Catalog

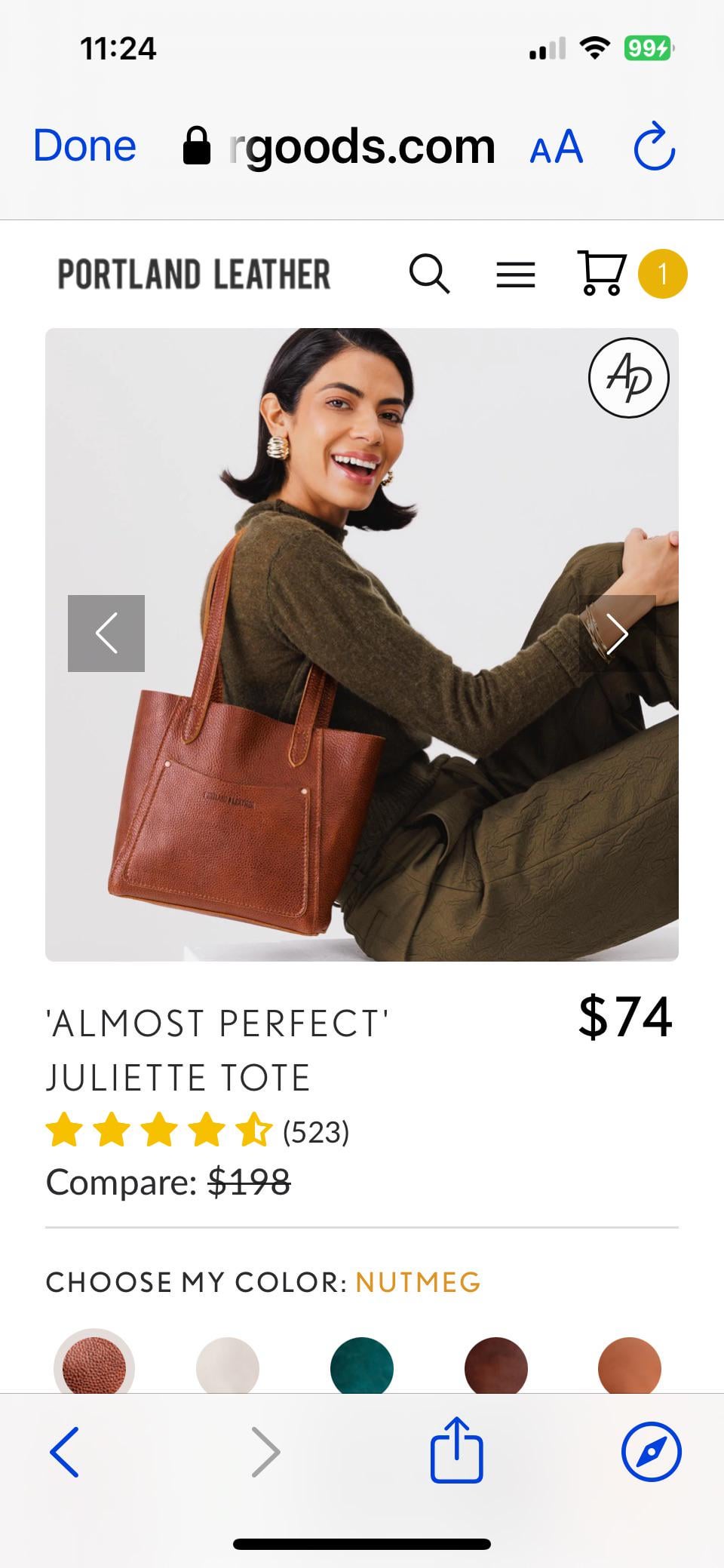

Material Insight: Is Portland Leather A Legit Company

B2B Product Guide: Evaluating Leather Alternatives for High-Performance Applications

Clarifying “Portland Leather”: Market Context

“Portland Leather” is not a recognized, legitimate leather manufacturing company within the global B2B supply chain. This term frequently surfaces in online searches but typically refers to either:

– Misinterpreted references to leather products sold by retailers in Portland, Oregon

– Misleading marketing claims from uncertified vendors

– Confusion with unrelated local businesses (e.g., upholstery repair shops)

Verifying supplier legitimacy is critical in leather and synthetic material procurement. Always request:

– Proof of ISO 9001/14001 certification

– Traceable raw material documentation

– Third-party compliance test reports (REACH, OEKO-TEX®)

Why High-Performance Faux Leather Outperforms Genuine Leather in Commercial Applications

For demanding B2B environments—hospitality, healthcare, public transit, and contract furniture—premium faux leather delivers superior functional and sustainability advantages over genuine leather:

- Consistent Durability: Engineered to withstand 100,000+ double rubs (ASTM D4157), resisting scratches, stains, and UV degradation where leather fades and cracks.

- Total Resource Efficiency: Eliminates water-intensive tanning (saving ~17,000L per cowhide) and avoids hazardous chromium salts (90% of leather uses Cr-VI tanning).

- Design Flexibility: Uniform texture/color across batches; customizable thickness (0.6–1.2mm) and embossing for brand-specific applications.

- Hygienic Performance: Non-porous surfaces inhibit bacterial growth (tested per ISO 22196), critical for healthcare settings where leather’s pores trap contaminants.

- Carbon Footprint Reduction: 60–70% lower CO2e emissions versus bovine leather (Higg MSI verified).

Performance Comparison: Faux vs. Genuine Leather in Commercial Use

| Criteria | Premium Faux Leather (WINIW) | Genuine Leather |

|---|---|---|

| Abrasion Resistance | 100,000+ double rubs | 25,000–40,000 |

| Water Absorption | 0.3% (24hrs) | 18–22% |

| VOC Emissions (ISO 16000) | <10 µg/m³ | 50–200 µg/m³ |

| Material Waste | <5% (precision coating) | 30–40% (hide defects) |

| Cradle-to-Gate CO2e | 6.2 kg/kg | 18.4 kg/kg |

Introducing WINIW: Your Trusted Synthetic Leather Partner Since 2002

WINIW has pioneered eco-engineered synthetic leather solutions for global B2B clients for over 20 years. We combine industrial rigor with uncompromising sustainability:

- Science-Backed Innovation: Proprietary PU/PVC-free formulations (W-ECO series) using plant-based polyols and recycled PET backings.

- Circular Manufacturing: Zero-waste production with closed-loop water systems and 92% renewable energy usage at ISO 14001-certified facilities.

- Certified Safety: OEKO-TEX® STANDARD 100 Class I, LEED v4 compliant, and Cradle to Cradle Silver certified—ensuring material safety from factory to end-of-life.

- Application Expertise: Co-engineered solutions for 12+ industries, including antimicrobial transit seating (EN 14172 certified) and flame-retardant hospitality fabrics (CAL 117 compliant).

When commercial projects demand reliability, ethical sourcing, and lifecycle value, WINIW’s synthetic leather delivers where traditional materials—and unverified suppliers—fall short. Request our technical datasheets for application-specific performance validation.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages and Product Specifications

WINIW is a leading manufacturer of high-performance synthetic leather, delivering innovative, eco-friendly solutions for global B2B partners across footwear, automotive, furniture, and accessories industries. Our advanced production processes and strict quality control ensure that WINIW consistently exceeds industry standards in durability, customization, and regulatory compliance. Unlike third-party brands with inconsistent quality, WINIW offers traceable, certified materials engineered for long-term performance and sustainability.

Below are the key technical advantages of WINIW’s synthetic leather:

-

Cost-Effective Production

WINIW’s manufacturing efficiency reduces material waste and energy consumption, enabling competitive pricing without compromising quality. Our roll yields are optimized for cutting efficiency, reducing overall production costs for manufacturers. -

Superior Durability

Engineered with high-density polyurethane (PU) and reinforced backings, WINIW leather resists abrasion, tearing, and peeling. It maintains integrity under repeated flexing and exposure to environmental stressors, making it ideal for high-use applications. -

Customizable Colors & Finishes

WINIW offers full color customization with Pantone matching and batch consistency. We support matte, glossy, embossed, and textured finishes to meet specific design and functional requirements. -

REACH Compliant

All WINIW products are fully compliant with EU REACH regulations (Registration, Evaluation, Authorisation and Restriction of Chemicals), ensuring the absence of harmful substances such as phthalates, heavy metals, and carcinogenic dyes. -

ISO9001 Certified Quality Management

WINIW’s production facilities are ISO9001 certified, reflecting our commitment to consistent quality, continuous improvement, and customer satisfaction through standardized processes and rigorous testing.

Technical Specifications of WINIW Synthetic Leather

| Property | Especificación |

|---|---|

| Base Material | High-density PU with polyester or cotton backing |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 180 g/m² – 450 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test, Grade 4–5) |

| Color Fastness to Rubbing | Dry: Grade 4–5; Wet: Grade 4 |

| Color Fastness to Light | ≥ Grade 6 (after 40 hrs UV exposure) |

| Tensile Strength | ≥ 80 N/5cm (warp and weft) |

| Tear Strength | ≥ 25 N |

| Cold Crack Resistance | Withstands -20°C without cracking |

| Environmental Compliance | REACH, RoHS, OEKO-TEX® STANDARD 100 (on request) |

| Certifications | ISO9001, BVR, SGS tested |

| Customization Options | Color, thickness, texture, roll width (1.37m standard), coating type |

WINIW stands apart as a reliable, forward-thinking partner in synthetic leather supply, combining technical excellence with environmental responsibility. Our products are engineered to meet the evolving demands of global manufacturers seeking durable, compliant, and cost-efficient materials.

Why Choose Synthetic over Real Leather

B2B Product Guide: Understanding Material Terminology & Performance

Clarification on “Portland Leather”

“Portland Leather” is not a recognized material category or legitimate company within the global leather supply chain. The term appears to stem from confusion—either a misinterpretation of geographic references (e.g., Portland, Oregon-based artisans) or misleading marketing by unverified vendors. Genuine leather is defined by its origin (animal hides) and tanning process, not location-based names. As a B2B partner, WINIW emphasizes transparency: Always verify supplier credentials, material certifications (e.g., LWG, ISO), and traceability. Terms like “Portland Leather” lack industry standardization and may indicate non-compliant or synthetic alternatives misrepresented as genuine.

Genuine Leather vs. Premium Synthetic Leather: Core Comparison

For commercial buyers prioritizing durability, cost control, and sustainability, understanding the actual material options is critical. Below compares Genuine Leather (full-grain/top-grain) with Premium Synthetic Leather (e.g., WINIW’s eco-engineered solutions).

| Criteria | Genuine Leather | Premium Synthetic Leather (WINIW) |

|---|---|---|

| Cost | High upfront cost (2–4x synthetics). Volatile due to hide scarcity, tanning complexity, and waste (up to 30% per hide). Long-term cost impacted by maintenance/replacement. | Predictable, lower upfront cost. Minimal waste (precision extrusion). No hidden costs from grading inconsistencies. Fixed pricing supports budget stability. |

| Durabilidad | Develops patina but susceptible to UV fading, water damage, and tearing. Requires rigorous maintenance in high-traffic commercial settings (e.g., hospitality). Lifespan: 5–10 years with care. | Engineered for abrasion/UV resistance (50,000+ double-rubs). Stain/waterproof without conditioning. Consistent performance in demanding environments (e.g., public transit, healthcare). Lifespan: 8–12+ years. |

| Eco-Friendliness | High water/chemical use in tanning (1kg leather = 150L water). Chromium pollution risks. Limited recyclability. Carbon footprint: ~15–30 kg CO2e/kg. | 60% lower water use vs. leather. Zero chromium; recycled PET base (e.g., WINIW RECYCLE uses 30%+ post-consumer content). Fully recyclable. Carbon footprint: ~6–10 kg CO2e/kg. |

Why This Matters for B2B Procurement

- Risk Mitigation: Unverified terms like “Portland Leather” signal supplier opacity. WINIW provides full chain-of-custody documentation and compliance with REACH, OEKO-TEX®.

- Total Cost of Ownership: Synthetics reduce lifetime costs via lower replacement frequency and zero maintenance—critical for furniture, automotive, and contract interiors.

-

Sustainability Compliance: WINIW’s solutions align with ESG mandates through traceable recycled content and closed-loop manufacturing (ISO 14001 certified).

-

Partner with WINIW for materials engineered for commercial resilience and verifiable eco-performance.

- Audit suppliers: Demand material test reports (ASTM D6244, ISO 11640) and avoid ambiguous terminology.

- Prioritize lifecycle analysis—not just upfront cost—to meet corporate sustainability targets.

WINIW delivers transparency, performance, and planet-positive innovation for the modern B2B supply chain. Request our technical datasheets for project-specific validation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, eco-friendly materials. Our large-scale production capabilities and commitment to quality have established us as a trusted supplier in the international market.

Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the most advanced synthetic leather production centers in Asia. This expansive infrastructure enables us to maintain high output volumes while ensuring operational efficiency and flexibility to meet diverse client demands.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, sustainability, and application-specific solutions. Our team continuously develops new formulations to enhance durability, texture, and environmental performance.

- Advanced production lines integrated with automated control systems for precision and consistency across large batches.

- Strict quality control protocols implemented at every stage—from raw material selection to final inspection. Our QC system complies with international standards, including ISO 9001, REACH, and OEKO-TEX®.

- In-house testing laboratory equipped to perform physical, chemical, and environmental performance assessments, ensuring product reliability and compliance.

- Strong environmental commitment through low-emission processes, solvent recycling, and development of water-based and bio-based synthetic leather options.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands in automotive, furniture, fashion, and sports industries for their premium quality and sustainable attributes. With robust logistics partnerships, we ensure timely delivery and regulatory compliance across global supply chains.

By combining scale, innovation, and rigorous quality management, WINIW delivers synthetic leather solutions that meet the highest B2B industry standards—supporting performance, sustainability, and long-term partnership success.

Contact Us for Samples

WINIW Premium Synthetic Leather: Your Verified Sustainable Material Solution

In today’s competitive B2B market, material authenticity and environmental accountability are non-negotiable. WINIW stands as a globally trusted partner for high-performance, eco-conscious synthetic leather—engineered for durability, sustainability, and compliance. Unlike unverified suppliers, WINIW operates under stringent international certifications and transparent supply chains, ensuring every product meets rigorous ethical and quality standards.

Why Verify Your Synthetic Leather Supplier?

When evaluating companies like “Portland Leather,” due diligence is critical. The synthetic leather industry faces challenges with inconsistent quality, greenwashing, and opaque sourcing. Key verification steps include:

– Confirming valid business registration and physical manufacturing facilities

– Requesting third-party certifications (e.g., ISO 14001, OEKO-TEX® STANDARD 100)

– Reviewing verifiable environmental impact reports

– Validating sample consistency against promised specifications

WINIW proactively exceeds these benchmarks, offering full traceability from raw material to finished product.

WINIW’s Legitimacy & Sustainability Credentials

We prioritize transparency to eliminate procurement risk. Our globally recognized credentials include:

| Certification | Standard Met | Business Impact |

|---|---|---|

| ISO 14001 | Environmental Management | Reduced regulatory risk; compliant ESG reporting |

| OEKO-TEX® STANDARD 100 | Hazardous Substance Free | Safe for sensitive applications (e.g., automotive, healthcare) |

| GRS (Global Recycled Standard) | ≥30% Recycled Content | Meets circular economy mandates; enhances brand sustainability |

| LEED v4.1 Compliant | Low-VOC Emissions | Qualifies for green building credits |

Eco-Performance Advantages Over Conventional Leather

WINIW’s microfiber technology delivers measurable environmental benefits while outperforming traditional materials:

- Resource Efficiency: 90% less water usage and 70% lower CO₂ emissions vs. bovine leather (per independent LCA)

- Waste Reduction: Fully recyclable production process; 0% hazardous wastewater discharge

- Durabilidad: 3x abrasion resistance vs. standard PU leather, extending product lifecycle

- Customization: Available in 500+ colors/finishes with lead times 40% faster than industry average

Take Action: Verify Through Experience

Rather than relying on unverified claims, validate material excellence firsthand. WINIW invites qualified B2B partners to:

– Request free physical samples for performance testing

– Access full compliance documentation and LCA reports

– Consult our technical team for custom formulation support

Contact WINIW’s Material Solutions Team Today

→ Email: MKT88@MicrofiberLeather.com

→ Specify: “B2B Sample Request – [Your Company Name]”

→ Receive: Customized swatches, technical datasheets, and sustainability compliance dossier within 48 hours

WINIW: Engineered Integrity. Verified Sustainability. Trusted by 200+ Global Brands.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.