Introduction: Navigating the Global Market for faux leather vs real leather

In the dynamic landscape of global commerce, sourcing materials that align with both market demands and consumer preferences can be challenging. For B2B buyers seeking to understand the nuances of faux leather versus real leather, the stakes are particularly high. Whether you are looking to procure high-quality upholstery for office furniture, stylish accessories, or durable fashion items, recognizing the differences between these leather types is crucial. This guide provides an in-depth analysis of various leather types, including genuine leather, bonded leather, and faux leather, along with their applications, durability, and cost implications.

Navigating this landscape requires careful consideration of supplier capabilities, ethical sourcing, and environmental impacts. By leveraging the insights provided herein, international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will be empowered to make informed purchasing decisions. This comprehensive resource not only outlines the essential characteristics of each leather type but also offers actionable strategies for supplier vetting and cost management. Equip your business with the knowledge to select the right materials that meet both your operational needs and your clientele’s expectations.

Table Of Contents

- Top 3 Faux Leather Vs Real Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather vs real leather

- Understanding faux leather vs real leather Types and Variations

- Key Industrial Applications of faux leather vs real leather

- 3 Common User Pain Points for ‘faux leather vs real leather’ & Their Solutions

- Strategic Material Selection Guide for faux leather vs real leather

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather vs real leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather vs real leather’

- Comprehensive Cost and Pricing Analysis for faux leather vs real leather Sourcing

- Alternatives Analysis: Comparing faux leather vs real leather With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather vs real leather

- Navigating Market Dynamics and Sourcing Trends in the faux leather vs real leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather vs real leather

- Strategic Sourcing Conclusion and Outlook for faux leather vs real leather

- Important Disclaimer & Terms of Use

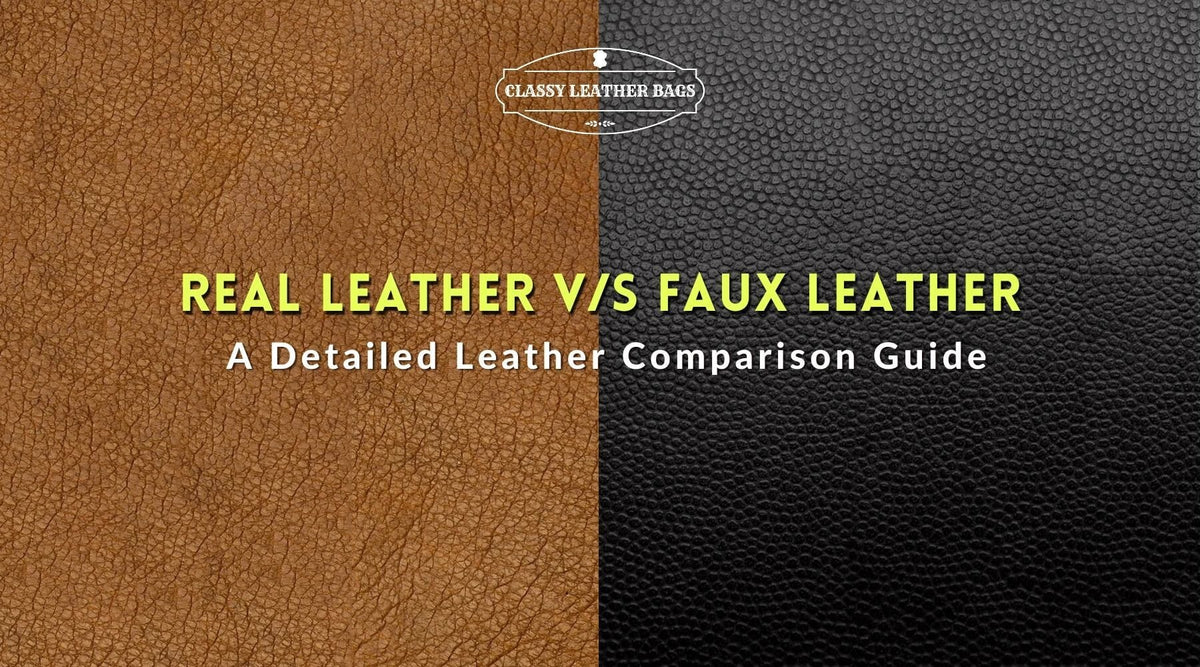

Understanding faux leather vs real leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Real Leather | Made from animal hides; includes full grain and top grain. | High-end furniture, luxury goods, apparel | Pros: Durable, develops patina, natural aesthetics. Cons: Expensive, requires maintenance. |

| Bonded Leather | Made from leather scraps and synthetic materials; lower quality. | Budget-friendly furniture, accessories | Pros: Cost-effective, sustainable use of scraps. Cons: Less durable, prone to peeling. |

| Faux Leather (PU) | Made from synthetic materials; vegan-friendly; looks like real leather. | Fashion items, upholstery, automotive interiors | Pros: Affordable, easy to clean, variety of colors. Cons: Less durable than real leather, can feel artificial. |

| Bicast Leather | Made from leather scraps with a polyurethane layer on top. | Budget furniture, accessories | Pros: Attractive finish, affordable. Cons: Less breathable, potential for peeling. |

| Eco-Leather | Made from recycled materials; lower environmental impact. | Sustainable fashion, eco-friendly products | Pros: Environmentally friendly, unique textures. Cons: Availability may vary, durability can be inconsistent. |

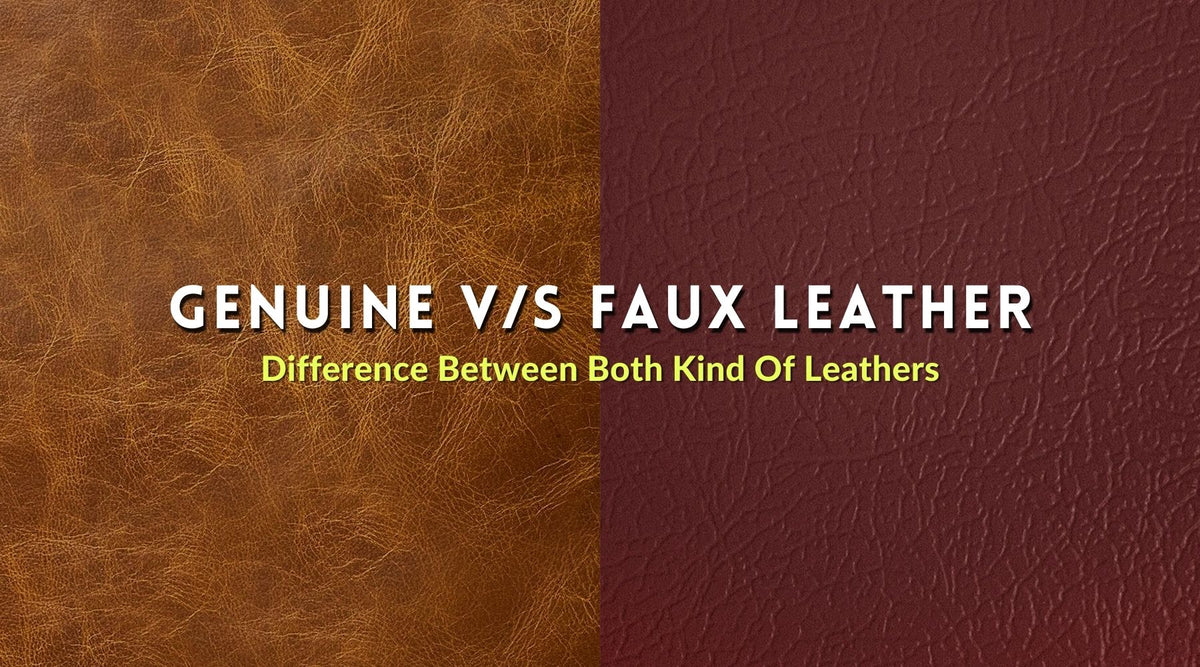

What are the Characteristics of Real Leather and Its B2B Suitability?

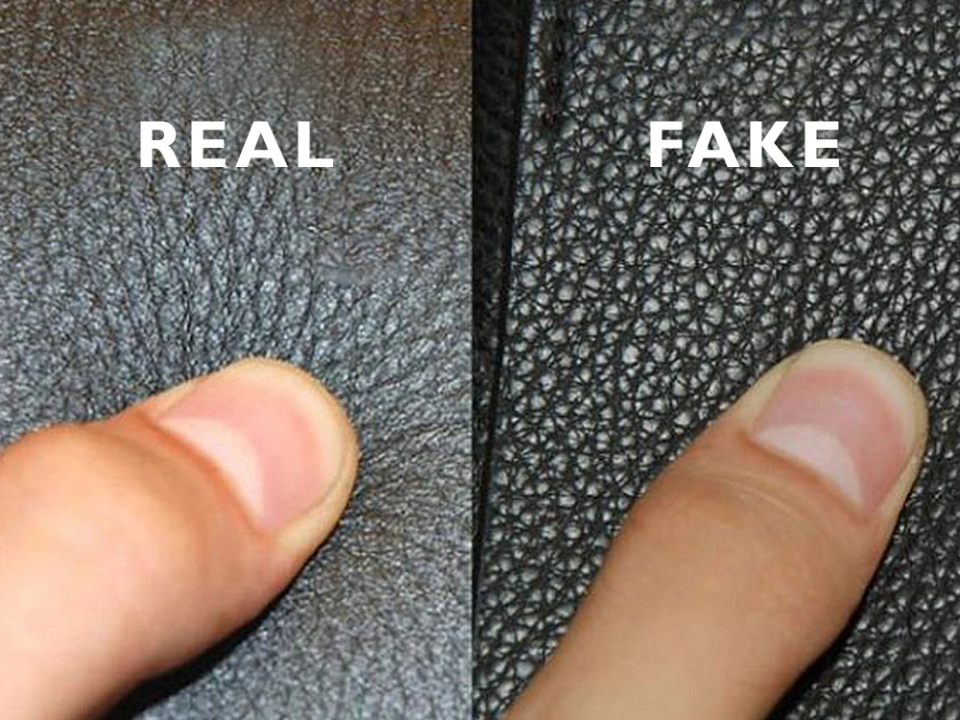

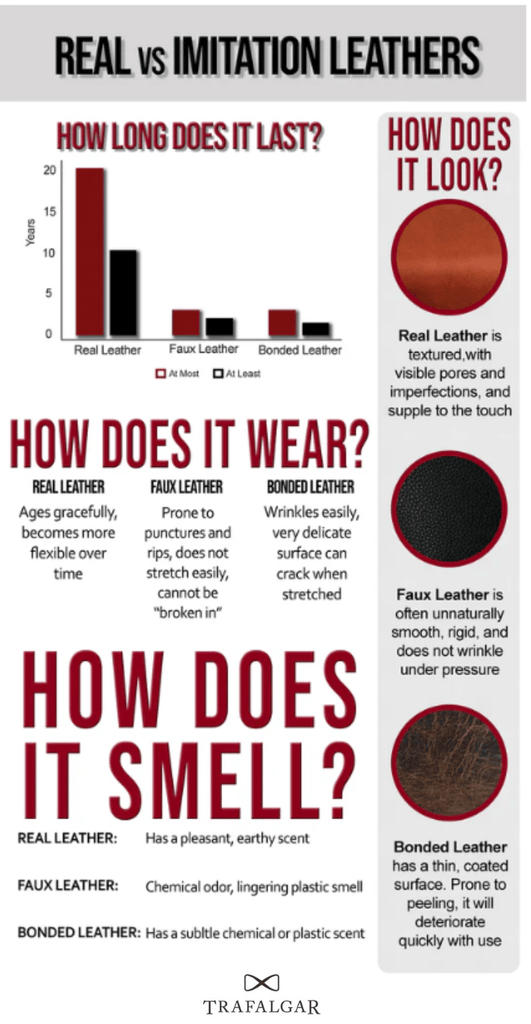

Real leather, derived from animal hides, is recognized for its durability and natural aesthetics. It is categorized into full grain and top grain varieties, with full grain being the highest quality. B2B buyers in sectors such as luxury furniture, high-end apparel, and automotive interiors often prefer real leather for its long-lasting qualities and ability to develop a unique patina over time. However, the higher cost and maintenance requirements may deter budget-conscious buyers.

How Does Bonded Leather Compare in Terms of B2B Applications?

Bonded leather consists of leather scraps mixed with synthetic materials, making it an economical choice for businesses looking to minimize costs. It is commonly used in budget-friendly furniture and accessories. While bonded leather is more affordable and utilizes waste materials, its durability is limited, as it can peel and wear over time. B2B buyers should consider the trade-off between cost and longevity when opting for this material.

What Makes Faux Leather (PU) a Popular Choice for B2B Buyers?

Faux leather, particularly polyurethane (PU) leather, is crafted from synthetic materials and is a vegan alternative to real leather. It is widely used in fashion items, upholstery, and automotive interiors due to its affordability and ease of maintenance. While faux leather offers a wide variety of colors and styles, it generally lacks the durability and natural feel of real leather. B2B buyers should weigh the benefits of cost and variety against the potential for reduced lifespan.

What is Bicast Leather and Its Target Market?

Bicast leather is made from leather scraps topped with a layer of polyurethane, providing an attractive finish at a lower price point. It is suitable for budget furniture and various accessories. Although it offers a stylish appearance, bicast leather may not provide the breathability and durability found in higher-quality leathers. B2B buyers should assess the visual appeal versus the functional limitations when considering this option.

Illustrative image related to faux leather vs real leather

How Does Eco-Leather Appeal to Environmentally Conscious Buyers?

Eco-leather is produced from recycled materials, catering to the growing demand for sustainable products. It is ideal for businesses focused on eco-friendly fashion and products. While eco-leather offers unique textures and lower environmental impact, its availability can be inconsistent, and durability may vary. B2B buyers prioritizing sustainability should explore eco-leather options while considering potential limitations in durability and supply.

Key Industrial Applications of faux leather vs real leather

| Industry/Sector | Specific Application of faux leather vs real leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car interiors | Faux leather offers cost savings and easy maintenance; real leather enhances luxury appeal. | Assess durability, climate resistance, and aesthetic preferences. |

| Fashion and Apparel | Clothing and accessories (jackets, handbags) | Faux leather provides a vegan option; real leather offers durability and a premium feel. | Evaluate ethical sourcing, consumer preferences, and market trends. |

| Muebles | Sofas, chairs, and other upholstered items | Faux leather is budget-friendly and easy to clean; real leather provides long-lasting quality. | Consider comfort, style, and care requirements for end-users. |

| Home Décor | Decorative items like cushions, wall art, and throws | Faux leather can be more affordable and versatile; real leather adds a touch of elegance. | Focus on design compatibility and sustainability practices. |

| Sports Equipment | Gear such as bags, gloves, and protective wear | Faux leather is lightweight and often water-resistant; real leather offers superior durability. | Ensure compliance with safety standards and performance expectations. |

How is Faux Leather Used in the Automotive Industry?

In the automotive sector, faux leather is commonly utilized for car upholstery due to its cost-effectiveness and low maintenance requirements. It is particularly appealing in budget-friendly vehicles, where manufacturers seek to reduce costs while still providing a visually appealing interior. Real leather, on the other hand, is favored in luxury cars for its durability and high-end aesthetic. Buyers in this sector must consider factors such as climate resilience, wear and tear, and overall aesthetic preferences when sourcing materials.

What are the Applications of Faux Leather in Fashion and Apparel?

Faux leather has gained significant traction in the fashion industry, especially among brands that cater to eco-conscious consumers. It allows for a wider variety of styles and colors while being a vegan alternative. Real leather, however, remains a staple for high-end fashion items due to its luxurious feel and longevity. B2B buyers should assess ethical sourcing, consumer preferences, and the latest fashion trends to make informed purchasing decisions.

Illustrative image related to faux leather vs real leather

How is Faux vs. Real Leather Used in Furniture?

In furniture manufacturing, faux leather is often chosen for its affordability and ease of cleaning, making it suitable for high-traffic areas. Real leather, however, is preferred for its durability and ability to develop a rich patina over time, appealing to consumers looking for long-lasting quality. Buyers should consider factors such as comfort, style, and maintenance requirements to ensure the materials meet their target market’s expectations.

What Role Does Faux Leather Play in Home Décor?

Faux leather is increasingly popular in home décor, used in items like cushions and wall art due to its affordability and versatility. It allows designers to create trendy pieces without a significant investment. Conversely, real leather adds elegance and sophistication to home settings, making it a desirable choice for luxury items. B2B buyers should focus on design compatibility and the sustainability practices of their suppliers when sourcing these materials.

How is Faux Leather Applied in Sports Equipment?

In the sports equipment sector, faux leather is often used in gear such as bags and gloves, valued for its lightweight and water-resistant properties. Real leather is preferred for its superior durability and performance in high-stress situations. Buyers in this market must ensure compliance with safety standards and performance expectations, making it crucial to evaluate the material’s specifications before purchasing.

3 Common User Pain Points for ‘faux leather vs real leather’ & Their Solutions

Scenario 1: Understanding the Cost Implications of Faux Leather vs Real Leather

The Problem: B2B buyers often face budget constraints when sourcing leather products for their businesses. With varying price points between faux leather, bonded leather, and real leather, it can be challenging to determine which material offers the best value. Buyers may be hesitant to invest in real leather due to its higher initial costs, fearing that it might exceed their budget while still aiming to provide quality products to their clients. This pressure can lead to confusion and a fear of making a poor purchasing decision.

The Solution: To navigate this dilemma, B2B buyers should conduct a total cost of ownership analysis for each type of leather. This involves not just the initial purchase price but also factors in durability, maintenance, and long-term performance. For instance, while real leather has a higher upfront cost, its durability often means it lasts significantly longer than faux leather, which may need replacement more frequently. Buyers should also consider the intended use of the leather products—luxury items or high-traffic furniture may justify the investment in real leather, while lower-cost faux options could suffice for temporary or promotional items. Establishing a clear understanding of the product lifecycle and quality expectations can help buyers make informed decisions that align with their budgetary constraints.

Illustrative image related to faux leather vs real leather

Scenario 2: Balancing Aesthetic Appeal with Functionality in Leather Selection

The Problem: Aesthetic appeal is crucial for B2B buyers, especially when sourcing leather products for retail or hospitality environments. However, the challenge lies in aligning the visual qualities of faux leather and real leather with functional requirements. Faux leather might offer a uniform appearance that appeals to some buyers, but it can lack the authenticity and texture that many consumers expect from high-quality leather products. Conversely, real leather provides a unique, luxurious look but may not be as stain-resistant or easy to clean, especially in high-use settings.

The Solution: Buyers should focus on a dual approach—selecting leather based on both aesthetic preferences and functional requirements. For environments where durability and ease of cleaning are paramount, consider investing in high-quality faux leather options that mimic the look of real leather while offering superior stain resistance. On the other hand, for high-end boutiques or luxury hotels where the tactile experience is part of the brand identity, real leather should be prioritized. Collaborating with suppliers who provide samples of both materials can help buyers assess their texture, appearance, and durability firsthand. Additionally, specifying protective coatings or finishes on real leather can enhance its practicality without compromising its visual appeal.

Scenario 3: Addressing Sustainability Concerns in Leather Sourcing

The Problem: Sustainability is increasingly becoming a critical factor for B2B buyers, especially in regions where environmental consciousness is on the rise. Buyers may struggle to reconcile the sourcing of real leather—which has a reputation for being less sustainable due to animal welfare concerns and environmental impacts of tanning processes—with the growing demand for eco-friendly products. This dilemma can create a barrier to purchasing decisions, as buyers are often torn between quality, ethics, and consumer expectations.

The Solution: B2B buyers can address these sustainability concerns by prioritizing suppliers who demonstrate transparent sourcing practices and certifications. For real leather, look for products that come from reputable tanneries that adhere to strict environmental standards and animal welfare regulations. Additionally, opting for vegetable-tanned leather can minimize chemical exposure and enhance biodegradability. For faux leather, consider sourcing 100% polyurethane (PU) options that are free from harmful chemicals and have a lower environmental footprint than traditional PVC leathers. Engaging in dialogue with suppliers about their sustainability practices and seeking certifications can empower buyers to make ethical choices that resonate with their clientele while ensuring product quality.

Strategic Material Selection Guide for faux leather vs real leather

What Are the Key Properties of Real Leather?

Real leather, particularly full grain and top grain leather, is derived from animal hides, making it a natural material with unique properties. It is known for its excellent durability, withstanding wear and tear better than many synthetic alternatives. Real leather also possesses a natural breathability, which allows it to regulate temperature and moisture, making it suitable for a variety of applications, from high-end furniture to luxury fashion items. However, the manufacturing complexity is higher due to the tanning process, which can impact production timelines and costs.

Illustrative image related to faux leather vs real leather

What Are the Pros and Cons of Faux Leather?

Faux leather, commonly made from polyurethane (PU) or polyvinyl chloride (PVC), offers a more cost-effective alternative to real leather. Its key advantages include a wide variety of colors and textures, ease of cleaning, and a vegan-friendly profile, appealing to environmentally conscious consumers. However, faux leather typically lacks the durability and breathability of real leather, making it less suitable for high-wear applications. The manufacturing process is less complex, allowing for quicker production, but the longevity of faux leather products can be a concern, particularly in demanding environments.

How Does Bonded Leather Compare to Real and Faux Leather?

Bonded leather is a composite material made from leather scraps and synthetic binders. While it is the most affordable option among leather types, its properties are significantly different from both real and faux leather. Bonded leather has lower durability and is prone to peeling and cracking over time, limiting its suitability for high-end applications. However, its cost-effectiveness makes it attractive for budget-conscious buyers. International buyers should be aware that bonded leather may not meet certain quality standards, which can vary by region.

What Should International B2B Buyers Consider?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the regional preferences and compliance requirements is crucial. For instance, markets in Germany and Brazil may have specific standards like DIN or ASTM that dictate material quality and safety. Additionally, cultural preferences for natural versus synthetic materials can influence purchasing decisions. Buyers should also consider the environmental impact of their choices, particularly in regions where sustainability is becoming increasingly important.

Summary Table of Material Comparisons

| Material | Typical Use Case for faux leather vs real leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Real Leather | High-end furniture, luxury fashion | Exceptional durability and aesthetic | Higher cost and complex manufacturing | Alta |

| Piel sintética | Budget-friendly furniture, fashion accessories | Cost-effective and vegan-friendly | Less durable and breathable | Medium |

| Bonded Leather | Budget furniture, low-cost accessories | Most affordable option | Prone to peeling and lower durability | Low |

This analysis provides a comprehensive overview of the key materials in the faux leather versus real leather debate, highlighting critical factors for B2B buyers to consider when making purchasing decisions.

Illustrative image related to faux leather vs real leather

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather vs real leather

What are the Key Stages in the Manufacturing Process of Faux Leather vs Real Leather?

The manufacturing processes for faux leather and real leather differ significantly, impacting both the final product’s quality and its marketability. Understanding these stages is crucial for B2B buyers aiming to source high-quality leather products.

Material Preparation

Para real leather, the process begins with the selection of animal hides, primarily from cows but also from goats, sheep, and exotic animals. The hides undergo a series of treatments to remove hair, flesh, and fat, and are then preserved using methods like salting or drying. This preparation is critical as the quality of the hide directly influences the leather’s durability and appearance.

In contrast, cuero de imitación manufacturing starts with synthetic materials, primarily thermoplastic polymers like polyurethane (PU) or polyvinyl chloride (PVC). These materials are processed to create a flexible, leather-like substrate. During preparation, additives may be included to enhance durability, color, and texture, ensuring the faux leather mimics the look and feel of real leather.

What Techniques are Used in Forming Faux Leather and Real Leather?

The forming stage varies significantly between the two types of leather.

Para real leather, the next step is tanning, which can be done using vegetable or chrome methods. Tanning stabilizes the collagen in the hide, preventing decomposition and enhancing its longevity. After tanning, the leather is dyed, conditioned, and sometimes embossed to add texture. This intricate process requires skilled craftsmanship to ensure the leather retains its natural characteristics while achieving the desired finish.

Illustrative image related to faux leather vs real leather

In the case of cuero de imitación, the forming process involves applying a layer of PU or PVC over a base material, often fabric or a paper-like substrate. Techniques such as coating, lamination, or extrusion are employed to create the final product. The surface may be embossed or printed to replicate the texture of real leather, allowing for a wide range of colors and designs.

How is Assembly and Finishing Handled for Faux Leather and Real Leather Products?

In the assembly stage, real leather products typically involve stitching or handcrafting, where artisans meticulously assemble items like bags, shoes, or furniture. This attention to detail ensures that each piece is not only functional but also aesthetically pleasing. The finishing touches may include polishing, waxing, or oiling, enhancing the leather’s natural beauty and providing protection against wear.

Para cuero de imitación, assembly often involves simpler processes like adhesive bonding or stitching, depending on the product’s design. The finishing stage includes applying protective coatings to enhance durability and resistance to stains and scratches. While faux leather can offer a variety of colors and textures, the finishing may not achieve the same depth and richness as real leather.

What Quality Control Measures Are Relevant in Faux Leather and Real Leather Manufacturing?

Quality assurance is essential in both faux and real leather manufacturing, ensuring that products meet international standards and customer expectations.

Illustrative image related to faux leather vs real leather

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with various international standards, such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards ensures that manufacturers maintain consistent quality and can effectively manage processes.

Additionally, in specific markets, products may need to meet CE marking requirements, which indicate compliance with European health, safety, and environmental protection standards. In the leather industry, there may also be industry-specific standards, such as API (American Petroleum Institute) for certain synthetic leathers.

What Are the Key Quality Control Checkpoints?

Effective quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials, including hides for real leather and polymers for faux leather. Ensuring high-quality inputs is critical for the final product’s performance.

-

In-Process Quality Control (IPQC): During production, ongoing inspections help identify defects early in the process. This stage often includes checks on tanning, forming, and finishing processes to ensure adherence to standards.

-

Final Quality Control (FQC): Before products are shipped, final inspections verify that they meet specifications. This includes assessing physical attributes like texture, color, and durability, as well as checking for any defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, ensuring that suppliers adhere to stringent quality control measures is essential. Here are some strategies to verify supplier quality:

Illustrative image related to faux leather vs real leather

-

Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and quality management systems. Buyers should consider conducting both announced and unannounced audits to gauge consistency.

-

Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help buyers assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer unbiased evaluations of the supplier’s processes and products. These inspections can be particularly beneficial for buyers operating in regions where local standards may vary.

What Nuances Should International B2B Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of various nuances when sourcing leather products:

-

Regional Standards: Different countries may have specific regulations regarding leather products, including labeling and safety standards. Understanding these requirements is crucial for compliance and market entry.

-

Cultural Preferences: Preferences for real versus faux leather can vary significantly across regions. Buyers should consider local consumer trends and environmental concerns, particularly regarding sustainability and animal welfare.

-

Logistics and Supply Chain: International shipping and logistics can impact product quality. Buyers should ensure that suppliers have robust supply chain management practices to mitigate risks associated with delays and environmental factors.

In conclusion, understanding the manufacturing processes and quality assurance measures for faux leather and real leather is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their quality expectations, regulatory requirements, and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather vs real leather’

Introducción

This practical sourcing guide is designed to assist B2B buyers in making informed decisions when procuring leather materials, specifically differentiating between faux leather and real leather. Understanding the nuances of each type will help you align your sourcing strategy with product quality, sustainability goals, and budget constraints.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing leather. Consider factors such as intended use (e.g., upholstery, garments), durability requirements, and aesthetic preferences. This clarity will guide you in choosing the appropriate type of leather that meets your product standards.

Step 2: Evaluate Material Characteristics

Assess the specific properties of faux leather versus real leather. Real leather is known for its durability, natural appearance, and ability to develop a unique patina over time, while faux leather offers a more uniform look and is often more affordable. Ensure that the material characteristics align with your product’s intended market and consumer expectations.

Illustrative image related to faux leather vs real leather

- Durability: Real leather typically lasts longer than faux leather, which may crack or peel.

- Aesthetic Appeal: Consider the look and feel that best suits your brand identity.

Step 3: Verify Supplier Certifications

Before engaging with suppliers, it’s crucial to verify their certifications and compliance with industry standards. Look for certifications related to sustainability, ethical sourcing, and quality control. This step ensures that you are partnering with reputable suppliers who adhere to best practices.

- Sustainability Certifications: Such as ISO 14001 or Leather Working Group certifications.

- Quality Assurance: Suppliers should have certifications like ISO 9001 to guarantee product consistency.

Step 4: Request Samples for Evaluation

Always request samples before finalizing any procurement decision. Evaluating samples allows you to assess the texture, color, and overall quality of the leather. This hands-on approach is vital for ensuring the materials meet your specifications and consumer expectations.

- Texture and Feel: Determine if the leather meets your desired tactile qualities.

- Color Consistency: Check for uniformity in color and finish across samples.

Step 5: Assess Cost Implications

Understanding the cost structure of faux leather versus real leather is essential for budgeting. Real leather often commands a higher price due to its quality and durability, while faux leather can be more cost-effective. Evaluate the long-term value of each option in relation to your product lifecycle and market positioning.

- Initial Cost vs. Longevity: Consider how the upfront cost aligns with expected lifespan and maintenance.

- Market Positioning: Assess how your choice impacts your pricing strategy and target market.

Step 6: Consider Environmental Impact

As sustainability becomes increasingly important, evaluate the environmental implications of your leather sourcing. Real leather has a larger carbon footprint due to animal husbandry, while faux leather may involve petrochemical processes that are not eco-friendly. Understanding these factors can guide you in making a responsible choice aligned with your corporate sustainability goals.

- Lifecycle Analysis: Assess the environmental impact of both materials from production to disposal.

- Consumer Demand: Consider the growing market for sustainable products and how your choice meets this demand.

Step 7: Finalize Supplier Agreements

Once you have selected your preferred leather type and supplier, ensure that you negotiate terms that protect your interests. This includes pricing, delivery timelines, and quality guarantees. A well-structured agreement will help avoid potential issues and ensure a smooth procurement process.

- Delivery Terms: Confirm logistics and lead times to align with your production schedule.

- Quality Clauses: Include provisions for quality checks and returns to safeguard your investment.

By following this checklist, B2B buyers can make informed decisions about sourcing faux leather versus real leather, aligning their procurement strategies with quality, cost, and sustainability objectives.

Comprehensive Cost and Pricing Analysis for faux leather vs real leather Sourcing

Understanding the cost and pricing dynamics between faux leather and real leather is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, price influencers, and provide strategic tips for navigating negotiations and procurement effectively.

What Are the Main Cost Components for Faux Leather and Real Leather?

-

Materials: The primary cost difference stems from the materials used. Real leather, derived from animal hides, is more expensive due to the costs associated with sourcing, tanning, and processing. Faux leather, typically made from polyurethane (PU) or polyvinyl chloride (PVC), involves lower raw material costs, making it a more affordable option.

-

Labor: Labor costs can vary significantly. Real leather often requires skilled artisans for tanning and crafting, resulting in higher labor costs. Conversely, faux leather production is more automated, which can reduce labor expenses but may still require skilled oversight for quality control.

-

Manufacturing Overhead: The overhead for real leather production can be substantial due to the need for specialized equipment and facilities for tanning and finishing. Faux leather manufacturing tends to have lower overhead, as the processes are generally less complex.

-

Tooling: Custom tooling for real leather products can be costly, especially if intricate designs are involved. Faux leather can often utilize standard molds and tooling, reducing setup costs.

-

Quality Control (QC): Real leather products require stringent QC to ensure durability and aesthetics, adding to overall costs. Faux leather, while still needing QC, can often adhere to different standards due to its synthetic nature.

-

Logistics: Shipping costs can differ based on the weight and bulk of materials. Real leather is typically heavier and bulkier than faux leather, potentially leading to higher logistics costs.

-

Margin: Suppliers often mark up real leather products higher due to their perceived value and quality. Faux leather products usually have lower margins but can be sold in higher volumes.

What Influences Pricing in Faux Leather vs. Real Leather Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Larger orders can significantly reduce per-unit costs for both types of leather. However, the MOQ can vary widely by supplier and type of leather, impacting overall pricing.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs for both real and faux leather. Real leather may incur additional expenses due to the need for more intricate craftsmanship.

-

Materials and Quality Certifications: The presence of quality certifications (like ISO standards) can influence pricing. Real leather often comes with certifications that assure buyers of its quality, while faux leather may not carry the same level of certification.

-

Supplier Factors: Relationships with suppliers can affect pricing. Long-term partnerships may yield better pricing and terms. Additionally, geographic factors can influence costs based on local market conditions.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is essential, as they dictate who bears costs and risks at various stages of shipping, directly affecting the total landed cost.

How Can Buyers Optimize Costs in Leather Procurement?

-

Negotiation Tactics: Leverage volume purchasing to negotiate better prices. Don’t hesitate to seek multiple quotes from different suppliers to compare prices and terms.

-

Evaluating Total Cost of Ownership (TCO): Consider not just the purchase price but also the lifecycle costs associated with maintenance, durability, and potential replacements. Real leather, while more expensive upfront, may offer better longevity compared to faux leather.

-

Understanding Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties, especially when sourcing from different regions. This knowledge can help in budgeting accurately.

-

Sourcing Locally: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times, making it a cost-effective option.

Conclusion

The choice between faux leather and real leather involves a complex interplay of costs, quality, and market dynamics. By understanding the various cost components and pricing influencers, B2B buyers can make informed decisions that align with their business needs and financial goals. Always remember to evaluate the long-term implications of your sourcing decisions to ensure sustainability and profitability in your operations.

Alternatives Analysis: Comparing faux leather vs real leather With Other Solutions

Exploring Alternatives to Faux Leather and Real Leather

In the quest for materials that replicate the aesthetics and functionality of leather, various alternatives have emerged. This section delves into a comparative analysis of faux leather and real leather against two viable alternatives: high-performance textiles and sustainable plant-based leathers. Each option presents unique benefits and drawbacks, allowing B2B buyers to make informed decisions based on their specific needs and values.

Illustrative image related to faux leather vs real leather

| Comparison Aspect | Faux Leather Vs Real Leather | High-Performance Textiles | Sustainable Plant-Based Leathers |

|---|---|---|---|

| Performance | Moderate durability; may crack over time (faux) vs. high durability and natural aging (real). | Excellent abrasion resistance and flexibility; often waterproof. | Varies by type; some are highly durable, while others may be less so. |

| Cost | Generally lower than real leather but higher than bonded leather. | Moderate to high cost depending on the material and technology. | Competitive pricing, often lower than high-end leather. |

| Ease of Implementation | Easy to source and manufacture; versatile in design. | Requires specific manufacturing processes; may need specialized equipment. | Sourcing may be limited; growing market but still niche. |

| Maintenance | Low maintenance; easy to clean (faux) vs. requires regular conditioning (real). | Generally easy to clean; resistant to stains. | Maintenance varies; some may require specific care to maintain appearance. |

| Best Use Case | Fashion, upholstery, and accessories (faux); luxury items, high-end furniture (real). | Activewear, outdoor gear, and high-performance applications. | Eco-conscious products, vegan options, and innovative design. |

What Are the Benefits and Drawbacks of High-Performance Textiles?

High-performance textiles, such as Cordura or Kevlar, are engineered for durability and strength. These materials offer exceptional resistance to wear, tear, and environmental factors, making them ideal for outdoor and active applications. However, they may lack the luxurious feel associated with leather, which can be a drawback for high-end consumer markets. Additionally, sourcing can be more complex, requiring specialized manufacturing capabilities.

How Do Sustainable Plant-Based Leathers Compare?

Sustainable plant-based leathers, such as those made from pineapple leaves (Piñatex) or apple peels, provide an eco-friendly alternative to traditional leather. These materials are often biodegradable and reduce the environmental impact associated with animal farming. While they can offer a unique aesthetic, their durability can vary significantly based on the specific formulation and processing methods used. This makes it essential for buyers to assess the performance characteristics of each product before making a decision.

Conclusion: How Should B2B Buyers Choose the Right Leather Alternative?

When selecting between faux leather, real leather, and their alternatives, B2B buyers must consider factors such as performance requirements, budget constraints, and sustainability goals. By carefully evaluating the characteristics of each option, including their maintenance needs and best use cases, businesses can align their purchasing decisions with their brand values and market demands. Whether prioritizing luxury, performance, or eco-friendliness, understanding these alternatives will empower buyers to make strategic choices that meet their specific needs.

Essential Technical Properties and Trade Terminology for faux leather vs real leather

What Are the Key Technical Properties of Faux Leather and Real Leather?

Understanding the technical properties of faux leather and real leather is crucial for B2B buyers, as these specifications influence product quality, pricing, and suitability for various applications. Here are some essential properties to consider:

-

Material Grade

The material grade is a classification that indicates the quality of leather. Real leather is typically categorized into grades such as full grain, top grain, and genuine leather. Full grain leather is the highest quality, featuring the entire animal hide with natural imperfections. This grade is highly valued for its durability and aesthetic appeal. In contrast, faux leather, often made from polyurethane (PU), lacks the natural characteristics of real leather, impacting its perceived value and longevity. For buyers, understanding these grades helps in making informed purchasing decisions based on quality requirements and budget constraints. -

Durabilidad

Durability measures how well a material withstands wear, tear, and environmental factors. Real leather is known for its long lifespan, often developing a unique patina over time, while faux leather is less durable, with susceptibility to cracking and peeling. Bonded leather, made from leather scraps and adhesives, has the lowest durability. For B2B buyers, durability is a critical consideration, especially for products that will experience heavy use, such as furniture or automotive interiors. -

Breathability

Breathability refers to a material’s ability to allow air and moisture to pass through. Real leather is naturally breathable, providing comfort and reducing moisture buildup. Faux leather, particularly PU, is non-breathable, which can lead to discomfort in applications like upholstery. This property is vital for manufacturers in industries where comfort is paramount, such as fashion and furniture. -

Environmental Impact

The environmental impact of materials is increasingly important for B2B buyers concerned with sustainability. Real leather, while biodegradable, involves resource-intensive production processes. Faux leather, made from synthetic materials, is not biodegradable and can contribute to plastic pollution. Buyers must weigh the environmental implications of their choices, especially in regions with stringent sustainability regulations. -

Maintenance Requirements

Maintenance requirements dictate how easy or difficult it is to care for the material. Real leather requires regular conditioning to maintain its appearance and prevent drying, while faux leather is generally easier to clean and maintain. Bonded leather, however, may be more challenging to care for due to its composition. Understanding maintenance needs helps buyers anticipate long-term costs and operational efficiency.

What Are Common Trade Terms in the Leather Industry?

Navigating the leather industry involves familiarity with specific jargon and trade terms, which can streamline communication and enhance transaction efficiency. Here are some common terms:

Illustrative image related to faux leather vs real leather

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather industry, OEMs may manufacture leather goods for brands that sell under their own label. Understanding OEM relationships is vital for buyers looking to source products or components for their own brands. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects initial order sizes and inventory management. Suppliers often set MOQs based on production costs and logistics, so it’s essential to clarify these details before placing orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. In the leather industry, RFQs help buyers compare costs and negotiate terms with multiple suppliers, ensuring they receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers engaging in cross-border trade, as they dictate the cost and risk associated with transporting leather products. -

Lead Time

Lead time is the period required to manufacture and deliver products after an order is placed. In the leather industry, lead times can vary significantly based on material availability and production processes. Buyers must consider lead times when planning inventory and meeting customer demands. -

Tannery

A tannery is a facility where raw hides are processed into leather through tanning. Understanding the sourcing and production capabilities of tanneries can help buyers ensure the quality and ethical standards of their leather products.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting between faux leather and real leather, ultimately enhancing their product offerings and business strategies.

Navigating Market Dynamics and Sourcing Trends in the faux leather vs real leather Sector

What Are the Current Market Dynamics and Key Trends in the Faux Leather vs. Real Leather Sector?

The global leather market is experiencing significant shifts driven by changing consumer preferences, technological advancements, and sustainability concerns. B2B buyers from regions such as Africa, South America, the Middle East, and Europe must stay informed about these dynamics to make strategic sourcing decisions. Currently, the faux leather segment is witnessing a surge in demand due to its affordability and the rise of veganism, particularly in markets like Germany and Brazil. This trend is further fueled by technological innovations that enhance the quality and appearance of synthetic materials, allowing faux leather to mimic the look and feel of real leather more convincingly.

Moreover, the increasing awareness of animal rights and environmental sustainability is propelling buyers to consider alternatives to real leather. B2B tech solutions, such as AI-driven supply chain management tools and advanced analytics, are enabling companies to optimize sourcing processes and forecast demand more accurately. The integration of blockchain technology is also gaining traction, offering transparency in the supply chain and ensuring ethical practices.

As the market evolves, B2B buyers need to assess the durability, cost, and aesthetic appeal of leather products while considering regional preferences and regulations. With a more informed approach, international buyers can capitalize on emerging trends and align their procurement strategies with market demands.

How Does Sustainability and Ethical Sourcing Impact the Faux Leather vs. Real Leather Market?

Sustainability is a critical factor influencing sourcing decisions in the leather industry. The environmental impact of both faux and real leather varies significantly. Real leather production involves significant resource use, including water and energy, and raises ethical concerns regarding animal welfare. Conversely, while faux leather is often marketed as a more sustainable option, its production typically involves plastics that are not biodegradable, leading to long-term environmental issues.

B2B buyers are increasingly prioritizing ethical sourcing practices and seeking suppliers who adhere to sustainable standards. Certifications such as Global Organic Textile Standard (GOTS) for organic materials and OEKO-TEX for non-toxic textiles are becoming essential for manufacturers looking to establish credibility in the market. Furthermore, many companies are investing in research and development to create eco-friendly alternatives, such as bio-based faux leather made from plant materials.

Buyers must evaluate the entire lifecycle of leather products, from raw material sourcing to end-of-life disposal, to make informed decisions. By prioritizing sustainability and ethical practices, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

What Is the Evolution of Faux Leather and Real Leather in the B2B Context?

The evolution of faux leather and real leather dates back centuries, but significant advancements have occurred in recent decades. Initially, faux leather was perceived as a low-quality substitute for real leather, primarily used in budget-friendly products. However, technological advancements in material science have transformed the landscape, allowing faux leather to be produced with improved durability, aesthetic appeal, and functionality.

Illustrative image related to faux leather vs real leather

The introduction of polyurethane (PU) and other synthetic materials has paved the way for a broader acceptance of faux leather in luxury markets. As a result, many high-end brands are incorporating faux leather into their collections, appealing to environmentally conscious consumers and those seeking cruelty-free options. This shift has led to a more competitive market where both faux and real leather products coexist, catering to diverse consumer preferences.

In conclusion, the leather industry is at a pivotal moment where B2B buyers must navigate market dynamics influenced by sustainability, technological advancements, and changing consumer preferences. Understanding these trends is crucial for making informed sourcing decisions that align with both business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather vs real leather

-

How do I determine the best type of leather for my product line?

When selecting leather for your product line, consider the intended use and target market. Real leather, particularly full-grain, is ideal for high-end products due to its durability and luxurious appeal. In contrast, faux leather is suitable for budget-friendly options or products targeting eco-conscious consumers. Evaluate your brand’s positioning, desired aesthetics, and customer preferences to make an informed decision. Additionally, consider the environmental impact and sourcing challenges, especially in regions with varying regulations on leather production. -

What factors should I consider when sourcing faux leather vs real leather?

Key factors include cost, durability, aesthetics, and sustainability. Real leather tends to be more expensive but offers superior durability and a timeless look. Faux leather is generally more affordable and can meet vegan demands, but may not last as long. Evaluate supplier certifications for environmental practices and product quality. Additionally, assess the logistical aspects of sourcing, including lead times and shipping regulations, particularly when dealing with international suppliers from regions like Africa and Europe. -

What are the minimum order quantities (MOQs) typically required for leather products?

MOQs can vary widely depending on the supplier and the type of leather. For real leather, MOQs are often higher due to the cost of materials and production processes, typically ranging from 100 to 500 units. Faux leather may have lower MOQs, sometimes starting at 50 units, as it is generally easier to produce. It’s essential to clarify MOQs with potential suppliers upfront to align with your production capabilities and budget. -

How can I effectively vet suppliers for leather products?

To vet suppliers, start by researching their reputation and reliability through reviews and testimonials from previous clients. Request samples to evaluate the quality of both faux and real leather. Check for certifications that indicate compliance with international quality and environmental standards. Additionally, assess their production capacity, lead times, and flexibility in customization. Conducting on-site visits or audits can further ensure that suppliers meet your standards. -

What are common payment terms in international leather transactions?

Payment terms can vary by supplier but typically include options like net 30, 50% upfront and 50% upon delivery, or letters of credit for larger orders. Ensure you understand the terms clearly and negotiate favorable conditions that suit your cash flow. Familiarize yourself with the risks associated with international payments, such as currency fluctuations and transaction fees, especially when working with suppliers in diverse regions like South America and the Middle East. -

How do I ensure quality assurance for leather products sourced internationally?

Establishing a robust quality assurance process is critical. Define clear specifications and quality standards in your contracts. Consider implementing third-party inspections during production and before shipment to ensure compliance with your quality expectations. Regular communication with suppliers throughout the manufacturing process can also help address potential issues early. Additionally, consider requesting certifications or compliance documents to verify the materials and processes used. -

What logistics considerations should I keep in mind when importing leather?

When importing leather, consider shipping methods, customs regulations, and potential tariffs. Choose between air and sea freight based on urgency and cost-effectiveness. Understand the import regulations specific to your country and ensure all necessary documentation is in order to avoid delays. Collaborating with a logistics partner experienced in international trade can streamline the process, ensuring timely delivery while navigating complex customs requirements. -

How can I customize leather products to meet my brand’s needs?

Customization options vary between faux and real leather. Discuss your requirements with suppliers, such as color, texture, and pattern specifications. Some suppliers may offer embossing, dyeing, or finishing options to enhance the uniqueness of your products. Be prepared to share your design concepts and quantities, as this will help suppliers provide accurate quotes and timelines. Effective communication during the design phase can lead to successful collaborations that align with your brand vision.

Top 3 Faux Leather Vs Real Leather Manufacturers & Suppliers List

1. Radley London – Handbags and Accessories

Domain: radleylondon.com

Registered: 2008 (17 years)

Introduction: Faux Leather vs. Genuine Leather Handbags | Radley London offers a range of handbags, wallets, and accessories made from both real and faux leather. Real leather is made from animal skins and comes in various grades: full-grain (highest quality), top-grain, split-grain, genuine (lower quality), and bonded (very low quality). Faux leather is made from PVC or polyurethane, is cheaper, and is a vegan…

2. Buffalo Jackson – Authentic Leather Goods

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Real leather is made from animal hides, such as buffalo or cattle, while faux leather is made from polyvinyl chloride (PVC) or polyurethane. Real leather has a natural surface with imperfections, feels warm and stretches when pressed, and has a distinctive leathery smell. Faux leather has a uniform surface, feels cold and even, does not stretch, and has a plasticky smell. Real leather is more dura…

3. Real Leather – Sustainable Durability

Domain: realeather.com

Registered: 2005 (20 years)

Introduction: Real Leather vs. Faux Leather:

– Vegan leather is made from plastic-based materials like PVC and PU, often marketed as a sustainable alternative but has a negative environmental impact.

– Real leather is a byproduct of the meat industry, considered a renewable resource, and more durable than synthetic materials, reducing textile waste.

– Types of Leather:

1. Vegetable-Tanned Leather:

-…

Strategic Sourcing Conclusion and Outlook for faux leather vs real leather

In evaluating faux leather versus real leather, international B2B buyers must consider factors such as cost, durability, sustainability, and market trends. Real leather, while offering unmatched quality and longevity, comes at a premium price and raises ethical concerns. Conversely, faux leather presents a cost-effective alternative with a broader appeal, especially among environmentally conscious consumers. Its growing popularity in various markets can offer strategic advantages for businesses looking to align with consumer preferences.

Strategic sourcing in this context means not just evaluating the immediate costs but also understanding the long-term implications of your choices. By sourcing responsibly, businesses can enhance their brand image and cater to diverse markets, including those in Africa, South America, the Middle East, and Europe.

As the demand for sustainable and ethical products continues to rise, now is the time to reassess your leather sourcing strategies. Engage with suppliers who prioritize transparency and sustainability, and consider the evolving preferences of your target audience. By doing so, you position your business to thrive in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.