, leading to wasted resources and potential damage to their reputation.

The Solution: To effectively source high-quality leather, buyers should prioritize establishing relationships with reputable manufacturers who have a proven track record in the industry. This involves conducting thorough research on suppliers, including checking certifications like the Leather Working Group (LWG) which ensures compliance with environmental and quality standards. Buyers should request samples of leather before placing bulk orders to assess the quality firsthand. Additionally, maintaining open lines of communication with manufacturers allows buyers to specify their requirements clearly, ensuring that the final product aligns with their brand’s standards. Implementing a robust quality assurance process, including regular audits of suppliers, can further mitigate risks associated with leather sourcing.

Scenario 2: Adapting to Market Trends in Leather Goods

The Problem: The leather goods market is constantly evolving, with trends shifting towards sustainable and vegan alternatives. B2B buyers may feel pressured to adapt their product lines to meet these new consumer demands, yet they often lack the expertise or resources to identify suitable materials and manufacturers capable of producing these innovative products. This can lead to missed opportunities in the market and a decline in competitiveness.

The Solution: To stay ahead of market trends, B2B buyers should invest in market research to understand consumer preferences and emerging materials. Collaborating with manufacturers who specialize in sustainable practices is crucial. For instance, buyers should explore partnerships with companies that produce vegan leather or utilize eco-friendly tanning processes. Attending industry trade shows and networking events can provide valuable insights into new materials and manufacturing techniques. Additionally, establishing a feedback loop with customers can help buyers gauge the market’s response to new product offerings, allowing for agile adaptations in their inventory.

Illustrative image related to leather goods manufacturers

Scenario 3: Managing Production Timelines and Delivery Issues

The Problem: Timely delivery of products is critical in the B2B leather goods sector, yet many buyers face delays due to production bottlenecks or inefficient supply chain management. Such delays can disrupt sales cycles and lead to dissatisfied customers, ultimately impacting revenue and business growth. Buyers often find it challenging to hold manufacturers accountable for these delays.

The Solution: To effectively manage production timelines, buyers should implement clear communication and project management protocols with their manufacturers. Setting realistic timelines and establishing milestones can help ensure that both parties are aligned on delivery expectations. Buyers should also consider diversifying their supplier base to mitigate risks associated with relying on a single manufacturer. This can be achieved by identifying backup suppliers who can step in if delays occur. Additionally, leveraging technology, such as inventory management software, can enhance visibility across the supply chain, allowing buyers to track production progress and address potential issues proactively. Regular follow-ups and maintaining a relationship built on trust with manufacturers will also foster a collaborative approach to problem-solving when challenges arise.

Strategic Material Selection Guide for leather goods manufacturers

What Are the Key Materials for Leather Goods Manufacturers?

When selecting materials for leather goods manufacturing, understanding the properties and applications of various materials is crucial. This guide analyzes four common materials used in the industry: genuine leather, synthetic leather (vegan leather), suede, and canvas. Each material has unique characteristics, advantages, and limitations that can significantly impact product quality and market acceptance.

How Does Genuine Leather Perform in Leather Goods Manufacturing?

Genuine leather is renowned for its durability and aesthetic appeal. It typically boasts high tensile strength, making it resistant to wear and tear. Genuine leather can withstand a range of temperatures, although extreme heat can cause it to dry out and crack.

Pros: Genuine leather is highly durable, develops a unique patina over time, and is often perceived as a luxury material, making it suitable for high-end products.

Illustrative image related to leather goods manufacturers

Cons: The cost of genuine leather can be high, and its manufacturing process is complex, requiring skilled labor and time. Additionally, genuine leather may not be suitable for products that require high water resistance.

For international buyers, compliance with standards such as the Leather Working Group (LWG) certification can ensure quality and sustainability. Markets in Europe and the Middle East often prefer certified leather for its traceability and ethical sourcing.

What Are the Advantages of Synthetic Leather in Leather Goods?

Synthetic leather, often referred to as vegan leather, is made from a variety of materials, including polyurethane (PU) and polyvinyl chloride (PVC). It is designed to mimic the look and feel of genuine leather while being more affordable and easier to maintain.

Pros: Synthetic leather is typically water-resistant, lightweight, and available in a wide range of colors and textures. It is also more cost-effective than genuine leather, making it accessible for various markets.

Cons: While synthetic leather is durable, it may not have the same longevity as genuine leather and can degrade over time with exposure to heat and UV light. Additionally, some consumers may perceive synthetic materials as less luxurious.

Illustrative image related to leather goods manufacturers

For buyers in Africa and South America, the lower cost of synthetic leather can be a significant advantage in price-sensitive markets. However, compliance with environmental regulations regarding plastics is essential.

How Does Suede Compare for Leather Goods Manufacturing?

Suede, a type of leather with a napped finish, is soft and has a unique texture that appeals to many consumers. It is typically made from the underside of the animal hide, giving it a distinct feel.

Pros: Suede offers a luxurious look and feel, making it popular for items like handbags and shoes. It is also relatively lightweight compared to other leathers.

Illustrative image related to leather goods manufacturers

Cons: Suede is less durable than genuine leather and can be more susceptible to stains and water damage. It requires special care and maintenance to keep it looking good.

International buyers should consider the specific climate conditions of their target markets, as suede may not perform well in humid or wet environments. Compliance with animal welfare standards is also a consideration for markets in Europe.

What Role Does Canvas Play in Leather Goods Manufacturing?

Canvas is a durable fabric made from cotton or linen, often used in conjunction with leather for added strength and versatility. It is commonly used in bags, backpacks, and casual footwear.

Pros: Canvas is cost-effective, lightweight, and highly customizable, allowing for various prints and colors. It is also easy to clean and maintain.

Illustrative image related to leather goods manufacturers

Cons: While canvas is durable, it may not offer the same level of luxury as leather products. It can also be less resistant to water unless treated with a protective coating.

For international buyers, canvas products can appeal to younger demographics seeking affordable and trendy options. Understanding local preferences for materials can help manufacturers tailor their offerings.

Summary Table of Material Selection for Leather Goods Manufacturers

| Material | Typical Use Case for leather goods manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury handbags, wallets, and belts | High durability and luxury appeal | High cost and complex manufacturing process | Alta |

| Piel sintética | Affordable bags, shoes, and accessories | Cost-effective and water-resistant | Less durable than genuine leather | Medium |

| Suede | Handbags, shoes, and jackets | Luxurious texture and appearance | Susceptible to stains and water damage | Medium |

| Canvas | Casual bags, backpacks, and travel gear | Lightweight and customizable | Less luxurious and may require treatment | Low |

This strategic material selection guide provides insights into the essential properties and considerations for leather goods manufacturers, enabling international buyers to make informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturers

What Are the Key Stages in the Manufacturing Process of Leather Goods?

The manufacturing process of leather goods is intricate and requires a combination of traditional craftsmanship and modern technology. Understanding the stages involved can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: What Is Involved?

The initial stage involves sourcing high-quality raw materials, primarily leather, which can be sourced from various tanneries. Buyers should look for tanneries certified by organizations like the Leather Working Group (LWG) to ensure sustainable practices. The leather is then treated through a tanning process, which can vary from vegetable tanning, known for its eco-friendliness, to chrome tanning, which allows for a wider range of colors and finishes.

Once the leather is tanned, it undergoes cutting and shaping. This stage involves precision cutting of patterns to minimize waste and ensure that each piece meets the design specifications. For complex designs, digital cutting technology may be employed to enhance accuracy.

How Are Leather Goods Formed?

The forming stage involves creating the structure of the product. This may include sewing leather pieces together, adding linings, and incorporating other materials such as metal hardware or fabric. Techniques such as hand-stitching or machine stitching are commonly used, with hand-stitching often preferred for luxury products due to its durability and aesthetic appeal.

In addition, specialized techniques like embossing or debossing can be applied to personalize the goods or add branding elements. This is particularly important for B2B buyers looking to differentiate their products in the marketplace.

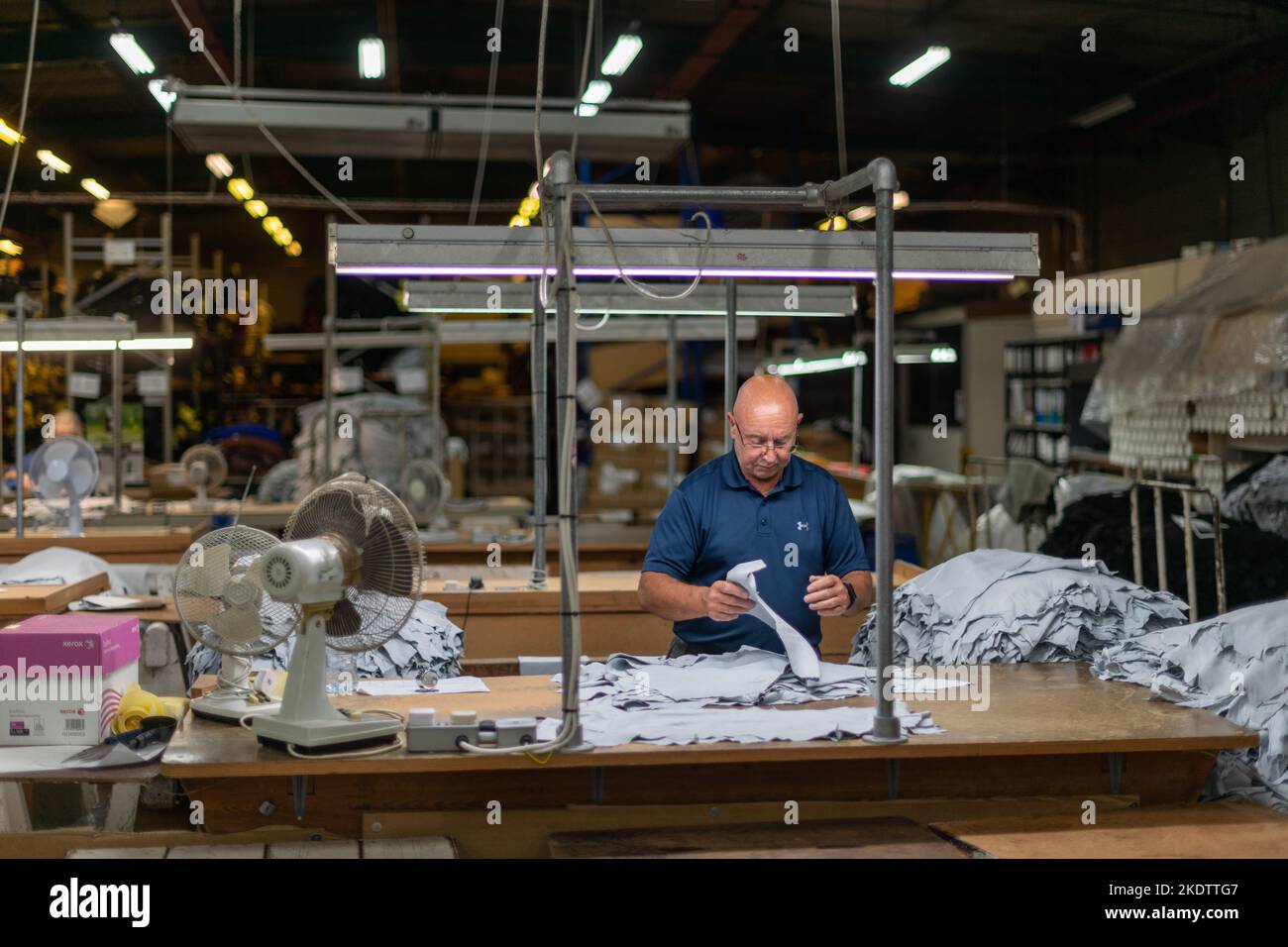

What Does the Assembly Process Look Like?

Assembly is where all components come together to create the final product. Quality control during this stage is critical, as it ensures that the assembled goods meet the desired specifications. Skilled artisans often perform this work, allowing for a high level of craftsmanship.

Illustrative image related to leather goods manufacturers

Additionally, this stage may involve quality checks to ensure that the stitching is even, there are no defects in the leather, and all components function correctly (e.g., zippers, clasps). It’s advisable for buyers to inquire about the assembly methods used and the skill level of the workers involved.

What Finishing Touches Are Applied?

The finishing stage is where the leather goods are polished and prepared for shipping. This may include applying protective coatings, conditioning the leather, and final inspections. Finishing techniques can significantly influence the product’s durability and aesthetic appeal.

Buyers should consider how the finishing processes align with their own brand values, especially if they prioritize sustainable practices. Some manufacturers may offer eco-friendly finishing options that appeal to environmentally conscious consumers.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is a vital aspect of leather goods manufacturing that ensures products meet international standards and customer expectations. Understanding the QA process can help buyers make informed decisions.

Which International Standards Are Relevant?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that a manufacturer has robust quality management practices in place.

Additionally, sector-specific certifications, such as CE marking for products sold within the European market, ensure compliance with health, safety, and environmental protection standards. For buyers in regions like Africa and South America, understanding these certifications can be crucial for import compliance and market acceptance.

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that the raw materials meet predefined specifications before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to identify and rectify any issues in real-time.

-

Final Quality Control (FQC): After assembly, a thorough inspection is conducted to ensure that the final products meet quality standards before shipping.

These checkpoints help mitigate the risk of defects and ensure that the final products are of high quality.

Illustrative image related to leather goods manufacturers

What Testing Methods Are Commonly Used?

Testing methods can vary based on product type and market requirements. Common testing methods include:

-

Physical Testing: Assessing the strength, durability, and functionality of the leather goods.

-

Chemical Testing: Ensuring that the leather does not contain harmful substances and meets safety standards.

-

Performance Testing: Evaluating how the product performs under various conditions, such as wear and tear.

B2B buyers should ask suppliers about their testing methodologies and any certifications that validate their testing processes.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that potential suppliers adhere to high-quality standards, B2B buyers can take several steps:

-

Conduct Audits: Requesting regular audits of the manufacturing facilities can provide insights into their quality management systems.

-

Review Quality Reports: Suppliers should provide documentation of their quality control processes and outcomes. Reviewing these reports can reveal trends in quality and areas for improvement.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections often include detailed reports that highlight compliance with international standards.

-

Certifications Verification: Buyers should verify that any claims of certification (e.g., ISO 9001, CE) are valid and up-to-date. This can typically be done through the certifying bodies.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers from diverse regions must navigate specific nuances in quality control. For instance, buyers from Europe may have stricter compliance requirements compared to those from Africa or South America. Therefore, understanding local regulations and market expectations is essential.

Additionally, cultural differences can impact communication regarding quality standards. Establishing clear expectations upfront and maintaining open lines of communication can help bridge these gaps and foster successful partnerships.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is crucial for B2B buyers in the leather goods industry. By paying attention to these details, buyers can ensure they partner with manufacturers who align with their quality expectations and brand values.

Illustrative image related to leather goods manufacturers

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturers’

The following practical sourcing guide aims to assist B2B buyers in navigating the complexities of procuring leather goods manufacturers. This checklist provides actionable steps to ensure that your sourcing process is efficient, effective, and tailored to your specific needs.

Step 1: Define Your Product Requirements

Begin by clearly outlining what types of leather goods you intend to source. This could range from handbags and wallets to custom leather accessories. Having specific product requirements helps in targeting the right manufacturers who can meet your quality and design expectations.

- Considerations:

- Material types (e.g., genuine leather, vegan leather)

- Design specifications (e.g., size, color, functionality)

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential manufacturers that specialize in leather goods. Utilize online directories, trade shows, and industry publications to gather a list of candidates.

- Resources to Explore:

- Manufacturer websites for product portfolios

- Industry reviews and ratings

- Social media platforms for customer feedback

Step 3: Evaluate Supplier Credentials

Before proceeding, verify the credentials of potential suppliers. Check for certifications, such as those from the Leather Working Group, which indicate adherence to sustainable and ethical practices.

Illustrative image related to leather goods manufacturers

- Key Certifications:

- Environmental management systems (ISO 14001)

- Quality management systems (ISO 9001)

Step 4: Request Samples and Prototypes

To assess the quality and craftsmanship of the leather goods, request samples or prototypes. This step is crucial to ensure that the manufacturer can deliver products that meet your standards.

- What to Look For:

- Material quality and finish

- Durability and functionality

- Craftsmanship details (e.g., stitching, hardware)

Step 5: Negotiate Terms and Pricing

Once you have narrowed down your options, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Clear communication at this stage helps prevent misunderstandings later on.

- Important Factors to Discuss:

- Payment schedules (e.g., deposits, payment on delivery)

- Lead times for production and delivery

- Warranty and return policies

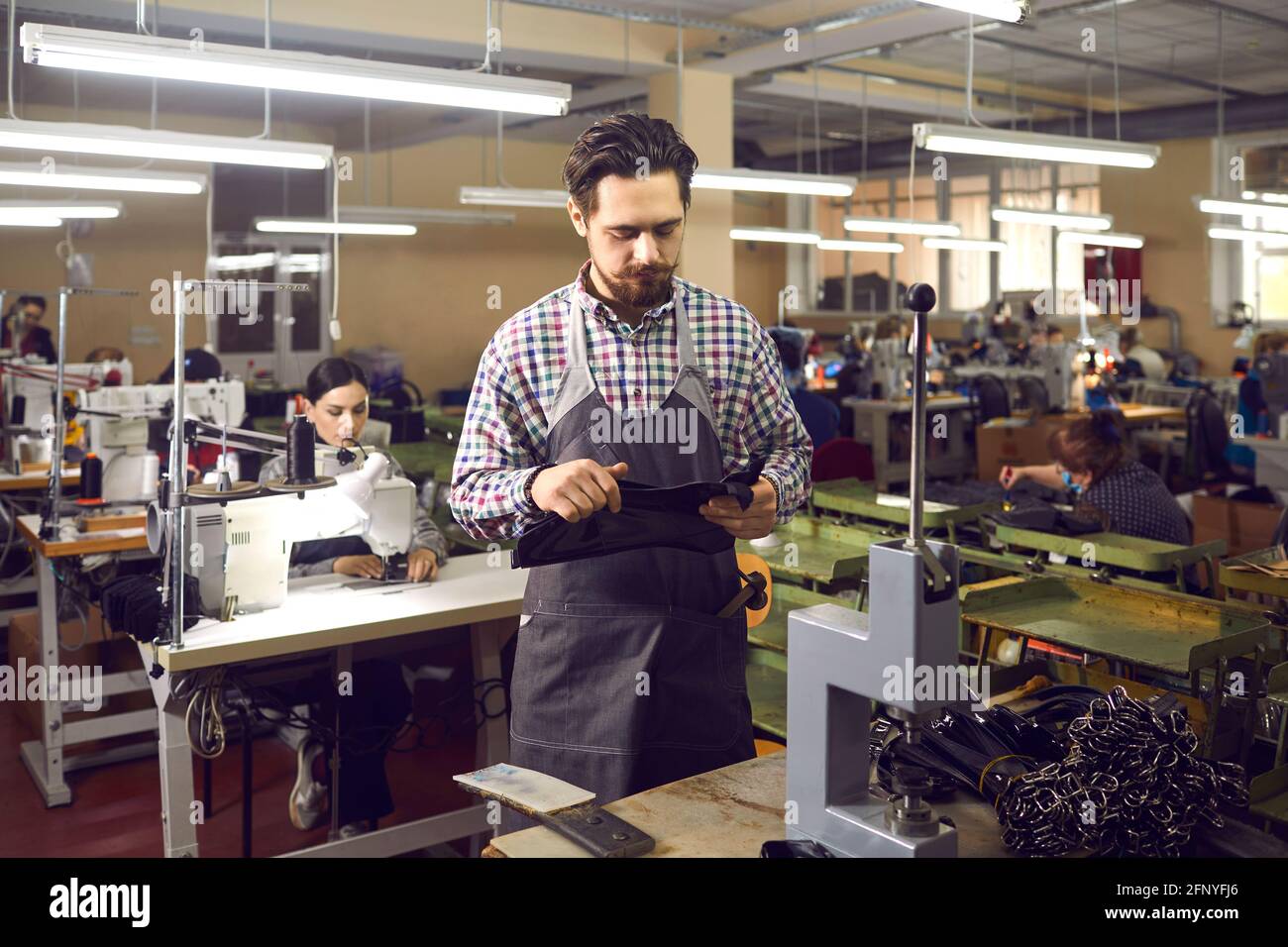

Step 6: Conduct a Factory Visit

If feasible, arrange a visit to the manufacturing facility. This allows you to inspect production processes, labor conditions, and overall operational standards firsthand.

Illustrative image related to leather goods manufacturers

- What to Observe:

- Compliance with health and safety regulations

- Use of sustainable practices and materials

- Quality control measures in place

Step 7: Establish a Communication Plan

After selecting a supplier, create a communication plan to facilitate ongoing dialogue. Regular updates can help address potential issues proactively and maintain alignment throughout the production process.

- Communication Tools:

- Scheduled check-ins via video calls or emails

- Project management software for tracking progress

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for leather goods manufacturers, ensuring they partner with reliable suppliers who meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for leather goods manufacturers Sourcing

What Are the Key Cost Components in Leather Goods Manufacturing?

Understanding the cost structure of leather goods manufacturing is crucial for B2B buyers. The primary components include:

Illustrative image related to leather goods manufacturers

-

Materials: Leather quality directly impacts cost. Premium leathers, such as full-grain or vegetable-tanned options, command higher prices due to their durability and aesthetic appeal. Synthetic alternatives, while often less expensive, may not offer the same longevity or brand prestige.

-

Labor: Skilled craftsmanship is essential in producing high-quality leather goods. Labor costs vary significantly by region; for instance, manufacturers in Southeast Asia may offer lower labor costs compared to those in Europe. However, the skill level and experience of the workforce can affect overall product quality.

-

Manufacturing Overhead: This includes the costs of utilities, rent, and administrative expenses. Efficient production processes can reduce these overheads, allowing manufacturers to offer competitive pricing.

-

Tooling: The initial investment in tools and machinery can be substantial, especially for custom designs. Buyers should consider these costs when assessing pricing, particularly for bespoke orders.

-

Quality Control (QC): Implementing stringent quality control measures ensures that products meet specified standards. This may increase costs but can enhance customer satisfaction and reduce returns.

-

Logistics: Shipping and handling costs can vary based on the distance to the buyer and the shipping method. Incoterms also play a role in determining who bears these costs, influencing the final price.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the market rate and the manufacturer’s positioning can help buyers negotiate better deals.

How Do Price Influencers Affect Leather Goods Sourcing?

Several factors can influence the final pricing of leather goods:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to discounts, while smaller orders might incur higher per-unit costs.

-

Specifications and Customization: Custom designs or specific requirements (like unique stitching or hardware) can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Materials and Certifications: The choice of materials and the presence of certifications (like LWG certification for tanneries) can affect costs. Eco-friendly or sustainably sourced materials may be pricier, but they can enhance brand value.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers with a history of quality may charge more, but they often provide better consistency and service.

-

Incoterms: Understanding international shipping terms is essential. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who is responsible for shipping costs, which can impact the overall price.

What Are the Best Negotiation Tips for International B2B Buyers?

For buyers from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings. Here are some actionable tips:

-

Research Market Prices: Familiarize yourself with the average prices for the products you are interested in. This knowledge empowers you during negotiations.

-

Leverage Volume Discounts: If your business model allows, consider placing larger orders to negotiate better pricing. Suppliers are often more willing to offer discounts for bulk purchases.

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term costs associated with sourcing leather goods, including maintenance, durability, and potential resale value. This perspective can justify higher upfront costs for better quality products.

-

Be Clear About Specifications: Clearly outline your requirements and specifications upfront. This clarity helps avoid misunderstandings and additional costs later in the process.

-

Build Relationships with Suppliers: Establishing a good rapport can lead to better terms, including pricing flexibility and priority service.

Conclusion: What Should Buyers Keep in Mind?

Navigating the cost structure and pricing of leather goods manufacturing requires careful consideration of various factors. By understanding the components that contribute to pricing and employing strategic negotiation techniques, international B2B buyers can make informed purchasing decisions. Always remember that prices can fluctuate based on market conditions, so maintaining flexibility and openness in negotiations is key.

Alternatives Analysis: Comparing leather goods manufacturers With Other Solutions

Introduction: Exploring Alternatives to Leather Goods Manufacturing

In the dynamic world of fashion and accessories, businesses often seek alternatives to traditional leather goods manufacturing. While leather goods manufacturers provide high-quality, durable products, there are other viable solutions that can meet varying demands in terms of sustainability, cost, and consumer preferences. This analysis will compare leather goods manufacturers with two prominent alternatives: synthetic leather production and handcrafted textile goods, providing B2B buyers with insights to inform their purchasing decisions.

Comparison Table

| Comparison Aspect | Leather Goods Manufacturers | Synthetic Leather Production | Handcrafted Textile Goods |

|---|---|---|---|

| Performance | High durability, luxury feel | Moderate durability, often less breathable | Varies by material, generally good durability |

| Cost | Higher due to raw materials and craftsmanship | Lower to moderate, depending on the quality of materials used | Generally lower, but varies widely based on craftsmanship |

| Ease of Implementation | Complex due to sourcing and production processes | Generally straightforward, with established supply chains | May require more time for sourcing skilled artisans |

| Maintenance | Requires specific care; long lifespan | Easier to clean, but can degrade over time | Varies; some are machine washable while others require special care |

| Best Use Case | Luxury markets, high-end products | Fast fashion, affordable products | Niche markets, eco-conscious consumers |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Synthetic Leather Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an affordable alternative to traditional leather. Its production typically requires less time and can be scaled quickly, making it suitable for fast fashion industries. However, while synthetic leather is generally easier to maintain and clean, it lacks the breathability and luxurious feel of genuine leather. Additionally, environmental concerns arise due to the petrochemical processes involved in its manufacturing, which can impact sustainability efforts.

How Do Handcrafted Textile Goods Compare?

Handcrafted textile goods, which include items made from fabrics such as cotton, linen, or recycled materials, cater to a growing market of eco-conscious consumers. These products can be produced sustainably and offer unique designs that appeal to niche markets. However, the durability and performance can vary significantly based on the materials and craftsmanship involved. Sourcing skilled artisans can be time-consuming, and the production process may not scale as efficiently as synthetic or leather goods, potentially leading to longer lead times.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting between leather goods manufacturers and alternative solutions like synthetic leather or handcrafted textile goods, B2B buyers should carefully assess their specific needs and target market. Factors such as brand positioning, desired product longevity, sustainability goals, and cost constraints will significantly influence the decision. By understanding the unique benefits and drawbacks of each option, businesses can make informed choices that align with their values and meet their customers’ expectations. Ultimately, the right solution will depend on balancing quality, cost, and consumer preferences in the ever-evolving marketplace.

Essential Technical Properties and Trade Terminology for leather goods manufacturers

What Are the Key Technical Properties of Leather Goods?

Understanding the essential technical properties of leather goods is crucial for manufacturers and B2B buyers alike. These properties not only affect product quality but also influence customer satisfaction and market competitiveness. Here are some critical specifications:

1. Material Grade

Material grade indicates the quality of leather used in production. Higher grades, such as full-grain or top-grain leather, exhibit superior durability, aesthetics, and aging characteristics. For B2B buyers, selecting the appropriate material grade is essential, as it directly impacts the product’s longevity and customer perception.

Illustrative image related to leather goods manufacturers

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. This is particularly important in leather goods, where precise cuts and stitching are essential for functionality and aesthetics. Understanding tolerance levels helps manufacturers maintain quality control, ensuring that each product meets design specifications and reduces waste.

3. Weight

The weight of leather can significantly affect the final product’s usability and appeal. For instance, lighter leathers are often preferred for bags and wallets, while heavier materials may be used for rugged items like belts or luggage. B2B buyers must consider weight in relation to the intended use of the product to meet customer expectations.

4. Finish

The finish of leather determines its texture, appearance, and resistance to wear and tear. Common finishes include aniline, pigmented, and embossed. Each finish serves different aesthetic and functional purposes, and understanding these can help manufacturers align their offerings with market trends and consumer preferences.

5. Breathability

Breathability refers to the ability of leather to allow air and moisture to pass through. This property is particularly important for items like footwear and bags that are in frequent contact with the body. A breathable leather enhances comfort and can extend the product’s lifespan, making it a crucial consideration for B2B buyers focused on quality.

Illustrative image related to leather goods manufacturers

6. Sustainability

Sustainability in leather production is increasingly becoming a priority for consumers and manufacturers. This includes the sourcing of raw materials, the tanning process, and the environmental impact of production methods. B2B buyers should seek manufacturers that prioritize sustainable practices, as this can enhance brand reputation and appeal to environmentally conscious consumers.

What Are Common Trade Terms in Leather Goods Manufacturing?

Familiarity with industry jargon is essential for effective communication between manufacturers and B2B buyers. Here are some key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods that are sold under another company’s brand name. In leather goods manufacturing, this often involves creating bespoke products for brands that may not have their own production facilities. Understanding OEM relationships can help buyers identify potential partners for custom solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and purchasing strategies. Knowing the MOQ helps buyers assess whether a supplier can meet their needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a critical step in the procurement process, allowing buyers to compare offers and negotiate terms effectively. Providing clear specifications in an RFQ can lead to better pricing and service agreements.

Illustrative image related to leather goods manufacturers

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in cross-border trade, as they dictate shipping responsibilities, risk transfer, and cost allocation.

5. LWG Certification (Leather Working Group)

LWG certification is a standard for sustainable leather production practices. It assesses tanneries on their environmental performance and ethical practices. B2B buyers should look for LWG-certified suppliers to ensure that their products are sourced responsibly, thereby enhancing brand credibility.

6. Tannery

A tannery is a facility that processes raw hides into leather. The quality of the tannery significantly affects the final product’s characteristics, such as durability and appearance. Buyers should consider the reputation and practices of tanneries when selecting suppliers to ensure high-quality leather goods.

Incorporating this knowledge of technical properties and trade terminology can empower B2B buyers to make informed decisions, ensuring that their partnerships with leather goods manufacturers yield high-quality, market-ready products.

Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturers Sector

What Are the Current Market Dynamics and Key Trends in Leather Goods Manufacturing?

The leather goods manufacturing sector is currently experiencing a significant transformation, driven by various global factors. Increased consumer demand for high-quality, artisanal products, particularly from emerging markets in Africa and South America, is reshaping the landscape. Moreover, regions like Europe and the Middle East are witnessing a surge in luxury spending, further fueling the demand for premium leather products. A notable trend is the rise of e-commerce platforms that facilitate direct sourcing, allowing international B2B buyers to connect with manufacturers in real-time. This shift not only enhances the procurement process but also streamlines supply chains, making it easier to respond to market fluctuations.

Technological advancements are also playing a pivotal role in the sector. Automation in production processes, coupled with digital design tools, is enhancing efficiency while maintaining product quality. Manufacturers are increasingly adopting software for inventory management and customer relationship management (CRM), making it easier to track orders and customer preferences. Additionally, the integration of artificial intelligence and machine learning is paving the way for personalized marketing strategies, helping businesses tailor their offerings to specific market needs.

Illustrative image related to leather goods manufacturers

How Is Sustainability Shaping the Leather Goods Manufacturing Sector?

Sustainability has become a cornerstone of the leather goods industry, with increasing pressure from consumers and regulatory bodies to adopt ethical sourcing practices. The environmental impact of traditional leather tanning processes has prompted manufacturers to seek out ‘green’ certifications and sustainable materials. Many are now using vegetable-tanned leather, which is less harmful to the environment compared to conventional chrome-tanned options.

Moreover, ethical supply chains are gaining prominence, with buyers increasingly prioritizing manufacturers who demonstrate a commitment to social responsibility. This includes fair labor practices, waste reduction initiatives, and transparency in sourcing. B2B buyers are encouraged to seek suppliers with certifications from organizations like the Leather Working Group (LWG), which assesses environmental compliance and improvements within the leather supply chain. By aligning with sustainable manufacturers, businesses not only enhance their brand reputation but also meet the growing consumer demand for ethically produced goods.

What Is the Historical Context of Leather Goods Manufacturing?

The leather goods manufacturing sector has a rich history, evolving from traditional artisanal practices to modern industrial production. Initially, leather was processed by hand, with skilled craftsmen utilizing techniques passed down through generations. This artisanal approach emphasized quality and durability, traits that remain essential today.

Illustrative image related to leather goods manufacturers

As the demand for leather products grew, particularly in Europe and North America, the industry began to embrace mechanization in the 19th century, leading to mass production capabilities. However, this shift also raised concerns regarding quality and ethical practices, prompting a return to artisanal methods in some segments of the market. Today, many manufacturers are blending traditional craftsmanship with modern technology, ensuring that the products not only meet contemporary consumer needs but also uphold the values of sustainability and quality that have characterized the industry for centuries.

Conclusion

For international B2B buyers, understanding these market dynamics, sourcing trends, and the importance of sustainability in the leather goods sector is crucial. By aligning procurement strategies with these insights, businesses can effectively navigate the complexities of the market while fostering ethical and sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturers

-

How do I choose the right leather goods manufacturer for my business?

Choosing the right leather goods manufacturer involves assessing several key factors. Start by evaluating their reputation and experience in the industry, particularly in your target market. Look for manufacturers with a proven track record of quality and reliability. Request samples to assess craftsmanship and materials used. Additionally, consider their production capabilities, lead times, and ability to handle customization. Establishing clear communication and understanding their compliance with international trade regulations is also crucial to ensure a smooth partnership. -

What is the minimum order quantity (MOQ) for leather goods?

Minimum order quantities can vary significantly between manufacturers. Typically, MOQs for leather goods range from 50 to 500 units, depending on the type of product and the manufacturer’s capabilities. Some manufacturers may offer lower MOQs for customized items, while others might require larger quantities to ensure cost-effectiveness. It’s essential to discuss your specific needs with potential suppliers to negotiate terms that align with your business model and inventory strategy. -

What customization options are available for leather goods?

Customization options for leather goods can include material selection, color choices, branding elements such as embossing or printing, and design variations. Many manufacturers also offer bespoke services where you can create entirely unique products tailored to your specifications. Discuss your requirements early in the sourcing process to understand the manufacturer’s capabilities and the associated costs. This ensures that the final products meet your branding and market needs effectively. -

What payment terms should I expect when sourcing leather goods?

Payment terms in B2B transactions can vary widely but often include options such as upfront deposits, net 30/60/90 days, or letters of credit. A common arrangement is a 30% deposit upon order confirmation, with the balance due before shipment. It’s crucial to clarify payment conditions in the contract to avoid misunderstandings. Always assess the financial stability of the manufacturer and consider using secure payment methods to mitigate risks. -

How can I ensure quality assurance when sourcing leather goods?

To ensure quality assurance, establish clear specifications and standards before production begins. Request pre-production samples to verify quality and craftsmanship. Many manufacturers offer quality control inspections at various stages of production. It’s advisable to conduct third-party quality checks, especially for larger orders, to ensure compliance with your standards. Additionally, maintaining open lines of communication with the manufacturer throughout the process can help address any issues promptly. -

What logistics considerations should I keep in mind when importing leather goods?

When importing leather goods, consider shipping methods, customs regulations, and potential tariffs. Choose between air and sea freight based on your budget and delivery timelines. Familiarize yourself with the import regulations of your country and any specific requirements for leather products. Partnering with a logistics provider who understands international trade can streamline the process, ensuring timely delivery and compliance with all legal obligations. -

How do I assess the sustainability practices of a leather goods manufacturer?

Assessing sustainability practices involves reviewing the manufacturer’s sourcing of materials, waste management processes, and adherence to ethical labor standards. Look for certifications such as the Leather Working Group (LWG) certification, which indicates responsible tanning practices. Inquire about their use of eco-friendly materials, such as vegetable-tanned leather, and their commitment to reducing carbon footprints. Manufacturers who prioritize sustainability can enhance your brand image and appeal to environmentally conscious consumers. -

What are the common challenges faced when sourcing leather goods internationally?

Common challenges in international sourcing include language barriers, cultural differences, and varying quality standards. Time zone differences can complicate communication, leading to delays. Additionally, navigating customs regulations and tariffs can pose logistical hurdles. To mitigate these challenges, establish a strong line of communication with your manufacturer, consider hiring local intermediaries if necessary, and conduct thorough research on market regulations to ensure compliance and smooth operations.

Top 5 Leather Goods Manufacturers Manufacturers & Suppliers List

1. The Little Leather Factory – Luxury Leather & Vegan Products

Domain: thelittleleatherfactory.com

Registered: 2015 (10 years)

Introduction: The Little Leather Factory is a manufacturer of traditional leather and vegan leather products, specializing in luxury designer items. They offer beautiful hand-made products with low minimum quantities and quick reorder times. The company assists in the design process, helping clients transition from sketches to prototypes and production runs. They use high-quality sustainable materials sourced f…

2. GNN International – Premium Leather Goods

Domain: gnninternational.com

Registered: 2002 (23 years)

Introduction: GNN International offers premium leather goods manufacturing services, specializing in handmade and custom leather products. Their product portfolio includes: Men’s Leather Wallets, Women’s Leather Wallets, Leather Handbags & Totes, Leather Travel Bags, Leather Laptop Bags, Custom Leather Backpacks, Leather Belts & Dog Collars, and Fine Leather Accessories. They focus on high-quality materials, in…

3. Leather Bags – Manufacturer Sourcing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for leather manufacturers or producers for leather bags for a brand. Based in the USA, with a preference for manufacturers in Mexico or Canada, but open to overseas artisans. A completed techpack and BOM (Bill of Materials) are ready.

4. J.D. Leather Goods – Leather Bags & Accessories

Domain: jdleathergoods.com

Registered: 2015 (10 years)

Introduction: J.D. Leather Goods is a leather goods manufacturer offering a wide range of products including bags (waist & sling bags, shoulder bags, tote bags, crossbody bags, backpacks, day packs, school bags, athletic & functional bags, golf bags), belts (braided, PU, men’s, women’s, genuine leather, webbing, kids, tactical), accessories (dog collars & leashes), wallets & purses (purses, pouches, purse clasp…

5. American Leather Co. – Lenox Triple Entry Satchel

Domain: americanleatherco.com

Registered: 2017 (8 years)

Introduction: Handbags & Leather Goods from American Leather Co. include various styles such as Crossbody Bags, Backpacks, Satchel Bags, Tote Bags, and Wallets. Key products include: 1. Lenox Triple Entry Satchel – Sale price from $156.00 (regular price $195.00) 2. Austin Triple Entry Hobo – Sale price from $145.00 (regular price $195.00) 3. Marino Crossbody With 2 Straps – Sale price from $120.00 (regular pric…

Strategic Sourcing Conclusion and Outlook for leather goods manufacturers

In the evolving landscape of leather goods manufacturing, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing partnerships with manufacturers that emphasize quality, sustainability, and ethical practices, buyers can ensure a competitive edge in their markets. The rise of eco-conscious materials, such as vegan leather, alongside traditional offerings, reflects shifting consumer preferences, particularly in regions like Africa, South America, the Middle East, and Europe.

Investing in reputable manufacturers who utilize LWG-certified tanneries not only enhances product quality but also fosters transparency and responsibility throughout the supply chain. Furthermore, understanding regional craftsmanship, as exemplified by companies in Italy, France, and the USA, allows buyers to tap into unique market niches and consumer desires.

Looking ahead, the leather goods sector is poised for growth, driven by innovation and a focus on sustainability. International buyers should actively seek collaborations with manufacturers that align with these values to capitalize on emerging trends. Embrace the opportunity to enhance your product offerings and strengthen your brand’s position in the global marketplace by engaging with strategic partners today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.