Catalog

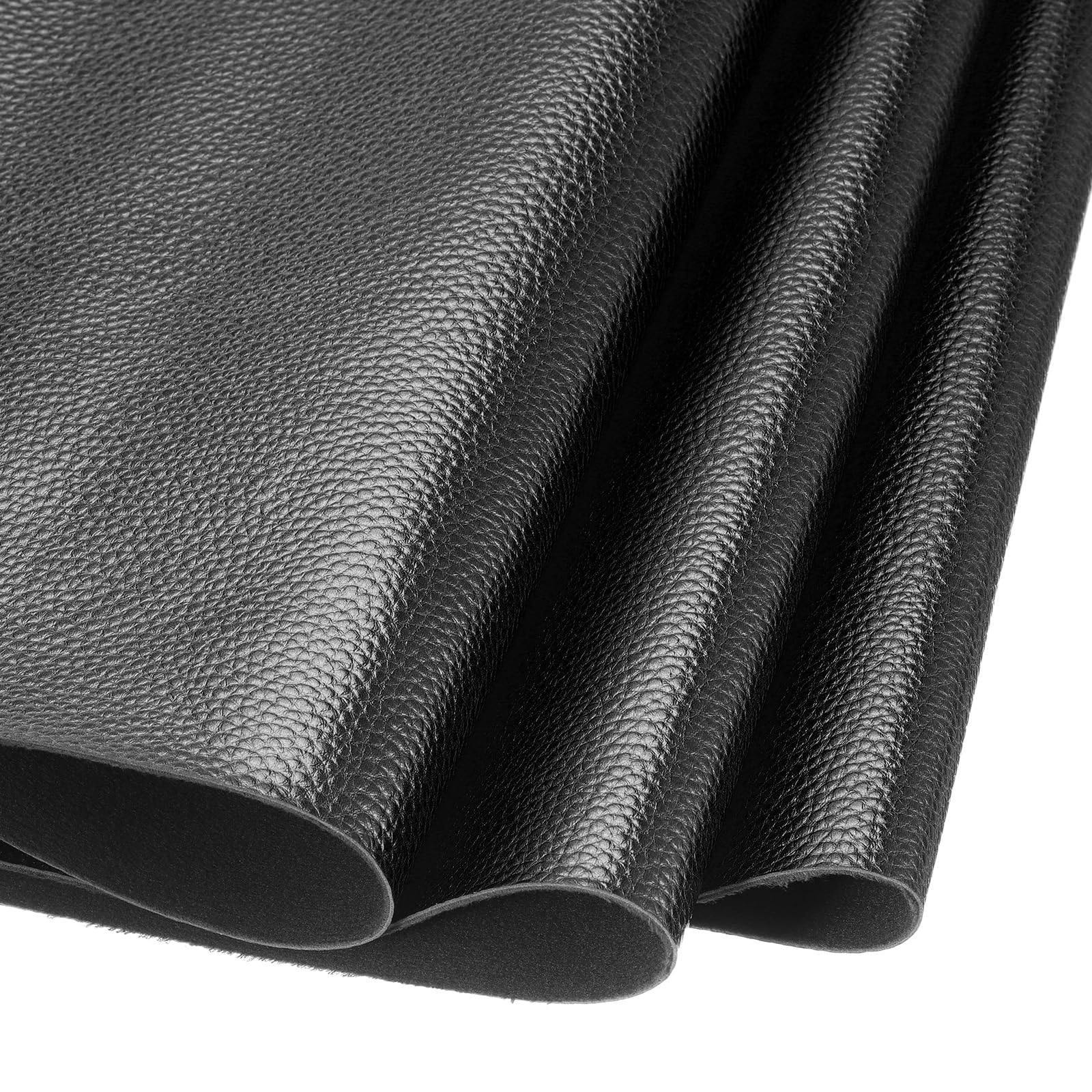

Material Insight: Automotive Leather Material

Automotive Leather Material: The Performance Standard for Modern Vehicle Interiors

For automotive manufacturers and tier suppliers, interior material selection is a critical balance of safety, durability, aesthetics, and sustainability. Automotive-grade synthetic leather has evolved beyond a mere alternative to become the engineered solution of choice for demanding vehicle applications. Unlike traditional materials, it delivers consistent performance under extreme conditions—from scorching desert heat to sub-zero climates—while meeting stringent global safety regulations and evolving consumer expectations for eco-conscious design.

Why Automotive Synthetic Leather is the Optimal Choice

- Unmatched Durability & Longevity: Engineered to withstand 50,000+ abrasion cycles, resist UV fading, and maintain structural integrity through rapid temperature fluctuations (-40°C to +85°C), ensuring cabin interiors retain premium appearance over the vehicle’s lifespan.

- Enhanced Safety Compliance: Meets or exceeds global flammability standards (FMVSS 302, ISO 3795) and low-VOC emissions requirements, critical for occupant health and regulatory approval in all major markets.

- Supply Chain Resilience: Eliminates volatility associated with natural leather (e.g., hide shortages, price spikes, ethical concerns) through stable, traceable manufacturing processes.

- Sustainability Integration: Modern formulations incorporate 30-50% recycled content (e.g., ocean-bound plastics, post-industrial fibers) and waterless dyeing technologies, directly supporting OEMs’ net-zero commitments without compromising performance.

- Design Flexibility: Enables precise color matching, texture replication, and seamless integration with heating/cooling systems or sensor technologies—accelerating innovation in smart cabin ecosystems.

WINIW: Powering Automotive Innovation for 20+ Years

WINIW has been a strategic partner to leading global automakers since 2003, specializing in high-performance synthetic leather engineered exclusively for transportation applications. Our vertically integrated R&D and production ecosystem—spanning material science, eco-manufacturing, and application engineering—ensures solutions that solve real-world challenges: reducing weight for EV range extension, cutting VOC emissions by 70% versus conventional synthetics, and achieving full traceability from raw material to finished component. With ISO 14001-certified facilities and partnerships across 15+ automotive supply chains, we deliver not just materials, but certified performance and compliance—turning sustainability targets into measurable production outcomes.

Next Section Preview: Technical Specifications & Performance Benchmarks

Technical Performance & Standards

WINIW Automotive Leather Material – B2B Product Technical Guide

WINIW specializes in high-performance synthetic leather solutions engineered for the demanding requirements of the automotive industry. Our automotive leather material is developed using advanced manufacturing processes and premium raw materials to deliver exceptional durability, safety, and environmental compliance. Designed for interior applications such as seating, door panels, armrests, and steering wheels, WINIW’s material sets a new benchmark in synthetic leather performance.

Key Technical Advantages

-

Abrasion Resistant: WINIW’s automotive leather is engineered with a reinforced fiber structure and high-density polyurethane coating, providing superior resistance to wear and tear. It consistently exceeds 50,000 cycles in Martindale abrasion testing, making it ideal for high-use vehicle interiors.

-

UV Resistant: The material incorporates advanced UV stabilizers that prevent color fading and surface degradation under prolonged exposure to sunlight. It maintains colorfastness and surface integrity after 1,000 hours of xenon arc testing (per ISO 4892-2), ensuring long-term aesthetic consistency.

-

VOC Free: WINIW’s production process eliminates the use of volatile organic compounds (VOCs). Emissions testing confirms VOC levels below 10 µg/g, meeting stringent automotive air quality standards and contributing to healthier cabin environments.

-

REACH Compliant: The material fully complies with the European REACH regulation (EC 1907/2006), including SVHC (Substances of Very High Concern) restrictions. All chemical components are documented and screened to ensure safe handling and end-of-life recyclability.

-

ISO 9001 Certified Production: WINIW’s manufacturing facilities are ISO 9001 certified, ensuring consistent quality through rigorous process control, traceability, and continuous improvement protocols. This certification guarantees reliability and performance uniformity across production batches.

Application Benefits for Automotive OEMs and Tier Suppliers

- Reduces maintenance and replacement costs due to long service life

- Supports sustainable vehicle design with low-emission, eco-conscious materials

- Facilitates global market access through compliance with EU and international safety standards

- Enables design flexibility with customizable textures, colors, and thicknesses

- Enhances brand reputation through use of environmentally responsible materials

Technical Specifications

| Property | Test Standard | WINIW Performance Value |

|---|---|---|

| Abrasion Resistance | ISO 12947 (Martindale) | >50,000 cycles (no breakdown) |

| Colorfastness to UV Light | ISO 4892-2 (Xenon) | ≥ Grade 4 after 1,000 hours |

| VOC Emissions | VDA 276 | <10 µg/g |

| REACH Compliance | EC 1907/2006 | Fully compliant, SVHC-free |

| Tensile Strength | ISO 1421 | ≥ 25 MPa (warp & weft) |

| Tear Strength | ISO 13937-1 | ≥ 80 N |

| Thickness | ISO 2417 | 0.8 mm – 1.5 mm (customizable) |

| Operating Temperature Range | — | -30°C to +85°C |

WINIW’s automotive leather material combines cutting-edge technology with environmental responsibility, offering a durable, safe, and sustainable alternative to traditional leather and lower-grade synthetics. Through ISO-certified quality management and adherence to global regulatory standards, WINIW empowers automotive manufacturers to deliver premium interiors with confidence.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Automotive Material Selection

Selecting the right upholstery material is critical for automotive OEMs and Tier-1 suppliers balancing performance, sustainability, and cost. WINIW specializes in high-performance synthetic leather engineered explicitly for automotive interiors. Below we objectively compare modern automotive-grade synthetic leather (e.g., WINIW’s PU/PVC-free collections) against premium full-grain real leather across key decision metrics.

Key Comparison: Automotive Synthetic Leather vs. Premium Full-Grain Real Leather

| Metric | Automotive Synthetic Leather (WINIW Grade) | Premium Full-Grain Real Leather |

|---|---|---|

| Cost (Initial) | 30-50% lower material cost per m² | High (driven by raw hide scarcity, labor-intensive processing) |

| Durabilidad | Superior abrasion resistance (50,000+ Martindale cycles); consistent UV/colorfastness; no cracking in extreme temps (-40°C to 85°C) | Moderate abrasion resistance (20,000-30,000 cycles); prone to fading, drying, and cracking without rigorous maintenance |

| Eco-Friendliness | Zero animal sourcing; 60% lower carbon footprint; water-based PU; up to 40% recycled content; OEKO-TEX® certified; fully recyclable at end-of-life | High water consumption (15,000L+ per hide); toxic tanning chemicals (chromium); significant land/water pollution; non-recyclable waste |

Why Automotive Synthetic Leather Delivers Strategic Value

- Supply Chain Resilience: Eliminates volatility in hide prices and ethical concerns tied to livestock agriculture.

- Design Flexibility: Uniform texture, color consistency, and customizable thickness (0.6mm–1.2mm) streamline manufacturing.

- Performance Compliance: Meets FMVSS 302, ISO 11402, and global VOC standards out-of-the-box—no post-treatment required.

- Circular Economy Alignment: WINIW materials integrate with take-back programs for closed-loop recycling, supporting OEM ESG targets.

Real leather retains niche appeal for ultra-luxury segments but imposes significant environmental liabilities and long-term maintenance costs in mass-market applications. WINIW’s synthetic alternatives provide uncompromised aesthetics while future-proofing your supply chain against tightening global sustainability regulations.

Partner with WINIW to develop automotive leather solutions that reduce ecological impact without sacrificing the premium tactile experience drivers expect. Request our full technical dossier and sample swatches for validation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility spanning 100,000 square meters. Our vertically integrated manufacturing campus enables full control over production processes, ensuring efficiency, consistency, and scalability to meet the demands of global B2B partners.

Our factory is equipped with advanced production lines and automated systems that support large-volume output without compromising on quality. This extensive manufacturing capacity allows us to deliver customized solutions for diverse industries, including automotive, furniture, apparel, and accessories.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, sustainability, and performance enhancement. The team continuously develops new formulations to meet evolving market needs, including eco-friendly, PU- and PVC-based synthetic leathers with superior durability, texture, and environmental compliance.

- A strict quality control (QC) system implemented at every stage of production. From raw material inspection to final product testing, WINIW adheres to international standards such as ISO 9001, REACH, and RoHS. Each batch undergoes rigorous physical and chemical testing to ensure consistency in color, thickness, abrasion resistance, and environmental safety.

- Strong global export capabilities, with products distributed to key markets including Europe and the USA. Our logistics network ensures timely delivery and compliance with regional regulatory requirements, supporting long-term partnerships with brands committed to quality and sustainability.

WINIW’s manufacturing excellence, backed by innovation and quality assurance, positions us as a trusted supplier for global brands seeking reliable, high-performance synthetic leather solutions.

Contact Us for Samples

WINIW Automotive Microfiber Leather: Premium Sustainable Interior Solutions

WINIW delivers high-performance synthetic leather engineered specifically for automotive applications where durability, aesthetics, and environmental responsibility converge. Our microfiber leather solutions meet rigorous OEM standards while significantly reducing ecological impact compared to traditional leather and conventional synthetics. Ideal for seating, door panels, consoles, and steering wheels, WINIW materials enhance both cabin luxury and lifecycle sustainability.

Key Advantages for Automotive Manufacturers

- Superior Durability: Withstands 50,000+ double-rub cycles (Martindale), resisting abrasion, tearing, and UV degradation for long-term interior integrity.

- Eco-Conscious Production: Made from 60%+ recycled polyester content; solvent-free manufacturing reduces VOC emissions by 90% versus PVC/PU alternatives.

- Design Versatility: Customizable textures (Nappa, grain, suede), colors, and thicknesses (0.8–1.5mm) to match brand-specific aesthetic and tactile requirements.

- Regulatory Compliance: Exceeds global standards (FMVSS 302, ISO 12947, REACH) for flammability, emissions, and chemical safety.

- Weight & Cost Efficiency: 30% lighter than genuine leather, optimizing fuel efficiency; consistent yield reduces material waste by up to 25%.

Technical Specifications Comparison

| Property | WINIW AutoLux™ | WINIW EcoDrive™ | Industry Standard PU |

|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles | 40,000+ cycles | 15,000–25,000 cycles |

| Tensile Strength | 35 MPa | 30 MPa | 18–22 MPa |

| Recycled Content | 65% | 70% | 0–10% |

| VOC Emissions (μg/g) | < 50 | < 40 | 200–500 |

| Weight (g/m²) | 480 | 450 | 600–700 |

Why Automotive Leaders Choose WINIW

- End-to-End Traceability: Full supply chain transparency from recycled feedstock to finished roll.

- Scalable Production: 10,000+ meters monthly capacity with JIT delivery options for global OEMs.

- Circular Economy Support: Take-back program for post-production waste to close the loop.

Elevate your vehicle interiors with materials that drive sustainability without compromising performance. Request free samples to experience WINIW’s premium automotive microfiber leather firsthand and validate its fit for your next-generation cabin designs.

Contact WINIW Marketing Today:

Correo electrónico MKT88@MicrofiberLeather.com for technical datasheets, compliance documentation, or to arrange sample shipments. Let’s co-create interiors that define the future of mobility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.