Introduction: Navigating the Global Market for cloth for shoes

The global market for cloth for shoes presents a unique challenge for B2B buyers seeking high-quality materials that meet diverse consumer demands. As international buyers from regions like Africa, South America, the Middle East, and Europe navigate this intricate landscape, understanding the nuances of various cloth types—ranging from microfiber to chamois—becomes essential. This guide addresses key considerations such as sourcing practices, material applications, supplier vetting processes, and cost factors, empowering businesses to make informed purchasing decisions.

In an industry where quality and durability are paramount, the right cloth can significantly enhance the performance and aesthetics of footwear products. Buyers will benefit from a comprehensive overview of the available materials, including their specific uses in cleaning, maintenance, and crafting shoes. Furthermore, insights into supplier reliability and pricing strategies will help mitigate risks associated with international procurement.

As the demand for sustainable and innovative materials continues to grow, this guide equips B2B buyers with the knowledge needed to select the best cloth for shoes that aligns with their business objectives. With actionable insights tailored to the unique needs of buyers from Nigeria to Vietnam, this resource serves as a crucial tool in navigating the complexities of the global cloth market, ensuring that businesses remain competitive and responsive to market trends.

Table Of Contents

- Top 6 Cloth For Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cloth for shoes

- Understanding cloth for shoes Types and Variations

- Key Industrial Applications of cloth for shoes

- 3 Common User Pain Points for ‘cloth for shoes’ & Their Solutions

- Strategic Material Selection Guide for cloth for shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for cloth for shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cloth for shoes’

- Comprehensive Cost and Pricing Analysis for cloth for shoes Sourcing

- Alternatives Analysis: Comparing cloth for shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for cloth for shoes

- Navigating Market Dynamics and Sourcing Trends in the cloth for shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cloth for shoes

- Strategic Sourcing Conclusion and Outlook for cloth for shoes

- Important Disclaimer & Terms of Use

Understanding cloth for shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Cloth | Highly absorbent, soft texture, quick-drying | Cleaning leather and synthetic shoes | Pros: Effective cleaning, reusable; Cons: May wear out faster than thicker fabrics. |

| Chamois Leather | Soft, supple texture, excellent for polishing | Shoe polishing and finishing touches | Pros: Superior shine, durable; Cons: Requires maintenance to keep in good condition. |

| Cotton Canvas | Breathable, durable, versatile, often used in casual shoes | Manufacturing of casual and sports shoes | Pros: Cost-effective, easy to dye; Cons: Less moisture-wicking compared to synthetics. |

| Nylon Fabric | Strong, lightweight, water-resistant | Production of athletic and outdoor footwear | Pros: High durability, easy to clean; Cons: Can be less breathable than natural fibers. |

| Denim | Sturdy, stylish, and available in various weights | Fashion-forward shoe designs | Pros: Trendy, durable; Cons: Heavier, may not suit all shoe types. |

What are the Characteristics and Suitability of Microfiber Cloth for Shoes?

Microfiber cloth is renowned for its superior absorbency and gentle texture, making it ideal for cleaning both leather and synthetic shoes. This type of cloth is particularly suitable for B2B buyers focused on shoe maintenance products, as it effectively removes dirt and grime without causing damage. When purchasing, consider the cloth’s size and durability, as these factors influence its longevity and cleaning efficacy.

How Does Chamois Leather Enhance Shoe Care?

Chamois leather is a premium material known for its softness and ability to produce a high shine on polished shoes. This cloth is widely used in B2B applications for shoe polishing services and high-end footwear maintenance. Buyers should evaluate the quality of the chamois, as it can vary significantly; investing in high-quality chamois ensures better performance and durability, ultimately enhancing the customer experience in shoe care.

Why is Cotton Canvas a Versatile Option for Shoe Manufacturing?

Cotton canvas is a durable and breathable fabric that is often utilized in the production of casual and sports shoes. Its versatility allows for easy dyeing and printing, making it a preferred choice among B2B buyers in the footwear industry looking for cost-effective materials. However, it is essential to consider that cotton canvas may not wick moisture as effectively as synthetic options, which could impact performance in certain applications.

What Advantages Does Nylon Fabric Offer for Athletic Footwear?

Nylon fabric is known for its strength, lightweight nature, and water resistance, making it a popular choice in the production of athletic and outdoor footwear. B2B buyers should prioritize nylon for its durability and ease of cleaning, which are crucial for performance-oriented shoes. However, it is important to note that nylon can be less breathable than natural fibers, so assessing the target market’s needs is vital when selecting materials.

How is Denim Used in Fashion-Forward Shoe Designs?

Denim is a trendy and robust fabric that adds a unique aesthetic to shoe designs, appealing particularly to fashion-conscious consumers. B2B buyers interested in creating stylish footwear should consider denim for its durability and versatility. However, the weight of denim may not be suitable for all shoe types, so it’s important to align the fabric choice with the intended design and market trends.

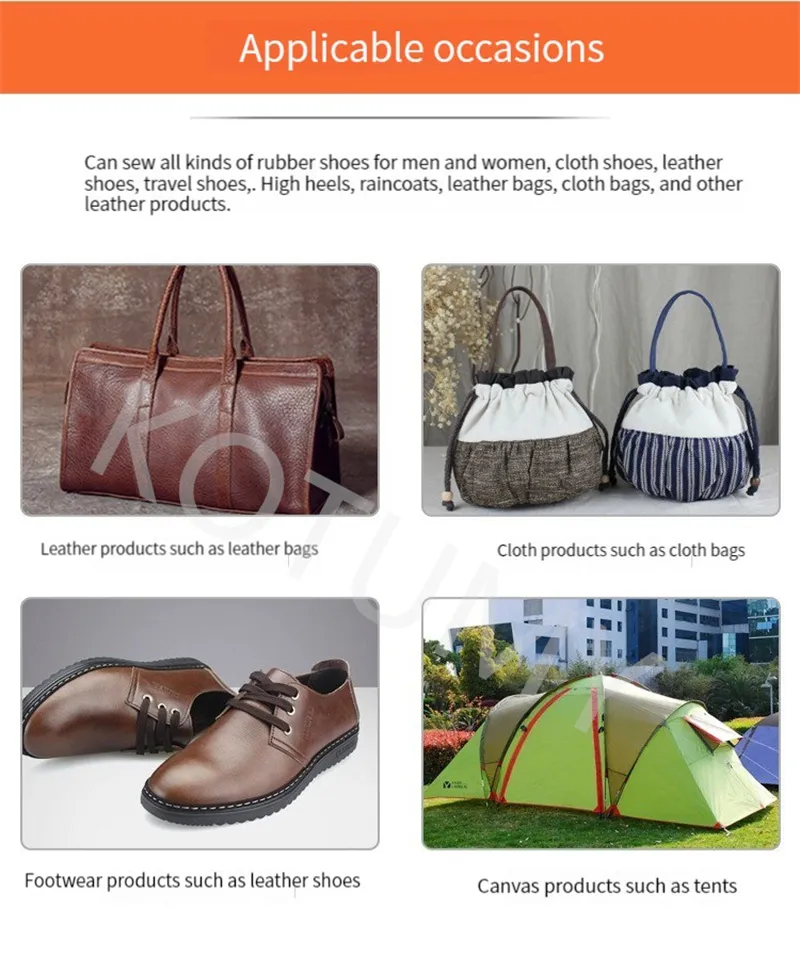

Key Industrial Applications of cloth for shoes

| Industry/Sector | Specific Application of cloth for shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Upper materials for athletic and casual shoes | Enhances product durability and performance | Material quality, weight, breathability, and cost |

| Shoe Care and Maintenance | Cleaning and polishing cloths for retail shoe care products | Promotes customer satisfaction and brand loyalty | Absorbency, softness, and durability of the cloth |

| Fashion and Apparel | Decorative and functional cloths for fashion footwear | Differentiates products in a competitive market | Trend alignment, color options, and fabric compatibility |

| Sports and Outdoor Equipment | Specialized cloth for waterproof and breathable shoes | Meets specific performance needs for outdoor activities | Weather resistance, flexibility, and comfort |

| E-commerce Retail | Packaging and protective cloths for shipping shoes | Reduces damage during transit, enhancing brand image | Cost-effectiveness, material strength, and eco-friendliness |

How is cloth for shoes utilized in footwear manufacturing, and what problems does it solve?

In the footwear manufacturing industry, cloth is predominantly used as upper materials for various shoe types, including athletic and casual footwear. These materials not only provide aesthetic appeal but also enhance the durability and performance of the shoes. Buyers should consider factors such as material quality, weight, and breathability when sourcing cloth, as these attributes directly impact the end product’s performance and customer satisfaction. In regions like Africa and South America, where weather conditions can vary, sourcing breathable and durable materials is crucial to meet consumer expectations.

What role do cloth applications play in shoe care and maintenance?

Cloth specifically designed for shoe care and maintenance serves as cleaning and polishing tools for retailers and consumers alike. These cloths are essential for maintaining the appearance and longevity of shoes, which can significantly boost customer satisfaction and brand loyalty. When sourcing these products, businesses should prioritize absorbency, softness, and durability to ensure effective cleaning without damaging the shoe materials. International buyers, particularly in the Middle East and Europe, may seek cloths that align with local preferences for quality and sustainability.

Illustrative image related to cloth for shoes

How does cloth contribute to fashion and apparel industries?

In the fashion and apparel sector, cloth is utilized for both decorative and functional purposes in footwear design. By incorporating unique fabrics and textures, brands can differentiate their products in a competitive market, appealing to style-conscious consumers. Buyers in this sector should consider trend alignment, color options, and fabric compatibility when sourcing materials. For example, European markets may favor eco-friendly fabrics, while African markets may prioritize vibrant colors and patterns that resonate with local aesthetics.

What are the specific needs for cloth in sports and outdoor equipment?

For sports and outdoor equipment, specialized cloth is essential for creating waterproof and breathable shoes that cater to active lifestyles. These materials address the specific performance needs of outdoor enthusiasts, providing comfort and protection in various weather conditions. When sourcing these cloths, businesses must focus on attributes such as weather resistance, flexibility, and comfort. International buyers, particularly from regions with diverse climates, need to ensure that the materials sourced can withstand local environmental challenges.

How does packaging with cloth enhance e-commerce retail for shoes?

In the e-commerce retail sector, cloth is often used for packaging and protecting shoes during shipping. Utilizing high-quality cloth can significantly reduce damage during transit, thereby enhancing the brand’s image and customer experience. Businesses should consider cost-effectiveness, material strength, and eco-friendliness when sourcing cloth for packaging. As online shopping grows in regions like South America and Africa, ensuring that packaging meets international shipping standards while being environmentally conscious can provide a competitive edge.

3 Common User Pain Points for ‘cloth for shoes’ & Their Solutions

Scenario 1: Difficulty in Maintaining Quality Standards for Shoe Care Products

The Problem: Many B2B buyers in the shoe manufacturing and retail sectors face the challenge of sourcing high-quality cloth for shoe care that meets their stringent quality standards. With an increasing emphasis on sustainability and performance, buyers often find that low-quality microfiber or chamois cloths do not perform well in cleaning or maintaining the integrity of shoes. This can lead to customer dissatisfaction, returns, and a negative impact on brand reputation.

Illustrative image related to cloth for shoes

The Solution: To ensure the procurement of high-quality cloth for shoe care, buyers should prioritize suppliers with a proven track record in the industry. Look for cloth made from premium microfiber, which is known for its moisture absorption and durability. When sourcing, request samples to evaluate the cloth’s texture, absorbency, and cleaning efficacy. Additionally, establishing long-term relationships with suppliers who can provide consistent quality and transparency in their sourcing practices will enable buyers to maintain high standards and improve customer satisfaction.

Scenario 2: Inconsistent Supply Chain and Availability Issues

The Problem: B2B buyers often struggle with inconsistent availability of cloth for shoes, which can disrupt production schedules and lead to delays in fulfilling customer orders. This issue is particularly prevalent for international buyers from regions like Africa and South America, where logistics and supply chain reliability can be problematic. Such disruptions can result in lost sales and strained relationships with retailers and consumers.

The Solution: To mitigate supply chain issues, B2B buyers should diversify their sourcing strategies. This may include working with multiple suppliers across different geographic locations to reduce dependency on a single source. Implementing just-in-time inventory practices can also help manage stock levels more effectively, reducing the risk of overstocking or stockouts. Additionally, buyers can negotiate long-term contracts with suppliers to ensure a more reliable supply and establish clear communication channels for real-time updates on inventory levels and expected delivery times.

Scenario 3: Lack of Knowledge About Proper Usage and Care Techniques

The Problem: Many B2B buyers may not be fully aware of how to effectively use different types of cloth for shoe care, leading to suboptimal results in cleaning and maintenance. This lack of knowledge can result in improper cleaning techniques that could damage shoes, causing financial losses and impacting customer trust. Additionally, incorrect cloth usage may not yield the desired cleaning effects, leading to increased customer complaints.

Illustrative image related to cloth for shoes

The Solution: To address the knowledge gap, B2B buyers should invest in training for their staff on the proper use of cloth for shoe care. This can include workshops led by product experts or comprehensive online training modules that cover topics such as the specific types of cloth for different materials (e.g., leather vs. synthetic), cleaning techniques, and maintenance best practices. Providing clear usage instructions and care guidelines alongside the product can also empower retailers and consumers to achieve the best results, thereby enhancing customer satisfaction and reducing the likelihood of product returns.

Strategic Material Selection Guide for cloth for shoes

When selecting materials for cloth used in shoes, it’s crucial to consider the unique properties and applications of various fabrics. Understanding the key characteristics, advantages, and limitations of these materials will help international B2B buyers make informed decisions. Below are analyses of four commonly used materials in shoe cloth, tailored for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Microfiber Cloth for Shoes?

Microfiber cloth is a synthetic material composed of ultra-fine fibers, typically made from polyester and polyamide. Its key properties include excellent moisture absorption, quick drying, and a soft texture that is gentle on surfaces. This makes it ideal for cleaning shoes without causing scratches. Microfiber is also resistant to mold and mildew, enhancing its durability in humid climates.

Pros: Microfiber is lightweight, highly absorbent, and machine washable, making it cost-effective over time. It is also versatile, suitable for various shoe materials, including leather and synthetics.

Cons: While microfiber is durable, it can be more expensive than traditional cotton cloths. Additionally, its production involves synthetic processes that may not appeal to environmentally conscious buyers.

Impact on Application: Microfiber cloth is particularly effective in regions with high humidity, where moisture management is crucial. It is compatible with various cleaning agents, enhancing its utility in shoe care.

How Does Cotton Fabric Compare for Shoe Applications?

Cotton is a natural fiber known for its breathability and comfort. It is widely used in casual footwear and lining materials. The key properties of cotton include good moisture absorption and softness, making it comfortable against the skin.

Illustrative image related to cloth for shoes

Pros: Cotton is generally less expensive than synthetic materials, making it an economical choice for mass production. It is also biodegradable, appealing to eco-friendly consumers.

Cons: Cotton is less durable than synthetic alternatives, particularly in wet conditions, where it can retain moisture and lead to mold growth. It may also require more frequent replacements.

Impact on Application: In regions with dry climates, cotton can be a suitable choice, but its limitations in moisture management may hinder its effectiveness in more humid areas.

What Are the Advantages of Synthetic Leather in Shoe Manufacturing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a leather-like appearance with added durability. Its key properties include resistance to water, stains, and UV light, making it an attractive option for various shoe styles.

Pros: Synthetic leather is often more affordable than genuine leather and can be produced in a variety of textures and colors. It is also easier to clean and maintain, which is beneficial for consumers.

Cons: While synthetic leather is durable, it may not have the same breathability as natural leather, which can affect comfort. Additionally, the environmental impact of synthetic materials can be a concern for some buyers.

Impact on Application: Synthetic leather is suitable for a wide range of climates, but its lack of breathability may be a drawback in hotter regions. Compliance with environmental regulations is also a consideration for international buyers.

Illustrative image related to cloth for shoes

How Does Canvas Fabric Fit into the Shoe Material Landscape?

Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It is known for its durability and versatility, making it a popular choice for casual shoes and sneakers.

Pros: Canvas is robust and can withstand wear and tear, making it ideal for outdoor footwear. It is also relatively inexpensive and can be easily dyed or printed, allowing for creative designs.

Cons: Canvas is less water-resistant than other materials, which can limit its use in wet conditions. It may also require special care to maintain its appearance over time.

Impact on Application: In regions with a strong outdoor culture, canvas shoes are favored for their durability. However, buyers should consider the climate and potential exposure to moisture when selecting canvas.

Illustrative image related to cloth for shoes

Summary Table of Material Selection for Shoe Cloth

| Material | Typical Use Case for cloth for shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Microfiber cloth | Shoe cleaning and maintenance | Highly absorbent and quick-drying | Higher cost compared to cotton | Medium |

| Cotton | Casual footwear and linings | Comfortable and biodegradable | Less durable in humid conditions | Low |

| Piel sintética | Fashion and outdoor shoes | Water and stain-resistant | Less breathable than natural leather | Medium |

| Canvas | Casual shoes and sneakers | Durable and cost-effective | Less water-resistant | Low |

This strategic material selection guide provides essential insights for international B2B buyers, helping them navigate the complexities of choosing the right cloth for shoes based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cloth for shoes

What Are the Main Stages of Manufacturing Cloth for Shoes?

The manufacturing process for cloth used in shoes involves several critical stages, each aimed at ensuring the final product meets the rigorous demands of quality, durability, and functionality. Understanding these stages is essential for B2B buyers to make informed decisions about sourcing materials.

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials include microfiber, cotton, polyester, and nylon, each chosen for their unique properties. For instance, microfiber is favored for its moisture-wicking capabilities and durability, making it ideal for sneaker cleaning and maintenance. The raw materials undergo rigorous quality checks to ensure they meet specified standards, including colorfastness, tensile strength, and abrasion resistance.

During this stage, suppliers must ensure that the materials are free from defects and contaminants. This often involves pre-treating fabrics to enhance their performance characteristics, such as water repellency or stain resistance, which are crucial for the end-use in shoes.

How Is the Cloth Formed into Usable Fabrics?

Once the materials are prepared, the next stage is forming the fabric. This involves various techniques such as weaving, knitting, or non-woven processes. Weaving is commonly used for creating strong, durable fabrics, while knitting offers elasticity and comfort. Non-woven techniques are often employed for specialized applications where traditional weaving is not feasible.

During this phase, it is essential to monitor the fabric’s density, texture, and overall quality. Advanced machinery may be used to control these parameters, ensuring consistent output that meets specifications.

What Assembly Techniques Are Commonly Used?

After the fabric is formed, it moves to the assembly stage, where it is cut and sewn into the desired shapes for shoe components. Automated cutting machines are often employed to ensure precision and reduce waste. Skilled labor is critical at this stage, as workers must ensure that seams are strong and that the fabric pieces fit together correctly.

Quality control in the assembly phase includes inspecting stitching quality, alignment, and the overall aesthetic of the shoe components. This is where attention to detail is paramount, as any flaws can compromise the final product’s durability and visual appeal.

What Finishing Processes Enhance the Quality of Shoe Cloth?

The final manufacturing stage involves finishing processes that enhance the fabric’s appearance and functionality. This may include dyeing, printing, and applying protective coatings. Finishing techniques can also add features like water resistance or UV protection, which are increasingly demanded by consumers.

During finishing, manufacturers must adhere to international standards for chemical safety and environmental impact. This is particularly important for B2B buyers who may be sourcing from regions with varying regulatory frameworks.

How Is Quality Assurance Implemented in the Manufacturing of Shoe Cloth?

Quality assurance (QA) is critical throughout the manufacturing process to ensure that the final product meets both international standards and specific customer requirements. Effective QA practices help prevent defects and enhance customer satisfaction.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 is a widely recognized quality management standard that outlines criteria for an effective quality management system. Compliance with ISO 9001 ensures that manufacturers consistently produce high-quality products and enhance customer satisfaction.

In addition to ISO 9001, there are industry-specific certifications, such as CE marking for products sold in Europe, which indicates compliance with health, safety, and environmental protection standards. Buyers from Africa, South America, the Middle East, and Europe should verify that their suppliers comply with these standards to ensure product safety and reliability.

Illustrative image related to cloth for shoes

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically implemented at several checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Any defective materials are rejected before they enter the production process.

-

In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify issues early. This may involve monitoring fabric properties, stitching quality, and adherence to production specifications.

-

Final Quality Control (FQC): Once production is complete, the final product undergoes a comprehensive inspection. This includes checking for defects, ensuring proper packaging, and confirming that products meet all relevant standards before shipment.

What Common Testing Methods Are Used for Shoe Cloth?

Common testing methods employed during the QC process include:

- Tensile Strength Testing: Measures the fabric’s resistance to being pulled apart.

- Abrasion Resistance Testing: Assesses how well the fabric withstands wear and tear.

- Water Repellency Testing: Evaluates the effectiveness of any water-resistant treatments applied to the fabric.

- Colorfastness Testing: Determines how well the fabric holds its color when exposed to various conditions, including washing and sunlight.

These tests provide valuable data that can help B2B buyers assess the quality and suitability of materials for their specific applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product quality. Here are some actionable steps:

Illustrative image related to cloth for shoes

What Should B2B Buyers Look for in Supplier Audits?

Conducting supplier audits is a critical step in verifying quality assurance practices. Buyers should look for:

- Documentation: Request documentation related to quality control processes, including records of testing and inspections.

- Certifications: Verify that the supplier holds relevant certifications, such as ISO 9001 or CE marking.

- Facility Visits: If feasible, visiting the manufacturing facility can provide insights into the supplier’s quality control practices and overall production capabilities.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further enhance confidence in supplier quality. These services can provide unbiased assessments of the manufacturing process and product quality, ensuring that suppliers adhere to specified standards and practices.

What Are the Unique QC Considerations for International Buyers?

When sourcing from different regions, B2B buyers must be aware of specific QC nuances, including:

-

Cultural Differences: Different regions may have varying approaches to quality and manufacturing practices. Understanding these cultural nuances can help buyers communicate effectively with suppliers.

-

Regulatory Compliance: Buyers should familiarize themselves with local regulations that may impact product quality and safety, particularly in regions with less stringent regulations.

-

Supply Chain Risks: Factors such as political stability, transportation logistics, and economic conditions can affect quality. Buyers should consider these risks when evaluating potential suppliers.

By understanding the manufacturing processes and quality assurance practices in the cloth for shoes industry, B2B buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Illustrative image related to cloth for shoes

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cloth for shoes’

When sourcing cloth for shoes, especially for B2B operations, a structured approach can significantly enhance the quality of your procurement process. This checklist will guide you through essential steps to ensure you select the right materials and suppliers to meet your business needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the cloth is crucial. Consider factors such as material composition (e.g., microfiber, cotton, synthetic blends), thickness, durability, and moisture absorption properties. Clearly defined specifications will help streamline supplier discussions and ensure that the materials meet your quality standards.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in shoe cloth materials. This includes exploring advancements in eco-friendly fabrics, moisture-wicking technologies, and antibacterial properties. Knowledge of market trends can provide you with a competitive edge and help you offer cutting-edge products to your customers.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet suppliers thoroughly. Request company profiles, certifications, and references from other buyers in your industry or region. Focus on suppliers who demonstrate a strong track record in quality assurance and timely delivery.

- Check for certifications like ISO or other industry-specific standards to ensure compliance with safety and quality regulations.

- Review customer testimonials to gauge the reliability and reputation of the supplier.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of their cloth materials. This step allows you to evaluate the quality, texture, and suitability of the cloth for your specific shoe designs. Assess how the material holds up under stress, moisture, and wear.

Illustrative image related to cloth for shoes

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, minimum order quantities, and payment terms. Transparent negotiations are vital to establishing a mutually beneficial relationship. Be clear about your expectations for pricing, but also consider the total cost of ownership, including shipping and potential customs duties for international orders.

Step 6: Verify Supply Chain Sustainability

In today’s market, sustainability is becoming increasingly important. Investigate your supplier’s supply chain practices to ensure they align with your company’s values and the expectations of your customers.

- Ask about sourcing practices: Are the materials ethically sourced?

- Inquire about waste management: What are their practices for reducing waste during production?

Step 7: Establish a Communication Protocol

Effective communication is key to a successful supplier relationship. Set up a clear communication protocol to ensure consistent updates regarding order status, quality issues, or any changes in specifications.

- Define point-of-contact roles: Ensure both parties know who to contact for specific issues.

- Schedule regular check-ins to assess ongoing performance and address any emerging concerns.

Following this checklist will help you navigate the complexities of sourcing cloth for shoes, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for cloth for shoes Sourcing

What Are the Key Cost Components in Sourcing Cloth for Shoes?

When sourcing cloth for shoes, understanding the cost structure is paramount for B2B buyers. The primary cost components include:

-

Materials: The type of fabric significantly influences costs. For instance, high-quality microfiber or specialized synthetic materials may command a premium. Buyers should assess the benefits of investing in durable materials against potential long-term savings.

-

Labor: Labor costs can vary widely based on the region and skill level required. Countries with lower labor costs may provide a competitive edge, but it’s essential to consider the trade-off with quality and craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, maintenance, and utilities. A supplier’s efficiency and production capacity can impact these costs, influencing the final pricing.

-

Tooling: If custom designs or specific finishes are required, tooling costs can be significant. This includes the creation of molds or specialized machinery setups, which can add to the upfront investment.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes incurs additional costs. Buyers should weigh the importance of QC in relation to their product standards.

-

Logistics: Transportation costs are critical, especially for international shipping. Factors like distance, shipping method, and incoterms can all affect overall logistics expenses.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on their positioning in the market and the value they provide.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence pricing when sourcing cloth for shoes:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their business needs.

-

Specifications and Customization: Customized orders often come at a premium. Buyers should clearly define their specifications to avoid unexpected costs later.

-

Materials and Quality Certifications: The quality of materials and any certifications (e.g., eco-friendly or safety standards) can significantly impact pricing. Buyers should evaluate whether the additional investment aligns with their brand values and customer expectations.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Establishing a relationship with a trustworthy supplier can lead to better pricing terms over time.

-

Incoterms: Understanding international shipping terms is crucial. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) can influence the total landed cost of the product.

What Tips Can Buyers Utilize for Cost-Efficient Sourcing?

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing. Leveraging your purchasing power and building long-term relationships can lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Don’t just focus on the initial purchase price. Consider maintenance, durability, and the potential need for replacements when evaluating costs.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, it’s essential to understand local market dynamics and currency fluctuations. These factors can impact pricing and should be factored into budget planning.

-

Stay Informed About Market Trends: Regularly monitor fabric trends and pricing changes. This can help buyers anticipate shifts in costs and negotiate better deals.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing prices and services from multiple suppliers can uncover hidden opportunities for savings.

Disclaimer on Indicative Prices

Prices for cloth for shoes can vary widely based on market conditions, supplier negotiations, and specific order requirements. The figures presented are indicative and should be validated through direct communication with suppliers. Always factor in additional costs such as shipping, tariffs, and local taxes when budgeting for your sourcing needs.

Alternatives Analysis: Comparing cloth for shoes With Other Solutions

Introduction: Exploring Alternatives to Cloth for Shoes

In the world of footwear maintenance and care, various solutions exist beyond traditional cloth options. While cloth for shoes offers effective cleaning and polishing capabilities, businesses may seek alternative methods or products that could provide enhanced performance, cost efficiency, or ease of use. This analysis will compare cloth for shoes with alternative solutions, helping B2B buyers make informed decisions that align with their specific operational needs.

Illustrative image related to cloth for shoes

Comparison Table

| Comparison Aspect | Cloth For Shoes | Microfiber Cloth | Chamois Leather Cloth |

|---|---|---|---|

| Performance | Good for cleaning and polishing; versatile across materials | Excellent moisture absorption; safe for delicate surfaces | Superior shine and polish; best for leather care |

| Cost | Moderate pricing, varies by type | Generally affordable, around $13 for a standard size | Higher cost, often $20 and above depending on quality |

| Ease of Implementation | Simple to use, requires minimal training | User-friendly, no special skills needed | Requires some technique for best results |

| Maintenance | Easy to wash and reuse, can wear out over time | Durable, machine washable; can last long with proper care | Requires specific cleaning methods to maintain quality |

| Best Use Case | General cleaning and maintenance for various shoe types | Ideal for sneaker and casual shoe cleaning | Best for high-end leather shoes needing a polished finish |

Detailed Breakdown of Alternatives

Microfiber Cloth

Microfiber cloths have gained popularity in shoe care due to their excellent moisture absorption and soft texture, which make them safe for use on delicate materials. They are particularly effective for cleaning sneakers and synthetic shoes, where gentle wiping is essential to avoid damage. The affordability and ease of washing are significant advantages; however, they may not provide the same level of shine as traditional chamois cloths. Businesses looking for a cost-effective and versatile cleaning solution would benefit from incorporating microfiber cloths into their shoe care routine.

Chamois Leather Cloth

Chamois leather cloths are renowned for their ability to provide a superior shine, making them a preferred choice for high-end leather footwear. The texture of chamois allows for effective polishing without scratching the surface, which is vital for maintaining the aesthetic appeal of luxury shoes. However, these cloths typically come at a higher price point and require careful maintenance to prevent degradation. Users must adopt specific cleaning techniques to ensure longevity, which may necessitate additional training. For B2B buyers focused on luxury markets, investing in chamois leather cloths can significantly enhance the presentation and care of their products.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the appropriate cloth solution for shoe maintenance, B2B buyers should assess their specific needs and the types of footwear they handle. For general cleaning and maintenance, cloth for shoes or microfiber options offer excellent versatility and cost-effectiveness. In contrast, businesses focused on high-end leather products may find greater value in chamois leather cloths, despite their higher cost and maintenance requirements. Ultimately, understanding the unique benefits and limitations of each option will enable buyers to make informed decisions that enhance their operational efficiency and product care standards.

Essential Technical Properties and Trade Terminology for cloth for shoes

What Are the Key Technical Properties of Cloth for Shoes?

When sourcing cloth for shoes, understanding the material properties is essential for making informed purchasing decisions. Here are several critical specifications that buyers should consider:

Illustrative image related to cloth for shoes

1. Material Composition

The primary materials used in shoe cloth include microfiber, cotton, and synthetic blends. Microfiber is popular for its moisture-wicking properties and durability, making it ideal for sneaker cleaning and maintenance. Cotton, while breathable and comfortable, may not offer the same level of durability as synthetic alternatives. Buyers should assess the intended use—whether for casual wear, formal occasions, or performance shoes—to select the appropriate material.

2. Weight and Thickness

The weight of the cloth, often measured in grams per square meter (GSM), significantly impacts its performance and feel. A heavier cloth may offer more durability and protection, while a lighter cloth could enhance breathability. Thickness also plays a role; thicker materials can provide better insulation and protection but may sacrifice flexibility. Buyers need to balance weight and thickness based on their specific application requirements.

3. Abrasion Resistance

Abrasion resistance indicates how well a fabric can withstand wear and tear, particularly important in high-friction areas of shoes. This property is crucial for ensuring longevity and maintaining the aesthetic appeal of footwear. Fabrics with high abrasion resistance are typically treated or engineered to withstand the rigors of daily use, which is a key selling point for B2B buyers focused on quality.

4. Moisture Management

Moisture management properties refer to a cloth’s ability to wick away sweat and moisture, keeping feet dry and comfortable. This is particularly important in athletic and performance footwear. Fabrics designed with moisture management properties can enhance user experience and contribute to the overall performance of the shoe, making them a desirable choice for sports brands and retailers.

5. Color Fastness

Color fastness is a measure of how well a fabric retains its color when exposed to washing, light, and other environmental factors. For B2B buyers, especially in fashion and retail, choosing materials with high color fastness ensures that products maintain their appearance over time, reducing the likelihood of returns and customer dissatisfaction.

Illustrative image related to cloth for shoes

What Are the Common Trade Terms Related to Cloth for Shoes?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the shoe industry, OEMs often provide specialized fabrics or components that brands incorporate into their products. Understanding OEM relationships can help buyers secure high-quality materials tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to produce or sell. It is crucial for B2B buyers to understand MOQs as they directly impact inventory levels, cash flow, and production planning. Negotiating favorable MOQs can lead to cost savings and better alignment with market demands.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific materials or products. This process enables buyers to compare prices, delivery times, and terms from multiple vendors, aiding in strategic sourcing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs, insurance, and liability during transit, which is especially important when sourcing materials globally.

Illustrative image related to cloth for shoes

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is vital for inventory management and planning. Longer lead times may necessitate adjustments in production schedules or inventory levels to meet market demand.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing cloth for shoes with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the cloth for shoes Sector

What Are the Current Market Dynamics and Key Trends in the Cloth for Shoes Sector?

The cloth for shoes sector is experiencing a dynamic transformation driven by several global factors. Increasing consumer awareness regarding sustainability and ethical practices is prompting manufacturers to innovate with eco-friendly materials. This shift is particularly evident in regions like Europe and North America, where buyers are increasingly seeking products that align with sustainable practices. As a result, materials such as organic cotton, recycled polyester, and biodegradable fabrics are gaining traction.

In addition, technology is reshaping sourcing trends. B2B buyers are increasingly utilizing digital platforms to streamline procurement processes. Innovations such as AI-driven analytics help companies forecast demand and manage inventory effectively, ensuring they meet market needs without overextending resources. Moreover, the rise of e-commerce has made it easier for international buyers, particularly from Africa and South America, to access a broader range of suppliers and materials, enhancing competition and choice.

Emerging markets are also becoming key players in the cloth for shoes sector. Countries like Vietnam and Nigeria are investing in local manufacturing capabilities, which not only reduces lead times but also cuts down on shipping costs. This evolution underscores the importance of regional sourcing strategies, enabling B2B buyers to tap into local resources while also addressing the demands of their specific markets.

How Is Sustainability and Ethical Sourcing Shaping the Cloth for Shoes Industry?

Sustainability is no longer a niche concern; it is a central tenet of the cloth for shoes sector. The environmental impact of traditional textile production is prompting companies to reevaluate their sourcing strategies. Ethical supply chains are becoming essential, as buyers seek transparency and accountability from their suppliers. This growing demand is leading to the adoption of green certifications, such as Global Organic Textile Standard (GOTS) and OEKO-TEX, which signal compliance with environmental and social standards.

The importance of using sustainable materials cannot be overstated. Buyers are increasingly looking for cloth that minimizes ecological footprints—such as fabrics derived from recycled plastics or organic fibers. Not only do these materials help reduce waste, but they also resonate with the values of environmentally conscious consumers. As a result, brands that prioritize sustainability are likely to enjoy a competitive advantage in the market.

Moreover, ethical sourcing practices enhance brand reputation and foster consumer loyalty. B2B buyers who prioritize ethical standards in their supply chains are not only contributing to environmental sustainability but are also aligning their businesses with the growing consumer demand for responsible production practices. This alignment can lead to increased sales, improved brand perception, and long-term business viability.

Illustrative image related to cloth for shoes

What Is the Evolution of the Cloth for Shoes Sector and Its Relevance to Today’s B2B Buyers?

Historically, the cloth for shoes sector has evolved from traditional, locally sourced materials to a globalized marketplace characterized by diverse offerings. In earlier times, shoe manufacturers primarily relied on natural materials like leather and cotton. However, the introduction of synthetic fibers in the mid-20th century transformed the landscape, allowing for greater versatility and durability in shoe design.

In recent years, the sector has witnessed a resurgence of interest in traditional craftsmanship, as well as a push towards sustainability. This evolution is relevant for today’s B2B buyers who are navigating a complex market. Understanding the historical context allows buyers to appreciate the significance of contemporary trends, particularly the shift towards eco-friendly materials and ethical sourcing.

As the sector continues to evolve, B2B buyers must stay informed about emerging trends and technologies that can influence their sourcing strategies. By leveraging historical insights alongside current market dynamics, buyers can make informed decisions that align with both their business objectives and the values of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of cloth for shoes

-

How do I choose the right cloth for shoe manufacturing?

Selecting the right cloth involves considering the intended use, durability, and aesthetic appeal. For sneakers, microfiber is an excellent choice due to its moisture-wicking properties and softness, which protects the shoe’s surface. For formal shoes, look for high-quality leather or synthetic materials that provide a luxurious finish. Assess the supplier’s samples to ensure the fabric meets your quality standards and aligns with your target market’s preferences. -

What are the key factors to consider when sourcing cloth for shoes?

When sourcing cloth, prioritize the supplier’s reputation, material quality, and compliance with international trade regulations. Check for certifications that ensure sustainability and ethical production practices. Additionally, consider lead times, minimum order quantities (MOQs), and the supplier’s ability to customize fabrics to meet your specific design needs. Establish clear communication regarding your requirements to avoid misunderstandings. -

What is the typical minimum order quantity (MOQ) for cloth suppliers?

MOQs can vary significantly among suppliers, often ranging from 50 to 500 meters for bulk orders. For specialized or custom fabrics, the MOQ may be higher due to production setup costs. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new product line. Some suppliers may offer sample sizes or smaller batches for initial orders to facilitate market testing. -

How can I ensure the quality of the cloth I purchase?

To ensure quality, request samples from suppliers before placing bulk orders. Conduct thorough inspections of the fabric for consistency in color, texture, and durability. Additionally, consider third-party quality assurance services that can conduct inspections and tests based on your specifications. Establishing a quality control process with your supplier can help ensure that every batch meets your standards. -

What payment terms should I expect when sourcing cloth internationally?

Payment terms can vary, but common arrangements include deposits of 30% upfront with the balance due before shipment. Some suppliers may offer letters of credit or escrow services for added security. It’s crucial to negotiate terms that protect both parties and ensure timely payment. Always clarify the currency used and any additional fees associated with international transactions. -

What logistical considerations should I keep in mind when importing cloth?

Logistics play a critical role in the sourcing process. Consider shipping methods (air vs. sea), delivery times, and potential customs duties. Work with a freight forwarder experienced in handling textile imports to navigate regulations and minimize delays. Also, ensure that your supplier provides the necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance. -

How do I handle customs duties and taxes for imported cloth?

Customs duties and taxes vary by country and depend on the fabric type and its origin. Research the import regulations of your destination country to estimate potential costs. Engage with a customs broker who can help you understand the tariffs applicable to your order. Keeping accurate records of your shipments will also assist in future imports and audits. -

What are the best practices for maintaining a relationship with cloth suppliers?

Building a strong relationship with suppliers involves regular communication, feedback, and collaboration on product development. Schedule periodic meetings to discuss performance, address issues, and explore new opportunities. Providing constructive feedback on quality and delivery can help suppliers improve their services, while timely payments and honoring agreements foster trust and reliability in the partnership.

Top 6 Cloth For Shoes Manufacturers & Suppliers List

1. Shoe Care Shop – Microfiber Cleaning Cloth

Domain: us.theshoecareshop.com

Registered: 2021 (4 years)

Introduction: Microfiber cloth for sneaker cleaning, 30x30cm. Ideal for cleaning leather and synthetic sneakers and shoes. Made from finely woven microfiber material that absorbs moisture effectively and dries quickly. Suitable for wiping off leftover dirt after washing shoes with a cleaner and for rubbing sneakers clean from surface soiling. Sale price: $13.00.

2. Jay Butler – Saphir Shoe Shine Chamois Cloth

Domain: jaybutler.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Saphir Shoe Shine Chamois Cloth”, “price”: “$8.00”, “color”: “White”, “shipping_info”: {“free_shipping_threshold”: “$125”, “shipping_methods”: [“USPS”, “FedEx Ground”], “shipping_time”: {“in_region”: “1-2 business days”, “out_of_region”: “2-5 business days”}}, “returns_policy”: {“return_period”: “30 days”, “condition”: “unused and unworn”, “shipping_cost_for_first_return”: “free”…

3. Lincoln Shoe Polish – Professional Shine & Buff Cloth

Domain: lincolnshoepolish.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Professional Shine & Buff Cloth (Pack of 3)”, “regular_price”: “$12.95”, “quantity”: “Pack of 3”, “material”: “Cotton flannel and cotton canvas”, “dimensions”: “Approximately 5 inches wide by 20 inches long”, “features”: [“Soft flannel nap for high-gloss shine”, “Sewn edges with blanket stitching to prevent fraying”, “Hand washable to maintain softness”, “Designed for professiona…

4. Kiwi – Polishing Cloth

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best cloth for polishing: Selvyt cloth; alternative: cotton (for finishing). Recommended polish brands: Kiwi, Saphir (preferred). Polishing method: 1. Use a non-abrasive cloth, wet it, apply a small amount of polish. 2. Use light pressure and small circles to apply polish evenly. 3. Use a polishing cloth, dampen it, and apply with light pressure until the shoe shines. Gradually reduce water usage …

5. FootFitter – Ultrasoft Microfiber Cleaning Cloth Pack

Domain: footfitter.com

Registered: 2007 (18 years)

Introduction: Ultrasoft Microfiber Cleaning and Conditioning Shoe Shine Cloth Pack, 6-Pack; SKU: 104-029-06; Regular price: $20.00 USD; Dimensions: 12.25″ x 12″; Made of gentle, lint-free microfiber; Machine washable and non-scratching; Designed for applying creams, lotions, or soft waxes; Each cloth features an extended stitched finger loop for enhanced grip; Total reviews: 19; Average rating: 4.63/5.0.

6. ShoeWash – Microfiber Cloths

Domain: shoewash.ca

Registered: 2021 (4 years)

Introduction: Microfiber cloths are crafted from ultra-fine fibers of synthetic materials, typically a blend of polyester and polyamide (nylon). They are effective at trapping dirt, moisture, and microscopic particles due to their unique composition. Microfiber cloths are much finer than human hair, creating a larger surface area for trapping dirt and dust. They are gentler on sensitive materials such as suede …

Strategic Sourcing Conclusion and Outlook for cloth for shoes

In the dynamic landscape of the footwear industry, the strategic sourcing of cloth for shoes has emerged as a pivotal factor for B2B buyers. By prioritizing high-quality materials such as microfiber and chamois cloth, businesses can enhance product durability and customer satisfaction. This not only strengthens brand loyalty but also positions companies to compete effectively in diverse markets, including Africa, South America, the Middle East, and Europe.

Effective sourcing strategies should emphasize quality, sustainability, and supplier reliability. Engaging with reputable suppliers who understand regional market dynamics can yield significant advantages. Additionally, leveraging technology to streamline procurement processes and maintain inventory can further improve operational efficiency and responsiveness to market trends.

Illustrative image related to cloth for shoes

Looking ahead, the demand for innovative and sustainable materials is expected to rise. B2B buyers are encouraged to stay ahead of trends by exploring new cloth technologies and eco-friendly options. By fostering strong supplier relationships and continuously adapting to market changes, businesses can ensure a robust supply chain that meets the evolving needs of consumers. Now is the time to invest in strategic sourcing practices that will lead to long-term success in the competitive footwear market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.