Catalog

Material Insight: Artificial Leather For Upholstery

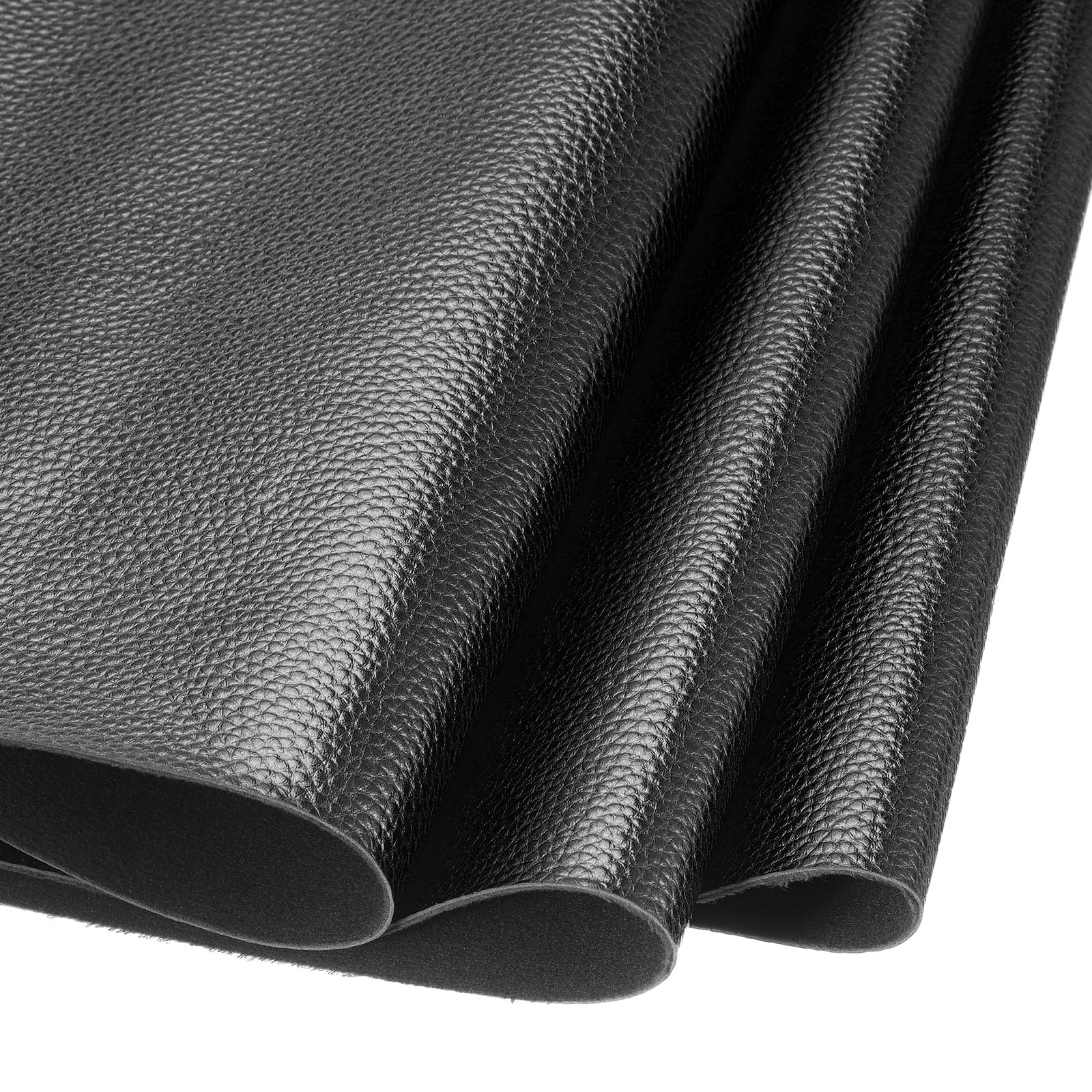

Artificial leather for upholstery has become a leading choice across furniture, automotive, and hospitality industries due to its durability, design flexibility, and sustainable advantages over traditional animal leather. As manufacturers and designers seek high-performance materials that align with eco-conscious values, synthetic upholstery leather offers a compelling solution—combining aesthetic appeal with long-term functionality.

Upholstery artificial leather is engineered to meet rigorous performance standards, making it ideal for high-traffic environments. It resists abrasion, staining, and fading while maintaining a soft, luxurious feel. Unlike natural leather, synthetic options provide consistent texture and thickness, reducing waste during production. Additionally, modern manufacturing processes significantly lower environmental impact by eliminating harmful tanning chemicals and reducing water consumption.

- Offers excellent resistance to wear, UV exposure, and cleaning agents

- Available in a wide range of colors, textures, and finishes for design versatility

- Easy to maintain and clean, ideal for commercial and residential use

- Cruelty-free and REACH-compliant, supporting sustainable and ethical sourcing

WINIW is a trusted leader in synthetic leather innovation, with over 20 years of expertise in developing high-quality, eco-friendly materials for global B2B clients. Our upholstery artificial leather is precision-engineered using advanced microfiber and polyurethane technologies, ensuring superior strength, breathability, and aesthetic consistency. With a strong commitment to sustainability, WINIW products are PVC-free, recyclable, and produced in ISO-certified facilities that prioritize energy efficiency and reduced emissions.

Backed by rigorous quality control and international certifications, WINIW delivers reliable, scalable solutions tailored to the demands of modern upholstery applications—from premium furniture to mass-transit seating.

Technical Performance & Standards

WINIW Premium Artificial Leather: Technical Product Guide for Upholstery Applications

WINIW delivers high-performance synthetic leather engineered specifically for demanding commercial and residential upholstery markets. Our advanced manufacturing process integrates stringent environmental stewardship with uncompromising technical specifications, providing furniture manufacturers and specifiers a sustainable, reliable, and premium alternative to traditional leather. Below are the key technical advantages validated through rigorous testing and certification.

Core Technical Advantages

-

Fire Retardant Performance (UK/US Standards Compliant):

WINIW upholstery leather exceeds critical fire safety regulations without compromising material integrity. Formulated with intrinsic fire-retardant polymers, it achieves:- UK: BS 5852:2006+ Amd 1:2010 (Cigarette & Match), Source 0 ignition source compliance.

- US: CAL TB 117-2013 (Smoldering ignition), NFPA 260 (Class I) for seating furniture.

- Technical Benefit: Eliminates need for secondary FR treatments, ensuring consistent safety performance throughout the product lifecycle and reducing flammability risks in high-occupancy environments.

-

Superior Easy Clean Properties:

Engineered with a non-porous, cross-linked PU surface layer resistant to stains, moisture, and microbial growth.- Resists common contaminants (coffee, ink, oils) with simple wipe-down using mild soap/water or standard upholstery cleaners.

- Maintains colorfastness (≥ Grade 4 on AATCC 61) after repeated cleaning cycles.

- Technical Benefit: Significantly reduces maintenance costs and extends product lifespan in healthcare, hospitality, and public transport settings.

-

Premium Soft Touch & Tactile Experience:

WINIW’s proprietary micro-foam backing and surface finishing technology replicates the suppleness of top-grain leather.- Achieves a consistently soft hand feel (measured 0.8-1.2 N/mm² tensile strength at 100% elongation).

- Surface gloss level optimized at 8-12 GU (60° gloss meter) for a natural, non-plastic aesthetic.

- Technical Benefit: Enhances user comfort and perceived quality, critical for premium furniture segments without sacrificing durability.

-

Full REACH SVHC Compliance:

WINIW proactively adheres to the EU REACH regulation (EC 1907/2006), ensuring complete safety for human health and the environment.- Zero Substances of Very High Concern (SVHC) above threshold limits in final product.

- Comprehensive 3rd party testing reports available for all restricted substances (e.g., phthalates, azo dyes, heavy metals).

- Technical Benefit: Guarantees market access across EU/UK and simplifies compliance for global supply chains, mitigating regulatory risks.

-

ISO 9001 Certified Quality Management:

Every batch is produced under WINIW’s ISO 9001:2015 certified quality system.- Strict in-line monitoring of thickness (±0.1mm), color consistency (ΔE < 0.5), and coating adhesion (>2.5 N/mm).

- Traceability from raw material sourcing to finished roll.

- Technical Benefit: Ensures batch-to-batch consistency, minimizes production waste for converters, and guarantees meeting technical specifications on every order.

Key Technical Specifications

| Property | WINIW Standard | Test Method | Compliance Level |

|---|---|---|---|

| Fire Resistance | BS 5852 Source 0 | BS 5852:2006+Amd1:2010 | Pass (Cigarette & Match) |

| CAL TB 117-2013 | CA Technical Bulletin | Pass (Smoldering) | |

| Abrasion Resistance | ≥ 50,000 cycles | ISO 12947-2 (Martindale) | Class 5 (Heavy Duty Commercial) |

| Color Fastness | ≥ Grade 4 | AATCC 61-2020 | After 50 washes |

| Tensile Strength | ≥ 25 N/mm² (Warp) | ISO 1767-2021 | Meets/exceeds EN 13360 |

| ≥ 22 N/mm² (Weft) | |||

| Tear Strength | ≥ 35 N (Warp) | ISO 13937-3:2017 | |

| ≥ 30 N (Weft) | |||

| REACH SVHC | None detected | EN 14372:2004 | Below detection limits (0.1% w/w) |

| VOC Emissions | < 10 µg/m³ (Total VOC) | ISO 16000-9:2006 | WELL Building Standard compliant |

| Backing Material | Recycled PET non-woven | Internal Spec. | ≥ 30% post-consumer recycled content |

WINIW’s upholstery artificial leather delivers a scientifically validated balance of safety, durability, user experience, and environmental responsibility. Our ISO 9001 framework ensures these properties are consistently met, providing B2B partners with a low-risk, high-value material solution for premium, sustainable furniture production. Custom formulations for specific fire codes, textures, or eco-content are available upon request.

Why Choose Synthetic over Real Leather

B2B Product Guide: Artificial Leather vs Real Leather for Upholstery

When selecting materials for upholstery in commercial and residential furniture, automotive interiors, or hospitality applications, businesses must weigh performance, cost, and sustainability. Two primary options dominate the market: artificial leather (also known as synthetic or faux leather) and real (genuine) leather. Each has distinct advantages and trade-offs depending on application and sustainability goals.

Artificial Leather for Upholstery

Artificial leather, particularly high-performance variants like polyurethane (PU) and microfiber leather, offers a durable, consistent, and increasingly eco-conscious alternative to real leather. Modern synthetic leathers are engineered to mimic the texture, softness, and aesthetic of genuine leather while providing greater design flexibility and lower environmental impact when produced responsibly.

- Consistent texture and color across batches, ideal for large-scale manufacturing

- Resistant to fading, staining, and cracking when high-quality materials are used

- Available in a wide range of colors, textures, and finishes—customizable for brand needs

- Easier to maintain and clean than real leather

- Can be made from recycled materials and produced with low-VOC, water-based processes

- Cruelty-free and suitable for vegan product lines

Real Leather for Upholstery

Real leather is derived from animal hides, typically bovine, and undergoes extensive tanning and finishing processes. It is valued for its natural beauty, breathability, and long-term patina development.

- Develops a unique, attractive patina over time, enhancing visual appeal

- Naturally breathable, making it suitable for seating in warm climates

- High tensile strength and long lifespan with proper care

- Perceived as a premium, luxury material in high-end markets

- Subject to natural variations (scars, grain differences), which may affect yield and consistency

- Requires chemical-intensive tanning processes (especially chrome tanning), raising environmental concerns

Comparative Analysis: Artificial Leather vs Real Leather

| Categoría | Piel artificial | Real Leather |

|---|---|---|

| Cost | Lower initial cost; economical for large-volume orders | Higher cost due to raw material scarcity and labor-intensive processing |

| Durabilidad | High resistance to abrasion, UV, and stains; consistent performance | Durable but prone to drying, cracking, and fading over time; performance varies by hide quality |

| Eco-friendliness | Can be made from recycled materials and water-based PU; lower carbon footprint when sustainably produced | High environmental cost: land use, methane emissions, and toxic tanning chemicals (e.g., chromium) |

Conclusion

For B2B manufacturers focused on scalability, consistency, and sustainability, artificial leather—especially eco-engineered solutions like WINIW’s water-based PU and recycled microfiber leathers—offers a compelling alternative to real leather. While real leather retains prestige in luxury markets, advancements in synthetic materials now deliver comparable aesthetics and superior performance in many commercial applications, all while aligning with global ESG and circular economy goals.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW operates one of the most advanced and environmentally conscious synthetic leather manufacturing facilities in Asia, engineered to deliver premium, sustainable materials for discerning global brands. Our vertically integrated production ecosystem ensures unparalleled control over quality, innovation, and ethical compliance from raw material sourcing to final shipment.

Core Manufacturing Capabilities

- Scale & Infrastructure: A state-of-the-art 100,000 sqm manufacturing complex featuring automated production lines, dedicated eco-processing zones, and integrated waste-reduction systems.

- R&D Leadership: 85+ engineers and material scientists driving innovation in water-based PU, bio-based polymers, and microfiber technologies. Annual R&D investment exceeds 5% of revenue, focused on durability, circularity, and low-carbon formulations.

- Garantía de calidad: Triple-stage QC protocols aligned with ISO 9001 and ISO 14001 standards. Every batch undergoes rigorous testing for colorfastness, abrasion resistance (Martindale >50,000 cycles), and eco-compliance (REACH, OEKO-TEX® STANDARD 100). Final inspection adheres to AQL 1.0 standards.

- Sustainability Integration: Closed-loop water treatment, 30%+ renewable energy usage, and traceable raw material sourcing (certified by SCS Global Services). All products are PVC-free and phthalate-free.

Global Export Excellence

WINIW supplies 50+ countries with seamless logistics and region-specific compliance. Key market adherence includes:

| Region | Key Certifications | Lead Time (Standard) | Minimum Order |

|---|---|---|---|

| Europe | REACH, OEKO-TEX®, EU Ecolabel | 25-30 days | 500 meters |

| North America | CPSIA, CA Prop 65, bluesign® | 20-25 days | 500 meters |

| Asia-Pacific | Japan Chemical Law, GB/T 22889 | 15-20 días | 300 meters |

Our factory’s scale enables consistent large-volume fulfillment (up to 1M meters/month) while maintaining batch-to-batch uniformity critical for international fashion, automotive, and furniture supply chains. All shipments include full documentation: test reports, certificates of origin, and carbon footprint statements.

Partner with WINIW for synthetic leather solutions where industrial capacity meets uncompromising eco-ethics—engineered for global brands demanding reliability, innovation, and responsibility.

Contact Us for Samples

B2B Product Guide: Artificial Leather for Upholstery by WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, specializing in eco-friendly, durable, and aesthetically versatile artificial leather for upholstery. Our advanced microfiber technology delivers a premium alternative to genuine leather—without the environmental impact or inconsistencies in supply.

Engineered for commercial and residential furniture manufacturers, automotive interiors, hospitality environments, and contract furnishings, WINIW’s upholstery leather combines superior tactile qualities with exceptional durability, making it the ideal material for high-traffic and design-focused applications.

Key Advantages of WINIW Artificial Leather for Upholstery

- High abrasion resistance: Exceeds 50,000+ double rubs (Martindale test), ideal for heavy-use environments

- Eco-conscious production: Made with solvent-free, low-VOC processes; compliant with REACH, RoHS, and OEKO-TEX® standards

- Superior softness and drape: Mimics the hand feel of top-grain leather with enhanced consistency across batches

- UV and colorfastness: Resists fading under prolonged exposure, maintaining appearance over time

- Easy maintenance: Wipe-clean surface resists stains, moisture, and microbial growth

- Customizable finishes: Available in matte, semi-gloss, embossed, and custom textures to match brand specifications

- Wide width rolls (up to 155 cm): Reduce seaming and increase yield in large-scale production

Technical Specifications Overview

| Property | Performance Standard |

|---|---|

| Thickness Range | 0.6 mm – 1.8 mm |

| Weight | 280 – 450 g/m² |

| Tensile Strength | ≥ 90 N/5cm (warp & weft) |

| Color Fastness (Light) | ≥ Grade 6 (after 40 hrs UV exposure) |

| Martindale Abrasion | 50,000 – 100,000 cycles |

| Fire Resistance | Meets CA117, BS5852, DIN 4102 (optional) |

| Base Material | Ultra-fine microfiber + PU coating |

Aplicaciones

- Residential and commercial seating (sofas, armchairs, dining chairs)

- Office furniture and ergonomic workspaces

- Automotive and transportation interiors

- Hospitality: hotels, lobbies, restaurants, and waiting areas

- Healthcare and senior living facilities

WINIW supports B2B partners with scalable production, rapid lead times, and full customization—from color matching (Pantone® or custom) to thickness and roll length. Our global logistics network ensures reliable delivery to manufacturers across North America, Europe, and Asia.

Request Free Samples

Experience the quality and versatility of WINIW artificial leather firsthand. We offer free samples for qualified business partners to evaluate performance, texture, and suitability for your upholstery projects.

For inquiries, sample requests, or technical support:

Contact: Marketing Department

Email: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.