Catalog

Material Insight: Custom Leather Works

B2B Product Guide: Custom Leather Works

Custom leather works serve a vital role across industries such as furniture, automotive interiors, fashion accessories, and hospitality, where tailored design, durability, and aesthetic precision are paramount. Whether for branded upholstery, specialty packaging, or high-end interior finishes, custom leather applications demand materials that offer consistency, design flexibility, and long-term performance. In this context, the choice of material significantly impacts both production efficiency and end-product quality.

Faux leather has emerged as the optimal solution for custom leather works due to its superior versatility and sustainable advantages over natural leather. Unlike animal hides, faux leather provides uniform texture and thickness, reducing waste during cutting and enabling precise replication across large production runs. It is also highly customizable—available in a wide range of colors, finishes, textures, and performance properties such as water resistance, UV stability, and abrasion resistance. Additionally, faux leather supports eco-conscious manufacturing, as it eliminates the environmental burden associated with livestock farming and toxic tanning processes.

WINIW is a leading innovator in high-performance synthetic leather, with over 20 years of expertise in developing tailored solutions for global B2B clients. Our advanced production technology and deep understanding of material science allow us to deliver custom faux leather that meets exact functional and aesthetic requirements. From concept to mass production, WINIW partners with manufacturers, designers, and brands to create sustainable, durable, and premium-quality leather alternatives.

Key advantages of choosing WINIW for custom leather works:

– Consistent material quality across batches for reliable production

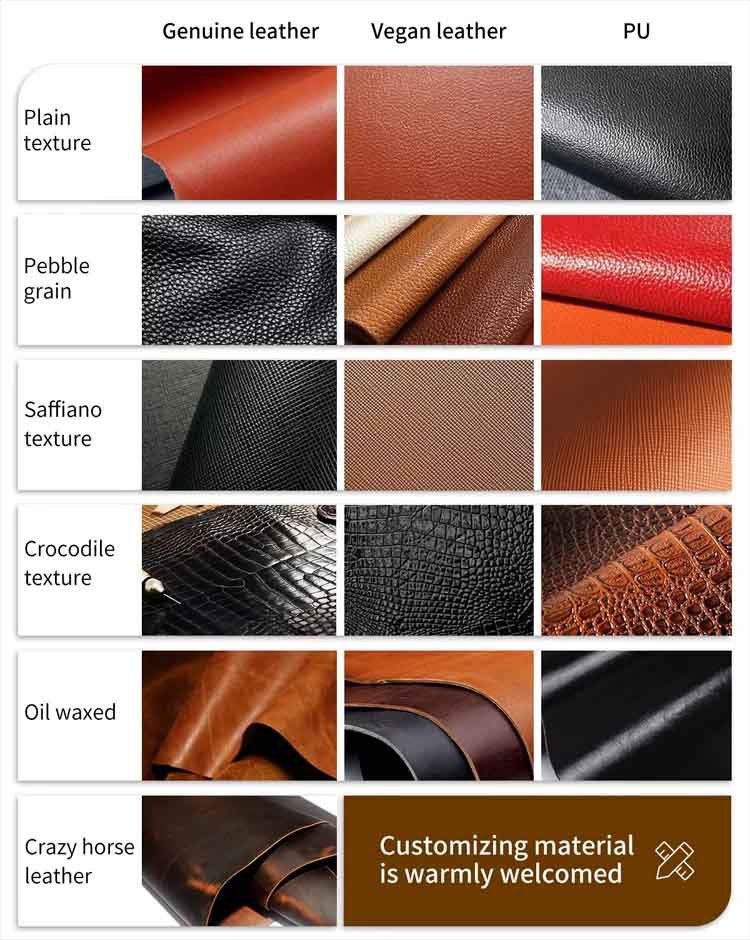

– Full customization in color, texture, thickness, and performance features

– Eco-friendly manufacturing with reduced carbon footprint and waste

– Compliance with international standards (REACH, RoHS, OEKO-TEX®)

– Fast turnaround and scalable production for global supply chains

Technical Performance & Standards

WINIW Custom Leather Works: Precision Engineered for Your Brand Success

WINIW’s Custom Leather Works platform delivers bespoke synthetic leather solutions engineered for B2B partners seeking uncompromised quality, sustainability, and operational efficiency. Moving beyond standard off-the-shelf materials, our end-to-end customization process integrates advanced manufacturing with rigorous quality control to align precisely with your product specifications, sustainability goals, and cost structures. We empower brands to differentiate through material innovation while mitigating supply chain risks.

Core Technical Advantages Driving Your ROI

- Cost-Effective Production Efficiency: Our lean manufacturing ecosystem minimizes waste through precision digital coating and cutting, reducing material scrap by up to 18% versus conventional processes. Low minimum order quantities (MOQs) and rapid color/formulation changeovers eliminate costly inventory holding, accelerating time-to-market without sacrificing unit economics.

- Engineered Durability for Longevity: WINIW substrates utilize high-tenacity polyester backing and cross-linked polyurethane matrices, achieving abrasion resistance exceeding 50,000 cycles (Martindale). This translates to 30% longer product lifespans in high-use applications (e.g., contract furniture, automotive interiors), reducing warranty claims and enhancing brand reputation for reliability.

- Unmatched Color & Finish Customization: Access 10,000+ certified color formulations with <1.5 ΔE color deviation (measured per ISO 105-A02). We support matte, gloss, embossed, and textured finishes—including vegan leather grain replication—without minimum batch sizes. Our digital color matching system ensures batch-to-batch consistency across global production runs.

- Guaranteed REACH Compliance & Chemical Safety: All Custom Leather Works formulations are rigorously screened against REACH Annex XVII restrictions. We proactively exclude SVHCs (Substances of Very High Concern) and provide full material disclosure (FMD) reports. Our phthalate-free, heavy-metal-free chemistry ensures seamless compliance for EU, US, and global markets, de-risking your supply chain.

- ISO 9001-Certified Quality Assurance: Every meter produced undergoes real-time quality monitoring under our ISO 9001:2015 certified management system. From raw material sourcing to final inspection, we implement statistical process control (SPC) to maintain <0.5% defect rates, ensuring predictable performance and reducing downstream production disruptions.

Technical Specifications: WINIW Custom Leather Works Platform

| Property | WINIW Standard | Test Method | Industry Benchmark |

|---|---|---|---|

| Abrasion Resistance | ≥ 50,000 cycles (Martindale) | ISO 12947-2 | 30,000–40,000 cycles |

| Color Fastness (Light) | Grade 7–8 (Blue Wool Scale) | ISO 105-B02 | Grade 5–6 |

| Color Fastness (Rubbing) | Dry: Grade 5 / Wet: Grade 4–5 | ISO 105-X12 | Dry: 4 / Wet: 3–4 |

| Tensile Strength | ≥ 80 N/50mm (warp & weft) | ISO 13934-1 | ≥ 60 N/50mm |

| REACH SVHC Compliance | Zero intentionally added SVHCs | Internal Screening | Varies by supplier |

| VOC Emissions | < 10 µg/g (Total VOCs) | ISO 16000-9 | < 50 µg/g typical |

| Production Lead Time | 15–20 days (post-approval) | – | 30+ days typical |

WINIW Custom Leather Works transforms material sourcing from a cost center into a strategic brand asset. By merging granular customization with uncompromised durability and regulatory assurance, we enable you to meet evolving market demands while optimizing total landed costs. Our platform is built for partners committed to sustainable growth without sacrificing performance or design integrity. Request a technical dossier and sample kit to validate performance against your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Works vs Real Leather

When sourcing materials for premium products in fashion, automotive, or furniture industries, material selection is critical. Two commonly considered options are custom leather works—often referring to high-quality synthetic or semi-synthetic leathers—and real (natural) leather. Each has distinct advantages and trade-offs in performance, cost, and sustainability.

This guide provides a professional comparison to support informed decision-making for B2B buyers focused on quality, scalability, and environmental responsibility.

Visión general

-

Custom Leather Works typically refers to engineered leather alternatives such as microfiber synthetic leather, PU leather, or composite materials designed to mimic the look and feel of real leather. These materials are customizable in texture, color, thickness, and performance attributes.

-

Real Leather is derived from animal hides (commonly bovine, ovine, or porcine) and undergoes tanning and finishing processes. It is valued for its natural grain, breathability, and aging characteristics.

While real leather has long been the standard for luxury applications, advancements in synthetic technology—especially in eco-conscious manufacturing—have positioned custom leather works as a competitive, sustainable alternative.

Comparative Analysis

The following table evaluates both material types across three key criteria: cost, durability, and eco-friendliness.

| Criteria | Custom Leather Works | Real Leather |

|---|---|---|

| Cost | – Lower to moderate upfront cost | – Higher cost due to raw material scarcity and processing |

| – Economical for bulk B2B orders | – Price volatility due to livestock and tanning costs | |

| Durabilidad | – High resistance to abrasion, UV, and moisture | – Prone to cracking and fading over time if not maintained |

| – Consistent performance across batches | – Natural variations may affect longevity | |

| – Ideal for high-use applications (e.g., automotive seating) | – Requires conditioning and care | |

| Eco-Friendliness | – Lower environmental footprint when using PU/microfiber with eco-processes | – High water and energy consumption in tanning |

| – Recyclable options available; reduced CO₂ emissions | – Chrome tanning produces hazardous waste | |

| – No animal sourcing; aligns with cruelty-free standards | – Byproduct of meat industry; raises ethical concerns |

Key Considerations for B2B Buyers

-

Scalability & Customization: Custom leather works offer greater design flexibility—ideal for brands requiring consistent color, texture, or performance enhancements (e.g., flame resistance, anti-microbial finishes).

-

Sustainability Goals: Brands committed to ESG (Environmental, Social, and Governance) targets often favor custom leather solutions that reduce reliance on animal agriculture and toxic tanning methods.

-

End-Use Application: Real leather remains preferred in luxury goods where natural aging and tactile authenticity are valued. However, custom leather works are increasingly specified in automotive interiors, commercial furniture, and performance apparel due to their reliability and lower lifecycle impact.

-

Regulatory Compliance: Custom leather works can be engineered to meet international safety and environmental standards (e.g., REACH, RoHS), supporting global market access.

Conclusion

The choice between custom leather works and real leather depends on your brand’s priorities: cost efficiency, durability under industrial use, and sustainability commitments. For forward-thinking B2B partners, custom leather works represent a technologically advanced, eco-responsible alternative without compromising on aesthetics or performance. WINIW supports this transition with innovative, customizable synthetic leather solutions designed for durability and environmental stewardship.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global B2B Partners

WINIW stands as a leading innovator in high-performance synthetic leather, engineered to meet the exacting demands of global brands and manufacturers. Our vertically integrated manufacturing ecosystem, grounded in sustainability and precision, delivers consistent quality and technical excellence for diverse applications—from luxury automotive interiors and premium upholstery to performance footwear and eco-conscious fashion.

Core Manufacturing Strengths

Our operational scale and technical expertise form the foundation of reliable, high-volume supply for international partners:

- Integrated Production Facility: Operates across a dedicated 100,000 sqm manufacturing campus, enabling end-to-end control from raw material processing to finished roll goods. This scale supports large-volume orders while maintaining agile responsiveness to custom specifications.

- Advanced R&D Center: A specialized team of 50+ material scientists and engineers drives continuous innovation, focusing on:

- Developing bio-based and recycled content formulations (up to 70% renewable resources)

- Enhancing physical properties (abrasion resistance, tear strength, color fastness)

- Creating low-VOC, water-based coating systems compliant with EU REACH and US CPSIA

- Stringent Quality Control: Multi-stage QC protocols exceed industry benchmarks:

- In-line spectrophotometer color matching (ΔE < 0.5 tolerance)

- Automated thickness and width monitoring at 0.01mm precision

- Full-batch physical testing per ISO 17698 standards (AQL 1.0 for critical defects)

- Dedicated eco-compliance lab verifying heavy metal absence and phthalate-free status

Global Supply Chain Reliability

WINIW serves Tier 1 suppliers and brands across key markets with certified, traceable logistics:

| Region | Key Certifications Maintained | Typical Lead Time | Sustainability Compliance Verified |

|---|---|---|---|

| Europe | OEKO-TEX® STANDARD 100, Blue Angel | 25-35 days | EU Ecolabel, ZDHC MRSL v3.1 |

| North America | CPSIA, California Prop 65 | 20-30 days | Greenguard Gold, BIFMA Level® 3 |

| Asia-Pacific | GRS, OEKO-TEX® STeP | 15-25 days | Japan Chemical Substances Control Law |

Our facility holds ISO 9001:2015 and ISO 14001:2015 certifications, with annual third-party audits ensuring ethical labor practices (SA8000) and closed-loop water treatment systems. By combining industrial-scale production with granular eco-technical oversight, WINIW provides B2B partners with future-proof materials that align with circular economy goals without compromising performance or delivery timelines. Partner with us for synthetics engineered for responsibility and resilience.

Contact Us for Samples

WINIW Synthetic Leather: Premium Microfiber Solutions for B2B Applications

WINIW is a leading innovator in high-performance synthetic leather, delivering sustainable, durable, and customizable microfiber materials for a wide range of industrial and commercial applications. Engineered for excellence, our products meet the rigorous demands of furniture, automotive, fashion, footwear, and interior design sectors—without compromising on aesthetics or environmental responsibility.

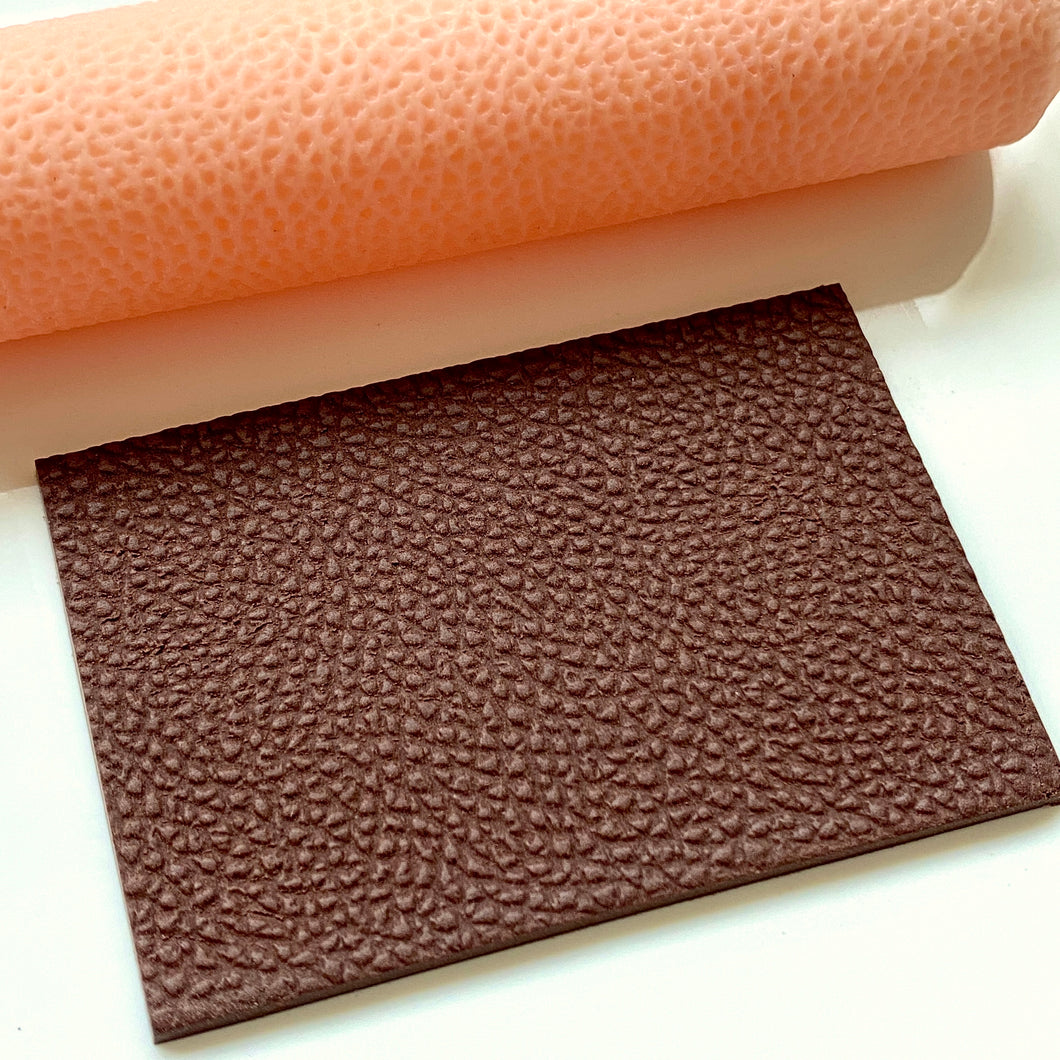

Our advanced manufacturing process produces microfiber leather that closely mimics the texture, breathability, and strength of genuine leather, while offering superior resistance to abrasion, UV rays, and wear. As a B2B partner, WINIW provides scalable solutions tailored to your production needs, ensuring consistent quality and on-time delivery.

Why Choose WINIW Synthetic Leather?

- Eco-Friendly Production: Our microfiber leather is manufactured using low-impact processes, reducing water consumption and chemical waste. Fully REACH and Oeko-Tex® compliant.

- High Durability: Exceptional tensile and tear strength ideal for high-use environments.

- Customization Options: Available in a broad spectrum of colors, textures, thicknesses, and finishes—including matte, glossy, soft-touch, and embossed patterns.

- Consistent Quality: Uniform grain structure and roll-to-roll consistency ensure seamless integration into automated production lines.

- Lightweight & Flexible: Optimized for ease of cutting, sewing, and lamination across various substrates.

- Animal-Free & Sustainable: 100% cruelty-free alternative with recyclable backing options.

Industry Applications

- Furniture & Upholstery: Ideal for sofas, chairs, and office seating with high abrasion resistance and easy maintenance.

- Automotive Interiors: Used in car seats, door panels, and steering wheels—meeting strict safety and durability standards.

- Footwear & Accessories: Offers flexibility and breathability for premium shoes, handbags, and belts.

- Apparel & Sportswear: Lightweight and stretchable variants suitable for jackets, gloves, and performance gear.

- Interior Design: Fire-retardant and antimicrobial options available for hospitality and healthcare environments.

Technical Specifications (Standard Grade)

| Property | Especificación |

|---|---|

| Thickness Range | 0.6 mm – 2.0 mm |

| Weight | 200 – 400 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness | Grade 4–5 (ISO 105-B02) |

| Tensile Strength | >25 MPa |

| Elongation at Break | >80% |

| Backing Options | Knit fabric, non-woven, PU foam |

| Certifications | REACH, OEKO-TEX® STANDARD 100 |

Custom formulations—including waterproof, anti-microbial, flame-retardant, and recyclable options—are available upon request.

Partner with Us for Custom Leather Works

WINIW specializes in end-to-end customization, from concept to production. Whether you require a unique texture, proprietary color matching, or performance-enhancing additives, our R&D team collaborates with you to develop a material solution that aligns with your brand values and technical requirements.

- Tailored thickness and width per roll (up to 2.0 m)

- Low MOQs for flexible prototyping and scaling

- Fast turnaround for sample development

- Global logistics support

Request Free Samples Today

Experience the quality and versatility of WINIW microfiber leather firsthand. We offer complimentary samples to qualified B2B partners.

Contact our marketing team to start your custom project:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable performance. Choose WINIW—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.