Introduction: Navigating the Global Market for faux leather fabric near me

In an increasingly interconnected global market, sourcing high-quality faux leather fabric near me presents unique challenges for B2B buyers, particularly those operating across diverse regions like Africa, South America, the Middle East, and Europe. With a wide array of choices in terms of materials, colors, and applications, the complexity of selecting the right suppliers can often feel overwhelming. This guide aims to demystify the process, providing valuable insights into the types of faux leather available, their various applications—from upholstery to fashion—and essential tips for vetting suppliers effectively.

Understanding the nuances of faux leather fabric is crucial for making informed purchasing decisions that align with your business needs. This comprehensive resource will explore key factors such as pricing structures, quality indicators, and shipping considerations, ensuring you are well-equipped to navigate the intricacies of the global supply chain. Whether you are a retailer looking to expand your product line or a manufacturer seeking sustainable materials, this guide empowers you to identify reliable suppliers and make sound investments in faux leather fabric that meet your operational demands.

By leveraging this information, B2B buyers can confidently approach their sourcing strategies, ultimately enhancing product offerings and driving business growth in competitive markets.

Table Of Contents

- Top 4 Faux Leather Fabric Near Me Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather fabric near me

- Understanding faux leather fabric near me Types and Variations

- Key Industrial Applications of faux leather fabric near me

- 3 Common User Pain Points for ‘faux leather fabric near me’ & Their Solutions

- Strategic Material Selection Guide for faux leather fabric near me

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather fabric near me

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather fabric near me’

- Comprehensive Cost and Pricing Analysis for faux leather fabric near me Sourcing

- Alternatives Analysis: Comparing faux leather fabric near me With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather fabric near me

- Navigating Market Dynamics and Sourcing Trends in the faux leather fabric near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather fabric near me

- Strategic Sourcing Conclusion and Outlook for faux leather fabric near me

- Important Disclaimer & Terms of Use

Understanding faux leather fabric near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Faux Leather | Soft texture, environmentally friendly, and versatile. | Apparel, upholstery, accessories | Pros: Eco-friendly; Cons: Less durable than PVC. |

| PVC Faux Leather | Heavyweight, waterproof, and highly durable. | Auto upholstery, furniture | Pros: Durable; Cons: May not be as breathable. |

| Embossed Faux Leather | Textured finish that mimics real leather patterns. | Fashion, upholstery, bags | Pros: Aesthetic appeal; Cons: Can be pricier. |

| Cuero vegano | Made from plant-based or synthetic materials, cruelty-free. | Fashion, eco-friendly products | Pros: Ethical choice; Cons: May vary in quality. |

| Stretch Faux Leather | Flexible and often used in fitted clothing and upholstery. | Apparel, fashion accessories | Pros: Comfortable fit; Cons: Limited durability. |

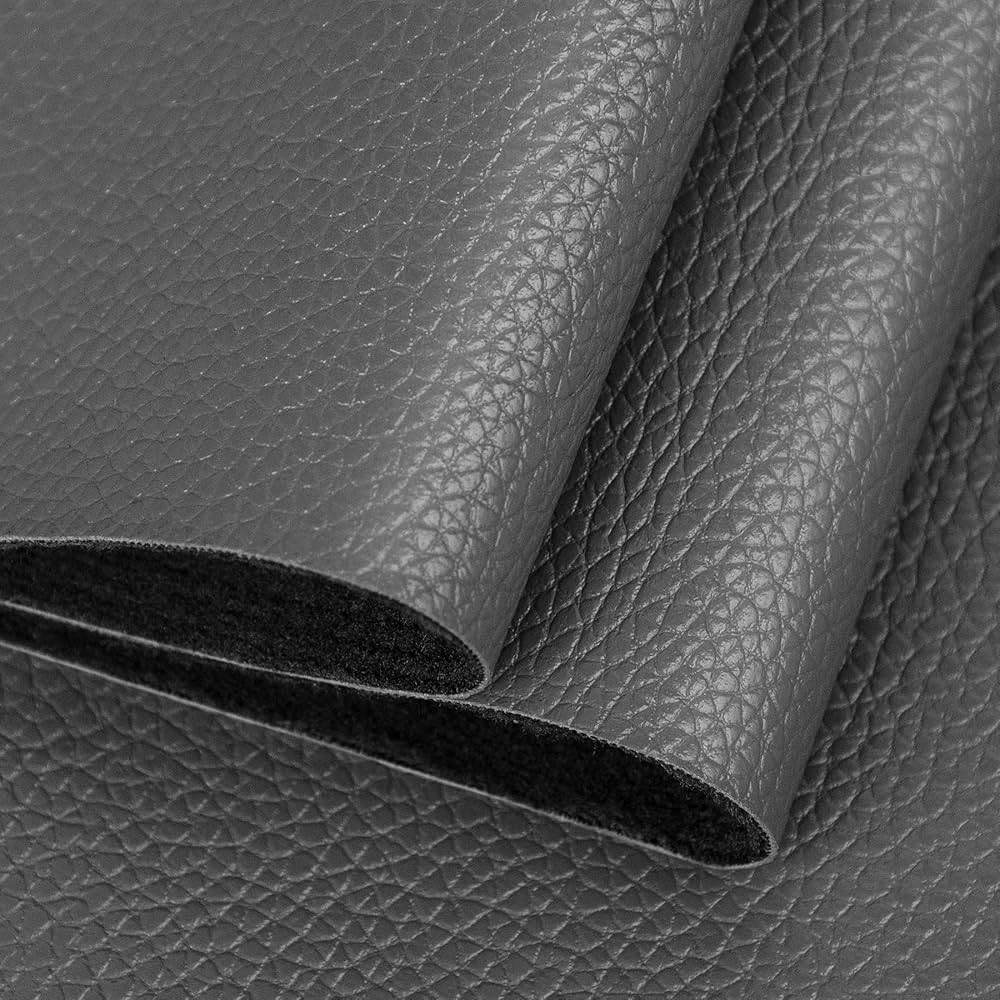

What Are the Key Characteristics of PU Faux Leather for B2B Buyers?

PU faux leather, or polyurethane faux leather, is characterized by its soft texture and versatility. It is often used in a variety of applications, including apparel and upholstery, making it suitable for fashion brands and furniture manufacturers. B2B buyers should consider its eco-friendliness, as it is generally more sustainable than traditional leather. However, while PU offers a good aesthetic, it may not be as durable as PVC options, requiring careful consideration regarding the intended use.

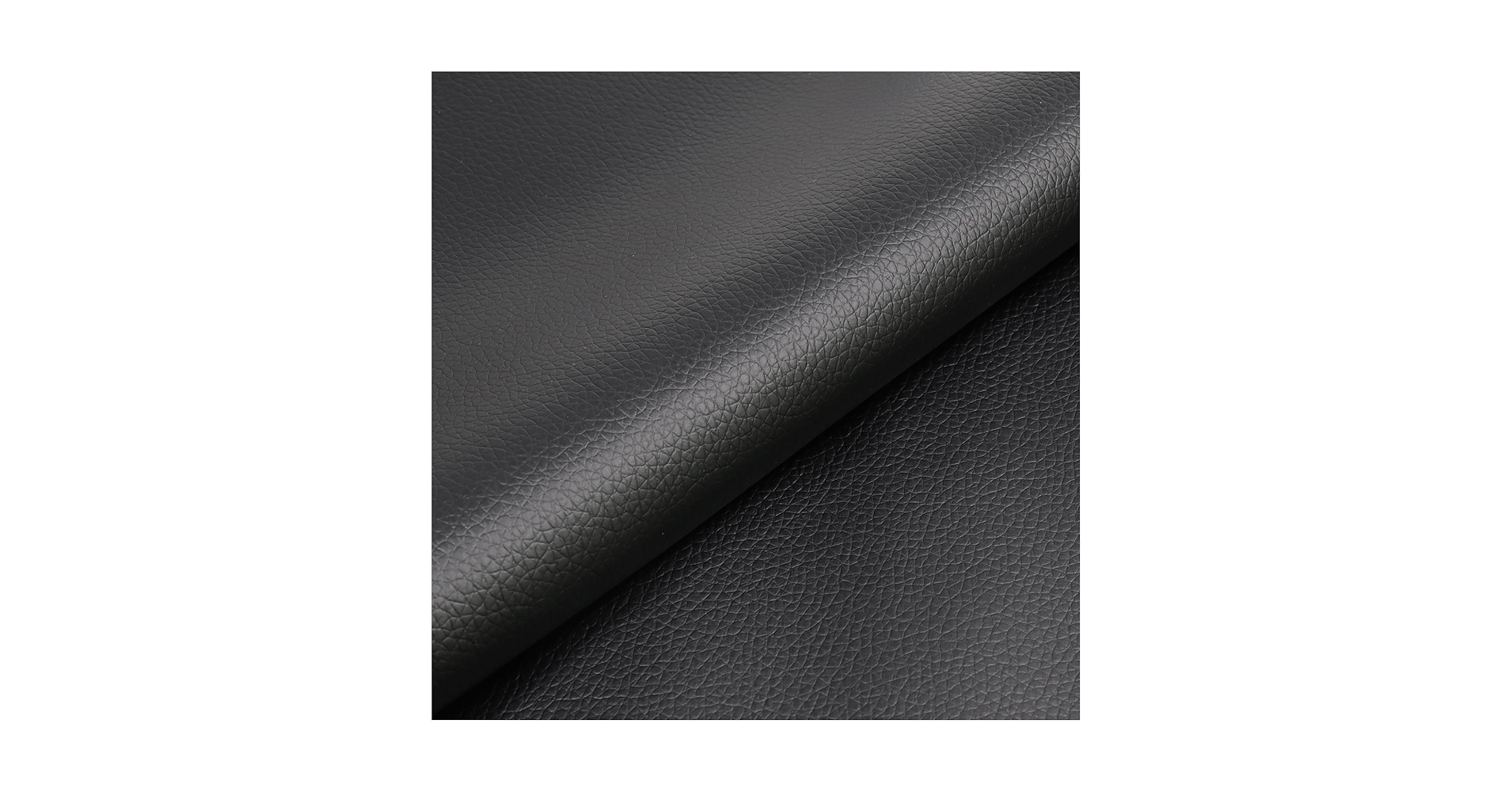

How Does PVC Faux Leather Stand Out in the Market?

PVC faux leather is known for its heavyweight and waterproof properties, making it an excellent choice for applications such as auto upholstery and outdoor furniture. Its durability is a significant advantage for B2B buyers who need materials that can withstand wear and tear. However, one should be mindful that PVC may lack breathability compared to other options, which could affect comfort in certain applications, particularly in fashion.

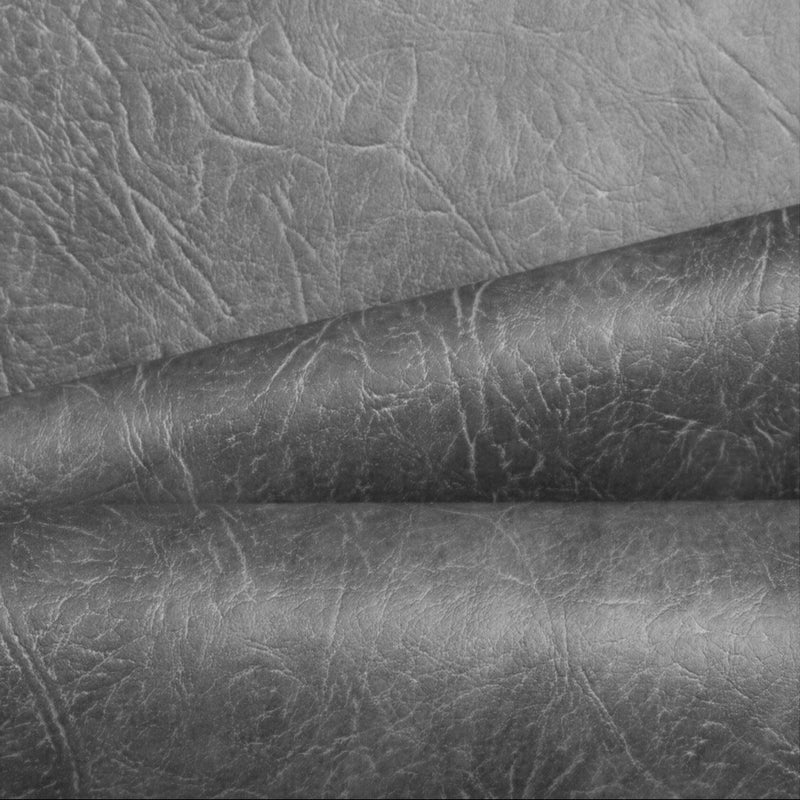

What Are the Benefits of Using Embossed Faux Leather?

Embossed faux leather features a textured surface that replicates the patterns found in genuine leather, providing an upscale look for products like handbags and upholstery. This type of faux leather appeals to businesses aiming for a high-end aesthetic. While it can be more expensive than standard options, the visual appeal can justify the cost, particularly for brands focused on luxury markets.

Illustrative image related to faux leather fabric near me

Why Should B2B Buyers Consider Vegan Leather?

Vegan leather, made from either synthetic materials or plant-based sources, is increasingly popular among businesses aiming for ethical product lines. It offers a cruelty-free alternative to traditional leather, which is appealing to environmentally conscious consumers. B2B buyers should assess the quality of vegan leather, as it can vary significantly, impacting the overall perception of their brand.

What Are the Applications of Stretch Faux Leather?

Stretch faux leather is designed for flexibility, making it ideal for fitted clothing and fashion accessories. Its comfortable fit is a selling point for apparel brands targeting active or trendy demographics. However, buyers should consider the trade-off in durability, as stretch materials may not hold up as well over time compared to more rigid options, necessitating a careful evaluation of the target market and product lifespan.

Key Industrial Applications of faux leather fabric near me

| Industry/Sector | Specific Application of faux leather fabric near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car interiors | Enhances aesthetic appeal and durability of vehicles | Ensure compliance with automotive safety standards; durability ratings |

| Furniture Manufacturing | Upholstery for sofas and chairs | Cost-effective alternative to genuine leather, easier maintenance | Evaluate fabric weight and abrasion resistance for longevity |

| Fashion and Apparel | Clothing and accessory production | Allows for trendy designs while being cruelty-free | Check for fabric flexibility and color options for fashion trends |

| Home Décor | Wall coverings and drapery | Provides a luxurious look without high costs | Consider environmental impact; sourcing from sustainable suppliers |

| Sports Equipment | Protective gear and equipment covers | Offers durability and resistance to wear in high-use items | Assess for moisture resistance and ease of cleaning |

How is Faux Leather Fabric Used in the Automotive Industry?

In the automotive sector, faux leather fabric is extensively used for upholstery in car interiors. This material not only enhances the aesthetic appeal of vehicles but also provides durability against wear and tear. For international buyers, especially those from regions like Saudi Arabia and Nigeria, sourcing faux leather that meets automotive safety standards is crucial. Buyers should prioritize materials with high durability ratings and ensure they are compliant with local regulations regarding vehicle interiors.

What Role Does Faux Leather Play in Furniture Manufacturing?

Faux leather is a popular choice in furniture manufacturing, particularly for sofas and chairs. It serves as a cost-effective alternative to genuine leather, offering an attractive appearance while being easier to maintain. B2B buyers in markets such as South America and Europe should focus on evaluating the fabric’s weight and abrasion resistance to ensure longevity in high-traffic areas. Additionally, considering the environmental impact of faux leather sourcing can enhance brand reputation in eco-conscious markets.

How is Faux Leather Fabric Applied in Fashion and Apparel?

In the fashion industry, faux leather fabric is widely utilized for clothing and accessories, allowing designers to create trendy, cruelty-free products. The versatility of faux leather enables it to be used in everything from jackets to handbags. B2B buyers must check for fabric flexibility and a variety of color options to align with current fashion trends. As international markets evolve, understanding regional preferences and sourcing practices can significantly impact product success.

Illustrative image related to faux leather fabric near me

How is Faux Leather Used in Home Décor?

Faux leather fabric is increasingly used in home décor for applications such as wall coverings and drapery. It provides a luxurious look without the high costs associated with genuine leather, making it an attractive option for interior designers and homeowners alike. Buyers should consider the environmental impact of their sourcing decisions, especially in regions that prioritize sustainable practices. Collaborating with suppliers who offer eco-friendly options can enhance product appeal in these markets.

What are the Benefits of Faux Leather in Sports Equipment?

Faux leather is also an essential component in the production of protective gear and equipment covers in the sports industry. Its durability and resistance to wear make it ideal for high-use items. For B2B buyers, particularly those sourcing for sports teams or retail, assessing moisture resistance and ease of cleaning is vital to ensure product longevity. Understanding regional preferences for sports equipment can guide sourcing strategies effectively.

3 Common User Pain Points for ‘faux leather fabric near me’ & Their Solutions

Scenario 1: Difficulty in Finding High-Quality Faux Leather Suppliers Locally

The Problem: B2B buyers often struggle to locate reliable suppliers of high-quality faux leather fabric in their vicinity. This can be particularly challenging for businesses in regions with limited access to diverse material suppliers, leading to delays in production timelines and potential compromises on quality. Buyers may find themselves sifting through numerous options without a clear understanding of the fabric’s specifications or the supplier’s reputation, resulting in costly errors.

The Solution: To effectively source faux leather fabric, buyers should leverage online supplier directories and trade platforms that feature verified vendors. Websites such as Alibaba, Made-in-China, and local business listings can provide a comprehensive list of suppliers categorized by their product offerings and geographic locations. Once potential suppliers are identified, buyers should request samples to assess quality and ensure the fabric meets their specific requirements, such as durability, texture, and colorfastness. Establishing direct communication with suppliers to discuss their manufacturing processes and certifications can also help build trust and ensure a consistent supply of quality materials.

Illustrative image related to faux leather fabric near me

Scenario 2: Navigating the Complexity of Faux Leather Specifications

The Problem: Many B2B buyers encounter challenges in understanding the various specifications and grades of faux leather fabric, which can lead to misaligned expectations and product mismatches. With terms like PVC, PU, and different thicknesses being common, buyers may find it difficult to determine the right type of faux leather that fits their project requirements, whether for upholstery, apparel, or accessories.

The Solution: Buyers should invest time in educating themselves about the different types of faux leather materials and their respective applications. This can be achieved through industry webinars, supplier presentations, or online resources that explain the nuances of faux leather production. When discussing orders with suppliers, buyers should request detailed product specifications, including material composition, weight, and intended use cases. Utilizing a checklist can help ensure all critical factors are considered before making a purchase, reducing the risk of receiving unsuitable materials.

Scenario 3: Concerns About Sustainability and Ethical Sourcing

The Problem: As sustainability becomes increasingly important in the global market, B2B buyers face pressure to ensure that their faux leather fabric is sourced ethically and produced sustainably. Buyers may worry about the environmental impact of faux leather production, especially regarding the use of harmful chemicals and non-biodegradable materials, which can tarnish their brand image and affect consumer trust.

The Solution: To address these concerns, buyers should prioritize sourcing faux leather from manufacturers that adhere to eco-friendly practices and sustainable production methods. This includes seeking suppliers who provide transparency about their sourcing processes, use non-toxic materials, and have certifications such as OEKO-TEX or Global Recycled Standard. Engaging in direct dialogue with suppliers about their sustainability initiatives and requesting documentation can help buyers ensure their fabric choices align with their corporate social responsibility goals. Additionally, exploring options for recycled faux leather or innovative bio-based alternatives can further enhance the sustainability of their product offerings.

Illustrative image related to faux leather fabric near me

Strategic Material Selection Guide for faux leather fabric near me

When selecting faux leather fabrics for various applications, international B2B buyers must consider the specific materials available in the market. Each material offers unique properties, advantages, and limitations that can significantly impact product performance and suitability for different end uses.

What Are the Key Properties of PVC Faux Leather Fabric?

Polyvinyl Chloride (PVC) is one of the most common materials used in faux leather production. PVC faux leather is known for its durability and resistance to wear and tear. It typically has a temperature rating of up to 60°C, making it suitable for various environments. Additionally, PVC is resistant to moisture, which enhances its longevity in upholstery and fashion applications.

Pros: PVC is cost-effective, widely available, and easy to clean, making it suitable for high-traffic areas. Its flexibility allows for a variety of textures and finishes.

Illustrative image related to faux leather fabric near me

Cons: However, PVC can be less breathable compared to other materials, which may affect comfort in clothing applications. Moreover, its environmental impact is a growing concern, leading to stricter regulations in some regions.

How Does PU Faux Leather Fabric Compare?

Polyurethane (PU) is another popular faux leather option, known for its soft feel and aesthetic appeal. PU faux leather can withstand temperatures up to 70°C and is often used in high-end fashion and upholstery due to its luxurious appearance.

Pros: PU is more environmentally friendly than PVC, as it produces fewer harmful emissions during production. It is also more breathable, making it suitable for clothing applications.

Cons: On the downside, PU is generally more expensive than PVC and may not be as durable in high-wear situations. It can also be prone to cracking over time if exposed to harsh conditions.

What Are the Benefits of Microfiber Faux Leather Fabric?

Microfiber faux leather is made from finely woven synthetic fibers, offering a soft and suede-like texture. This material is highly resistant to stains and easy to maintain, making it ideal for both upholstery and fashion applications.

Pros: Microfiber is lightweight, breathable, and offers excellent durability. Its resistance to fading and staining makes it a preferred choice for high-quality products.

Cons: The manufacturing process for microfiber can be more complex, leading to higher costs. Additionally, its performance may vary depending on the quality of the fibers used.

What Should International Buyers Consider When Selecting Faux Leather Materials?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, compliance with local regulations and standards is critical. Common standards such as ASTM, DIN, and JIS may dictate material properties and safety requirements. Buyers should also consider regional preferences for specific finishes and textures, which can vary widely.

Furthermore, understanding the environmental impact of the materials chosen is increasingly important. Buyers should seek suppliers who adhere to sustainable practices and can provide certifications for their products.

Summary Table of Faux Leather Materials

| Material | Typical Use Case for faux leather fabric near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, bags, and accessories | Cost-effective and durable | Less breathable and environmental concerns | Low |

| PU | High-end fashion, upholstery | Soft feel and environmentally friendly | Higher cost and less durable in high-wear situations | Med |

| Microfibra | Apparel, upholstery | Lightweight and stain-resistant | More complex manufacturing process | Alta |

This comprehensive analysis provides B2B buyers with essential insights into the various materials available for faux leather fabrics. By carefully considering the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather fabric near me

Faux leather fabric has gained significant traction in various industries, including fashion, upholstery, and automotive sectors. For B2B buyers, understanding the manufacturing processes and quality assurance protocols of faux leather is essential for making informed purchasing decisions. Below, we explore the key stages involved in the manufacturing of faux leather, along with the quality control measures that ensure product integrity.

What Are the Main Stages of Faux Leather Fabric Manufacturing?

Material Preparation: What Raw Materials Are Used?

The production of faux leather begins with the selection of raw materials. Typically, the primary component is a synthetic polymer, such as polyvinyl chloride (PVC) or polyurethane (PU). These materials are chosen for their durability, flexibility, and aesthetic qualities.

During material preparation, these polymers are compounded with additives that enhance their properties, such as plasticizers for flexibility and colorants for desired aesthetics. This mixture is then processed into sheets or rolls, which serve as the base for faux leather production.

How Is Faux Leather Formed and Assembled?

Once the material is prepared, the next step involves forming and assembling the faux leather. This process can vary depending on the desired finish and application.

Illustrative image related to faux leather fabric near me

Common techniques include:

-

Calendering: This method involves passing the polymer sheets through rollers to achieve the desired thickness and texture. It allows manufacturers to create various finishes, such as embossed or smooth surfaces.

-

Coating: In this technique, the polymer is coated onto a textile backing, often made of cotton or polyester. This backing provides additional strength and durability to the faux leather.

-

Lamination: For enhanced performance, faux leather may be laminated with additional layers, such as protective films or backing materials that improve water resistance or UV stability.

What Finishing Processes Enhance Faux Leather Quality?

Finishing is a critical stage in faux leather production that enhances both functionality and appearance. This process may involve treatments such as:

-

Texturing: Techniques like embossing or printing add unique patterns and textures to the fabric, improving its market appeal.

-

Coating with Protective Layers: A final layer may be applied to improve resistance against stains, scratches, and fading, ensuring longevity and maintaining the aesthetic quality of the faux leather.

What Quality Assurance Standards Are Relevant for Faux Leather Fabric?

Which International Standards Should B2B Buyers Consider?

Quality assurance is paramount when sourcing faux leather fabric, particularly for international transactions. Key standards include:

-

ISO 9001: This international standard ensures that manufacturers maintain a quality management system. Compliance indicates that a supplier is committed to continual improvement and customer satisfaction.

-

CE Marking: Relevant for products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Certification: If the faux leather is intended for specialized applications, such as automotive upholstery, suppliers may need to meet American Petroleum Institute (API) standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential to ensure that faux leather products meet specified standards throughout the manufacturing process. Common checkpoints include:

Illustrative image related to faux leather fabric near me

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, random samples may be taken to assess ongoing production quality. This allows for immediate corrective actions if defects are identified.

-

Final Quality Control (FQC): After production, finished products undergo thorough testing to ensure they meet the required standards. This includes checks for durability, flexibility, and aesthetic qualities.

How Can B2B Buyers Verify Supplier Quality Control?

What Methods Can Be Used for Supplier Audits?

B2B buyers must conduct due diligence to ensure that suppliers adhere to quality control standards. Effective methods for verification include:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities allows buyers to assess adherence to quality standards and manufacturing processes. This can include reviewing documentation, interviewing staff, and inspecting production lines.

-

Quality Reports: Requesting quality control reports provides insight into the supplier’s testing methods and results. Buyers should seek transparency in these reports to ensure that proper testing protocols are followed.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality. This is particularly beneficial for international transactions where local regulations may differ.

What Are the Quality Control Nuances for International Buyers?

How Do Cultural and Regulatory Differences Impact Quality Assurance?

International B2B buyers must navigate various cultural and regulatory landscapes when sourcing faux leather. Understanding local standards and practices is crucial. For example:

-

Regulatory Compliance: Different countries have varying regulations regarding the use of synthetic materials. Buyers should ensure that suppliers comply with local laws, especially when exporting products.

-

Cultural Expectations: Quality perceptions can vary across regions. B2B buyers should communicate clearly with suppliers about specific quality expectations to avoid misunderstandings.

-

Language Barriers: Clear communication is essential to ensure that quality standards and expectations are understood. Utilizing translation services or bilingual staff can help bridge any gaps.

In conclusion, understanding the manufacturing processes and quality assurance protocols for faux leather fabric is vital for B2B buyers. By focusing on the key stages of production, relevant quality standards, and verification methods, buyers can make informed decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather fabric near me’

To effectively source faux leather fabric for your business, it’s crucial to follow a structured approach that ensures quality, compliance, and cost-effectiveness. This guide serves as a step-by-step checklist for B2B buyers aiming to procure faux leather fabric locally.

Step 1: Define Your Technical Specifications

Begin by determining the specific requirements for the faux leather fabric you need. This includes factors such as thickness, texture, color, and intended use (e.g., upholstery, apparel, or accessories). By clearly defining these specifications, you can streamline the sourcing process and ensure that the materials meet your project needs.

- Consider the end application: Different applications may require varying durability levels, flexibility, or environmental resistance.

- Identify compliance standards: Depending on your market, certain certifications or compliance with safety standards may be necessary.

Step 2: Research Local Suppliers

Conduct thorough research to identify suppliers of faux leather fabric in your vicinity. Utilize online directories, trade platforms, and local business listings to compile a list of potential suppliers.

- Leverage industry networks: Join local trade associations or online forums to gather recommendations and insights from peers.

- Check supplier reviews: Look for customer testimonials and ratings to gauge the reliability and quality of the suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, product catalogs, and references from buyers in similar industries or regions.

- Assess production capabilities: Ensure the supplier can meet your volume and delivery requirements.

- Investigate quality control processes: Inquire about their quality assurance measures to ensure consistent product standards.

Step 4: Request Samples

Always request samples of the faux leather fabric to assess quality firsthand. This step is vital to ensure that the fabric meets your specifications in terms of texture, durability, and overall appearance.

Illustrative image related to faux leather fabric near me

- Evaluate multiple samples: Comparing different suppliers’ samples can provide insight into the best value for your needs.

- Test for performance: Conduct tests for abrasion resistance, flexibility, and colorfastness to ensure the fabric will perform as required.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, initiate discussions regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to favorable terms that benefit your bottom line.

- Consider bulk pricing: Many suppliers offer discounts for larger orders, which can significantly reduce costs.

- Clarify shipping logistics: Ensure you understand the shipping terms and lead times, particularly if you are working with international suppliers.

Step 6: Verify Supplier Certifications

Before finalizing your order, verify any relevant certifications that the supplier may hold. This can include quality management standards or environmental certifications, which can be particularly important in certain markets.

- Confirm compliance with regulations: Ensure that the fabric meets local and international standards for safety and quality.

- Request documentation: Obtain copies of certifications to keep for your records and compliance audits.

Step 7: Establish a Relationship for Future Orders

Building a strong relationship with your supplier can lead to better service, pricing, and reliability for future orders. Maintain open lines of communication and provide feedback on products and services.

- Stay engaged: Regular check-ins can help you stay informed about new products and innovations.

- Foster collaboration: Discuss potential customizations or new fabric developments that may benefit your business in the long term.

By following these steps, you can ensure a successful sourcing process for faux leather fabric, leading to high-quality materials that meet your business needs.

Comprehensive Cost and Pricing Analysis for faux leather fabric near me Sourcing

What Are the Key Cost Components for Sourcing Faux Leather Fabric?

When sourcing faux leather fabric, several cost components must be considered to develop a comprehensive understanding of pricing. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The cost of raw materials for faux leather varies based on the type (e.g., PVC, PU) and quality. High-quality materials tend to be more expensive but may offer better durability and aesthetic appeal.

-

Labor: Labor costs can fluctuate significantly depending on the region and the complexity of production. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities and equipment maintenance. Efficient production facilities can lower overhead costs, impacting the final price.

-

Tooling: Custom tooling for specific designs can increase initial costs. However, if a buyer expects large volumes, the tooling costs can be amortized over a greater number of units, leading to lower per-unit costs.

-

Quality Control (QC): Ensuring the faux leather meets specific quality standards may involve additional testing and inspection costs. This is especially critical for international buyers needing compliance with local regulations.

-

Logistics: Transportation and shipping costs are significant, particularly for international orders. Factors such as distance, shipping method, and Incoterms can greatly influence logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s reputation, market demand, and exclusivity of the product.

How Do Price Influencers Affect Faux Leather Fabric Costs?

Several factors can influence the pricing of faux leather fabric, especially for B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Bulk orders usually receive discounts, making it vital for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs or specific fabric specifications can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Fabrics with certifications (e.g., eco-friendly, hypoallergenic) may command higher prices. Buyers should weigh the benefits against the additional costs.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can affect pricing. Established suppliers may charge more but could offer reliability and superior service.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities between buyers and sellers, influencing overall costs and risk management.

What Are Some Buyer Tips for Cost-Efficiency?

To maximize value while minimizing costs when sourcing faux leather fabric, consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer discounts or favorable payment terms to secure a deal.

-

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider logistics, potential wastage, and long-term durability to determine the true cost.

-

Research Market Prices: Conduct thorough market research to understand pricing trends. This knowledge can empower buyers during negotiations and help identify fair prices.

-

Leverage Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers may reduce shipping costs and lead times, improving overall efficiency.

-

Consider Quality vs. Cost: While lower-priced options may be tempting, prioritize quality to avoid issues related to durability and customer satisfaction. Investing in higher-quality faux leather can lead to better long-term results.

Conclusion

While the cost structure of faux leather fabric sourcing can be complex, understanding the components and influencers is crucial for international B2B buyers. By employing strategic negotiation, evaluating total ownership costs, and focusing on quality, buyers can make informed decisions that align with their business objectives. Always remember that prices can vary significantly based on location, order volume, and specific requirements, so maintaining flexibility and open communication with suppliers is key to successful sourcing.

Alternatives Analysis: Comparing faux leather fabric near me With Other Solutions

When considering sourcing materials for upholstery and fashion, it’s crucial for B2B buyers to evaluate various alternatives to faux leather fabric. While faux leather is a popular choice for its aesthetic appeal and functionality, other options may also meet specific business needs, depending on factors like cost, performance, and application.

| Comparison Aspect | Faux Leather Fabric Near Me | Genuine Leather | Synthetic Textiles |

|---|---|---|---|

| Performance | Durable, water-resistant | Highly durable, breathable | Varies by type, generally less durable |

| Cost | Moderate ($10-$30 per yard) | High ($50+ per yard) | Low to moderate ($5-$20 per yard) |

| Ease of Implementation | Easy to sew, available locally | Requires specialized tools for leatherwork | Generally easy to work with, widely available |

| Maintenance | Spot clean, durable | Requires regular conditioning | Easy to clean, but may stain |

| Best Use Case | Fashion, upholstery, accessories | High-end fashion, luxury goods | Casual wear, home textiles |

What Are the Advantages and Disadvantages of Genuine Leather as an Alternative?

Genuine leather is often viewed as the premium option, offering unparalleled durability and a classic aesthetic. It breathes well, making it comfortable for clothing and upholstery. However, the high cost can be prohibitive for many businesses, especially those looking to produce budget-friendly products. Additionally, genuine leather requires more maintenance to retain its appearance, necessitating regular conditioning to prevent cracking and drying.

Illustrative image related to faux leather fabric near me

How Do Synthetic Textiles Compare to Faux Leather Fabric?

Synthetic textiles, such as polyester or nylon blends, provide a cost-effective alternative to faux leather. These materials are typically lighter and can be easier to care for, as they are often machine washable and resistant to staining. However, their performance varies widely; some may not provide the same durability or luxurious look associated with faux leather. This makes them better suited for casual applications rather than high-end products.

Conclusion: How Should B2B Buyers Choose the Right Material for Their Needs?

Ultimately, the choice between faux leather fabric and its alternatives depends on the specific needs of your business. Consider your target market, budget constraints, and the intended application of the material. If you are focused on cost-efficiency and ease of maintenance, synthetic textiles may be the ideal choice. For high-end products that require a touch of luxury, genuine leather could justify the investment. Faux leather stands out for its balance of affordability and aesthetic appeal, making it a versatile option for various applications. By analyzing these factors, B2B buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for faux leather fabric near me

What Are the Key Technical Properties of Faux Leather Fabric?

Understanding the technical properties of faux leather fabric is crucial for B2B buyers, especially when sourcing materials for manufacturing or upholstery. Here are some critical specifications to consider:

-

Material Composition

– Faux leather is typically made from polyurethane (PU) or polyvinyl chloride (PVC). The choice of material affects durability, flexibility, and cost. PU is often regarded as higher quality due to its breathability and texture, while PVC is more affordable and offers better water resistance. Buyers should assess the intended application to choose the right material. -

Width and Weight

– Faux leather fabrics generally come in widths ranging from 54 to 60 inches. The weight is also a critical factor, measured in ounces per square yard. A heavier weight (e.g., 12-14 oz) is suitable for upholstery, while lighter weights (e.g., 6-10 oz) are more appropriate for apparel. Understanding these metrics helps ensure that the fabric will perform adequately in its intended use. -

Durability Rating

– Durability is measured using the Martindale test, which assesses how many double rubs the fabric can withstand before showing signs of wear. A high durability rating (e.g., 50,000 rubs and above) is essential for upholstery applications, where the fabric will experience regular use. For buyers, this rating helps in determining the longevity of the fabric in various environments. -

Flammability Standards

– Faux leather fabrics must adhere to specific flammability standards, especially for applications in commercial settings. Buyers should verify compliance with regulations such as the California Technical Bulletin 117 or similar standards relevant in their region. This compliance is crucial for safety and legal considerations in product development. -

Care Instructions

– The care and maintenance of faux leather are often dictated by its material properties. Most faux leathers can be spot cleaned with mild soap and water, but some may require special care, such as avoiding exposure to high heat or direct sunlight. Knowing the care instructions helps businesses communicate proper maintenance to end-users, ensuring product longevity.

What Are Common Trade Terms in Faux Leather Fabric Procurement?

Navigating the procurement process involves familiarizing oneself with industry jargon. Here are some essential trade terms that B2B buyers should understand:

Illustrative image related to faux leather fabric near me

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of faux leather, this could involve sourcing materials from manufacturers who produce fabric specifically for brands that create finished goods. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For faux leather fabric, understanding MOQ is vital for managing inventory costs and ensuring that production needs align with supplier capabilities. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers requesting pricing and other details for specific quantities of products. For faux leather, an RFQ helps buyers compare prices and terms across multiple suppliers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and risk management. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Familiarity with Incoterms helps ensure smooth logistics and cost management. -

Lead Time

– Lead time refers to the time between placing an order and receiving the goods. For faux leather, this can vary significantly based on the supplier’s location, production capacity, and shipping methods. Understanding lead times is crucial for planning production schedules and meeting customer deadlines. -

Color Fastness

– Color fastness indicates how well a fabric maintains its color when exposed to washing, light, or rubbing. This property is critical for faux leather used in consumer goods, as it affects the aesthetic and longevity of the product. Buyers should seek fabrics with high color fastness ratings to ensure customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing faux leather fabric, ultimately leading to better product outcomes and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the faux leather fabric near me Sector

What Are the Key Market Trends Impacting Faux Leather Fabric Sourcing?

The faux leather fabric market is experiencing robust growth, driven by a combination of consumer demand for sustainable alternatives to genuine leather and advancements in manufacturing technologies. International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focused on sourcing faux leather that meets both quality and ethical standards. Emerging trends include the rise of digital platforms that facilitate B2B transactions, allowing buyers to access a wider range of suppliers and products. Moreover, innovations in material science are leading to the development of more durable and aesthetically pleasing faux leather options, which cater to diverse applications from fashion to automotive upholstery.

In addition to product quality, there is a growing emphasis on transparency in the supply chain. Buyers are now more inclined to work with suppliers who can demonstrate responsible sourcing practices and compliance with international standards. The integration of technologies like blockchain is also gaining traction, enabling buyers to trace the origins of materials and ensure ethical production processes. This trend is particularly pronounced in markets such as Saudi Arabia and Nigeria, where regulatory frameworks are evolving to promote sustainable practices.

How Is Sustainability Shaping the Faux Leather Fabric Industry?

Sustainability is a critical concern for B2B buyers in the faux leather fabric sector. The environmental impact of traditional leather production is significant, prompting a shift towards synthetic alternatives that minimize ecological footprints. Faux leather, particularly those made from recycled materials or bio-based resources, is increasingly seen as a viable solution. Buyers are encouraged to look for suppliers that offer ‘green’ certifications, such as Global Recycle Standard (GRS) or OEKO-TEX, which validate the sustainable practices in production.

Illustrative image related to faux leather fabric near me

Ethical sourcing is also paramount. Companies are expected to maintain transparent supply chains, ensuring that labor practices are fair and materials are sourced responsibly. This is particularly relevant for buyers in regions like Europe, where consumer awareness regarding ethical manufacturing is high. As a result, suppliers who prioritize sustainability and ethical considerations are not only meeting regulatory demands but also enhancing their market appeal among conscientious buyers.

What Has Been the Evolution of Faux Leather Fabric in B2B Markets?

The faux leather industry has evolved significantly over the past few decades. Initially, faux leather was perceived as a low-cost alternative to genuine leather, often lacking in durability and aesthetic appeal. However, advancements in technology have transformed this perception. Modern faux leather materials, made from high-quality PVC, polyurethane, and innovative textiles, now offer durability, versatility, and a luxurious look that rivals genuine leather.

This evolution has been crucial for B2B markets, particularly as designers and manufacturers seek materials that align with both performance and sustainability goals. The increasing demand for faux leather in various sectors, including fashion, automotive, and furniture, reflects a broader shift towards responsible consumerism. As international buyers continue to seek high-quality, ethically produced materials, the faux leather fabric sector is positioned for continued growth and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather fabric near me

1. How do I source high-quality faux leather fabric for my business?

To source high-quality faux leather fabric, begin by researching suppliers with a proven track record in your target market. Look for manufacturers that offer samples to assess the material’s texture, durability, and color accuracy. Verify their certifications, such as ISO or OEKO-TEX, to ensure compliance with international standards. Additionally, consider attending trade shows or industry events to meet suppliers in person and establish relationships. Networking with other businesses in your industry can also lead to valuable recommendations.

2. What are the key factors to consider when choosing a faux leather supplier?

When selecting a faux leather supplier, evaluate their product range, quality, and manufacturing processes. Assess their ability to meet your specific needs, including customization options, color variations, and fabric finishes. Check their minimum order quantities (MOQs) to ensure they align with your purchasing capabilities. Furthermore, consider their shipping policies, lead times, and payment terms to avoid any disruptions in your supply chain. Supplier reviews and testimonials can provide additional insights into their reliability and customer service.

Illustrative image related to faux leather fabric near me

3. How can I ensure the faux leather fabric meets my quality standards?

To ensure that the faux leather fabric meets your quality standards, implement a comprehensive quality assurance process. Request samples to conduct thorough inspections for color consistency, texture, and durability. Establish clear specifications and guidelines with your supplier regarding the expected quality levels. Regular audits and inspections during production can help identify any deviations from your standards early. Consider investing in third-party quality inspection services for additional assurance, especially for larger shipments.

4. What are the typical payment terms for international faux leather fabric purchases?

Payment terms for international faux leather fabric purchases can vary widely by supplier and region. Common terms include a deposit upfront (typically 30% to 50%) with the balance due before shipment. Some suppliers may offer letter of credit options for larger orders, providing additional security for both parties. It’s essential to clarify payment methods, such as wire transfers or credit terms, and ensure they align with your cash flow management. Always document agreements in a formal contract to avoid misunderstandings.

5. What is the minimum order quantity (MOQ) for faux leather fabrics?

Minimum order quantities (MOQs) for faux leather fabrics can vary significantly based on the supplier and the specific product type. Generally, MOQs can range from as low as 10 yards to several hundred yards for custom designs or specialty materials. It’s essential to discuss MOQs upfront with potential suppliers to determine if they fit your purchasing needs. Some suppliers may offer flexibility on MOQs for first-time buyers or larger orders, so negotiating terms can be beneficial.

Illustrative image related to faux leather fabric near me

6. How do I handle logistics and shipping for faux leather fabric imports?

Handling logistics for faux leather fabric imports involves selecting a reliable freight forwarder familiar with international shipping regulations. Discuss shipping options that best fit your budget and timeframe, including air freight for faster delivery or sea freight for larger shipments. Ensure that all customs documentation is correctly prepared to avoid delays at the border. It’s also advisable to factor in potential tariffs or import duties when calculating total costs. Clear communication with your supplier regarding shipping timelines and tracking is crucial for successful logistics management.

7. What customization options are available for faux leather fabrics?

Customization options for faux leather fabrics can include color selection, embossed patterns, and varying textures. Many manufacturers offer the ability to create bespoke designs that align with your brand’s aesthetic. When discussing customization with suppliers, clarify the minimum quantities required for custom orders, as they may differ from standard offerings. Additionally, inquire about lead times for custom products to ensure they align with your project timelines. Requesting samples of custom designs can help you assess their quality before placing a larger order.

8. How can I find local suppliers of faux leather fabric in my region?

Finding local suppliers of faux leather fabric can be achieved through various channels. Start by searching online business directories and trade platforms specific to your region. Networking within local industry associations or chambers of commerce can also yield valuable contacts. Attend regional trade shows or exhibitions where fabric suppliers showcase their products. Additionally, utilizing social media platforms like LinkedIn can connect you with suppliers and industry professionals in your area, facilitating potential partnerships.

Top 4 Faux Leather Fabric Near Me Manufacturers & Suppliers List

1. Hobby Lobby – Black Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {“SKU”:”1533819″,”Original Price”:”$15.99 YDS”,”Description”:”Black Faux Leather Fabric features a soft, leather-like feel and a versatile, solid black color.”,”Available In”:”1-yard increments”,”Average Bolt Size”:”approximately 9 yards”,”Width”:”55 inches”,”Vertical Repeat”:”8.66 inches”,”Horizontal Repeat”:”8.66 inches”,”Color”:”Black”,”Weight”:”Heavyweight”,”Durability”:”Heavy Duty – 55,000 Do…

2. Yelp – Reupholstering Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Reupholstering Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard and is a vegan alter…

4. Fabric Wholesale Direct – Faux Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for faux leather fabric near me

In navigating the landscape of faux leather fabric sourcing, international B2B buyers must recognize the importance of strategic partnerships and local availability. The growing demand for high-quality, versatile faux leather products—suitable for upholstery, apparel, and various décor applications—underscores the need for suppliers who can deliver both quality and reliability. Establishing connections with local fabric suppliers not only reduces shipping costs and lead times but also enhances the potential for customized solutions tailored to specific market needs.

Illustrative image related to faux leather fabric near me

As you explore sourcing options for faux leather fabric, consider the diverse range of products available, from heavy-duty upholstery materials to lightweight options ideal for fashion applications. Emphasizing sustainability and ethical sourcing can also resonate with consumers increasingly concerned about environmental impact.

Looking ahead, the faux leather market is poised for growth across regions, particularly in Africa, South America, the Middle East, and Europe. Now is the time for B2B buyers to leverage local resources, engage with reliable suppliers, and anticipate market trends to stay ahead of the competition. Embrace the opportunities that strategic sourcing presents to elevate your business and meet the evolving demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to faux leather fabric near me

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.