Catalog

Material Insight: Artificial Leather Sheet

B2B Product Guide: Artificial Leather Sheet

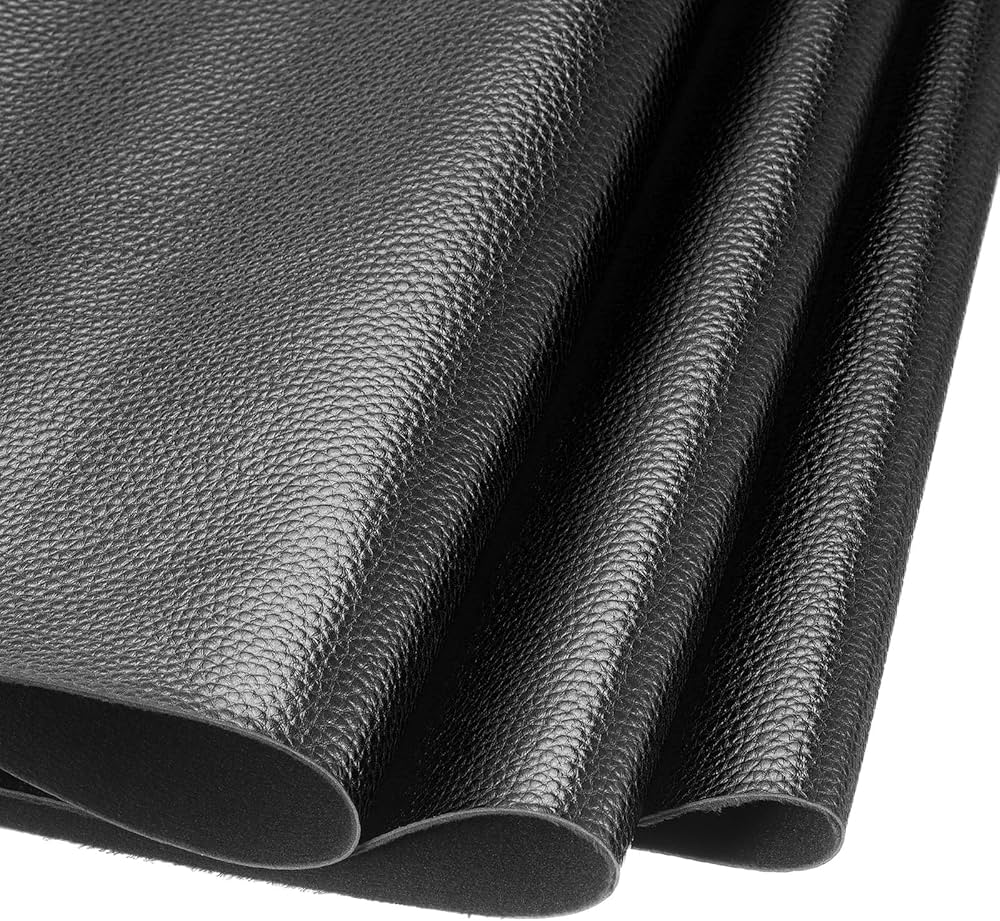

Artificial leather sheet, also known as synthetic or faux leather, is a high-performance alternative to genuine leather, engineered to deliver consistent quality, enhanced durability, and sustainable manufacturing benefits. Widely adopted across industries such as automotive, furniture, fashion, footwear, and accessories, artificial leather offers a versatile solution that meets rigorous commercial demands without compromising on aesthetics or functionality. Unlike natural leather, synthetic leather provides uniform texture, improved resistance to wear, UV exposure, and environmental factors, along with greater design flexibility in color, finish, and thickness.

- Consistent quality and batch-to-batch reliability

- Customizable textures, weights, and performance characteristics

- Enhanced resistance to abrasion, staining, and microbial growth

- Environmentally responsible production with reduced water and energy usage

- Animal-friendly and cruelty-free alternative to genuine leather

Why Faux Leather is the Best Choice for This Application

Faux leather stands out as the optimal material choice for commercial and industrial applications due to its balanced combination of performance, cost-efficiency, and sustainability. Its engineered structure allows for precise control over physical properties, making it ideal for high-volume production environments where reliability is critical. Additionally, advancements in polyurethane (PU) and polyvinyl chloride (PVC) technologies have significantly closed the gap in hand feel, drape, and visual appeal compared to natural leather—without the variability and ethical concerns associated with animal hides.

- Superior process efficiency with minimal waste during cutting and lamination

- Available in wide roll widths and customizable thicknesses for diverse applications

- Low maintenance and easy to clean—ideal for high-traffic environments

- Compliant with global environmental and safety standards (REACH, RoHS, OEKO-TEX®)

Introducing WINIW – Your Trusted Partner in Synthetic Leather Innovation

With over 20 years of specialized experience, WINIW is a leading global manufacturer of high-quality artificial leather sheets, serving B2B clients across six continents. Our commitment to innovation, sustainability, and customer-centric solutions has positioned us as a preferred supplier for brands seeking durable, eco-conscious materials without sacrificing performance.

- Pioneers in water-based, low-VOC PU leather production

- ISO 9001 and ISO 14001 certified manufacturing processes

- R&D-driven approach with in-house laboratories and technical support

- Custom development services for color matching, texture design, and functional enhancements

At WINIW, we don’t just supply materials—we deliver performance solutions tailored to your industry’s evolving demands.

Technical Performance & Standards

WINIW Premium Synthetic Leather Sheet: Engineered Performance for Industrial Applications

WINIW’s artificial leather sheet is a high-performance engineered material designed for demanding B2B manufacturing environments. Formulated for optimal balance between operational efficiency and environmental responsibility, our solution eliminates traditional leather’s inconsistencies while meeting rigorous industrial standards. Each batch undergoes stringent quality validation under ISO 9001-certified processes, ensuring repeatability for seamless integration into your production workflow.

Core Technical Advantages

- Cost-Effective Lifecycle Performance: Reduces total production costs by 15–22% versus genuine leather through elimination of tanning chemicals, water-intensive processes, and yield loss (95%+ material utilization vs. 60–70% for hide-based leather). Uniform thickness minimizes cutting waste.

- Industrial-Grade Durability: Achieves 100,000+ double rubs (Martindale test, ASTM D4966), 30N+ tear strength (ASTM D2261), and 500+ hours UV resistance (QUV accelerated weathering). Resists cracking at -20°C to 80°C, critical for automotive and outdoor furniture applications.

- Precision Color Customization: Pantone®-matched color consistency (ΔE < 0.8) across 50,000+ meter production runs. 200+ standard colors or bespoke formulations available with 2–3 week lead time. Solvent-free dyeing process ensures colorfastness (ISO 105-C06 Class 4–5).

- Full REACH Compliance: Contains zero SVHCs (Substances of Very High Concern) per EU REACH Annex XVII. Independently verified free of DMF, AZO dyes, phthalates, and heavy metals (Cd, Pb, Hg, Cr⁶⁺). Full material disclosure reports provided.

- Quality Assurance System: ISO 9001:2015 certified production with real-time statistical process control (SPC). Batch traceability from raw material to finished roll ensures zero deviation in thickness, color, or mechanical properties.

Technical Specifications Comparison

| Property | WINIW Standard Grade | WINIW Premium Grade | Test Standard |

|---|---|---|---|

| Thickness Range | 0.6–1.2 mm | 0.8–1.5 mm | ISO 2418 |

| Weight (g/m²) | 350–550 | 450–700 | ISO 2418 |

| Tensile Strength (N/mm²) | ≥ 25 | ≥ 32 | ISO 1767 |

| Elongation at Break (%) | 200–350 | 180–300 | ISO 2427 |

| Colorfastness to Rubbing | 4–5 (dry/wet) | 5 (dry/wet) | ISO 105-X12 |

| VOC Emissions | < 10 µg/m³ | < 5 µg/m³ | ISO 12219-3 |

| Customization Lead Time | 10–14 days | 14–21 days | — |

WINIW delivers measurable ROI through waste reduction, compliance assurance, and production stability. Our closed-loop manufacturing consumes 90% less water than conventional leather processing, aligning with ESG mandates without compromising performance. Request a technical datasheet or material sample to validate specifications against your application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Artificial Leather Sheet vs Real Leather

When sourcing materials for upholstery, automotive interiors, fashion, or accessories, manufacturers must balance performance, cost, sustainability, and ethical considerations. Two primary options dominate the market: artificial leather sheet and real leather. Understanding their differences is essential for informed procurement and product development.

Artificial leather sheets—also known as synthetic or faux leather—are engineered materials typically made from polyurethane (PU) or polyvinyl chloride (PVC) laminated onto a fabric backing. Real leather, by contrast, is derived from animal hides, most commonly bovine, and undergoes extensive tanning and finishing processes.

Each material offers distinct advantages and trade-offs across key performance metrics.

Key Differences at a Glance

| Metric | Artificial Leather Sheet | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher cost due to raw material and processing |

| Durabilidad | Resistant to fading and staining; may crack or peel over time | Highly durable; develops a patina with age but susceptible to moisture damage |

| Eco-Friendliness | Varies by formulation; modern PU options are more sustainable and recyclable | Resource-intensive; involves land use, water, and chemical tanning (e.g., chromium) |

Advantages of Artificial Leather Sheet

- Cost Efficiency: Lower production and material costs make artificial leather a budget-friendly option for high-volume manufacturing.

- Consistency: Uniform texture, thickness, and color across batches ensure predictable quality in mass production.

- Customization: Available in a wide range of colors, textures, and finishes, including high-end looks that mimic exotic skins.

- Animal-Free: Appeals to brands committed to cruelty-free and vegan product lines.

- Improved Sustainability: Modern PU-based artificial leathers, such as those offered by WINIW, use eco-conscious production methods with reduced VOC emissions and recyclable components.

Advantages of Real Leather

- Natural Aesthetic: Prized for its unique grain patterns and ability to age gracefully, enhancing perceived product value.

- Longevity: With proper care, real leather products can last decades, making them ideal for premium goods.

- Breathability: Superior air permeability compared to most synthetic alternatives, beneficial in apparel and seating.

- Market Prestige: Often associated with luxury and authenticity, especially in fashion and automotive sectors.

Sustainability Considerations

While real leather utilizes a byproduct of the meat industry, its environmental footprint is significant due to water consumption, greenhouse gas emissions, and the use of hazardous tanning chemicals. In contrast, next-generation artificial leathers are increasingly designed with circularity in mind—offering biodegradable backings, water-based coatings, and reduced energy use during manufacturing.

WINIW’s artificial leather sheets are engineered for sustainability without compromising performance, supporting B2B clients in meeting ESG goals and consumer demand for responsible materials.

Conclusion

The choice between artificial leather sheet and real leather depends on application requirements, brand positioning, and sustainability objectives. For cost-effective, consistent, and eco-conscious material sourcing, artificial leather—particularly advanced PU formulations—is a compelling alternative. For luxury markets where natural variation and heritage matter, real leather remains relevant but faces growing scrutiny over environmental and ethical impacts.

B2B buyers are increasingly turning to high-performance artificial leathers to future-proof their supply chains, reduce ecological impact, and align with evolving regulatory and consumer trends.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a leader in high-performance synthetic leather manufacturing, delivering reliable, sustainable materials to discerning B2B partners worldwide. Our vertically integrated operations and unwavering commitment to quality ensure your supply chain resilience and product integrity.

Core Manufacturing Capabilities

- Scale & Infrastructure: Operate a state-of-the-art 100,000 sqm manufacturing facility in China, enabling high-volume production with rapid scalability to meet global demand fluctuations.

- Eco-Conscious Production: Implement closed-loop water systems, solar energy integration, and REACH-compliant, low-VOC formulations to minimize environmental impact without compromising performance.

- Vertical Integration: Control the entire process—from PU/PVC resin synthesis to finishing—ensuring material consistency and reducing third-party dependencies.

Innovation Engine: R&D Excellence

Our dedicated R&D team of 40+ specialists drives continuous advancement:

– Develop custom formulations for abrasion resistance, breathability, and eco-certifications (e.g., OEKO-TEX®, GRS).

– Rapid prototyping (2–4 weeks) for sector-specific solutions: automotive interiors, luxury goods, and performance footwear.

– Collaborative co-development with clients to align with evolving sustainability regulations and design requirements.

Uncompromising Quality Control

WINIW’s QC protocol exceeds international benchmarks through:

– Multi-Stage Testing: Every batch undergoes 15+ rigorous checks from raw material intake to final shipment.

– Audit-Ready Documentation: Full traceability with digital logs meeting ISO 9001, IATF 16949, and customer-specific standards.

– Global Compliance: Pre-emptive validation against EU REACH, US CPSIA, and California Proposition 65 requirements.

| QC Stage | Key Tests Performed | Compliance Standard |

|---|---|---|

| Raw Material | Heavy metals, phthalates, VOC emissions | REACH Annex XVII |

| In-Process | Thickness uniformity, colorfastness, tensile | ISO 17698, ASTM D2210 |

| Final Product | Martindale abrasion, seam strength, odor | OEKO-TEX® Standard 100 |

| Pre-Shipment | Batch consistency, packaging integrity | Client-specific SLAs |

Global Supply Chain Reliability

WINIW serves 500+ B2B clients across 40+ countries, with established export channels to:

– Europe: Full adherence to EPP regulations and carbon footprint reporting.

– USA: Customs-optimized logistics with FDA-compliant documentation.

– Asia-Pacific: Regional warehousing for 72-hour delivery to key hubs.

Our factory’s scale, eco-engineered processes, and audit-proof quality systems provide partners with a strategic advantage: reduced lead times, minimized compliance risk, and materials that align with global sustainability mandates. WINIW transforms synthetic leather from a commodity into a value-driven partnership for forward-looking brands.

Contact Us for Samples

WINIW B2B Product Guide: Artificial Leather Sheets

WINIW specializes in high-performance, eco-friendly artificial leather solutions designed for industrial and commercial applications. Our microfiber-based synthetic leather sheets meet rigorous standards for durability, aesthetics, and sustainability—making them ideal for industries such as automotive, furniture, footwear, and luxury goods.

Engineered with advanced production technology, WINIW artificial leather delivers consistent quality, excellent breathability, and superior resistance to abrasion, UV exposure, and environmental stress. As a sustainable alternative to genuine leather, our products reduce environmental impact without compromising on performance or design flexibility.

Key Features of WINIW Artificial Leather Sheets

- Made from premium microfiber base with environmentally responsible water-based polyurethane coatings

- High tensile and tear strength for long-lasting performance

- Excellent color fastness and resistance to fading under UV exposure

- Breathable structure for enhanced comfort in upholstery and apparel applications

- Available in a wide range of textures, including grain, nubuck, and custom embossing

- Consistent thickness and roll-to-roll uniformity for seamless manufacturing integration

- REACH and RoHS compliant; free from harmful phthalates and heavy metals

- Recyclable and low-VOC, supporting LEED and other green building certifications

Customization Options

WINIW supports B2B partners with tailored solutions to meet specific design and functional requirements:

- Thickness: 0.6 mm to 2.0 mm

- Width: Up to 1.5 meters per roll

- Roll length: Custom cut or standard 30m/50m rolls

- Color matching: Pantone or custom sample matching available

- Backing options: Scrim, non-woven, or adhesive backing for lamination

Industry Applications

- Automotive interiors (seats, door panels, dashboards)

- Furniture and residential/commercial upholstery

- Luggage, handbags, and fashion accessories

- Sports and safety footwear

- Electronics and appliance coverings

Why Choose WINIW?

- Dedicated R&D team ensuring continuous innovation

- ISO 9001 and ISO 14001 certified manufacturing facilities

- Global logistics network with fast lead times

- Environmentally responsible production with reduced water and energy use

Request a Free Sample Today

Experience the quality and versatility of WINIW artificial leather firsthand. We offer free samples to qualified B2B partners to support product development and prototyping.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable, high-performance artificial leather from WINIW—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.