Introduction: Navigating the Global Market for tear mender instant fabric and leather adhesive

In today’s competitive global market, sourcing high-quality tear mender instant fabric and leather adhesive poses a significant challenge for B2B buyers. As businesses look to enhance their product offerings and customer satisfaction, finding reliable adhesive solutions that are both effective and environmentally friendly becomes paramount. This comprehensive guide delves into the world of Tear Mender, a leading adhesive known for its rapid bonding capabilities, non-toxic formulation, and versatility across various applications, from clothing repairs to upholstery maintenance.

Throughout this guide, we will explore the different types of Tear Mender products available, their specific applications, and best practices for supplier vetting to ensure you partner with reputable manufacturers. Additionally, we will provide insights into cost considerations and market trends that impact pricing and availability. By equipping international buyers—particularly those from Africa, South America, the Middle East, and Europe, including regions like Vietnam and Nigeria—with the knowledge needed to make informed purchasing decisions, this guide aims to streamline the sourcing process.

Understanding the nuances of Tear Mender instant fabric and leather adhesive will empower you to select the right products that meet your business needs, enhance operational efficiency, and ultimately drive customer loyalty. Join us as we navigate this essential component of your supply chain, ensuring you have the tools necessary to thrive in the ever-evolving marketplace.

Table Of Contents

- A Look at Tear Mender Instant Fabric And Leather Adhesive Manufacturers & Suppliers

- Introduction: Navigating the Global Market for tear mender instant fabric and leather adhesive

- Understanding tear mender instant fabric and leather adhesive Types and Variations

- Key Industrial Applications of tear mender instant fabric and leather adhesive

- 3 Common User Pain Points for ‘tear mender instant fabric and leather adhesive’ & Their Solutions

- Strategic Material Selection Guide for tear mender instant fabric and leather adhesive

- In-depth Look: Manufacturing Processes and Quality Assurance for tear mender instant fabric and leather adhesive

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tear mender instant fabric and leather adhesive’

- Comprehensive Cost and Pricing Analysis for tear mender instant fabric and leather adhesive Sourcing

- Alternatives Analysis: Comparing tear mender instant fabric and leather adhesive With Other Solutions

- Essential Technical Properties and Trade Terminology for tear mender instant fabric and leather adhesive

- Navigating Market Dynamics and Sourcing Trends in the tear mender instant fabric and leather adhesive Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tear mender instant fabric and leather adhesive

- Strategic Sourcing Conclusion and Outlook for tear mender instant fabric and leather adhesive

- Important Disclaimer & Terms of Use

Understanding tear mender instant fabric and leather adhesive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

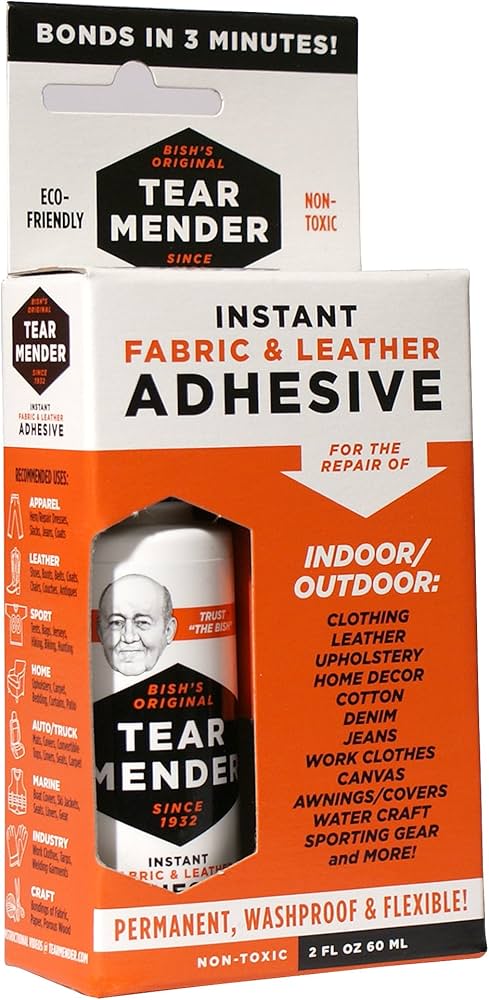

| Tear Mender Instant Fabric Adhesive (2 oz) | Compact size, quick-drying, non-toxic | Apparel repairs, craft projects | Pros: Easy to use, portable. Cons: Limited quantity for larger projects. |

| Tear Mender Instant Fabric Adhesive (32 oz) | Larger volume, cost-effective for bulk applications | Upholstery, home decor, large-scale repairs | Pros: Economical for high-volume use. Cons: Less portable. |

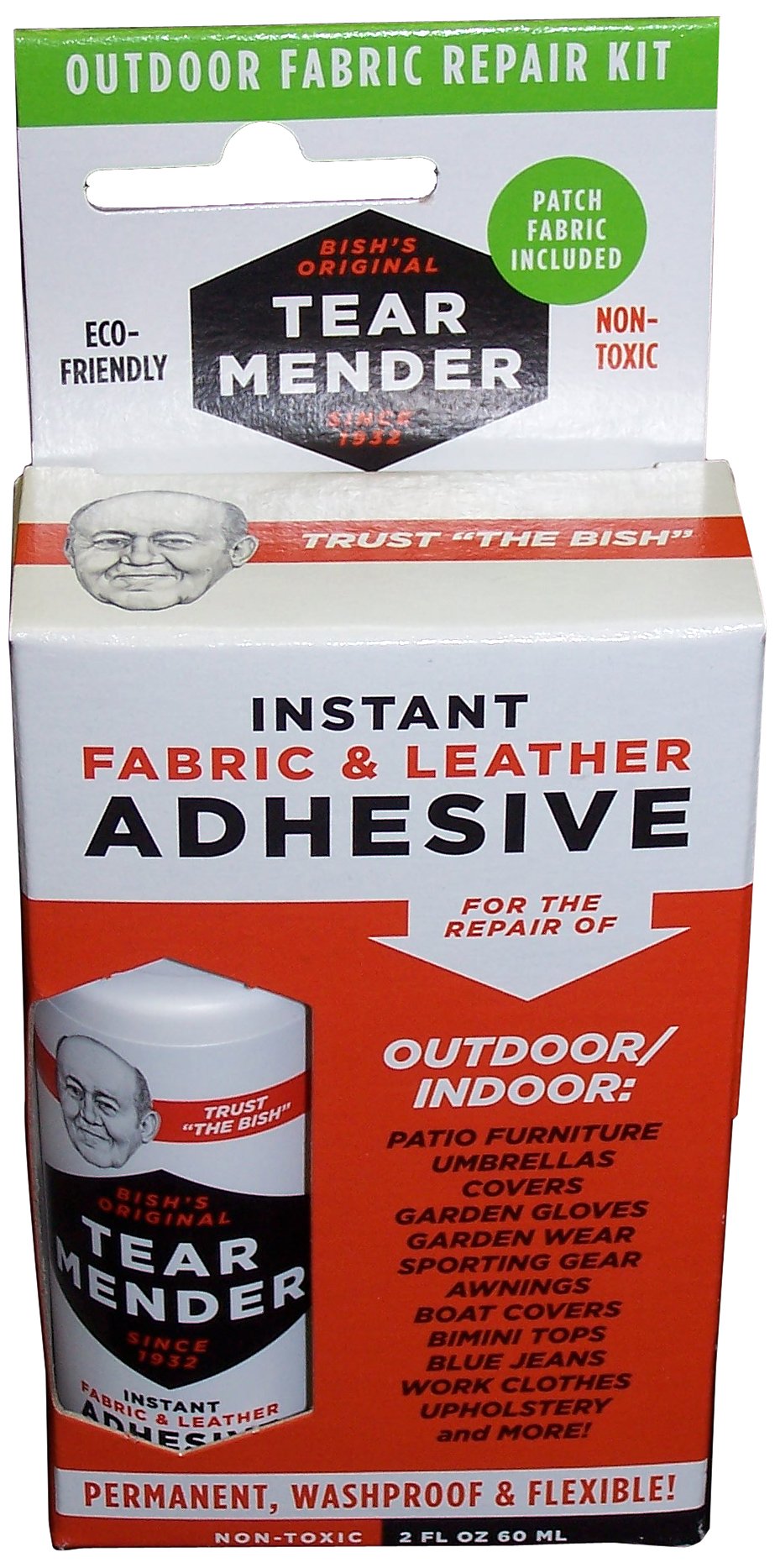

| Tear Mender Outdoor Adhesive | UV resistant, waterproof, designed for outdoor materials | Outdoor furniture, marine applications | Pros: Durable for outdoor use. Cons: May not bond well with all indoor fabrics. |

| Tear Mender Premium Leather Repair Kit | Includes patches, specifically formulated for leather repairs | Leather goods, upholstery, automotive interiors | Pros: Comprehensive solution for leather. Cons: Higher initial investment. |

| Vinyl Mender Value Kit | Tailored for vinyl materials, includes necessary tools | Vinyl upholstery, marine applications | Pros: Specialized for vinyl, effective. Cons: Limited to vinyl use only. |

What Are the Key Characteristics of Tear Mender Instant Fabric Adhesive Variants?

Tear Mender Instant Fabric Adhesive (2 oz) is ideal for small repairs and crafting needs. Its compact size makes it easy to carry, making it a go-to for on-the-spot fixes in apparel and craft projects. B2B buyers should consider this option for quick, portable applications, although it may not suffice for larger repairs due to its limited volume.

Tear Mender Instant Fabric Adhesive (32 oz) offers a more economical solution for businesses requiring larger quantities for upholstery or home decor repairs. This larger size is particularly beneficial for manufacturers and repair shops, allowing for significant cost savings per unit. However, its bulkiness may limit portability for fieldwork.

Tear Mender Outdoor Adhesive is specifically designed for outdoor applications, featuring UV resistance and waterproof capabilities. This variant is essential for businesses dealing with outdoor furniture or marine products, where durability against the elements is crucial. Buyers should ensure compatibility with indoor fabrics, as it may not bond effectively with all materials.

Tear Mender Premium Leather Repair Kit provides a comprehensive solution for leather repairs, including patches and specialized adhesive. This kit is invaluable for businesses focused on leather goods, upholstery, and automotive interiors, offering a tailored approach to leather restoration. While the initial investment is higher, the kit’s effectiveness can justify the cost for quality-conscious buyers.

Vinyl Mender Value Kit is designed for repairing vinyl materials, making it suitable for upholstery and marine applications. This specialized kit includes the necessary tools and adhesives to ensure a reliable bond. While its focus on vinyl is a strength, it limits versatility for businesses needing a more general adhesive solution.

Illustrative image related to tear mender instant fabric and leather adhesive

Key Industrial Applications of tear mender instant fabric and leather adhesive

| Industry/Sector | Specific Application of Tear Mender Instant Fabric and Leather Adhesive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Repairing damaged fabric during production processes | Reduces waste and enhances production efficiency | Bulk purchasing options, eco-friendly certifications, and lead times |

| Automotive Upholstery | Mending tears in car seats and interior fabrics | Improves customer satisfaction by providing quick repairs | Compatibility with various materials, durability under UV exposure |

| Sports Equipment | Fixing rips in sports gear such as jerseys and equipment bags | Extends the lifespan of expensive gear, reducing replacement costs | Waterproof properties, ease of application, and drying time |

| Furniture Repair | Repairing upholstery tears in chairs and sofas | Enhances product longevity and customer retention | Non-toxic formulation, flexibility in application, and bulk pricing |

| Marine Industry | Mending canvas awnings and boat covers | Protects assets from environmental damage, ensuring longevity | Resistance to water and UV, compliance with marine safety standards |

How is Tear Mender Used in Textile Manufacturing?

In the textile manufacturing sector, Tear Mender instant fabric adhesive plays a crucial role in repairing damaged fabric during production. By quickly mending tears or defects, manufacturers can minimize waste and ensure that materials are utilized efficiently. This not only improves production efficiency but also contributes to sustainability efforts by reducing fabric wastage. For B2B buyers in this sector, considerations such as bulk purchasing options and eco-friendly certifications are vital to align with corporate social responsibility goals.

What Role Does Tear Mender Play in Automotive Upholstery?

In the automotive upholstery industry, Tear Mender is used to repair tears in car seats and interior fabrics. The quick-drying, flexible adhesive allows automotive service providers to offer immediate repairs, enhancing customer satisfaction and loyalty. With the high costs associated with replacing upholstery, this adhesive provides a cost-effective solution. Buyers in this field should prioritize the adhesive’s compatibility with various materials and its durability under UV exposure to ensure long-lasting results.

How Does Tear Mender Benefit Sports Equipment Repair?

The sports equipment sector benefits significantly from the use of Tear Mender for fixing rips in jerseys and equipment bags. By extending the lifespan of high-value sports gear, teams and organizations can save on replacement costs, making it a financially sound choice. The adhesive’s waterproof properties and ease of application are crucial for busy sports facilities needing quick fixes. B2B buyers should focus on the adhesive’s drying time and performance under various weather conditions to meet the demands of outdoor sports.

Why is Tear Mender Important for Furniture Repair?

In the furniture repair industry, Tear Mender is essential for mending upholstery tears in chairs and sofas. This not only enhances the longevity of furniture but also aids in customer retention by providing efficient and effective repair solutions. The non-toxic formulation ensures safety for both technicians and customers, making it a preferred choice. Buyers should consider factors such as flexibility in application and bulk pricing to optimize repair processes while maintaining quality.

How is Tear Mender Used in the Marine Industry?

In the marine industry, Tear Mender is utilized for mending canvas awnings and boat covers, protecting these assets from environmental damage. Its waterproof and UV-resistant properties ensure that repairs last longer, safeguarding investments in marine equipment. For B2B buyers in this sector, compliance with marine safety standards and the adhesive’s resistance to harsh conditions are critical factors to consider when sourcing materials for repair and maintenance.

3 Common User Pain Points for ‘tear mender instant fabric and leather adhesive’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Adhesive for Diverse Materials

The Problem:

B2B buyers in sectors such as upholstery, fashion, or textile manufacturing often face challenges in selecting the right adhesive that can effectively bond various materials. For instance, a furniture manufacturer may need to repair leather upholstery but also frequently works with canvas and other fabrics. Choosing an adhesive that works across these diverse materials can be daunting, particularly when considering factors like flexibility, durability, and washability. Missteps in adhesive selection can lead to product failures, increased costs, and dissatisfied customers.

The Solution:

To effectively address this challenge, buyers should focus on sourcing Tear Mender Instant Fabric and Leather Adhesive due to its versatile formula that bonds well with both porous and non-porous materials. When specifying this adhesive, it’s essential to highlight its non-toxic, eco-friendly properties, which appeal to modern consumers and businesses alike. For optimal results, buyers should conduct a small-scale test on each material type before full application. This not only validates the adhesive’s performance but also allows for adjustments in application techniques based on the material’s characteristics. Additionally, leveraging the how-to videos available on the Tear Mender website can provide practical insights into application methods that maximize adhesion strength for different fabrics.

Scenario 2: Concerns Over Long-Term Durability and Performance

The Problem:

Buyers in industries that rely heavily on fabric and leather repairs—such as fashion retail or outdoor gear—often worry about the long-term durability of adhesive solutions. A common scenario involves a retailer needing to repair returned items that have sustained minor damage. They require assurance that the repairs will last through multiple washes and everyday wear, ensuring customer satisfaction and reducing the frequency of returns due to failed repairs.

The Solution:

To mitigate concerns regarding durability, B2B buyers should emphasize the features of Tear Mender that ensure long-lasting performance. The adhesive sets quickly, forming a strong bond that is both waterproof and UV resistant, allowing repaired items to withstand regular use and exposure to elements. Buyers should communicate these benefits to their teams and customers, providing confidence in the repairs. Additionally, implementing a standard operating procedure for applying Tear Mender, which includes allowing the adhesive to cure fully (up to 30 minutes for non-breathable materials), can further enhance the longevity of repairs. Documenting successful repair cases can also serve as a valuable marketing tool to assure customers of the product’s reliability.

Scenario 3: Limited Knowledge and Expertise in Adhesive Application

The Problem:

In industries such as manufacturing or retail, staff may lack the necessary training or experience in adhesive application, leading to improper usage and suboptimal results. For example, a clothing manufacturer may employ staff who are skilled in sewing but are not as proficient in using adhesives like Tear Mender. This gap in knowledge can result in wasted materials, increased labor costs, and ultimately, product returns due to poor repairs.

Illustrative image related to tear mender instant fabric and leather adhesive

The Solution:

To overcome the knowledge gap, companies should invest in training sessions focused on the correct application of Tear Mender Instant Fabric and Leather Adhesive. These sessions can include hands-on demonstrations and best practice guidelines, emphasizing techniques such as applying the adhesive in thin layers and pressing materials together effectively. Furthermore, creating easy-to-follow reference guides or checklists for staff can streamline the repair process and ensure consistent results. Utilizing the available how-to videos from Tear Mender can also serve as an excellent supplementary resource, allowing staff to learn at their own pace and revisit techniques as needed. By prioritizing training, businesses can enhance efficiency, reduce errors, and ultimately improve product quality.

Strategic Material Selection Guide for tear mender instant fabric and leather adhesive

What Are the Key Materials Compatible with Tear Mender Instant Fabric and Leather Adhesive?

When selecting materials for use with Tear Mender Instant Fabric and Leather Adhesive, it is essential to consider the compatibility and performance characteristics of various substrates. Below, we analyze four common materials that are frequently repaired or bonded using this adhesive, providing insights relevant to international B2B buyers.

How Does Cotton Fabric Perform with Tear Mender Adhesive?

Key Properties: Cotton is a natural fiber known for its breathability and softness. It can withstand moderate temperatures but may degrade under prolonged exposure to high heat.

Pros & Cons: Cotton’s durability is generally good, making it suitable for a variety of applications, including apparel and home textiles. However, it can be prone to shrinkage and fading over time, particularly when washed frequently. The cost of cotton is relatively low, but the manufacturing process can vary significantly depending on the quality and source.

Impact on Application: Cotton fabrics are compatible with Tear Mender, allowing for quick repairs on clothing and upholstery. The adhesive bonds effectively, providing a flexible and washable repair.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the cotton used meets local quality standards, such as ASTM D5034 for breaking strength. Additionally, eco-friendly certifications may be preferred in European markets.

What About Synthetic Fabrics Like Polyester?

Key Properties: Polyester is a synthetic fiber known for its strength, durability, and resistance to shrinking and stretching. It can withstand higher temperatures than cotton but may be susceptible to UV degradation over time.

Pros & Cons: The durability of polyester makes it a popular choice for outdoor applications, such as tents and awnings. However, it can be more expensive than cotton and may require special care during manufacturing and bonding processes. Tear Mender can bond well with polyester, but users must be cautious of its compatibility with high-content polyester blends.

Impact on Application: Polyester fabrics benefit from the quick-drying and flexible nature of Tear Mender, making it ideal for repairing sports gear and outdoor textiles.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ISO 13934 for tensile strength, especially when sourcing polyester from different regions.

How Does Leather Interact with Tear Mender Adhesive?

Key Properties: Leather is a natural material known for its durability and flexibility. It can withstand a wide range of temperatures and is generally resistant to wear and tear.

Pros & Cons: Leather’s strength makes it suitable for high-end products like jackets and furniture. However, it can be costly, and the manufacturing process often requires specialized skills. Tear Mender provides a strong bond for leather repairs, but users should note that it may take longer to cure compared to fabric.

Impact on Application: Tear Mender is effective for mending leather items, offering a quick and permanent solution for repairs on shoes, bags, and upholstery.

Considerations for International Buyers: Buyers should ensure that the leather used complies with local environmental regulations regarding tanning and treatment processes, especially in regions like Europe where sustainability is a priority.

What Role Does Canvas Play in Tear Mender Applications?

Key Properties: Canvas is a heavy-duty fabric made from cotton or synthetic fibers, known for its strength and durability. It is often used in outdoor applications and can withstand various weather conditions.

Pros & Cons: The durability of canvas makes it ideal for items like tents and backpacks. However, its weight can make it less suitable for lightweight applications. The cost of canvas can vary based on the material composition and quality.

Impact on Application: Tear Mender adheres well to canvas, making it an excellent choice for repairing outdoor gear and heavy-duty items.

Considerations for International Buyers: Buyers should be aware of the specific standards for outdoor fabrics, such as ASTM D751 for water resistance, particularly in regions with variable climates like the Middle East.

Summary Table of Material Selection

| Material | Typical Use Case for tear mender instant fabric and leather adhesive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Apparel, home textiles, upholstery | Breathable and soft | Prone to shrinkage and fading | Low |

| Polyester | Sports gear, outdoor textiles | High durability and strength | More expensive, care required | Medium |

| Leather | High-end products, shoes, bags, upholstery | Strong bond and flexibility | Higher cost, longer curing time | Alta |

| Canvas | Tents, backpacks, heavy-duty items | Excellent for outdoor applications | Heavier weight may limit use cases | Medium |

This analysis provides a comprehensive overview of the materials compatible with Tear Mender Instant Fabric and Leather Adhesive, offering valuable insights for B2B buyers across various regions. Understanding the properties, pros, cons, and compliance considerations will help in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for tear mender instant fabric and leather adhesive

What Are the Main Stages in the Manufacturing Process of Tear Mender Instant Fabric and Leather Adhesive?

The production of Tear Mender Instant Fabric and Leather Adhesive involves several critical stages, ensuring that the final product meets the high standards expected in the market.

Material Preparation

The first step in the manufacturing process is the careful selection and preparation of raw materials. The primary ingredients include non-toxic polymers and bonding agents that provide the adhesive with its unique properties—such as quick-drying, flexibility, and waterproof characteristics. Suppliers of these raw materials are typically vetted for quality to ensure compliance with international standards, particularly for non-toxic and eco-friendly certifications.

Forming the Adhesive

Once the materials are prepared, they undergo a mixing process where specific ratios of the ingredients are combined. This stage often involves advanced machinery that ensures uniformity and consistency in the mixture. The adhesive is then subjected to a controlled environment to facilitate optimal bonding properties. During this phase, techniques such as high-shear mixing may be employed to achieve a homogenous blend, which is crucial for the adhesive’s performance.

Assembly and Packaging

After forming, the adhesive is transferred to filling machines where it is dispensed into various container sizes—ranging from 2 oz to 32 oz bottles. Each container is then sealed, labeled, and packaged for distribution. Automation plays a significant role in this stage to minimize human error and enhance efficiency.

Finishing Touches

The final stage includes quality checks and the application of any necessary finishes. This can involve adding UV-resistant properties or ensuring that the adhesive is machine washable. The products are then stored in a controlled environment until they are ready for shipment.

How Is Quality Assurance Implemented in the Production of Tear Mender Adhesive?

Quality assurance (QA) is a critical aspect of the manufacturing process for Tear Mender, as it ensures that each batch meets the established standards for performance and safety.

What International Standards Govern Quality Assurance?

Tear Mender’s manufacturing processes adhere to several international standards, including ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has a systematic approach to quality management, encompassing all aspects from raw material sourcing to customer satisfaction. Additionally, certifications such as CE mark and compliance with the American National Standards Institute (ANSI) may apply, particularly for products sold in international markets.

What Are the Key Quality Control Checkpoints?

To maintain high-quality standards, the production process incorporates multiple quality control checkpoints:

Illustrative image related to tear mender instant fabric and leather adhesive

-

Incoming Quality Control (IQC): This initial inspection verifies that all raw materials meet predefined specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as viscosity and drying time are monitored to ensure consistency. This stage allows for real-time adjustments to the process if any discrepancies are detected.

-

Final Quality Control (FQC): Once the adhesive is packaged, a final inspection ensures that the product meets all safety and performance specifications. Testing methods may include tensile strength tests, drying time assessments, and environmental resistance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is paramount.

What Audits and Reports Should Buyers Request?

Buyers should request access to the supplier’s quality management system documentation, including ISO certifications and internal audit reports. Regular third-party audits conducted by reputable organizations can also provide insights into the supplier’s adherence to quality standards.

What Role Does Third-Party Inspection Play?

Engaging a third-party inspection service can further assure buyers of product quality. These services can conduct unannounced inspections during the manufacturing process and provide independent verification of compliance with safety and quality standards.

Illustrative image related to tear mender instant fabric and leather adhesive

What Testing Methods Are Commonly Used for Quality Assurance?

Testing methods employed in quality assurance for Tear Mender Adhesive include:

-

Tensile Strength Testing: Evaluates the adhesive’s bonding capability under stress.

-

Water Resistance Testing: Assesses the adhesive’s performance when exposed to moisture, ensuring it meets waterproof claims.

-

UV Resistance Testing: Determines how well the adhesive withstands UV exposure, critical for products intended for outdoor use.

What Nuances Should International Buyers Be Aware Of Regarding Quality Control?

International buyers must navigate varying regulations and standards across different regions. For instance, products exported to the European market may require additional certifications, such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) compliance, which is not always necessary in other markets.

Moreover, cultural and logistical differences can affect supply chain transparency. Building strong relationships with suppliers and maintaining open communication channels are essential for ensuring quality throughout the procurement process.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Tear Mender Instant Fabric and Leather Adhesive is crucial for international B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they source products that meet their quality standards while also adhering to relevant international regulations. This knowledge not only enhances trust in supplier relationships but also contributes to the long-term success of their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tear mender instant fabric and leather adhesive’

This practical sourcing guide is designed for international B2B buyers interested in procuring Tear Mender Instant Fabric and Leather Adhesive. It provides a step-by-step checklist to help you make informed purchasing decisions, ensuring you acquire a high-quality product that meets your business needs.

Step 1: Identify Your Specific Needs

Before sourcing, clearly define your requirements. Consider the types of materials you will be repairing, such as leather, denim, or upholstery. Understanding your specific needs helps in selecting the right variant, such as the 2 oz or 32 oz bottles, and ensures compatibility with your applications.

Illustrative image related to tear mender instant fabric and leather adhesive

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of Tear Mender products. Look for manufacturers with a proven track record in fabric adhesives, as well as those with experience in international shipping, particularly to your target regions like Africa, South America, or Europe. Check online marketplaces, manufacturer websites, and industry trade shows for reputable suppliers.

Step 3: Evaluate Product Specifications

Examine the technical specifications of Tear Mender products. Key attributes to consider include:

– Bonding Time: Tear Mender bonds in just 3 minutes, making it ideal for quick repairs.

– Durability: Ensure the adhesive is waterproof, UV resistant, and machine washable, which is crucial for long-lasting repairs.

Understanding these features will help you assess whether the product meets your operational standards.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples from shortlisted suppliers. Testing the adhesive on your specific materials will allow you to evaluate its effectiveness and ease of use. Pay attention to how it adheres to various fabrics and whether it meets your quality expectations.

Step 5: Verify Supplier Credentials

Ensure that your potential suppliers have the necessary certifications and quality assurances. Look for:

– ISO Certifications: These indicate adherence to international quality management standards.

– Safety Data Sheets (SDS): Confirm that the product is non-toxic and safe for use in your intended applications.

Validating these credentials reduces the risk of sourcing from unreliable suppliers.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, minimum order quantities, and delivery timelines. Establish clear terms that include payment methods, shipping costs, and return policies. Effective negotiation can lead to better pricing and favorable terms, benefiting your overall procurement strategy.

Illustrative image related to tear mender instant fabric and leather adhesive

Step 7: Plan for Logistics and Distribution

Consider the logistics involved in receiving your order. Ensure that the supplier can meet your delivery timelines and that you have a reliable distribution plan in place. This is particularly important when dealing with international shipments, as customs regulations and transit times may impact your supply chain.

By following this checklist, you can streamline the procurement process for Tear Mender Instant Fabric and Leather Adhesive, ensuring that you make well-informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for tear mender instant fabric and leather adhesive Sourcing

In the competitive landscape of fabric and leather adhesives, understanding the cost structure and pricing dynamics of Tear Mender Instant Fabric and Leather Adhesive is crucial for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and practical tips for optimizing procurement strategies.

What Are the Key Cost Components of Tear Mender Instant Fabric and Leather Adhesive?

The cost structure for Tear Mender includes several vital components:

-

Materials: The primary ingredients in Tear Mender’s formulation are non-toxic, eco-friendly compounds that provide a strong bond. The sourcing of these materials can fluctuate based on availability, quality, and environmental regulations.

-

Labor: Labor costs encompass the wages for workers involved in production, packaging, and quality control. Efficient labor practices can mitigate costs, especially in regions with varying wage standards.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. A well-managed overhead can significantly influence the overall pricing strategy.

-

Tooling: Initial setup costs for production lines and molds can be substantial. However, these costs are amortized over large production runs, impacting pricing based on order volume.

-

Quality Control (QC): Strict QC processes ensure that each batch meets safety and performance standards, which can add to operational costs but is essential for maintaining brand integrity.

-

Logistics: Transportation and warehousing costs play a critical role, especially for international shipping. Factors such as distance, shipping methods, and customs duties can significantly affect the final price.

-

Margin: The manufacturer’s margin, which reflects profit expectations, will also influence pricing. This varies depending on market positioning and competition.

How Do Price Influencers Affect the Cost of Tear Mender Adhesive?

Several factors can influence the pricing of Tear Mender Adhesive:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom formulations or packaging may increase costs. Buyers should clarify their requirements early to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or specific certifications (e.g., eco-friendly) can lead to increased costs. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: Reliability, reputation, and the supplier’s location can impact pricing. Engaging with reputable suppliers who offer consistent quality can reduce long-term costs.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for budgeting total costs. These terms define who bears the shipping costs and risks, impacting overall expenditure.

What Tips Can Help Buyers Optimize Their Procurement Strategy?

To maximize the value derived from sourcing Tear Mender products, consider the following tips:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for bulk orders or long-term contracts. Leverage your purchasing power to secure better terms.

-

Focus on Cost-Efficiency: Calculate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential waste. This holistic view can reveal more cost-effective options.

-

Understand Pricing Nuances for International Purchases: Buyers in regions like Africa or South America should account for exchange rates, tariffs, and local market conditions that may affect pricing. Researching local suppliers may provide competitive advantages.

-

Stay Informed on Market Trends: Regularly monitor market trends in adhesive production and pricing fluctuations. This knowledge can provide leverage during negotiations and help identify the best times to purchase.

By comprehensively analyzing these cost components and price influencers, B2B buyers can make informed decisions when sourcing Tear Mender Instant Fabric and Leather Adhesive, ensuring they achieve the best value for their investments.

Alternatives Analysis: Comparing tear mender instant fabric and leather adhesive With Other Solutions

Exploring Alternatives to Tear Mender Instant Fabric and Leather Adhesive

In the realm of fabric and leather repair, various solutions exist that cater to different needs and preferences. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational requirements and budget constraints. Below is a comparative analysis of Tear Mender Instant Fabric and Leather Adhesive against two viable alternatives: fabric repair tape and contact cement.

| Comparison Aspect | Tear Mender Instant Fabric And Leather Adhesive | Fabric Repair Tape | Contact Cement |

|---|---|---|---|

| Performance | Bonds porous materials quickly (3 minutes); waterproof and flexible | Quick fixes but less durable; best for temporary repairs | Strong bond; suitable for heavy-duty applications |

| Cost | $8.99 (2 oz), $32.99 (32 oz) | $5-$10 per roll | $10-$20 per tube |

| Ease of Implementation | Easy to use; requires minimal tools | Simple application; no drying time needed | Requires careful application; can be messy |

| Maintenance | Low; long-lasting bond with no special care needed | Low; can be removed easily but may need frequent replacement | Moderate; requires proper storage and application techniques |

| Best Use Case | Ideal for permanent repairs on clothing, upholstery, and leather | Best for quick, temporary fixes on non-porous surfaces | Excellent for bonding non-porous materials like wood and metal |

What Are the Pros and Cons of Fabric Repair Tape?

Fabric repair tape offers a quick and straightforward solution for minor repairs. Its primary advantage lies in its ease of use; simply peel and stick, and no drying time is required. This makes it ideal for urgent fixes, especially in environments where time is critical, such as in retail or hospitality settings. However, the durability of fabric repair tape is often a concern; it may not withstand repeated washings or heavy wear, making it a less suitable choice for long-term repairs.

How Does Contact Cement Compare in Performance?

Contact cement is renowned for its strong bonding capabilities, making it a preferred choice for heavy-duty applications. It forms a robust bond with a variety of materials, including fabric, leather, and even wood. The downside, however, is that it can be messy to apply and requires precise handling to avoid unwanted adhesion. Additionally, contact cement typically requires more time to set compared to Tear Mender, which could slow down repair processes in fast-paced environments.

Conclusion: How Should B2B Buyers Choose the Right Repair Solution?

When selecting the right adhesive solution, B2B buyers should consider the specific needs of their operations. For businesses focused on quick, temporary repairs, fabric repair tape may suffice. However, for those seeking a reliable, long-lasting bond, especially in sectors like fashion or upholstery manufacturing, Tear Mender Instant Fabric and Leather Adhesive stands out as a superior option. Contact cement may appeal to industries requiring robust bonds for heavy-duty applications, but it demands a more careful application process. Ultimately, assessing factors such as performance, cost, ease of use, and maintenance will guide buyers toward the most effective solution for their unique repair challenges.

Essential Technical Properties and Trade Terminology for tear mender instant fabric and leather adhesive

What Are the Key Technical Properties of Tear Mender Instant Fabric and Leather Adhesive?

Understanding the essential technical properties of Tear Mender Instant Fabric and Leather Adhesive is crucial for B2B buyers in industries ranging from textile manufacturing to retail. Here are some of the critical specifications that define this product:

-

Bonding Time: Tear Mender is designed to bond porous materials within 3 minutes, making it an efficient solution for quick repairs. This rapid setting time is particularly important for businesses that require immediate results, such as clothing manufacturers or repair shops, minimizing downtime and enhancing productivity.

-

Water Resistance: This adhesive is waterproof, ensuring that repairs hold up even when exposed to moisture. For businesses involved in outdoor apparel or marine applications, the ability to withstand water is vital, as it guarantees durability and extends the lifespan of repaired items.

-

Flexibilidad: The adhesive maintains flexibility after curing, allowing for movement without cracking or breaking the bond. This property is essential for applications in apparel and upholstery, where fabric needs to stretch and flex without compromising the repair.

-

UV Resistance: Tear Mender is resistant to UV light, which prevents degradation from sun exposure. This feature is particularly beneficial for outdoor products, ensuring that repairs remain intact and visually appealing over time, thus enhancing customer satisfaction.

-

Non-Toxic Formulation: The non-toxic and eco-friendly formula makes it safe for use in various environments, including schools and homes. This aspect appeals to businesses that prioritize sustainability and health-conscious practices, which can be a competitive advantage in today’s market.

What Are the Common Trade Terminology and Concepts Related to Tear Mender?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to Tear Mender and similar products:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality adhesives that meet specific manufacturing standards.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers to know, as it affects inventory management and cash flow. For example, Tear Mender may have an MOQ that aligns with bulk purchasing, making it more economical for businesses to stock up.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Buyers should prepare a detailed RFQ when seeking Tear Mender to ensure they receive accurate pricing and availability information tailored to their needs.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is vital for B2B transactions involving Tear Mender, as they dictate costs, risks, and logistics involved in transporting the adhesive from supplier to buyer.

-

Lead Time: This refers to the amount of time from placing an order to its delivery. For businesses, knowing the lead time for Tear Mender is essential for planning and inventory management, particularly if the adhesive is critical for ongoing production processes.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their respective markets.

Navigating Market Dynamics and Sourcing Trends in the tear mender instant fabric and leather adhesive Sector

What Are the Current Market Dynamics and Key Trends in the Tear Mender Instant Fabric and Leather Adhesive Sector?

The global market for instant fabric and leather adhesives, including Tear Mender, is experiencing significant growth, driven by increasing demand for quick and effective repair solutions across various sectors such as apparel, upholstery, and outdoor gear. Key trends include a surge in DIY culture, amplified by social media platforms showcasing innovative repair techniques. This trend is particularly strong in regions like Africa and South America, where economic factors encourage consumers to extend the life of their products.

Furthermore, the rise of e-commerce has transformed the sourcing landscape for international B2B buyers. Suppliers are leveraging digital platforms to reach wider audiences, making it easier for businesses in developing countries to access high-quality adhesives. Additionally, advancements in adhesive technology are leading to products that are not only more effective but also versatile, catering to a broader range of materials and applications.

Illustrative image related to tear mender instant fabric and leather adhesive

Emerging market dynamics also reveal a growing preference for non-toxic and eco-friendly adhesives, aligning with global health and safety standards. This trend is particularly relevant for buyers in the Middle East and Europe, where regulatory frameworks increasingly emphasize the importance of sustainable materials.

How Is Sustainability and Ethical Sourcing Shaping the Tear Mender Adhesive Market?

Sustainability is becoming a critical consideration for B2B buyers in the fabric and leather adhesive sector. With rising awareness of environmental issues, companies are prioritizing products that minimize ecological impact. Tear Mender’s non-toxic, eco-friendly formula positions it favorably in this context, appealing to businesses seeking to align with sustainable practices.

Ethical sourcing is another crucial aspect, as buyers increasingly demand transparency in supply chains. This shift is particularly pronounced in regions like Europe, where consumers are more informed about the origins of the products they purchase. Suppliers who can demonstrate sustainable practices and certifications, such as eco-labels, are likely to gain a competitive edge.

Illustrative image related to tear mender instant fabric and leather adhesive

The emphasis on sustainability extends to packaging as well. Buyers are seeking suppliers who utilize recyclable materials and minimize waste in their operations. For international buyers, especially those in emerging markets, aligning with brands that prioritize these values can enhance their corporate image and consumer trust.

What Is the Historical Context of Tear Mender Instant Fabric and Leather Adhesive?

Tear Mender has a rich history dating back to 1932, when it was first developed to provide a reliable solution for fabric and leather repairs. Initially targeting consumers in the U.S., the product quickly gained popularity due to its effectiveness and ease of use. Over the decades, it has evolved to meet changing consumer needs, adapting to advancements in material science and shifting market demands.

Today, Tear Mender is recognized as a trusted brand not just in North America, but also gaining traction in international markets, including Africa and South America. Its focus on non-toxic ingredients and versatility has solidified its reputation as a go-to solution for both personal and professional use, further enhancing its appeal to B2B buyers looking for reliable and sustainable adhesive options.

In summary, understanding the market dynamics, sustainability imperatives, and historical context of Tear Mender can significantly inform B2B buyers’ sourcing strategies and product offerings, ultimately leading to more informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of tear mender instant fabric and leather adhesive

-

How do I solve issues with fabric and leather repairs in my business?

Tear Mender Instant Fabric and Leather Adhesive is an effective solution for various repair needs, whether for upholstery, apparel, or sporting gear. Its quick-drying formula sets in just three minutes, allowing for rapid repairs that can withstand washing and wear. To optimize the adhesive’s performance, ensure surfaces are clean and apply a thin layer, pressing the materials together securely. For tougher materials, consider using a patch underneath for added strength. This versatility helps reduce downtime and maintain product quality in your offerings. -

What is the best adhesive for repairing leather and fabric?

Tear Mender Instant Fabric and Leather Adhesive stands out as a top choice for repairing both leather and fabric due to its non-toxic, waterproof, and UV-resistant properties. It provides a permanent bond that is flexible, making it suitable for various applications from clothing to upholstery. The adhesive is easy to use, dries quickly, and is machine washable, making it an ideal solution for businesses needing reliable repair options. When sourcing, consider the volume of usage and specific applications to ensure it meets your operational needs. -

What are the minimum order quantities (MOQ) for Tear Mender products?

The minimum order quantity for Tear Mender products typically depends on the specific item and supplier. For bulk purchases, many suppliers offer shelf packs or cases, with increments often starting at three units. It’s crucial to communicate with your supplier to understand their MOQ policies, especially when importing to regions such as Africa, South America, or the Middle East. This ensures you can meet your business demands while managing inventory effectively. -

What payment terms can I expect when purchasing Tear Mender products internationally?

Payment terms for international orders of Tear Mender products can vary by supplier and region. Common practices include upfront payment, partial payment with the balance upon delivery, or net terms (e.g., net 30 days). It’s advisable to clarify these terms before placing an order to avoid misunderstandings. Establishing a good relationship with your supplier may also provide opportunities for more favorable payment arrangements as your business grows. -

How can I ensure the quality of Tear Mender products before purchasing?

To ensure product quality, request samples from suppliers before committing to a bulk order. Conducting your own testing on various fabric and leather types will help assess the adhesive’s performance. Additionally, reviewing certifications and quality assurance processes from the manufacturer can provide insight into their production standards. Engaging with other B2B buyers and reading reviews can also offer valuable information regarding the reliability of the product. -

What logistics considerations should I keep in mind when sourcing Tear Mender?

When sourcing Tear Mender products internationally, consider shipping costs, lead times, and customs regulations specific to your region. Understanding the logistics involved can help you plan better and avoid delays. For example, opting for suppliers with established shipping partnerships can streamline the import process. Be sure to factor in potential tariffs or duties that may apply to your shipment, especially when importing to countries with strict import regulations. -

Can Tear Mender products be customized for specific business needs?

Customization options for Tear Mender products may be available depending on the supplier. This could include private labeling or packaging that aligns with your brand. It is essential to discuss your specific needs with potential suppliers early in the negotiation process. This approach can help you create a unique product offering tailored to your market while enhancing brand recognition. -

What are the common applications of Tear Mender in various industries?

Tear Mender is used across several industries, including fashion, upholstery, marine, and sports. It effectively repairs clothing, leather goods, outdoor gear, and home decor items. Its versatility makes it a valuable product for businesses in retail, manufacturing, and repair services. Understanding the various applications can help you identify new opportunities for using Tear Mender in your business, enhancing your service offerings and customer satisfaction.

A Look at Tear Mender Instant Fabric And Leather Adhesive Manufacturers & Suppliers

Could not verify enough suppliers for tear mender instant fabric and leather adhesive to create a list at this time.

Strategic Sourcing Conclusion and Outlook for tear mender instant fabric and leather adhesive

In today’s competitive landscape, effective strategic sourcing of Tear Mender Instant Fabric and Leather Adhesive can significantly enhance operational efficiency and customer satisfaction for businesses across various sectors. With its rapid bonding capabilities—setting in just three minutes—and robust, non-toxic formulation, Tear Mender is an invaluable asset for companies involved in textile manufacturing, leather goods production, and repair services. The versatility of this adhesive extends to multiple applications, from household items to outdoor gear, enabling businesses to meet diverse customer needs while reducing downtime and repair costs.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, embracing strategic sourcing practices can unlock new opportunities for growth and innovation. By prioritizing quality products like Tear Mender, businesses can not only enhance their service offerings but also foster long-term relationships with their clients through reliable solutions.

Looking ahead, we encourage buyers to leverage the benefits of strategic sourcing and explore the vast potential of Tear Mender Instant Fabric and Leather Adhesive. Investing in quality adhesives will not only streamline operations but also position your business as a leader in durability and customer satisfaction. Reach out today to discover how Tear Mender can transform your repair processes and elevate your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to tear mender instant fabric and leather adhesive

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.