Introduction: Navigating the Global Market for fabric for car roof

In the competitive landscape of the automotive industry, sourcing high-quality fabric for car roofs presents a significant challenge for B2B buyers. Whether you’re looking to enhance the interior of luxury vehicles or provide durable solutions for commercial fleets, the right headliner fabric can influence not just aesthetics but also comfort, durability, and resale value. This comprehensive guide aims to equip international buyers—especially those from Africa, South America, the Middle East, and Europe—with the insights needed to make informed decisions when sourcing these essential materials.

Throughout this guide, you will explore various types of headliner fabrics, including foam-backed options, synthetic leathers, and weather-resistant materials. Each section delves into their specific applications, advantages, and how they can meet diverse environmental demands. Furthermore, we provide strategies for vetting suppliers, understanding pricing structures, and ensuring compliance with regional standards.

By addressing key factors such as durability, maintenance, and installation ease, this guide empowers you to navigate the global market confidently. With the right knowledge at your fingertips, you can enhance your offerings and cater to your customers’ needs effectively, ensuring your business thrives in a dynamic marketplace.

Table Of Contents

- Top 4 Fabric For Car Roof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric for car roof

- Understanding fabric for car roof Types and Variations

- Key Industrial Applications of fabric for car roof

- 3 Common User Pain Points for ‘fabric for car roof’ & Their Solutions

- Strategic Material Selection Guide for fabric for car roof

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric for car roof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for car roof’

- Comprehensive Cost and Pricing Analysis for fabric for car roof Sourcing

- Alternatives Analysis: Comparing fabric for car roof With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric for car roof

- Navigating Market Dynamics and Sourcing Trends in the fabric for car roof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric for car roof

- Strategic Sourcing Conclusion and Outlook for fabric for car roof

- Important Disclaimer & Terms of Use

Understanding fabric for car roof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Foam-Backed Fabric | Extra insulation, sound absorption, and easier installation | Automotive upholstery, restoration projects | Pros: Excellent durability and comfort; Cons: May be pricier than standard fabrics. |

| Vinilo | Highly durable, moisture-resistant, and easy to maintain | Outdoor vehicles, marine applications | Pros: Weather-resistant; Cons: Less breathable than fabric options. |

| Suede & Microsuede | Luxurious feel, premium aesthetic, and soft texture | High-end vehicles, custom interiors | Pros: Upscale appearance; Cons: Requires more maintenance. |

| Piel sintética | Affordable alternative to real leather, water-resistant | Luxury car interiors, upholstery upgrades | Pros: Easy to clean; Cons: May lack the authentic feel of real leather. |

| Polyester Knit Fabric | Lightweight, flexible, and breathable design | Everyday vehicles, modern car interiors | Pros: Easy to install; Cons: May not offer the same durability as heavier materials. |

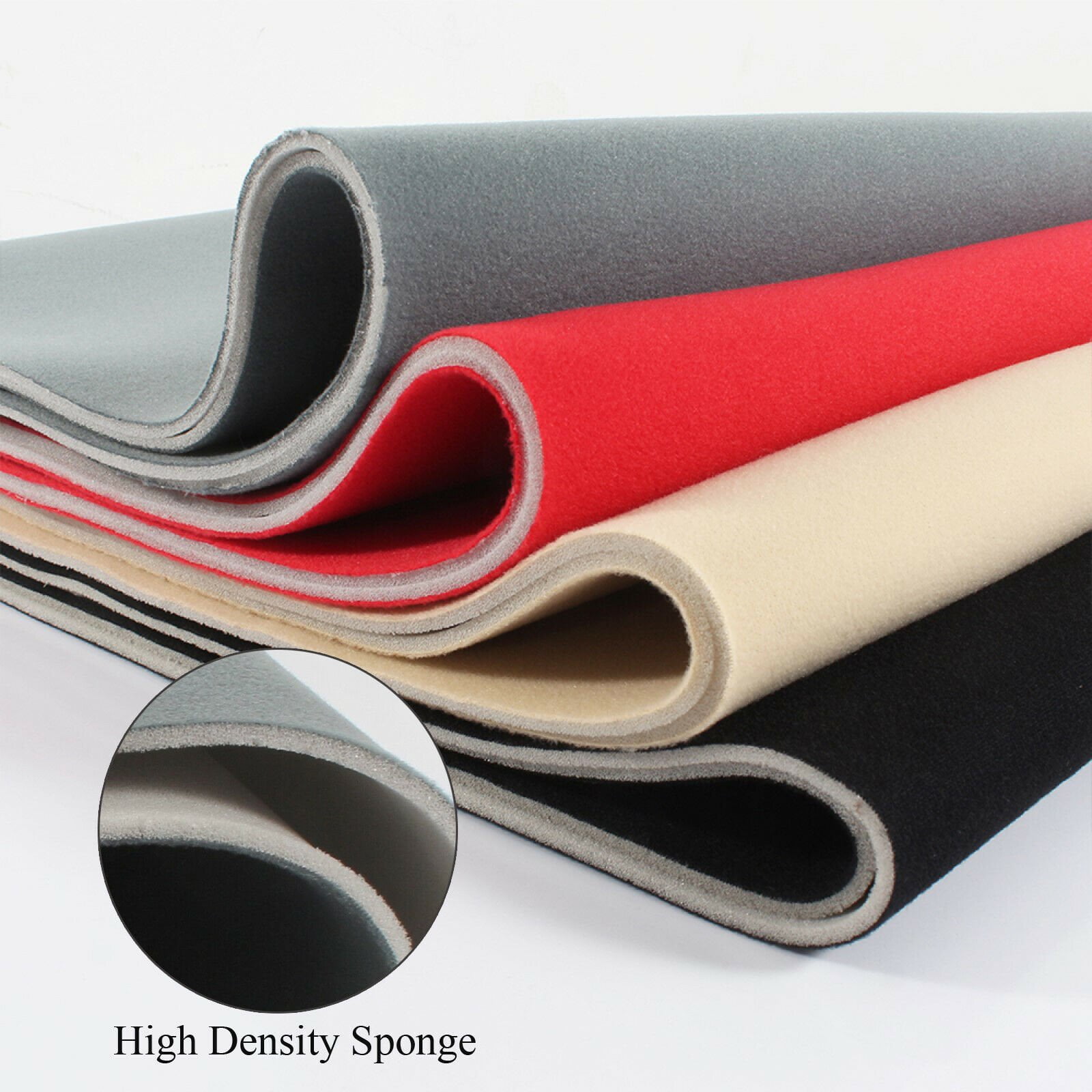

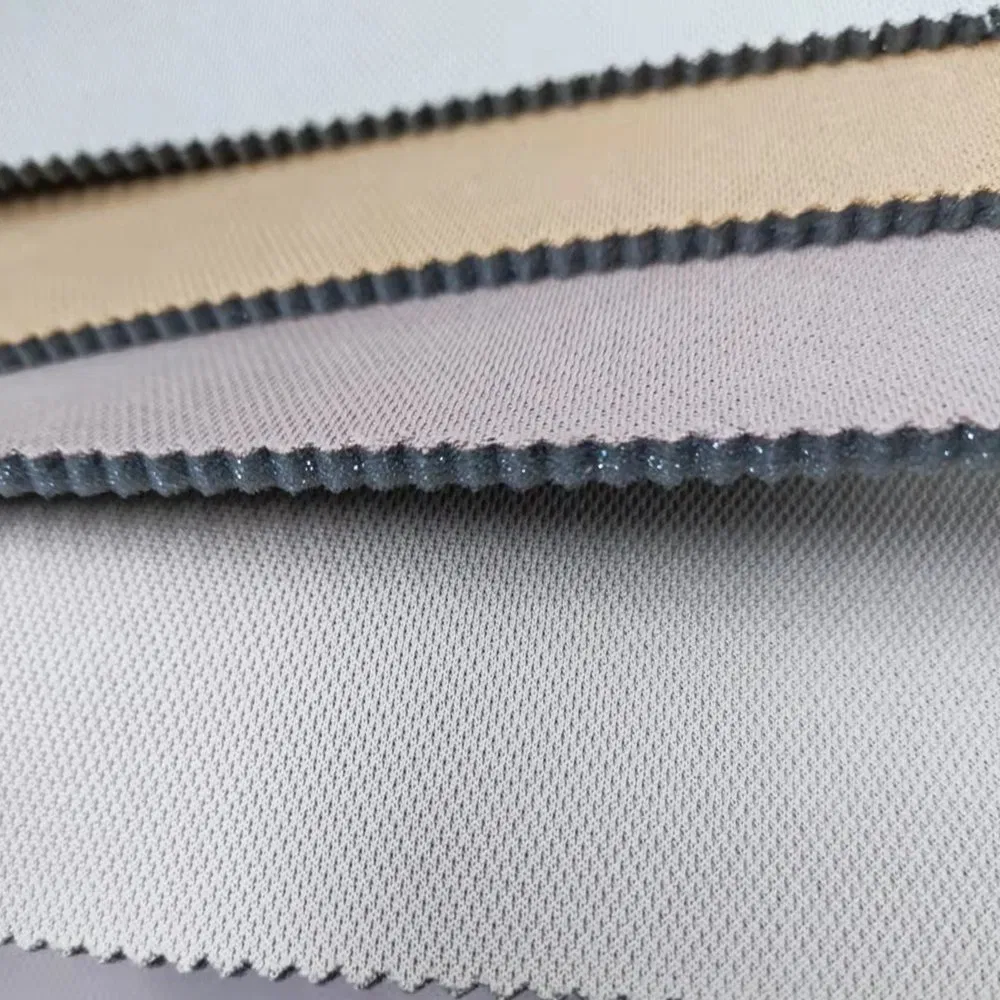

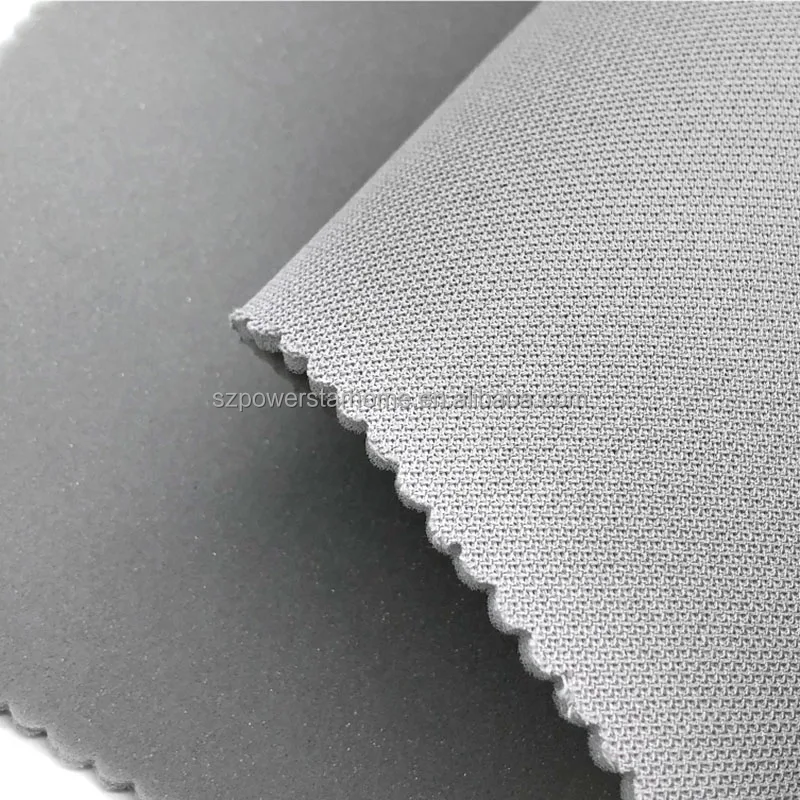

What Are the Characteristics of Foam-Backed Fabric for Car Roofs?

Foam-backed fabric is a popular choice for automotive interiors due to its enhanced durability and comfort. The foam layer not only provides additional insulation but also improves sound absorption, making it ideal for various vehicle types. B2B buyers should consider the installation ease, as foam-backed options typically adhere better and lay flatter against the vehicle’s structure. When purchasing, it’s essential to evaluate the long-term performance, particularly in climates with extreme temperatures.

Why Choose Vinyl for Car Roof Applications?

Vinyl is recognized for its robust durability and moisture resistance, making it a preferred option for vehicles exposed to harsh environmental conditions. Its easy maintenance and ability to repel dust and moisture make it suitable for outdoor and marine applications. Buyers in the automotive sector should prioritize vinyl for projects involving convertibles or vehicles frequently used in wet conditions. However, it’s important to note that while vinyl is durable, it may lack breathability compared to fabric alternatives.

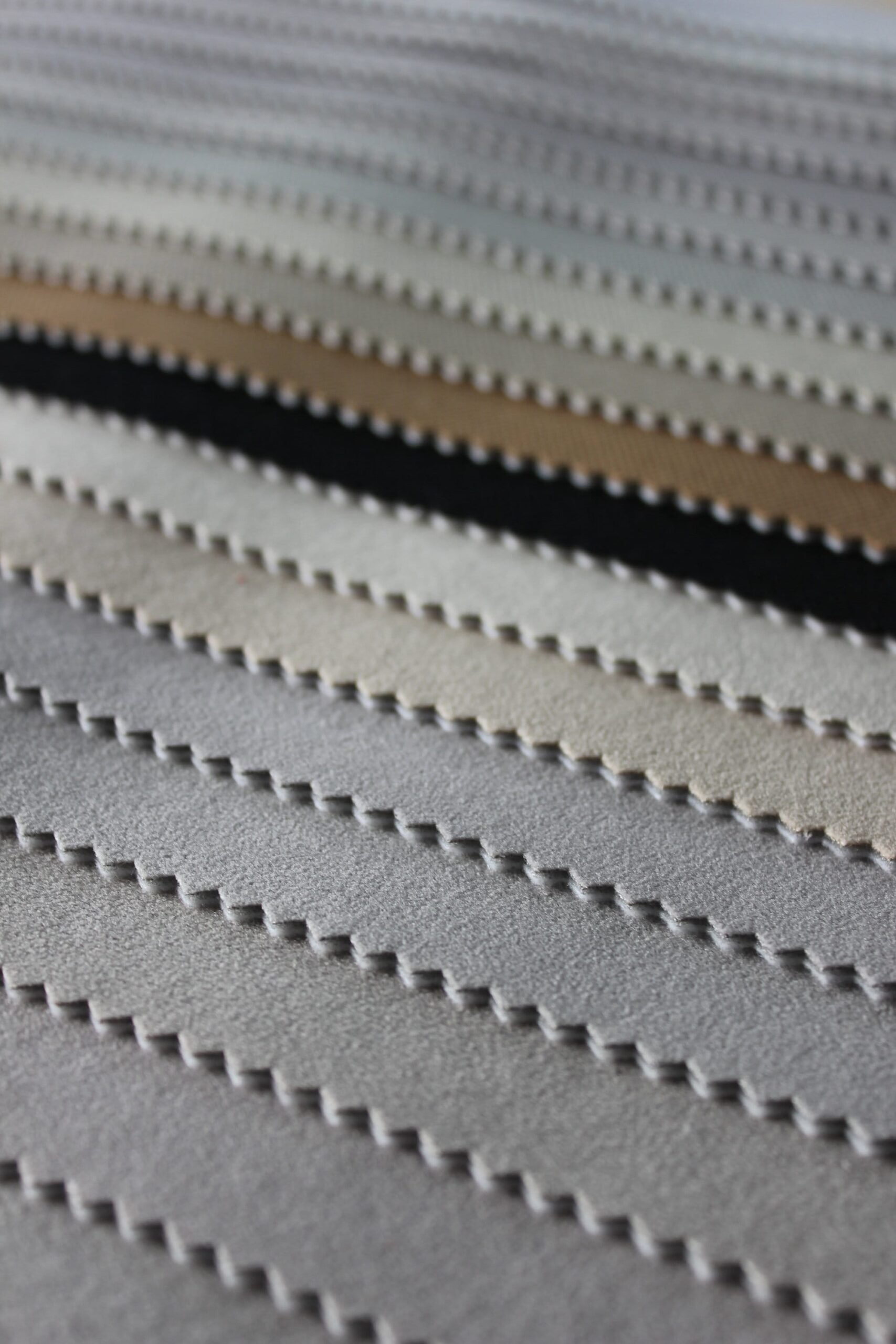

Illustrative image related to fabric for car roof

What Are the Benefits of Using Suede and Microsuede?

Suede and microsuede offer a luxurious touch to car interiors, appealing to buyers focused on aesthetics and premium quality. These materials provide a soft texture that enhances the visual appeal of high-end vehicles and custom projects. However, B2B buyers should be aware that these fabrics require more maintenance to keep them looking pristine. When considering suede options, factors such as wear resistance and cleaning methods should be evaluated to ensure longevity.

How Does Synthetic Leather Compare in Car Roof Fabrics?

Synthetic leather serves as an affordable and practical alternative to genuine leather, offering a water-resistant surface that is easy to clean. It is commonly used in luxury vehicle interiors and upholstery upgrades, appealing to buyers looking for a high-end appearance without the associated costs of real leather. When sourcing synthetic leather, it’s crucial to assess the material’s quality and resistance to wear and tear, particularly for high-traffic areas within the vehicle.

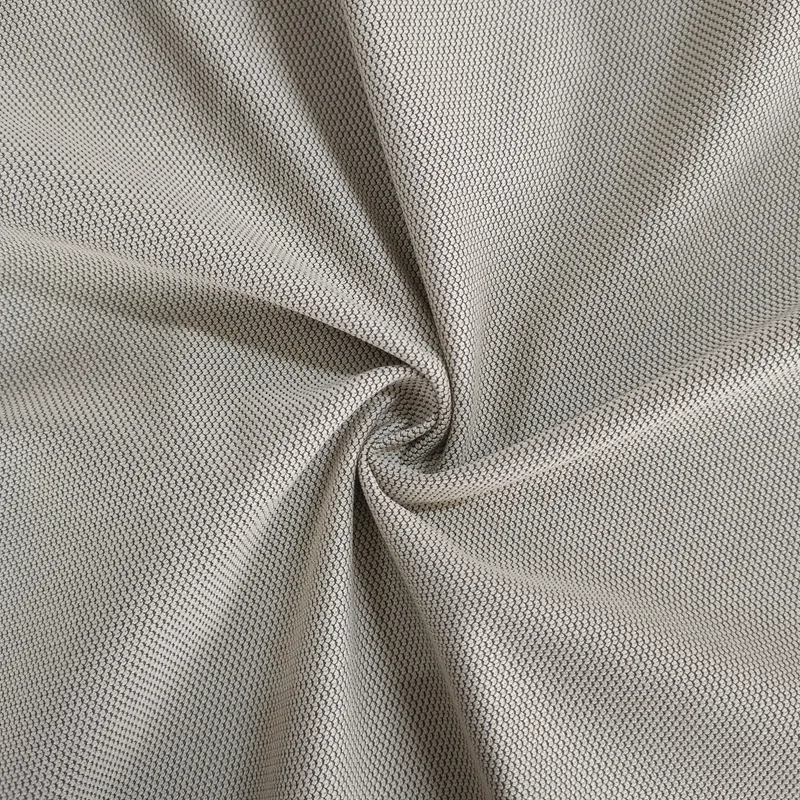

Why Is Polyester Knit Fabric Suitable for Everyday Vehicles?

Polyester knit fabric is lightweight and flexible, making it an excellent choice for everyday vehicle interiors. Its breathable design contributes to comfort, while its stretchiness simplifies installation on curved surfaces. B2B buyers should consider polyester knit for projects that prioritize ease of installation and cost-effectiveness. However, it’s worth noting that while polyester is versatile, it may not offer the same level of durability as heavier fabrics, making it essential to match the material to the vehicle’s intended use.

Illustrative image related to fabric for car roof

Key Industrial Applications of fabric for car roof

| Industry/Sector | Specific Application of fabric for car roof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Headliner Fabric for Vehicle Interiors | Enhances aesthetic appeal and comfort; improves resale value | Durability, weather resistance, and ease of installation are critical. Consider local climate impacts. |

| Automotive Aftermarket | Replacement Headliners for Classic Cars | Restores vehicle value and aesthetic; caters to niche markets | Look for materials that match original specifications; durability and ease of installation are key. |

| Recreational Vehicles (RVs) | Waterproof and UV-resistant Roof Fabrics | Protects against harsh weather conditions; enhances comfort | Ensure materials are lightweight yet durable; consider ease of cleaning and maintenance. |

| Marine Vehicles | Marine-Grade Headliner Fabrics | Resists moisture and mildew; maintains interior aesthetics | Must be water-resistant and UV-stable; sourcing should consider marine-specific certifications. |

| Luxury Vehicle Customization | Premium Suede and Leather Headliners | Provides a high-end look and feel; enhances brand prestige | Focus on high-quality materials; consider sourcing from suppliers with luxury automotive experience. |

How is Headliner Fabric Used in Automotive Manufacturing?

In the automotive manufacturing sector, headliner fabric is crucial for vehicle interiors. It not only serves as a functional cover for the car roof but also significantly enhances the aesthetic appeal and comfort level of the vehicle. High-quality fabrics can improve sound insulation and temperature regulation, which are essential for customer satisfaction. For international buyers, sourcing durable materials that withstand varying climates—especially in regions like Africa and the Middle East—can be a significant factor in maintaining vehicle integrity over time.

What Role Does Headliner Fabric Play in the Automotive Aftermarket?

In the automotive aftermarket, headliner fabrics are essential for restoring classic cars. These fabrics can match original specifications, which is vital for preserving the vehicle’s authenticity and value. Businesses in this sector must prioritize sourcing materials that are not only visually appealing but also durable enough to withstand the rigors of time. Buyers from South America and Europe may seek materials that align with local restoration standards and aesthetics, ensuring that their investment in classic vehicles is both functional and stylish.

Why is Waterproof Fabric Important for Recreational Vehicles?

Waterproof and UV-resistant fabrics are indispensable for recreational vehicles (RVs). These materials protect against harsh weather conditions, ensuring that the interiors remain comfortable and free from water damage. For businesses involved in RV manufacturing or refurbishing, sourcing lightweight yet durable materials is crucial. Buyers in regions with high humidity, such as parts of Africa and Southeast Asia, should prioritize fabrics that are easy to clean and maintain, as this will enhance the longevity of the vehicle’s interior.

How are Marine-Grade Fabrics Beneficial for Marine Vehicles?

Marine-grade headliner fabrics are specifically designed to resist moisture and mildew, making them ideal for marine vehicles. These materials maintain aesthetic appeal while providing protection against harsh marine environments. Businesses in the marine sector must ensure that the fabrics they source are not only water-resistant but also UV-stable to prevent fading and degradation. Buyers should consider suppliers who specialize in marine textiles to ensure compliance with industry standards, particularly in regions with significant boating activities.

What is the Value of Premium Fabrics in Luxury Vehicle Customization?

In the luxury vehicle customization market, premium suede and leather headliners are sought after for their high-end look and feel. These materials enhance the overall aesthetic of the vehicle, contributing to brand prestige and customer satisfaction. For businesses involved in luxury automotive customization, sourcing high-quality materials is paramount. Buyers need to focus on suppliers with experience in luxury automotive textiles, ensuring that the fabrics meet both durability and aesthetic standards, especially in competitive markets in Europe and the Middle East.

3 Common User Pain Points for ‘fabric for car roof’ & Their Solutions

Scenario 1: Sourcing Durable Headliner Fabrics for Diverse Climates

The Problem: A B2B buyer in a region with fluctuating climates, such as Nigeria or parts of South America, often struggles to find headliner fabrics that can withstand extreme temperatures and humidity without degrading. Their challenge lies in sourcing materials that not only look good but also endure environmental stresses, preventing issues like sagging, fading, or mildew growth. This could lead to costly replacements and dissatisfied customers, impacting their reputation and bottom line.

The Solution: To address this issue, buyers should prioritize sourcing high-quality, weather-resistant headliner fabrics specifically designed for their climate conditions. Look for materials with UV protection and moisture resistance, such as vinyl or foam-backed options, which can provide better insulation and durability. Engaging with suppliers who offer samples and detailed specifications will allow buyers to assess the materials’ performance in real-world conditions. Additionally, consider building relationships with local manufacturers who understand the unique environmental challenges of your region and can provide tailored solutions.

Scenario 2: Balancing Aesthetics and Functionality in Vehicle Interiors

The Problem: Many B2B buyers face the dilemma of choosing between aesthetically pleasing fabrics and those that are practical for heavy use. For example, a buyer for a luxury car manufacturer may want a fabric that enhances the vehicle’s interior but also needs it to be stain-resistant and easy to clean. The fear of compromising on either aspect can lead to indecision and project delays, ultimately affecting production timelines and costs.

The Solution: To effectively balance aesthetics and functionality, buyers should consider investing in synthetic leather or high-quality microsuede. These materials not only provide a luxurious appearance but are also durable and easier to maintain than traditional fabrics. Collaborating with designers to create a cohesive interior concept that incorporates both visual appeal and practical performance will ensure customer satisfaction. Additionally, sourcing from suppliers that offer a variety of textures and colors can help buyers find the perfect fabric that meets both aesthetic and functional needs without compromising on quality.

Scenario 3: Installation Challenges with Headliner Fabrics

The Problem: A significant pain point for B2B buyers is the complexity involved in the installation of headliner fabrics, especially for those with limited experience in automotive upholstery. Buyers may encounter difficulties such as improper fitting, bubbling, or wrinkles, which can detract from the overall quality of the vehicle’s interior. This issue can lead to increased labor costs and potential rework, making it a significant concern for those managing production efficiency.

The Solution: To mitigate installation challenges, buyers should opt for foam-backed fabrics that offer greater ease of handling and a more forgiving installation process. These materials are less likely to sag and provide a smoother finish, reducing the likelihood of installation errors. Additionally, providing training sessions for staff on best practices for installation techniques can be invaluable. Suppliers who offer detailed installation guides or videos can also assist in ensuring that the team is well-equipped to handle the process effectively. Investing in quality materials and proper training will lead to smoother installations and higher-quality results, ultimately enhancing the buyer’s reputation in the market.

Strategic Material Selection Guide for fabric for car roof

When selecting materials for car roof fabrics, B2B buyers must consider a variety of factors that influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in car roof fabrics, focusing on their properties, advantages, disadvantages, and considerations for international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Foam-Backed Fabric for Car Roofs?

Foam-backed fabric is a popular choice for car roofs due to its superior insulation and soundproofing capabilities. This material typically features a layer of foam that enhances comfort and durability. It can withstand a wide range of temperatures, making it suitable for various climates. Additionally, foam-backed fabric is relatively lightweight, which aids in installation.

Pros & Cons: The primary advantage of foam-backed fabric is its excellent sound absorption and temperature regulation, which creates a more comfortable driving experience. However, it can be more expensive than traditional fabrics, and the manufacturing process may be more complex due to the foam layer.

Impact on Application: This material is particularly effective in vehicles that experience significant noise or temperature fluctuations, such as convertibles or SUVs.

International Considerations: Buyers in regions with extreme climates should ensure that the foam-backed fabric meets local standards for heat and UV resistance. Compliance with ASTM or DIN standards may also be necessary for automotive applications.

Illustrative image related to fabric for car roof

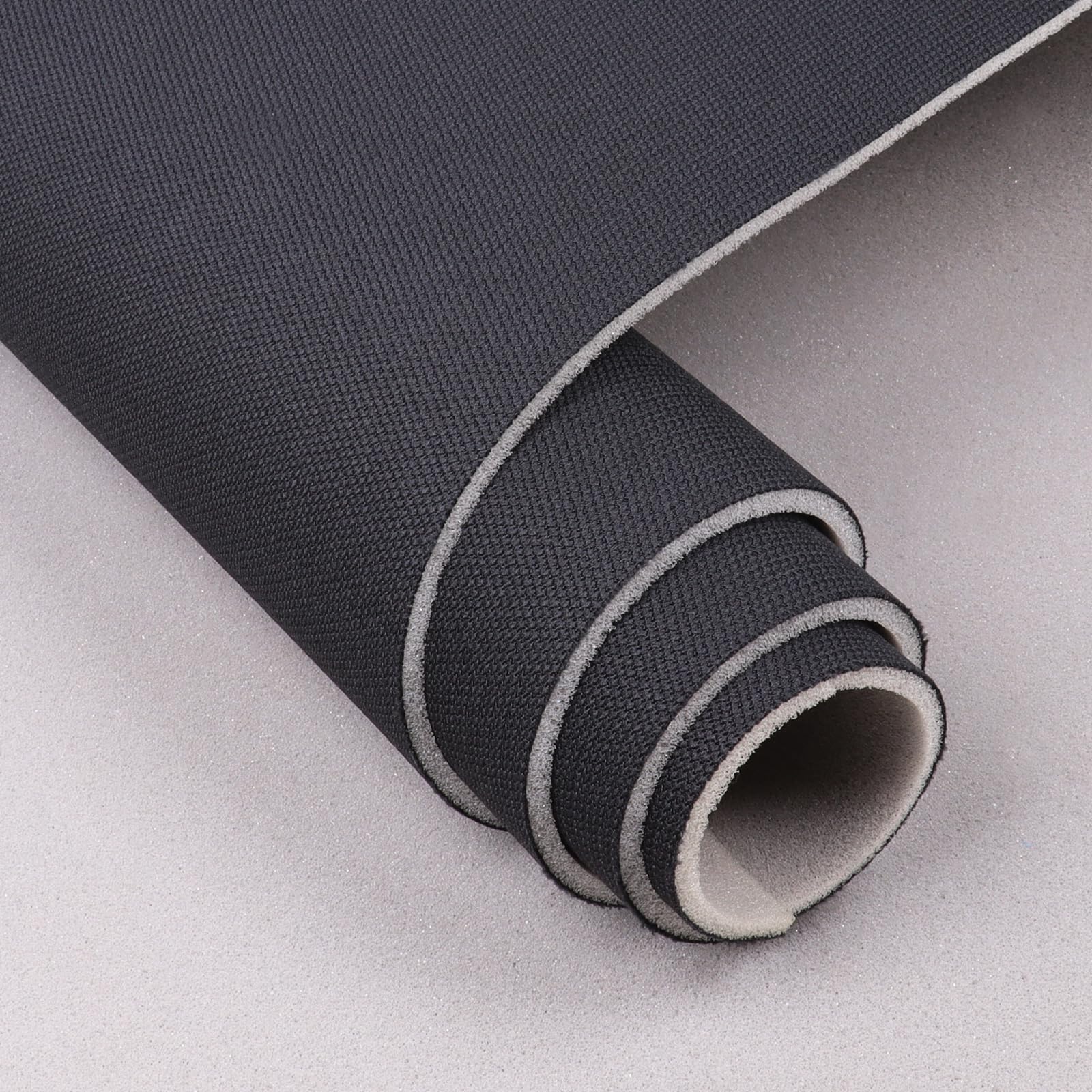

How Does Synthetic Leather Compare for Car Roof Fabrics?

Synthetic leather is another common material for car roofs, known for its durability and aesthetic appeal. It mimics the look of real leather while offering enhanced resistance to moisture and stains. This material can withstand high temperatures and is often treated to resist UV damage.

Pros & Cons: The key advantage of synthetic leather is its low maintenance requirement and luxurious appearance, making it a popular choice for high-end vehicles. However, it may not provide the same level of sound insulation as foam-backed fabrics, and its cost can be on the higher side.

Impact on Application: Synthetic leather is ideal for premium vehicles where aesthetics are crucial, but it may not be the best choice for off-road vehicles or those exposed to harsh conditions.

Illustrative image related to fabric for car roof

International Considerations: Buyers should verify that synthetic leather complies with environmental regulations regarding VOC emissions, especially in Europe and North America.

What are the Benefits of Vinyl for Car Roof Applications?

Vinyl is a highly durable and moisture-resistant material that is often used in car roofs, particularly for convertibles and vehicles exposed to the elements. It is known for its ease of cleaning and maintenance, making it a practical choice for everyday vehicles.

Pros & Cons: Vinyl’s primary advantage is its durability and resistance to fading, which is crucial for vehicles in sunny climates. However, it may not offer the same level of comfort as fabric options and can be less breathable.

Impact on Application: Vinyl is particularly suitable for vehicles that require a waterproof solution, such as those used in marine environments or off-road conditions.

International Considerations: Buyers should consider the specific vinyl grades that meet local automotive standards, such as those set by JIS in Japan or DIN in Europe, to ensure quality and compliance.

What Role Does Polyester Knit Fabric Play in Car Roofs?

Polyester knit fabric is a lightweight option that provides a modern aesthetic and good breathability. This material is often chosen for its flexibility, making it easier to install on curved surfaces.

Pros & Cons: The main advantage of polyester knit fabric is its affordability and ease of installation. However, it may not be as durable as other options and could require more frequent replacement.

Impact on Application: This fabric is suitable for vehicles with less demanding applications, such as city cars or those not exposed to harsh environmental conditions.

Illustrative image related to fabric for car roof

International Considerations: B2B buyers should ensure that polyester knit fabrics comply with fire safety regulations, especially in regions with stringent automotive safety standards.

Summary Table of Material Selection for Car Roof Fabrics

| Material | Typical Use Case for fabric for car roof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Foam-Backed Fabric | SUVs, Convertibles | Excellent sound absorption and comfort | Higher cost and complex manufacturing | Alta |

| Piel sintética | Luxury Vehicles | Low maintenance and premium look | Less sound insulation | Alta |

| Vinilo | Off-road and Marine Vehicles | Highly durable and moisture-resistant | Less breathable and comfort | Medium |

| Polyester Knit Fabric | City Cars | Affordable and easy to install | Lower durability | Low |

This strategic material selection guide provides B2B buyers with critical insights into the various options available for car roof fabrics, enabling informed decisions that align with their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric for car roof

What Are the Key Manufacturing Processes for Car Roof Fabrics?

The manufacturing of car roof fabrics involves several distinct stages that ensure the final product meets the necessary standards for durability, aesthetics, and functionality. Understanding these processes can help B2B buyers make informed decisions when sourcing materials for their automotive projects.

Material Preparation: What Materials Are Used in Car Roof Fabrics?

The first stage in manufacturing car roof fabrics involves selecting and preparing the raw materials. Common materials include polyester, nylon, vinyl, and foam backing. Each material has its unique properties, such as weight, durability, and resistance to heat and moisture.

Illustrative image related to fabric for car roof

-

Material Sourcing: Manufacturers often source high-quality fibers from trusted suppliers. This can include recycled materials for eco-friendly options, which are gaining popularity among consumers.

-

Pre-Treatment: The raw materials undergo treatments to enhance their properties. For example, polyester fibers might be treated for UV resistance, while vinyl may be processed for improved flexibility and durability.

Forming: How Are Fabrics Created?

Once the materials are prepared, the next step is the forming process, which includes weaving, knitting, or non-woven methods.

-

Weaving: This traditional method interlaces threads to create a strong fabric. It is often used for polyester or nylon materials, providing a balance of strength and flexibility.

-

Knitting: This technique involves looping threads together, resulting in a stretchable fabric. Knitted fabrics are often used for headliners that require a snug fit.

-

Non-Woven Techniques: For certain applications, manufacturers may opt for non-woven fabrics, which are produced by bonding fibers together through heat or adhesives. This method can produce lightweight and cost-effective options.

Assembly: What Is Involved in the Fabric Assembly Process?

After forming the fabric, it proceeds to assembly, where additional components may be added.

-

Foam Backing: Many car roof fabrics feature foam backing, which provides insulation and soundproofing. The foam is bonded to the fabric using adhesives or heat-sealing techniques.

-

Cutting and Shaping: The fabric is cut into specific sizes and shapes according to the vehicle’s design requirements. This stage may also involve the addition of features such as perforations or embossed designs for aesthetic appeal.

-

Sewing and Finishing Touches: Some fabrics may require sewing for added durability or to create specific designs. Finishing touches, such as edge binding or adding decorative elements, are applied to enhance the final product.

What Quality Assurance Measures Are Essential in Car Roof Fabric Manufacturing?

Quality assurance is critical in ensuring that car roof fabrics meet international standards and customer expectations. Implementing rigorous quality control processes helps mitigate risks and ensures product reliability.

What Are the Relevant International Standards for Automotive Fabrics?

B2B buyers should be aware of the standards that govern the manufacturing of automotive fabrics. Key standards include:

-

ISO 9001: This international standard focuses on quality management systems and ensures that manufacturers maintain consistent quality across their processes.

-

CE Marking: In Europe, car roof fabrics must meet safety and health requirements, which are validated through CE marking. This certification signifies compliance with EU legislation.

-

API Standards: For specialized applications, such as in extreme environments, adherence to American Petroleum Institute (API) standards may be necessary, particularly for fabrics used in off-road or marine vehicles.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each stage meets predefined standards.

-

Incoming Quality Control (IQC): Before production begins, raw materials are inspected for quality, ensuring they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to identify any deviations from quality standards. This includes checking fabric strength, color consistency, and adherence to design specifications.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo a thorough inspection, which may include testing for durability, colorfastness, and environmental resistance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial for ensuring product reliability and compliance.

Illustrative image related to fabric for car roof

-

Conduct Supplier Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality control systems. This includes reviewing their adherence to international standards and checking their production facilities.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports, including test results and compliance certificates. These documents serve as evidence of the quality measures in place.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct random checks and offer detailed feedback on production processes.

What Are the QC Nuances for International Buyers?

International B2B buyers should be aware of the unique challenges and considerations when sourcing car roof fabrics globally.

-

Cultural and Regulatory Differences: Understanding the local manufacturing practices and regulations in countries like Nigeria or Vietnam is essential. This may include different standards for environmental sustainability or labor practices.

-

Supply Chain Risks: Consideration of logistics and supply chain risks is vital, especially in regions with less stable infrastructure. Buyers should evaluate the reliability of transportation and delivery systems.

-

Customization Needs: B2B buyers may require customization for their specific markets. Ensuring that suppliers can accommodate these requests while maintaining quality standards is crucial.

By understanding the manufacturing processes and quality assurance measures for car roof fabrics, B2B buyers can make informed decisions that align with their operational needs and customer expectations. Sourcing from reputable suppliers who prioritize quality will ultimately lead to better products and enhanced customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for car roof’

Introducción

Sourcing high-quality fabric for car roofs is critical for businesses in the automotive and upholstery industries. This guide provides a practical, step-by-step checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right materials that meet your specifications and enhance your product offerings.

Step 1: Define Your Technical Specifications

Clearly outline the requirements for the headliner fabric you need. Consider factors such as durability, weather resistance, and aesthetic appeal.

– Durability: Identify the lifespan and wear resistance needed for your specific application.

– Environmental Factors: Consider the climate where the vehicles will be used, influencing the choice of materials (e.g., UV resistance, waterproofing).

Illustrative image related to fabric for car roof

Step 2: Research Available Fabrics

Explore the various types of headliner fabrics available in the market. Understanding the characteristics of each type will allow you to make informed decisions.

– Common Materials: Familiarize yourself with options like foam-backed fabric, vinyl, suede, and synthetic leather.

– Performance Attributes: Evaluate each fabric’s sound absorption, insulation, and ease of maintenance.

Step 3: Identify and Vet Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough due diligence.

– Request Documentation: Ask for company profiles, product catalogs, and certifications to assess their reliability.

– Review References: Seek feedback from other businesses that have sourced similar materials to gauge supplier performance and quality.

Step 4: Request Samples for Evaluation

Always request fabric samples before finalizing your order. This step allows you to assess the quality and suitability of the materials firsthand.

– Physical Assessment: Check for texture, color accuracy, and overall feel to ensure it meets your standards.

– Test Durability: If possible, conduct preliminary tests for wear and tear, UV resistance, and water repellency.

Step 5: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare their pricing structures and terms of sale.

– Cost Analysis: Look beyond the initial price; consider shipping costs, bulk discounts, and payment terms.

– Negotiation Opportunities: Engage in discussions to explore potential discounts or favorable terms, especially for larger orders.

Step 6: Confirm Compliance with Industry Standards

Ensure that the fabrics meet relevant industry standards and regulations. This step is crucial for avoiding future liabilities and ensuring product safety.

– Certification Checks: Verify any certifications related to fire resistance, toxicity, or environmental impact.

– Local Regulations: Be aware of any specific regulations in your target markets, particularly in regions with strict automotive standards.

Illustrative image related to fabric for car roof

Step 7: Finalize the Order and Logistics

After completing your evaluations and negotiations, finalize your order and arrange for logistics.

– Order Confirmation: Make sure that all details are documented, including quantities, delivery timelines, and payment arrangements.

– Shipping Arrangements: Coordinate shipping to ensure timely delivery, especially if you’re operating across international borders.

By following this checklist, B2B buyers can streamline their sourcing process for car roof fabric, ensuring they select high-quality materials that meet both their business needs and those of their customers.

Comprehensive Cost and Pricing Analysis for fabric for car roof Sourcing

What Are the Key Cost Components for Sourcing Fabric for Car Roofs?

When sourcing fabric for car roofs, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of fabric significantly impacts the price. Options range from basic polyester to premium suede or synthetic leather. Prices can vary widely based on material quality and source.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. Regions with lower labor costs can offer more competitive pricing, but this may affect quality and consistency.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturers often pass savings on to buyers, so evaluating potential suppliers on these metrics can yield better deals.

-

Tooling: Custom tooling for unique fabric specifications can increase initial costs. However, investing in specialized tooling may reduce long-term expenses through enhanced production efficiency.

-

Quality Control (QC): Implementing stringent QC processes ensures that the fabrics meet required standards. While this may add to upfront costs, it helps prevent costly returns and rework in the long run.

-

Logistics: Transportation costs are influenced by distance, shipping methods, and customs duties. International buyers should consider these factors to avoid unexpected expenses.

-

Margin: Suppliers typically apply a markup to cover their costs and ensure profitability. Understanding the average margin in the industry can help buyers negotiate better pricing.

How Do Price Influencers Impact Fabric Sourcing?

Several factors can influence the pricing of car roof fabrics, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Establishing a long-term partnership with suppliers may allow for favorable terms and bulk discounts.

-

Specifications and Customization: Customized fabrics to meet specific design or performance requirements may incur additional costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Materials and Quality Certifications: Fabrics that meet international quality certifications may command higher prices. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more, but they often deliver better quality and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) can affect overall costs. Buyers should clarify these terms to avoid hidden charges and ensure a smooth import process.

What Negotiation Strategies Can Enhance Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Research Market Rates: Familiarize yourself with industry pricing standards to build a strong negotiation position. Knowing the average costs for specific materials can empower your discussions.

-

Leverage Long-Term Relationships: Establishing a long-term partnership with suppliers can result in loyalty discounts and favorable terms. Regular communication can also foster trust and transparency.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential waste. A more expensive fabric may offer better longevity, leading to lower costs over time.

-

Be Flexible with Specifications: If certain specifications can be adjusted without compromising quality, suppliers may offer lower pricing. Discussing alternative materials or processes can yield cost savings.

-

Understand Regional Dynamics: Be aware of regional economic conditions and trade agreements that might affect pricing. For instance, tariffs or import duties can significantly impact costs for specific regions.

Conclusion: Navigating Pricing Nuances for International Buyers

Navigating the cost and pricing landscape for car roof fabrics requires a comprehensive understanding of various components and influencers. As an international buyer, focusing on strategic negotiation and a thorough assessment of the total cost of ownership can lead to significant savings. Always remember that prices can fluctuate based on market conditions, so maintaining flexibility and adaptability in your sourcing strategy is crucial.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on supplier, order volume, and market conditions. Always seek updated quotes for accurate pricing.

Alternatives Analysis: Comparing fabric for car roof With Other Solutions

Exploring Alternatives to Fabric for Car Roofs

In the automotive industry, selecting the right material for car roofs is crucial for both aesthetics and functionality. While fabric is a popular choice, there are several alternatives that offer unique benefits and drawbacks. This analysis will compare fabric for car roofs against two viable alternatives: synthetic leather and fiberglass panels.

| Comparison Aspect | Fabric For Car Roof | Piel sintética | Fiberglass Panels |

|---|---|---|---|

| Performance | Excellent sound absorption, good insulation | Good durability, water-resistant | High durability, impact resistance |

| Cost | Moderate, varies by material | Higher initial cost | Generally higher due to production |

| Ease of Implementation | Moderate; requires adhesive and skill | Easy to install, often pre-cut | Complex installation; requires professional handling |

| Maintenance | Regular cleaning needed; may stain | Easy to wipe clean; stain-resistant | Minimal upkeep; very durable |

| Best Use Case | Luxury vehicles, classic restorations | Modern vehicles, high-traffic areas | Commercial vehicles, performance cars |

Pros and Cons of Each Alternative

Piel sintética

Synthetic leather is an increasingly popular alternative to traditional fabric for car roofs. It mimics the look and feel of genuine leather while being more affordable and easier to maintain. Its water-resistant properties make it suitable for vehicles that may encounter wet conditions, and it is less prone to staining compared to fabric. However, it comes at a higher initial cost and may not provide the same level of sound absorption as fabric, which can impact the overall driving experience.

Fiberglass Panels

Fiberglass panels represent a more robust alternative, especially in commercial applications. They offer exceptional durability and impact resistance, making them ideal for vehicles exposed to harsh conditions. Fiberglass can also be molded into various shapes, allowing for innovative designs. On the downside, the installation process can be complex, requiring professional expertise, which may increase overall costs. Additionally, fiberglass may not provide the same aesthetic appeal as fabric or synthetic leather, potentially limiting its use in luxury vehicles.

Choosing the Right Solution for Your Needs

When considering the best material for car roofs, B2B buyers must evaluate their specific needs, including performance requirements, budget constraints, and aesthetic preferences. Fabric offers a balance of comfort and style, making it suitable for luxury and classic cars. Synthetic leather is ideal for modern vehicles requiring durability and easy maintenance, while fiberglass panels are perfect for commercial applications demanding high resilience. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for fabric for car roof

What Are the Key Technical Properties of Fabric for Car Roof?

When sourcing fabric for car roofs, it is crucial to understand specific technical properties that can significantly impact performance, durability, and overall vehicle aesthetics. Here are some essential specifications to consider:

1. Material Composition

The material used in headliner fabrics can vary widely, including options like polyester, vinyl, and suede. Polyester is lightweight and often used for standard applications, while vinyl offers superior moisture resistance, making it suitable for vehicles exposed to extreme weather. Understanding the material composition helps buyers ensure they select the right fabric for their specific needs.

Illustrative image related to fabric for car roof

2. Weight and Thickness

The weight (measured in grams per square meter, or GSM) and thickness of the fabric affect its durability and ease of installation. Heavier fabrics tend to be more durable and provide better sound insulation, while lighter options may be easier to work with during installation. B2B buyers should consider the vehicle’s intended use and the installation process when evaluating these properties.

3. UV Resistance

Fabrics that are UV resistant are essential for vehicles exposed to direct sunlight, as they prevent fading and degradation over time. This property is particularly important for headliners in convertibles and vehicles used in sunny climates. Sourcing UV-resistant fabrics can enhance the longevity and aesthetic appeal of the vehicle’s interior.

4. Fire Resistance

Compliance with fire safety standards is a critical consideration, especially for vehicles. Fabrics that meet specific flammability ratings ensure safety and compliance with regulations. For B2B buyers, verifying fire resistance is not just about safety but also about meeting legal requirements in different regions.

5. Abrasion Resistance

This property determines how well the fabric can withstand wear and tear over time. Fabrics with high abrasion resistance are ideal for vehicles that experience heavy use or rough conditions, such as off-road vehicles. Buyers should assess this property to ensure the fabric will maintain its integrity and appearance.

6. Foam Backing

Foam-backed fabrics provide additional insulation, soundproofing, and comfort. This feature enhances the overall user experience by minimizing road noise and improving temperature control. For B2B buyers, investing in foam-backed options can lead to increased customer satisfaction and vehicle resale value.

What Are Common Trade Terms in the Fabric for Car Roof Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in the manufacturing of vehicles. When sourcing fabrics, buyers may seek OEM-certified materials to ensure compatibility and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of fabric that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively, particularly when dealing with large-scale projects or specific vehicle models.

Illustrative image related to fabric for car roof

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific materials or services. Using an RFQ can streamline the procurement process by ensuring all suppliers provide comparable offers, aiding in decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and manage risks associated with global sourcing.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for planning and ensuring timely delivery, especially in industries with tight production schedules.

Illustrative image related to fabric for car roof

6. Warranty

A warranty is a promise from the supplier regarding the quality and performance of the fabric. Buyers should inquire about warranty terms to protect their investment and ensure they have recourse in case of defects or performance issues.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing fabric for car roofs, ensuring they choose options that meet their specific needs and expectations.

Navigating Market Dynamics and Sourcing Trends in the fabric for car roof Sector

What are the Current Market Dynamics and Key Trends in the Fabric for Car Roof Sector?

The global automotive fabric market, particularly for car roofs, is currently influenced by several key drivers that are shaping B2B sourcing trends. Firstly, the increasing demand for vehicle customization is prompting manufacturers to explore a wider range of headliner fabrics that not only enhance aesthetics but also improve functionality. This trend is particularly pronounced in emerging markets such as Nigeria and Vietnam, where consumer preferences are shifting towards personalized vehicle interiors.

Technological advancements are also playing a crucial role in the market dynamics. Innovations in fabric manufacturing, such as the development of lightweight, durable, and environmentally friendly materials, are gaining traction. For international B2B buyers, this means sourcing fabrics that offer superior performance while meeting stringent quality standards. Additionally, the rise of e-commerce platforms is simplifying the procurement process, allowing buyers to access a broader selection of fabrics at competitive prices.

Illustrative image related to fabric for car roof

Moreover, the shift towards electric and hybrid vehicles is influencing fabric choices. Manufacturers are increasingly focusing on materials that contribute to vehicle weight reduction, thereby enhancing energy efficiency. As a result, fabrics that provide thermal insulation and soundproofing are in higher demand, especially in regions with extreme climates, such as the Middle East.

How is Sustainability and Ethical Sourcing Impacting the Fabric for Car Roof Sector?

The importance of sustainability and ethical sourcing in the automotive fabric sector cannot be overstated. As consumers and businesses alike become more environmentally conscious, the demand for sustainable materials is surging. B2B buyers are increasingly seeking fabrics made from recycled or organic materials, which not only reduce environmental impact but also enhance brand reputation.

In addition to material sustainability, ethical supply chains are paramount. Ensuring that fabrics are produced under fair labor practices is becoming a critical criterion for many businesses. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for B2B buyers looking to align with eco-friendly practices. These certifications guarantee that the textiles meet strict environmental and social criteria, making them more appealing to environmentally conscious consumers.

Illustrative image related to fabric for car roof

Furthermore, the growing trend towards circular economy models is leading to innovations in fabric recycling and reuse. B2B buyers who prioritize suppliers engaged in these practices can not only improve their sustainability credentials but also potentially reduce costs associated with waste management.

What is the Evolution of Fabric for Car Roofs and Its Relevance for B2B Buyers?

The evolution of fabrics for car roofs has been significant over the decades, transitioning from traditional materials to modern, high-performance options. Initially, fabrics were primarily focused on aesthetics and basic functionality. However, advancements in technology have introduced materials that offer enhanced durability, weather resistance, and sound insulation.

The introduction of foam-backed fabrics marked a turning point, as these materials provide additional comfort and longevity, making them popular among manufacturers and consumers alike. As automotive design has evolved, so too has the need for fabrics that complement innovative interior designs, leading to a greater emphasis on customization and material performance.

For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions. As the market continues to innovate, staying abreast of the latest trends and technologies will enable buyers to select fabrics that not only meet current demands but also anticipate future consumer preferences. This proactive approach is essential for maintaining competitiveness in a rapidly changing market.

Illustrative image related to fabric for car roof

Frequently Asked Questions (FAQs) for B2B Buyers of fabric for car roof

-

How do I solve issues with sagging or damaged headliner fabric in vehicles?

To address sagging or damaged headliner fabric, start by removing the old fabric and cleaning the surface to eliminate any residual adhesive or foam. Next, choose a high-quality replacement fabric that suits your vehicle’s environment, considering options like foam-backed materials for added durability. Ensure you apply a strong adhesive designed for automotive applications for a secure fit. If the task feels overwhelming, hiring a professional can ensure a flawless installation, enhancing both comfort and aesthetics in the vehicle. -

What is the best fabric type for car roof applications in extreme climates?

For vehicles exposed to extreme climates, vinyl and synthetic leather are the best options due to their durability and weather resistance. These materials are designed to withstand high temperatures and humidity, making them ideal for regions with harsh weather. Waterproof options are also available for off-road vehicles, ensuring protection against moisture. Consider breathable fabrics for everyday cars, as they can help regulate temperature and provide comfort for passengers. -

How can I verify the quality of headliner fabric suppliers?

To verify the quality of headliner fabric suppliers, request samples of their materials to assess texture, durability, and finish. Check for certifications that indicate adherence to international quality standards, such as ISO certifications. Additionally, reading customer reviews and testimonials can provide insights into the supplier’s reliability and product performance. Engaging in a dialogue with the supplier about their sourcing and manufacturing processes can also help gauge their commitment to quality. -

What are the common minimum order quantities (MOQ) for headliner fabric?

Minimum order quantities (MOQ) for headliner fabric can vary significantly based on the supplier and the type of fabric. Generally, MOQs range from 50 to 500 yards, depending on the material and customization options. When negotiating with suppliers, inquire about bulk pricing for larger orders, as this can result in cost savings. Additionally, some suppliers may offer flexibility on MOQs for first-time buyers or long-term partnerships. -

What payment terms are typically offered by fabric suppliers in international trade?

Payment terms can vary widely among fabric suppliers, particularly in international trade. Common arrangements include payment in advance, a 30% deposit with the balance upon shipment, or net 30/60 terms post-delivery. It’s crucial to clarify these terms upfront and consider using secure payment methods such as letters of credit or escrow services for high-value transactions. Establishing a good relationship with your supplier can also lead to more favorable terms over time. -

How do I ensure quality assurance for headliner fabric shipments?

To ensure quality assurance for headliner fabric shipments, establish clear quality control protocols with your supplier. This includes requesting pre-shipment inspections, where a third-party service can assess the fabric quality and adherence to specifications. Additionally, consider implementing a return policy for defective goods. Regularly communicating with the supplier about quality expectations and conducting periodic audits can also help maintain high standards. -

What logistics considerations should I keep in mind when importing headliner fabric?

When importing headliner fabric, consider logistics aspects such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the specific requirements for textile imports in your region. Be aware of potential tariffs and duties that may apply, and ensure all documentation is accurate and complete to avoid delays. Planning for contingencies, such as delays in shipping or customs clearance, will help maintain your supply chain efficiency. -

Can I customize headliner fabrics to match specific design requirements?

Yes, many suppliers offer customization options for headliner fabrics, allowing you to choose colors, textures, and patterns that fit your design requirements. Discuss your specific needs with the supplier, including any unique specifications for your target market. Customization may involve additional lead time and costs, so it’s advisable to confirm these details during the initial negotiation phase. This flexibility can enhance your product offering and help differentiate your brand in a competitive market.

Top 4 Fabric For Car Roof Manufacturers & Suppliers List

1. Midwest Fabrics – Headliner Fabric

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Headliner Fabric | Headliner Material By The Yard

2. Reddit – Car Headliner Repair Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The ceiling fabric (headliner) of a car has come unstuck and needs to be reattached. Suggested solutions include using spray adhesive like Super77 to reattach the fabric, or completely removing and re-gluing the headliner for a more permanent fix. It’s also recommended to check for leaks around the sunroof, as they can cause the headliner to fall.

3. eBay – Car Headliner Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car Headliner Fabric available in various materials including Cotton, Foam, Linen, Marine Vinyl, Polyester, Suede, Velvet, and Wool. Sizes offered include By the Yard, 1-2 yards, 3-5 yards, and panels. Color options include Beige, Black, Blue, Brown, Gray, Green, Multicolor, Pink, Red, and White. Suitable for applications such as Quilting, Upholstery, Apparel, Crafts, Cushions, Pillows, and Curtai…

4. 3M – 77 Spray Adhesive

Domain: natnkat.wordpress.com

Registered: 2000 (25 years)

Introduction: 3M 77 spray adhesive, fabric (big enough to cover the headliner), screwdriver, scissors, bristle brush

Strategic Sourcing Conclusion and Outlook for fabric for car roof

In conclusion, the strategic sourcing of fabric for car roofs is pivotal for enhancing vehicle aesthetics, comfort, and durability. By selecting the right materials—such as foam-backed fabrics for improved insulation or waterproof vinyl for rugged applications—businesses can significantly boost the quality and longevity of their automotive interiors. Key considerations include durability, weather resistance, and ease of maintenance, all of which directly influence customer satisfaction and resale value.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, leveraging these insights can lead to more informed purchasing decisions. Establishing strong supplier relationships will not only facilitate access to high-quality materials but also foster innovation in design and functionality tailored to diverse climates and consumer preferences.

As the automotive industry continues to evolve, staying ahead of trends in fabric technology and consumer demands will be crucial. Engage with suppliers who understand your market needs and explore sustainable options that align with global standards. Start your journey towards enhancing your automotive offerings today—invest in high-quality fabrics that reflect your commitment to excellence and innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to fabric for car roof

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.