Introduction: Navigating the Global Market for what is pu leather material

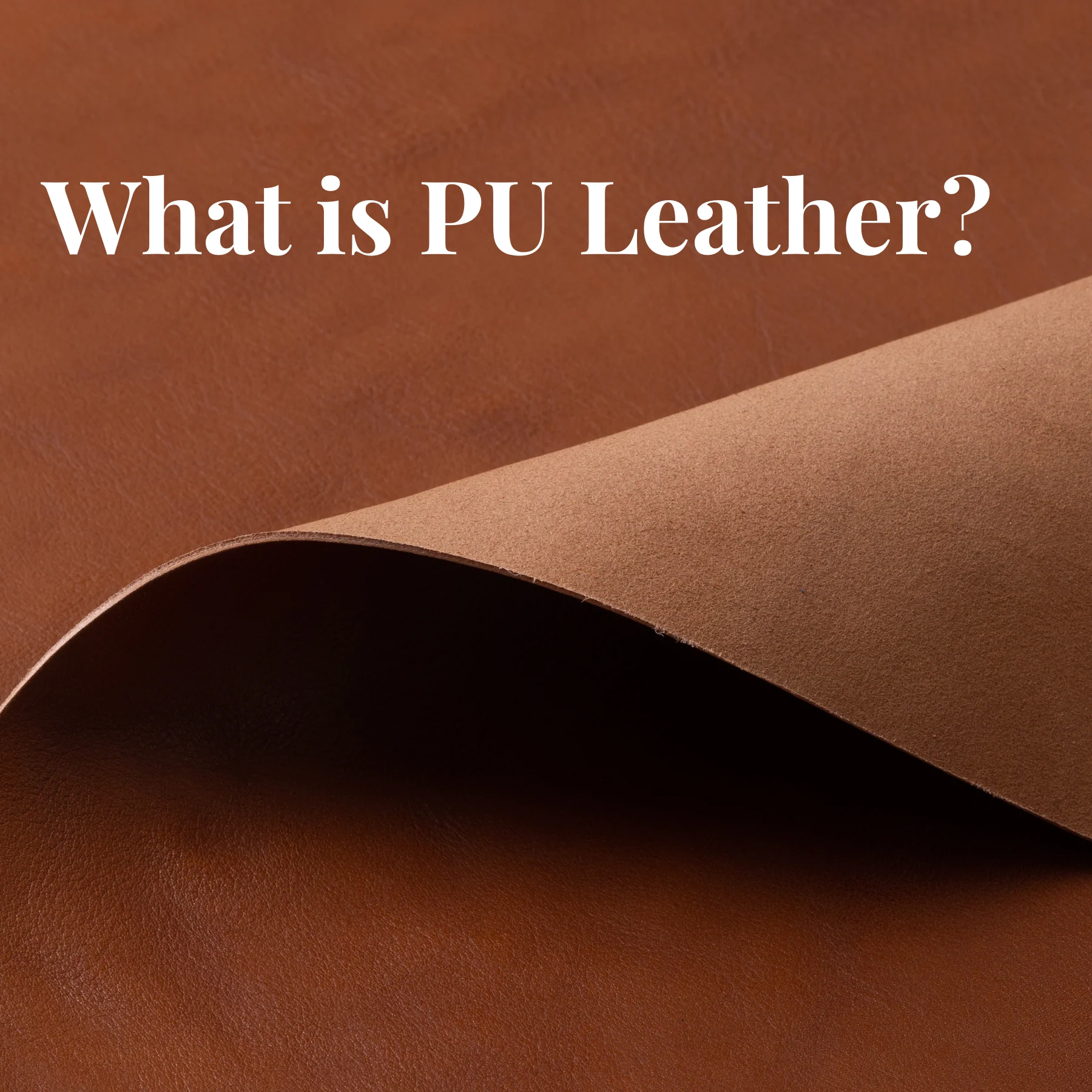

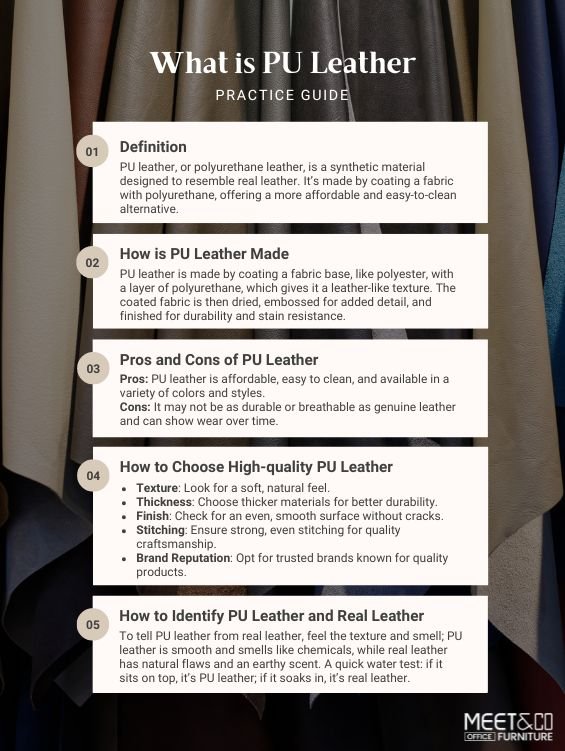

In an increasingly competitive global market, sourcing high-quality PU leather materials presents a significant challenge for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, including Germany and Nigeria. PU leather, or polyurethane leather, has gained popularity as a cost-effective alternative to genuine leather, yet understanding its characteristics, applications, and potential drawbacks is crucial for making informed purchasing decisions. This guide delves into the intricacies of PU leather, examining various types, their applications across industries, supplier vetting processes, and cost considerations.

By navigating the complexities of PU leather materials, international buyers can better assess their options, ensuring they select products that meet quality standards and align with their ethical and environmental values. The guide also highlights the importance of recognizing the differences between PU leather and genuine leather, including durability, environmental impact, and maintenance requirements. Armed with this knowledge, B2B buyers can engage in meaningful discussions with suppliers, negotiate better terms, and ultimately enhance their product offerings. In a landscape where consumer preferences are evolving towards sustainability and quality, this comprehensive resource empowers businesses to make strategic, informed choices that resonate with their clientele while maintaining a competitive edge.

Table Of Contents

- Top 4 What Is Pu Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is pu leather material

- Understanding what is pu leather material Types and Variations

- Key Industrial Applications of what is pu leather material

- 3 Common User Pain Points for ‘what is pu leather material’ & Their Solutions

- Strategic Material Selection Guide for what is pu leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for what is pu leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu leather material’

- Comprehensive Cost and Pricing Analysis for what is pu leather material Sourcing

- Alternatives Analysis: Comparing what is pu leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for what is pu leather material

- Navigating Market Dynamics and Sourcing Trends in the what is pu leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is pu leather material

- Strategic Sourcing Conclusion and Outlook for what is pu leather material

- Important Disclaimer & Terms of Use

Understanding what is pu leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coated PU Leather | Fabric backing with a polyurethane coating; smooth finish | Fashion items, upholstery, bags | Pros: Affordable, versatile. Cons: Less durable, may crack over time. |

| Recycled PU Leather | Made from recycled materials; eco-friendlier option | Eco-conscious fashion brands, furniture | Pros: Sustainable, lowers waste. Cons: May have variable quality. |

| Microfiber PU Leather | Ultra-fine fibers create a soft texture; breathable | Automotive interiors, high-end fashion | Pros: Durable, soft feel. Cons: Generally more expensive. |

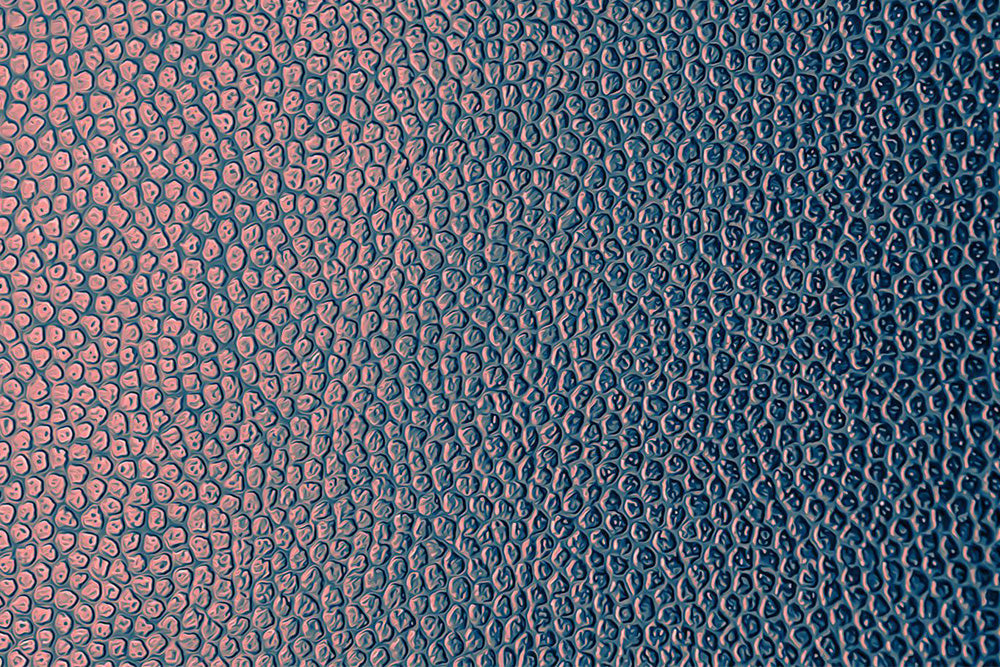

| Embossed PU Leather | Textured surface that mimics real leather grains | Accessories, footwear, furniture | Pros: Aesthetic appeal, cost-effective. Cons: Can wear down faster than genuine leather. |

| Waterproof PU Leather | Specially treated to resist moisture; often used in outdoor products | Outdoor gear, bags, and apparel | Pros: Functional for specific uses, easy to clean. Cons: Less breathable than other types. |

What Are the Characteristics of Coated PU Leather?

Coated PU leather is characterized by its fabric backing coated with a layer of polyurethane, providing a smooth and uniform finish. This type is commonly used in fashion items, upholstery, and bags due to its affordability and versatility. However, buyers should consider its longevity, as it may crack or peel with frequent use, requiring replacements every 1-2 years. When purchasing, B2B buyers should weigh the cost against potential long-term durability.

How Does Recycled PU Leather Stand Out?

Recycled PU leather is produced from repurposed materials, making it a more sustainable choice for environmentally-conscious businesses. It is gaining traction in eco-conscious fashion brands and furniture design. While it helps reduce waste, buyers should be aware that quality may vary depending on the source of the recycled materials. Companies prioritizing sustainability should explore this option for its environmental benefits, despite the possible inconsistency in quality.

What Are the Benefits of Microfiber PU Leather?

Microfiber PU leather features ultra-fine fibers that create a soft, luxurious texture while also being breathable. This type is particularly favored in automotive interiors and high-end fashion due to its durability and aesthetic appeal. However, it tends to be more expensive than standard PU leather. B2B buyers should consider this option for premium products where quality and longevity are crucial.

Illustrative image related to what is pu leather material

What Makes Embossed PU Leather a Popular Choice?

Embossed PU leather is designed with a textured surface that mimics the grains of genuine leather, making it visually appealing for accessories, footwear, and furniture. This type is cost-effective and can provide a high-end look without the associated price tag of real leather. However, it may wear down faster than genuine leather, so businesses should evaluate their target market’s expectations for product longevity when making purchasing decisions.

Why Choose Waterproof PU Leather for Specific Applications?

Waterproof PU leather is treated to resist moisture, making it ideal for outdoor gear, bags, and apparel. Its easy-to-clean surface adds to its functionality, appealing to businesses focused on practicality. However, this type may sacrifice breathability, which can be a consideration for products used in warmer climates. B2B buyers should assess the specific needs of their applications to determine if the benefits of waterproofing outweigh the potential downsides.

Key Industrial Applications of what is pu leather material

| Industry/Sector | Specific Application of what is pu leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Clothing and Accessories | Cost-effective alternative to genuine leather, appealing to budget-conscious consumers. | Ensure compliance with international safety standards and regulations regarding VOCs. |

| Automotive | Upholstery and Interior Trims | Durable and easy-to-clean material that enhances aesthetics while reducing overall vehicle weight. | Assess the material’s resistance to wear and tear, as well as its fire-retardant properties. |

| Muebles | Sofas and Upholstered Items | Provides a stylish look with lower maintenance needs, appealing to a wide range of consumers. | Evaluate the environmental impact of sourcing and ensure sustainable practices are followed. |

| Footwear | Shoes and Boots | Offers a lightweight, flexible option that mimics leather without the associated costs. | Check for breathability and moisture resistance to ensure comfort for end-users. |

| Home Décor | Decorative Items and Wall Panels | Versatile and customizable, allowing for unique designs that cater to various aesthetics. | Prioritize suppliers with certifications for non-toxicity and environmental safety. |

How is PU Leather Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, PU leather is utilized for a range of products including jackets, bags, and accessories. Its cost-effectiveness allows brands to offer leather-like products at lower price points, appealing to a broader audience. International buyers must consider the quality of the PU leather, ensuring it meets safety standards, particularly regarding volatile organic compounds (VOCs) which can pose health risks.

What Role Does PU Leather Play in the Automotive Industry?

The automotive industry employs PU leather primarily for upholstery and interior trims due to its durability and ease of cleaning. This material enhances vehicle aesthetics while contributing to weight reduction, which can improve fuel efficiency. Buyers in this sector should evaluate the material’s performance against wear and tear, as well as its fire-retardant properties to meet stringent safety regulations.

Why is PU Leather Preferred for Furniture Applications?

In furniture manufacturing, PU leather is favored for sofas and other upholstered items due to its stylish appearance and low maintenance requirements. It offers a practical solution for homeowners looking for an affordable alternative to genuine leather. When sourcing PU leather for furniture, businesses should consider the environmental implications of the production process and opt for suppliers committed to sustainable practices.

Illustrative image related to what is pu leather material

How is PU Leather Beneficial in Footwear Production?

PU leather is commonly used in the footwear industry for making shoes and boots, providing a lightweight and flexible alternative that mimics the look of genuine leather. This material allows manufacturers to produce comfortable and stylish footwear at competitive prices. Buyers should focus on ensuring that the PU leather used is breathable and moisture-resistant, enhancing the overall comfort for consumers.

What are the Advantages of Using PU Leather in Home Décor?

In home décor, PU leather is utilized for decorative items and wall panels, offering versatility and customization options. Its ability to mimic various textures makes it attractive for interior design projects. Buyers should prioritize sourcing from suppliers who provide certifications for non-toxicity and environmental safety, ensuring that the products meet health standards while appealing to eco-conscious consumers.

3 Common User Pain Points for ‘what is pu leather material’ & Their Solutions

Scenario 1: Concerns About Durability and Longevity of PU Leather Products

The Problem: B2B buyers often face the challenge of selecting materials that will withstand the rigors of their applications. PU leather, while appealing due to its lower price point, is notorious for its lack of durability. Over time, it can crack, peel, and fade, leading to high replacement costs and dissatisfied customers. Buyers must consider the long-term implications of their material choices, especially when they are sourcing products for industries like furniture, fashion, or automotive where durability is paramount.

The Solution: To effectively address durability concerns, B2B buyers should prioritize sourcing high-quality PU leather that is specifically designed for the intended application. Look for manufacturers that conduct rigorous quality testing and provide transparency about their material specifications. For instance, inquire about the thickness of the polyurethane layer and whether it has been treated with additives that enhance its resistance to wear and environmental factors. Additionally, consider establishing long-term relationships with suppliers who offer warranties or guarantees on their products. This not only assures quality but also enables buyers to access better support in case of issues. Implementing a proper maintenance plan can also extend the lifespan of PU leather products. Regular cleaning and the use of protective sprays can help preserve its appearance and functionality, ultimately improving customer satisfaction.

Scenario 2: Navigating Toxicity and Environmental Impact of PU Leather

The Problem: Increasingly, B2B buyers are facing scrutiny regarding the environmental footprint of their materials, including concerns about the toxic chemicals used in PU leather production. The presence of volatile organic compounds (VOCs) and other hazardous materials can pose risks not only to human health but also to the environment. Buyers who fail to address these concerns may find themselves at a competitive disadvantage, facing backlash from consumers who prioritize sustainability.

Illustrative image related to what is pu leather material

The Solution: To navigate these challenges, buyers should seek out PU leather manufacturers committed to sustainable practices. This includes sourcing materials that are free from harmful chemicals and utilizing eco-friendly production processes. When evaluating suppliers, request certifications that confirm the absence of VOCs and other toxic substances. Additionally, engaging with suppliers who adopt a transparent approach to their manufacturing processes can provide assurance regarding their environmental responsibility. Consider investing in PU leather that has been certified by recognized environmental standards, such as OEKO-TEX or GOTS. By choosing responsibly produced materials, buyers not only mitigate health risks but also enhance their brand’s reputation in a market increasingly driven by sustainability.

Scenario 3: Difficulty Distinguishing Between PU Leather and Genuine Leather

The Problem: Many B2B buyers struggle with the challenge of differentiating between PU leather and genuine leather, which can lead to misrepresentation and customer dissatisfaction. Misleading labeling and marketing tactics can make it difficult for buyers to make informed decisions, particularly when they are tasked with meeting specific quality standards or consumer expectations.

The Solution: To overcome this issue, B2B buyers should prioritize education and transparency in their sourcing strategies. One effective approach is to establish clear criteria for evaluating leather products, including understanding the composition, manufacturing process, and durability of the materials. Buyers should ask for detailed product specifications and samples to conduct their assessments. It can also be beneficial to develop partnerships with suppliers that offer educational resources, such as workshops or informational materials, on distinguishing between different types of leather. Implementing a clear labeling system within their own product lines can further enhance transparency for end consumers. By fostering an informed purchasing process, buyers can confidently choose the right materials that meet both quality and ethical standards, thereby enhancing their credibility in the market.

Illustrative image related to what is pu leather material

Strategic Material Selection Guide for what is pu leather material

What Materials Comprise PU Leather and Their Implications for B2B Buyers

PU leather, or polyurethane leather, is a synthetic alternative to genuine leather, primarily composed of polyurethane and a backing material. Understanding the materials involved in its production and their implications is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

What is Polyurethane and Its Role in PU Leather?

Key Properties: Polyurethane is a versatile polymer known for its flexibility, durability, and resistance to abrasion. It can withstand a range of temperatures and pressures, making it suitable for various applications. However, its performance can vary significantly depending on the formulation.

Pros & Cons: The primary advantage of polyurethane is its cost-effectiveness compared to genuine leather. It is easier to manufacture, allowing for mass production. However, its durability is often questioned; PU leather typically lasts between 6 to 24 months, whereas genuine leather can last decades. Additionally, PU leather is prone to cracking and peeling, especially in high-stress applications.

Impact on Application: PU leather is often used in fashion items, upholstery, and accessories. Its compatibility with various media is generally good, but it may not perform well in extreme conditions or high-wear environments.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Germany may prioritize certifications that ensure product safety and environmental impact, while those in Nigeria might focus on cost and availability.

What is the Backing Material in PU Leather?

Key Properties: The backing material, typically a blend of fabric and other synthetic fibers, provides structural support to PU leather. This material can vary widely in strength and durability, impacting the overall performance of the finished product.

Pros & Cons: A strong backing material enhances the durability of PU leather, making it more suitable for applications requiring a robust structure. However, lower-quality backing materials can lead to premature wear and tear, affecting the product’s lifespan.

Impact on Application: The choice of backing material can influence the weight, flexibility, and overall feel of the PU leather, making it essential for applications in fashion and furniture.

Illustrative image related to what is pu leather material

Considerations for International Buyers: Buyers should evaluate the sourcing of backing materials, especially in regions where quality standards may differ. Ensuring that the backing is compliant with local regulations can prevent future complications.

What Chemicals are Involved in PU Leather Production?

Key Properties: The production of PU leather often involves various chemicals, including solvents and additives that enhance durability and resistance to moisture. These chemicals can also introduce volatile organic compounds (VOCs) into the environment.

Pros & Cons: While these chemicals can improve the performance of PU leather, they raise concerns regarding toxicity and environmental impact. Buyers must weigh the benefits of enhanced durability against potential health risks associated with VOC exposure.

Illustrative image related to what is pu leather material

Impact on Application: The presence of harmful chemicals may limit the suitability of PU leather for certain applications, particularly in products intended for children or sensitive populations.

Considerations for International Buyers: Compliance with environmental regulations is critical. Buyers in Europe, for instance, may require products that meet stringent EU regulations regarding chemical safety, while those in South America may have different standards.

Summary Table of PU Leather Materials

| Material | Typical Use Case for what is pu leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Fashion accessories, upholstery | Cost-effective and versatile | Short lifespan, prone to cracking and peeling | Low |

| Backing Material | Structural support in PU leather | Enhances durability and feel | Quality varies, can lead to premature wear | Medium |

| Chemicals | Enhancements in durability and moisture resistance | Improves performance | Potential toxicity and environmental impact | Medium |

This strategic material selection guide provides B2B buyers with insights into the components of PU leather, enabling informed decisions aligned with their specific market needs and compliance requirements.

Illustrative image related to what is pu leather material

In-depth Look: Manufacturing Processes and Quality Assurance for what is pu leather material

What Are the Main Stages in the Manufacturing Process of PU Leather?

The manufacturing process of PU leather involves several critical stages, each requiring specialized techniques to ensure the final product meets quality standards. The process typically includes material preparation, forming, assembly, and finishing.

How is Material Prepared for PU Leather Production?

Material preparation is the first step in producing PU leather. This involves selecting the appropriate backing material, which is often a fabric blend designed to provide structural integrity. The backing is treated to enhance its adhesion properties and may undergo a pre-coating process to ensure a smooth application of the polyurethane layer.

The polyurethane is synthesized through a chemical reaction between diisocyanate and polyol, creating a versatile polymer. The formulation can be adjusted to achieve desired properties such as flexibility, durability, and texture. Quality control begins at this stage, with suppliers often required to provide certificates of analysis to confirm material specifications.

What Techniques Are Used in the Forming Process of PU Leather?

The forming stage involves coating the prepared backing material with a layer of polyurethane. This is typically achieved through techniques such as:

- Roller Coating: A method where the backing material passes through rollers that apply a uniform layer of polyurethane.

- Spray Coating: This technique uses spray nozzles to apply the polyurethane, allowing for more intricate textures and finishes.

- Foam Coating: Involves applying a foamy layer of polyurethane for enhanced cushioning properties.

Once coated, the material is embossed with textures that mimic genuine leather, enhancing its aesthetic appeal. This process is crucial for achieving the desired look and feel that competes with natural leather.

How Is PU Leather Assembled and Finished?

After forming, the PU leather is cut into the desired shapes for various applications, such as upholstery, bags, or garments. The assembly stage can involve stitching, bonding, or welding pieces together, depending on the end product’s requirements.

Finishing techniques may include applying additional protective coatings, such as anti-scratch or water-resistant layers, to enhance durability. This stage may also involve quality checks to ensure that the finished product meets the specified design and functional requirements.

What Quality Assurance Standards Are Relevant for PU Leather Manufacturing?

Quality assurance in PU leather manufacturing is critical for maintaining product integrity and safety. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers adhere to consistent quality practices.

Which Industry-Specific Certifications Should B2B Buyers Look For?

In addition to ISO certifications, industry-specific standards can further assure quality. For instance, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area. Buyers in sectors like automotive or furniture may also look for certifications from organizations like the American Petroleum Institute (API) for materials that meet specific performance criteria.

Illustrative image related to what is pu leather material

What Are the Key Quality Control Checkpoints in PU Leather Production?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process to ensure that the final product meets required specifications. Common QC checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications. This includes checking the backing materials and polyurethane components for defects or inconsistencies.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the coating and forming processes. This ensures that any deviations from quality standards are addressed immediately.

-

Final Quality Control (FQC): After production, the finished PU leather undergoes rigorous testing to evaluate its durability, texture, and overall quality. This may include visual inspections, physical tests for wear and tear, and chemical tests for harmful substances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps to ensure that suppliers meet quality standards:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Consider using third-party auditing services for an unbiased evaluation.

-

Request QC Reports: Suppliers should be able to provide documentation of their quality control processes, including test results, certifications, and compliance reports. This information is essential for assessing their commitment to quality.

-

Engage in Third-Party Inspections: Utilizing independent inspection services can further validate the quality of materials and finished products. These inspections can be conducted at various stages, including during production and before shipment.

What Testing Methods Are Commonly Used in PU Leather Quality Assurance?

Several testing methods are employed to assess the quality of PU leather, including:

- Tensile Strength Testing: Measures the material’s resistance to stretching and breaking.

- Tear Resistance Testing: Evaluates how well the material can withstand tearing forces.

- Abrasion Resistance Testing: Assesses the durability of the surface against wear from friction.

- Chemical Resistance Testing: Determines how the material reacts to various chemicals it may encounter in everyday use.

By understanding these testing methods, B2B buyers can better assess the quality and durability of PU leather products, ensuring they are making informed purchasing decisions.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers operating in different regions must be aware of the nuances in quality control practices due to varying regulations and standards. For example, buyers in Europe may face stricter regulations regarding the use of chemicals in PU leather production compared to suppliers in other regions.

Buyers should familiarize themselves with local laws and international trade regulations that may affect product quality. Building relationships with suppliers who are knowledgeable about these nuances can facilitate smoother transactions and compliance with market requirements.

In conclusion, understanding the manufacturing processes and quality assurance protocols for PU leather is essential for B2B buyers. By focusing on quality standards, verification methods, and testing techniques, companies can ensure they source high-quality PU leather that meets their specific needs and aligns with their values.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu leather material’

This guide aims to assist international B2B buyers in understanding and sourcing PU leather material effectively. As PU leather continues to be a popular alternative to genuine leather, it is essential to navigate the procurement process with a clear strategy. The following steps will help you make informed decisions while ensuring quality and compliance with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the PU leather you require is crucial. Consider factors such as thickness, texture, color, and intended application (e.g., upholstery, accessories). By defining these parameters, you can communicate your needs effectively to potential suppliers, ensuring that the material meets your quality and aesthetic standards.

Step 2: Research Supplier Credentials

Before engaging with suppliers, conduct thorough research to verify their credentials. Look for certifications related to quality management (ISO 9001), environmental standards (ISO 14001), and safety compliance (REACH). Supplier credibility can significantly impact the quality of the PU leather, so prioritize those with a solid reputation and positive reviews from past clients.

Step 3: Evaluate Supplier Manufacturing Processes

Investigating how suppliers manufacture their PU leather is essential for understanding its quality and sustainability. Inquire about the types of materials used, the production techniques employed, and any chemicals involved in the process. This step helps ensure that the PU leather is not only durable but also compliant with environmental regulations and free from harmful substances.

Step 4: Request Sample Materials

Requesting samples of PU leather from shortlisted suppliers allows you to assess the material firsthand. Pay attention to the texture, flexibility, and overall appearance. This evaluation will help you determine if the samples meet your specifications and expectations, reducing the risk of dissatisfaction upon bulk delivery.

Step 5: Inquire About Environmental Impact

Given the growing emphasis on sustainability, it’s important to discuss the environmental impact of the PU leather products. Ask suppliers about their waste management practices and whether they employ eco-friendly materials or processes. This inquiry not only aligns with corporate social responsibility goals but can also appeal to environmentally conscious consumers.

Step 6: Assess Pricing and Payment Terms

Price is a significant factor in the procurement process, but it should not be the sole consideration. Compare pricing structures across different suppliers while evaluating the quality of the PU leather offered. Additionally, clarify payment terms to ensure they align with your cash flow and budgeting strategies, minimizing potential financial strain.

Step 7: Negotiate Contracts and Terms of Delivery

Once you have selected a supplier, it’s time to negotiate contracts that detail all agreed-upon terms. Ensure that the contract includes specifications, pricing, delivery timelines, and penalties for non-compliance. Clear documentation protects your interests and lays the groundwork for a successful long-term partnership.

Illustrative image related to what is pu leather material

By following these steps, B2B buyers can navigate the procurement of PU leather material with greater confidence and clarity, ensuring that they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for what is pu leather material Sourcing

What Are the Key Cost Components for Sourcing PU Leather Material?

When analyzing the cost structure of PU leather sourcing, several key components play a pivotal role in determining the final price. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The primary material for PU leather is polyurethane, which is derived from petrochemical sources. The cost of raw materials fluctuates based on global oil prices and supply chain dynamics. Additionally, the backing fabric, often made from cotton or polyester, contributes to the overall material costs.

-

Labor: Labor costs vary significantly by region. In countries with lower wage standards, such as some in Africa and South America, labor may be less expensive, but this can also correlate with varying levels of craftsmanship and quality assurance.

-

Manufacturing Overhead: This includes utilities, maintenance of machinery, and general operational costs. Factories with modern, efficient production lines may offer competitive pricing compared to older facilities that require more resources to operate.

-

Tooling: Custom molds and machinery used for producing specific PU leather products can be a significant upfront investment. The costs associated with tooling must be amortized over the production run, influencing the pricing structure, especially for small volume orders.

-

Quality Control (QC): Ensuring that PU leather meets international standards and certifications can add to costs. Buyers should consider the implications of QC processes on pricing, as higher quality often results in higher costs.

-

Logistics: Shipping and transportation costs can vary greatly depending on the supplier’s location, the shipping method, and any tariffs or import duties applicable in the buyer’s region. Incoterms will influence the final landed cost of the goods.

-

Margin: Suppliers will typically apply a profit margin that reflects their operational costs and market positioning. This margin can vary based on the supplier’s reputation, quality of product, and market demand.

How Do Price Influencers Impact PU Leather Sourcing Costs?

Several factors can influence the pricing of PU leather in the international market:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often yield better per-unit pricing, while smaller orders may incur higher costs due to less favorable economies of scale.

-

Specifications and Customization: Custom designs or specific characteristics (e.g., color, texture) may add to the cost. Buyers should be clear about their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: The presence of certifications (such as eco-friendliness or compliance with safety standards) can impact the cost. Higher quality PU leather that meets rigorous standards will typically be priced higher.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may charge more, but they also reduce risks associated with poor product quality or delays.

-

Incoterms: Understanding the implications of Incoterms is essential for pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will affect who bears the transportation costs and risks, ultimately influencing the total cost.

What Negotiation Tips Should B2B Buyers Consider for PU Leather?

International B2B buyers should adopt several strategies to ensure cost efficiency and favorable pricing:

-

Conduct Market Research: Familiarize yourself with market prices and trends for PU leather to strengthen your negotiating position. Utilize industry reports and competitor pricing as benchmarks.

-

Leverage Volume: If possible, consolidate orders to meet MOQs and negotiate better pricing. Suppliers are more likely to offer discounts for larger commitments.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the longevity and performance of PU leather products. Cheaper options may incur higher costs over time due to frequent replacements.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better terms and pricing. Regular communication and transparency about your needs can foster trust.

-

Be Cautious of Pricing Nuances: Understand that pricing can vary based on geopolitical factors, currency fluctuations, and economic conditions in the supplier’s country. Always seek clarity on potential price changes before finalizing contracts.

Disclaimer on Indicative Prices

It is essential to note that the pricing of PU leather materials can vary widely based on numerous factors mentioned above. The information provided serves as a guideline and may not reflect current market conditions. Buyers are encouraged to conduct their own due diligence and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing what is pu leather material With Other Solutions

Exploring Alternatives to PU Leather: A Comparative Analysis

In the quest for sustainable and effective materials in various industries, PU leather has emerged as a popular choice due to its affordability and leather-like appearance. However, it is essential to consider viable alternatives that may offer superior performance, durability, and environmental benefits. This analysis will compare PU leather with two significant alternatives: genuine leather and recycled materials, providing insights that can assist B2B buyers in making informed decisions.

Illustrative image related to what is pu leather material

Comparison Table

| Comparison Aspect | What Is PU Leather Material | Genuine Leather | Recycled Materials |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling | High durability; ages well and develops unique patina | Varies; can be durable depending on the source material |

| Cost | Low initial cost | Higher initial investment, but long-term value | Moderate; often depends on sourcing and processing |

| Ease of Implementation | Widely available; easy to manufacture | Requires skilled craftsmanship; longer production time | Variable; dependent on the recycling process |

| Maintenance | Low maintenance; easy to clean | Requires regular conditioning for longevity | Depends on material; some may require more care |

| Best Use Case | Budget-friendly products; fashion accessories | High-end goods; luxury markets | Eco-conscious products; sustainable brands |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Genuine Leather?

Genuine leather is a time-honored material known for its exceptional durability and luxurious appeal. Unlike PU leather, it ages gracefully, developing a distinctive patina that enhances its character over time. However, the higher cost and ethical concerns regarding animal welfare can deter some buyers. Genuine leather is best suited for premium products in industries like fashion, furniture, and automotive, where quality and longevity are paramount.

How Do Recycled Materials Compare to PU Leather?

Recycled materials represent an innovative solution aimed at sustainability. By repurposing waste products, they can significantly reduce environmental impact. While some recycled materials can match PU leather in terms of aesthetics, their performance varies widely based on the original materials used. The cost can also be moderate, depending on the processing involved. Recycled materials are ideal for brands focused on eco-friendly practices, making them suitable for products targeting environmentally conscious consumers.

Conclusion: How Can B2B Buyers Choose the Right Material?

When considering alternatives to PU leather, B2B buyers must evaluate their specific needs, including budget constraints, product longevity, and environmental impact. Genuine leather offers unmatched durability and aesthetic appeal, making it a prime choice for luxury markets. In contrast, recycled materials can align with sustainability goals and appeal to eco-conscious consumers. By carefully assessing these options, businesses can select materials that not only meet their functional requirements but also resonate with their brand values and market positioning.

Essential Technical Properties and Trade Terminology for what is pu leather material

What Are the Key Technical Properties of PU Leather Material?

When assessing PU leather, understanding its technical properties is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Composition

PU leather is primarily composed of polyurethane, a synthetic polymer created through a chemical reaction between diisocyanate and polyol. This composition allows it to mimic the appearance of genuine leather while being more affordable. Buyers should be aware of the material’s synthetic nature, as it can affect the product’s longevity and environmental impact.

Illustrative image related to what is pu leather material

2. Durability and Lifespan

Typically, PU leather has a lifespan of 6 to 24 months, depending on usage conditions. Its durability is often lower compared to natural leather, which can last several years. For businesses, this means considering replacement cycles and potential long-term costs when sourcing PU leather products.

3. Moisture Resistance

PU leather is generally water-resistant, making it suitable for various applications, including furniture and fashion. However, it is essential to understand that while it repels moisture, prolonged exposure can lead to degradation. B2B buyers should evaluate the specific moisture resistance requirements of their intended applications.

4. Tensile Strength

Tensile strength refers to the material’s ability to withstand pulling forces without breaking. PU leather typically exhibits lower tensile strength than genuine leather, which can impact its suitability for heavy-duty applications. Buyers should assess their product requirements to ensure the selected PU leather meets necessary durability standards.

5. Environmental Impact

The production of PU leather involves petroleum-based processes, raising concerns about its environmental footprint. Understanding the environmental implications is crucial for businesses aiming for sustainable practices. Consideration of eco-friendly alternatives, such as vegetable-tanned leather, may also be beneficial.

6. Surface Texture and Finish

PU leather can be manufactured with various textures and finishes, ranging from smooth to embossed patterns. This versatility allows it to suit different aesthetic needs. Buyers should evaluate the texture requirements based on their market and consumer preferences.

What Are Common Trade Terms Associated with PU Leather?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms related to PU leather:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on another company’s design specifications. In the context of PU leather, an OEM might produce finished goods like bags or furniture for brands looking to outsource production. Understanding OEM relationships can help buyers find suitable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size a supplier is willing to accept. For PU leather products, MOQs can vary significantly depending on the supplier and product type. Buyers should consider their inventory needs and budget when negotiating MOQs with suppliers.

Illustrative image related to what is pu leather material

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. In the PU leather industry, submitting an RFQ can help businesses compare prices and make informed purchasing decisions. It’s an essential step in procurement, particularly for bulk orders.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers sourcing PU leather globally, as they outline costs, risks, and logistics responsibilities. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight).

5. Lead Time

Lead time refers to the time taken from placing an order until it is delivered. In the context of PU leather, lead times can vary based on production schedules and shipping methods. Buyers should factor lead times into their planning to ensure timely product availability.

6. Certification Standards

Certification standards, such as ISO or REACH, indicate compliance with specific safety and environmental regulations. For PU leather, certification can assure buyers of product quality and safety, making it an important consideration when selecting suppliers.

By understanding these technical properties and trade terms, B2B buyers can enhance their procurement strategies and make more informed decisions in the competitive PU leather market.

Illustrative image related to what is pu leather material

Navigating Market Dynamics and Sourcing Trends in the what is pu leather material Sector

What Are the Key Market Dynamics and Sourcing Trends in the PU Leather Sector?

What Are the Global Drivers and Emerging B2B Trends for PU Leather?

The PU leather market has witnessed significant growth, driven primarily by its affordability and versatility. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek cost-effective alternatives to genuine leather, PU leather emerges as a favored option. Key trends include the integration of digital sourcing platforms, which streamline the procurement process and enhance supplier visibility. The rise of e-commerce also facilitates access to diverse suppliers, enabling buyers to compare prices and quality effectively.

Moreover, there is a growing inclination towards customization in PU leather products, particularly in fashion and automotive sectors. This trend is supported by advancements in manufacturing technologies, allowing businesses to offer tailored solutions to meet specific customer demands. Additionally, as consumer awareness around product origins increases, B2B buyers are emphasizing traceability in their sourcing strategies, seeking suppliers who can provide transparency in their production processes.

How Does Sustainability and Ethical Sourcing Impact PU Leather Procurement?

Sustainability is becoming a critical consideration in the sourcing of PU leather. The environmental impact of synthetic materials, particularly in terms of their non-biodegradability and potential toxicity, raises concerns among conscientious B2B buyers. Many suppliers are now prioritizing eco-friendly practices, including the use of non-toxic chemicals and sustainable production methods.

Buyers are increasingly looking for suppliers who can provide certifications that validate the sustainability of their products. Certifications such as OEKO-TEX® or Global Recycled Standard (GRS) are gaining traction, as they assure buyers that the materials used in PU leather production meet strict environmental and safety criteria. Ethical sourcing practices, including fair labor standards and responsible sourcing of raw materials, are also becoming essential in supplier evaluations, particularly for buyers in Europe and regions with stringent regulatory frameworks.

What Is the Historical Context of PU Leather Development?

The evolution of PU leather is rooted in the broader advancements of synthetic materials throughout the 20th century. Originally synthesized in Germany in 1937, polyurethane was first utilized for industrial applications. By the 1960s, innovators began to explore its potential as a leather alternative, leading to the development of PU leather as a more affordable and accessible option for consumers.

Over the decades, PU leather has adapted to changing market demands, becoming synonymous with fast fashion and mass production. Despite its initial appeal, the material’s limitations, including reduced durability and environmental concerns, have prompted a shift towards more sustainable alternatives. Understanding this historical context is crucial for B2B buyers, as it highlights the material’s lifecycle and the growing demand for responsible sourcing in today’s market.

By staying informed about market dynamics, sustainability trends, and the historical context of PU leather, international B2B buyers can make more strategic sourcing decisions, aligning their procurement practices with evolving consumer expectations and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of what is pu leather material

1. How do I assess the quality of PU leather materials from suppliers?

When sourcing PU leather, evaluating quality is crucial. Request samples to inspect the texture, flexibility, and durability. High-quality PU leather should feel smooth and have a consistent finish without visible flaws or peeling. Additionally, inquire about the manufacturing process and the types of chemicals used, as this can impact both product quality and environmental sustainability. Certifications or compliance with international standards can also indicate a reliable supplier. Establishing clear quality benchmarks will help ensure that the materials meet your expectations.

Illustrative image related to what is pu leather material

2. What are the key differences between PU leather and genuine leather?

PU leather is a synthetic alternative designed to mimic the appearance of genuine leather but lacks its durability and longevity. Genuine leather is derived from animal hides and develops a unique patina over time, while PU leather tends to crack and peel, usually requiring replacement every 1-2 years. Additionally, genuine leather is often more expensive due to the craftsmanship involved, whereas PU leather is mass-produced and more affordable. Understanding these differences is essential for making informed purchasing decisions based on your product needs and market demands.

3. What customization options are available for PU leather products?

Customization options for PU leather can vary by supplier but generally include choices in color, texture, thickness, and even embossing or printing designs. Many manufacturers are open to creating bespoke products tailored to your specifications, which can enhance your brand identity. It’s advisable to discuss your specific requirements upfront and review any minimum order quantities (MOQs) that may apply to customized orders. Collaborating closely with your supplier will ensure the end product aligns with your vision and market expectations.

4. What are typical minimum order quantities (MOQs) for PU leather products?

Minimum order quantities for PU leather can range widely depending on the manufacturer and the complexity of the product. Generally, MOQs might start from 100 units for basic designs but can increase significantly for customizations or specialized finishes. When negotiating with suppliers, clarify the MOQ upfront to ensure it aligns with your purchasing capabilities and market strategy. Consider discussing the potential for smaller initial orders or a phased purchasing approach if you’re testing new products.

5. How should I evaluate potential suppliers for PU leather?

To effectively evaluate suppliers, start by researching their reputation within the industry. Check for certifications, client testimonials, and their adherence to environmental standards. Request samples to assess product quality and consistency. It’s also beneficial to inquire about their production capacity and lead times to ensure they can meet your demand. Establishing a direct line of communication can facilitate better negotiation terms and help build a collaborative relationship, which is vital for long-term partnerships.

Illustrative image related to what is pu leather material

6. What payment terms are commonly accepted for international PU leather purchases?

Payment terms for international transactions can vary significantly by supplier and region. Common practices include a deposit (often 30-50%) upfront, with the balance due upon completion of the order or before shipment. Some suppliers may accept letters of credit or payment through secure platforms. Always clarify payment terms before finalizing contracts to avoid misunderstandings. It’s advisable to work with suppliers who offer transparent payment processes and are willing to accommodate your financial policies.

7. How do logistics and shipping impact the sourcing of PU leather?

Logistics and shipping are critical factors in the sourcing process, particularly for international buyers. Consider the supplier’s location, shipping methods, and potential tariffs or customs duties that may apply. Effective communication regarding lead times and delivery schedules is essential to prevent delays. Additionally, partnering with a logistics provider experienced in international shipping can help streamline the process and ensure compliance with local regulations, ultimately reducing the risk of unexpected costs.

8. What environmental considerations should I be aware of when sourcing PU leather?

Sourcing PU leather involves understanding its environmental impact, as it is a petroleum-based product that is non-biodegradable. Many PU leather manufacturing processes release volatile organic compounds (VOCs), which can harm both health and the environment. When evaluating suppliers, inquire about their sustainability practices, such as waste management and the use of eco-friendly chemicals. Opting for suppliers who prioritize environmental responsibility will not only align with global sustainability trends but can also enhance your brand’s reputation in eco-conscious markets.

Top 4 What Is Pu Leather Material Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Solutions

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – PU Leather Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Carl Friedrik – PU Leather Products

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a type of plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl, mimicking the look and feel of animal leather. 100% PU leather is vegan-friendly, while PU applied to split leather (animal hide) is not. Benefits include being softer, lighter, UV resistant, easy to c…

3. HowStuffWorks – PU Leather Insights

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan, with no animal skin involved. There are two types of PU leather: full-synthetic (totally vegan) and semi-synthetic (which has a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors. However, it lacks the authentic appearance and t…

4. Billy Tannery – PU Leather

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: PU leather, or polyurethane leather, is a synthetic leather alternative designed to mimic the look and feel of real leather. It is made from a base layer of polyester or similar fabric, topped with a polyurethane coating. PU leather is considered vegan and is used for products like furniture, shoes, bags, and wallets. It is generally cheaper than real leather and offers a variety of colors and tex…

Strategic Sourcing Conclusion and Outlook for what is pu leather material

In navigating the complexities of PU leather, it is crucial for B2B buyers to weigh the material’s affordability against its long-term implications. While PU leather may seem like a cost-effective alternative to genuine leather, its durability concerns, potential toxicity, and environmental impact can affect brand reputation and customer satisfaction. Strategic sourcing of materials requires a comprehensive understanding of these factors to make informed decisions that align with both business objectives and ethical practices.

By considering alternatives, such as vegetable-tanned leather, companies can invest in sustainable, high-quality products that not only enhance their brand image but also contribute positively to the environment. Emphasizing transparency and responsible sourcing can help businesses build trust with consumers who are increasingly prioritizing sustainability.

As you explore your sourcing options, focus on partnerships that prioritize quality, safety, and sustainability. Engage with suppliers who are committed to ethical practices and can provide clear information about their materials. The future of your brand hinges on these choices—make them wisely to ensure long-lasting success in the competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is pu leather material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.