Introduction: Navigating the Global Market for gray leather fabric

In an increasingly competitive global market, sourcing high-quality gray leather fabric presents both challenges and opportunities for B2B buyers. With the rise of sustainable practices and evolving consumer preferences, businesses must navigate a complex landscape where quality, cost, and ethical sourcing play pivotal roles. This guide offers a comprehensive exploration of gray leather fabric, addressing key aspects such as types, applications, supplier vetting, and pricing. Whether you are looking to procure materials for upscale furniture, automotive interiors, or fashion accessories, understanding the nuances of gray leather will enhance your purchasing strategy.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in sourcing. Factors such as varying quality standards, cultural preferences, and logistics can complicate the decision-making process. This guide aims to empower you with actionable insights and expert advice, enabling you to make informed choices that align with your business objectives. From identifying reputable suppliers to evaluating cost-effective options, we provide the tools you need to secure the best gray leather fabric for your projects. By the end of this guide, you will be equipped to confidently navigate the global market and enhance your product offerings with exquisite gray leather.

Table Of Contents

- Top 6 Gray Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for gray leather fabric

- Understanding gray leather fabric Types and Variations

- Key Industrial Applications of gray leather fabric

- 3 Common User Pain Points for ‘gray leather fabric’ & Their Solutions

- Strategic Material Selection Guide for gray leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for gray leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘gray leather fabric’

- Comprehensive Cost and Pricing Analysis for gray leather fabric Sourcing

- Alternatives Analysis: Comparing gray leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for gray leather fabric

- Navigating Market Dynamics and Sourcing Trends in the gray leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gray leather fabric

- Strategic Sourcing Conclusion and Outlook for gray leather fabric

- Important Disclaimer & Terms of Use

Understanding gray leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains natural grain and texture, high durability | High-end furniture, luxury goods | Pros: Premium quality, breathability. Cons: Higher cost, requires maintenance. |

| Top Grain Leather | Sanded down for a smoother finish, less durable than full grain | Upholstery, automotive interiors | Pros: Elegant appearance, easier to clean. Cons: Less durable than full grain. |

| Piel nobuk | Sanded surface creates a soft, velvety texture | Fashion accessories, high-end upholstery | Pros: Luxurious feel, unique look. Cons: Prone to staining, requires special care. |

| Suede Leather | Soft, napped finish, made from the underside of the hide | Apparel, furniture accents | Pros: Soft texture, stylish. Cons: Less durable, sensitive to moisture. |

| Piel sintética | Synthetic alternative, often more affordable | Budget-friendly upholstery, fashion items | Pros: Cost-effective, easy maintenance. Cons: Less breathable, may not have the same aesthetic appeal. |

What are the Characteristics and Suitability of Full Grain Leather for B2B Buyers?

Full grain leather is the highest quality leather available, maintaining the natural grain and imperfections of the hide. This type of leather is incredibly durable and ages beautifully, making it ideal for high-end furniture and luxury goods. B2B buyers should consider full grain leather when sourcing materials for products that require a premium finish and long-lasting quality. Its breathability enhances comfort, particularly in upholstery applications, but the higher price point necessitates careful consideration of target market demographics.

How Does Top Grain Leather Compare for Upholstery Needs?

Top grain leather is a popular choice among B2B buyers due to its refined appearance and increased resistance to stains compared to full grain leather. It is sanded to remove imperfections, resulting in a smoother finish that is visually appealing for upholstery and automotive interiors. While it offers a balance of quality and price, buyers should note that top grain leather is less durable than full grain, which may impact its longevity in high-traffic applications. Understanding the intended use can help buyers make informed decisions regarding their selections.

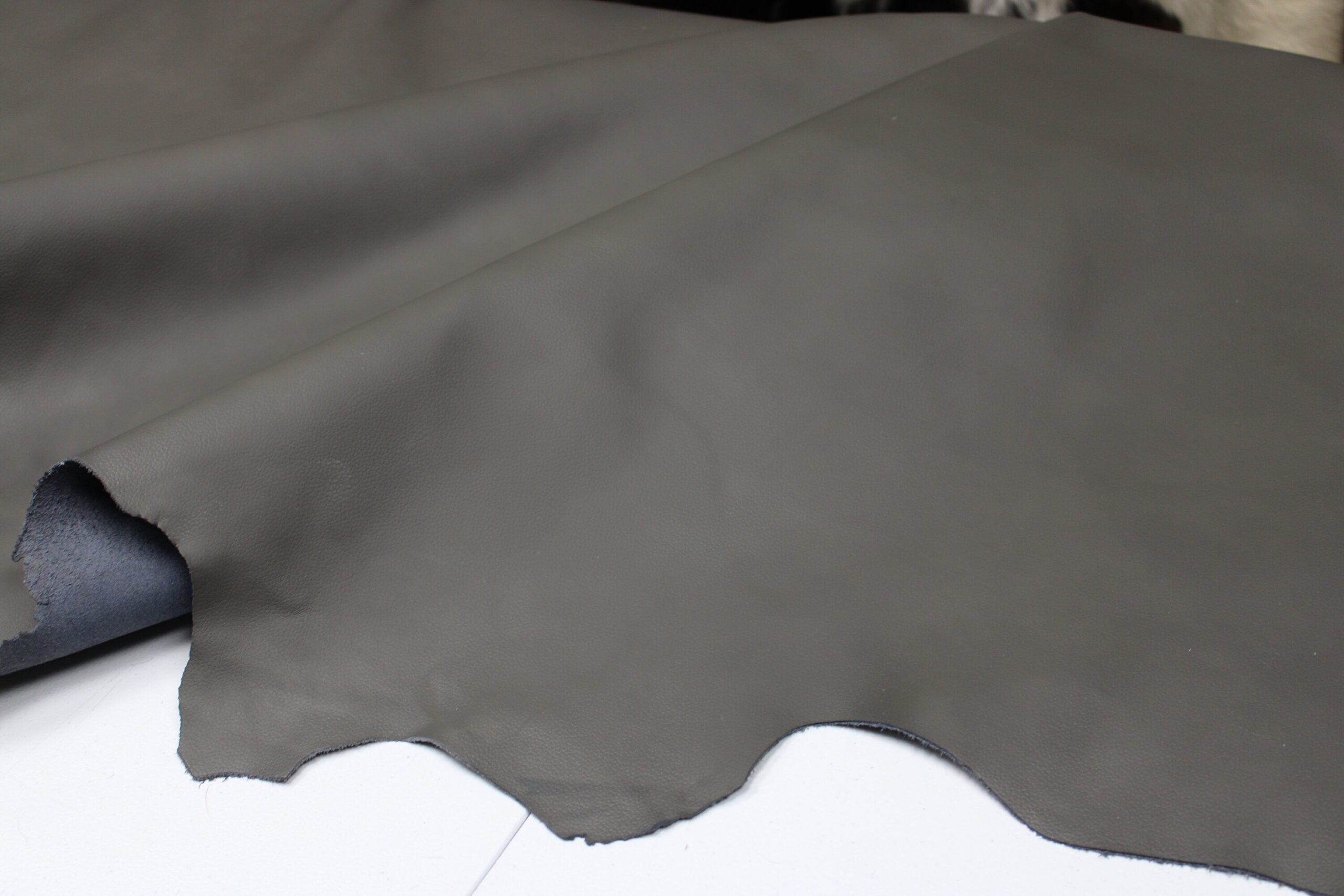

Illustrative image related to gray leather fabric

What Makes Nubuck Leather a Unique Option for Fashion Accessories?

Nubuck leather features a soft, velvety texture achieved through sanding the outer layer of the hide. Its luxurious feel makes it an attractive option for high-end upholstery and fashion accessories. However, B2B buyers must be aware of its susceptibility to stains and moisture, requiring specific care and maintenance protocols. When sourcing nubuck leather, businesses targeting the luxury market should weigh its aesthetic appeal against the potential for increased maintenance costs.

Why Choose Suede Leather for Apparel and Decorative Applications?

Suede leather, derived from the underside of the hide, offers a soft and stylish finish that is particularly suited for apparel and decorative furniture accents. Its napped texture adds a unique touch to products but can be less durable than other leather types, making it less ideal for high-wear applications. B2B buyers should evaluate the target market and potential usage scenarios when considering suede, as its sensitivity to moisture and staining may necessitate additional care measures.

How Does Faux Leather Fit into Budget-Conscious B2B Purchases?

Faux leather presents an attractive alternative for B2B buyers looking for budget-friendly options. Made from synthetic materials, it is often more affordable than genuine leather and offers easy maintenance. While faux leather may lack the breathability and aesthetic appeal of natural leather, it serves well in applications where cost is a primary concern, such as budget upholstery or fashion items. Buyers should consider the trade-offs between price and quality to align their sourcing decisions with market demands.

Key Industrial Applications of gray leather fabric

| Industry/Sector | Specific Application of gray leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas, chairs, and ottomans | Enhances aesthetic appeal and durability | Quality of leather, color consistency, and texture |

| Automotive | Interior trim and seating | Offers a luxurious look and long-lasting wear | Compliance with industry standards, flexibility in sourcing |

| Fashion & Accessories | Handbags, wallets, and apparel | Provides a modern, stylish appearance | Sourcing from reputable tanneries for quality assurance |

| Interior Design | Wall coverings and decorative accents | Adds sophistication and value to spaces | Availability of custom colors and textures |

| Hospitality | Upholstery for hotel furniture and decor | Improves guest experience and brand image | Bulk purchasing options and sustainability practices |

How is Gray Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, gray leather fabric is predominantly used for upholstery on sofas, chairs, and ottomans. Its neutral tones blend seamlessly with various interior design styles, making it a preferred choice for contemporary and modern aesthetics. By opting for gray leather, manufacturers can meet consumer demand for durable and stylish furniture, while also addressing concerns about wear and tear. Buyers should prioritize sourcing high-quality leather that maintains color consistency and texture to ensure a premium product.

What Role Does Gray Leather Fabric Play in the Automotive Industry?

The automotive industry utilizes gray leather fabric primarily for interior trim and seating, providing vehicles with a luxurious look and feel. This application not only enhances the visual appeal but also contributes to the longevity of the interiors against daily wear. For international buyers, especially in regions like Africa and South America, sourcing leather that complies with industry standards and offers flexibility in terms of bulk orders is crucial to meeting production demands and maintaining quality.

How is Gray Leather Fabric Incorporated in Fashion and Accessories?

In the fashion and accessories industry, gray leather fabric is favored for creating handbags, wallets, and apparel. Its modern and sophisticated appearance appeals to consumers looking for stylish yet durable items. For B2B buyers, sourcing from reputable tanneries that guarantee quality is essential to avoid issues with color fading and texture variations. Additionally, the ability to customize shades and finishes can provide a competitive edge in a saturated market.

How is Gray Leather Fabric Used in Interior Design?

Gray leather fabric finds significant application in interior design, particularly for wall coverings and decorative accents. Its versatility allows designers to create sophisticated spaces that resonate with modern aesthetics. For businesses in this sector, ensuring the availability of custom colors and textures is vital for meeting diverse client needs. Buyers should also consider sourcing practices that emphasize sustainability, as eco-conscious design is increasingly important in contemporary interiors.

What are the Benefits of Gray Leather Fabric in the Hospitality Sector?

In the hospitality sector, gray leather fabric is extensively used for upholstering hotel furniture and decor. This application not only enhances the guest experience through comfort and style but also elevates the brand image of the establishment. For B2B buyers in this industry, bulk purchasing options can lead to cost savings, while ensuring that the leather sourced is durable enough to withstand high traffic and maintain its aesthetic appeal over time.

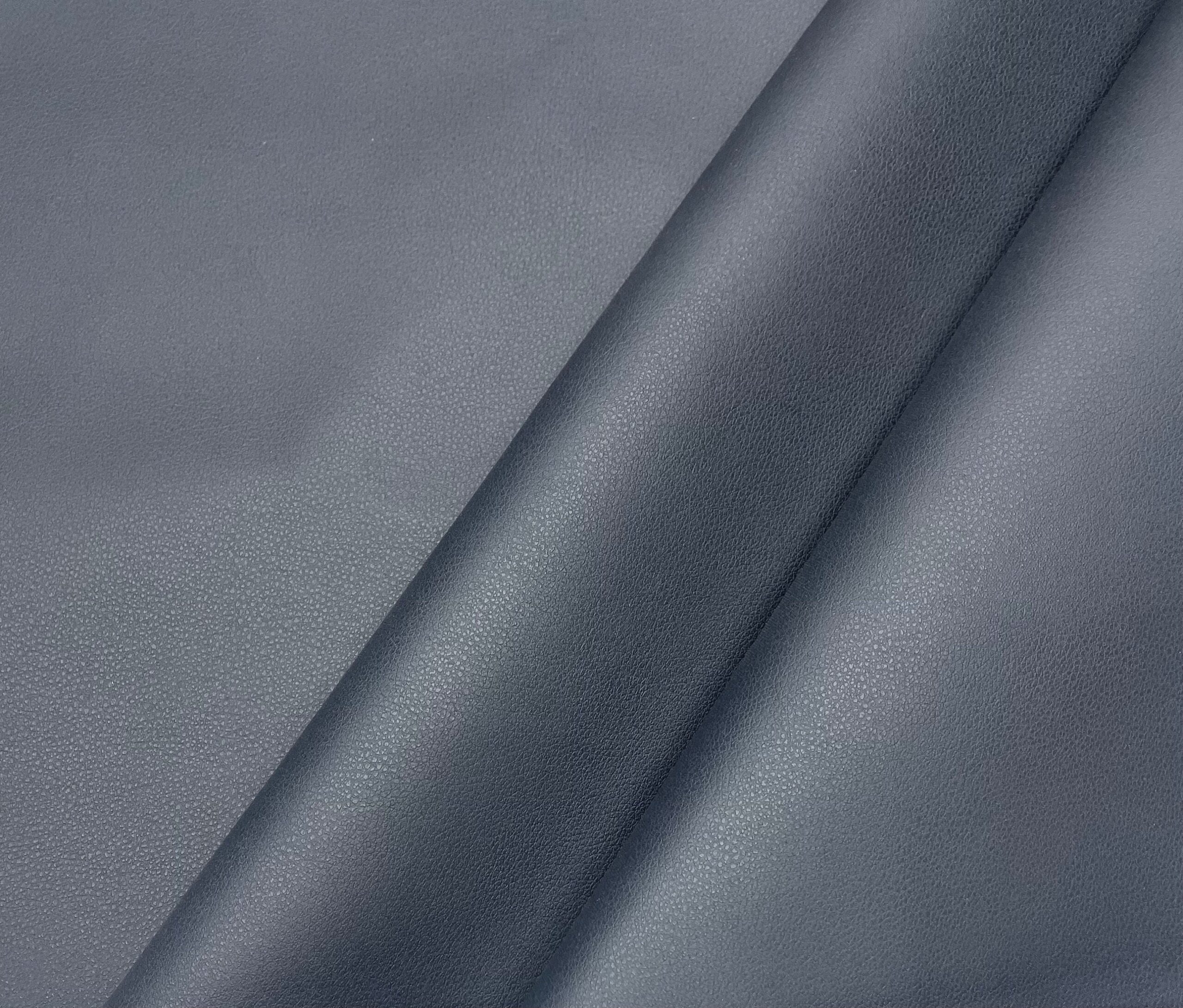

Illustrative image related to gray leather fabric

3 Common User Pain Points for ‘gray leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Gray Leather Fabric for Diverse Applications

The Problem: B2B buyers often struggle with sourcing high-quality gray leather fabric that meets their specific application needs. In regions such as Africa and South America, where local suppliers may not have a diverse inventory, buyers face challenges in finding leather that meets both aesthetic and functional requirements. They may encounter issues with inconsistent quality, inadequate color matching, or limited options in terms of textures and finishes, which can complicate their projects and lead to costly delays.

The Solution: To mitigate these challenges, buyers should establish relationships with reputable suppliers who specialize in gray leather fabric and offer a comprehensive range of products. It’s essential to request samples of various hides to assess quality and match specific project requirements before making bulk purchases. Additionally, buyers can leverage technology by utilizing virtual showrooms or online catalogs that provide detailed images and descriptions, ensuring they can visualize the fabric’s appearance and texture. Engaging in open dialogue with suppliers about specific project needs can also help in sourcing leather that aligns perfectly with their vision and application requirements.

Scenario 2: Managing Inventory and Stock Levels of Gray Leather Fabric

The Problem: Effective inventory management is a common pain point for B2B buyers dealing with gray leather fabric. Due to the variability in demand and the limited shelf life of leather products, businesses often find themselves overstocked with certain shades or finishes while running low on others. This imbalance not only ties up capital but can also lead to wastage of materials that may no longer be in vogue, especially in dynamic markets across Europe and the Middle East.

Illustrative image related to gray leather fabric

The Solution: Implementing a Just-In-Time (JIT) inventory system can significantly enhance inventory management for gray leather fabric. This approach involves working closely with suppliers to schedule deliveries based on projected demand, minimizing excess stock and reducing waste. Additionally, buyers should consider utilizing inventory management software that tracks usage patterns, allowing them to forecast needs more accurately. Collaborating with suppliers on a consignment basis could also provide flexibility, enabling buyers to maintain lower stock levels while ensuring quick access to the leather they need for projects.

Scenario 3: Understanding the Tanning Process and Its Impact on Gray Leather Fabric

The Problem: Many B2B buyers lack a comprehensive understanding of the tanning process and how it influences the quality and characteristics of gray leather fabric. This knowledge gap can lead to poor purchasing decisions, resulting in leather that does not meet durability or aesthetic expectations. For example, buyers may not realize that different tanning methods affect the leather’s softness, resistance to wear, and suitability for various applications such as upholstery or automotive interiors.

The Solution: Buyers should educate themselves on the various tanning processes—vegetable tanning, chrome tanning, and synthetic tanning—and how these methods impact the performance and appearance of gray leather. Attending industry workshops or training sessions can provide valuable insights into leather characteristics and help buyers make informed decisions. Moreover, establishing a partnership with suppliers who are transparent about their tanning methods can facilitate better product selection. When negotiating with suppliers, buyers can ask for detailed descriptions of the tanning process used for their gray leather options, ensuring they choose materials that align with their project’s needs and longevity expectations.

Strategic Material Selection Guide for gray leather fabric

What Are the Key Materials Used in Gray Leather Fabric?

When selecting gray leather fabric, international B2B buyers must consider various materials that influence performance, durability, and suitability for specific applications. Below, we analyze four common materials used in gray leather fabric, focusing on their properties, pros and cons, and considerations for buyers in diverse markets.

Illustrative image related to gray leather fabric

1. Top Grain Leather

Key Properties:

Top grain leather is derived from the uppermost layer of the hide, making it more durable and resistant to wear and tear. It typically has a temperature rating suitable for upholstery applications and can withstand moderate pressure.

Pros & Cons:

The primary advantage of top grain leather is its durability and aesthetic appeal, often featuring a natural grain pattern. However, it is more expensive than other leather types, which may affect budget considerations for some buyers. Additionally, while it is relatively easy to clean, it can be susceptible to scratching.

Impact on Application:

Top grain leather is ideal for high-end furniture and automotive interiors, where a refined look is essential. It is compatible with a range of upholstery media, enhancing the overall design.

Illustrative image related to gray leather fabric

Considerations for International Buyers:

Buyers from regions like Africa and South America should be aware of local climate conditions that might affect leather maintenance. Compliance with local standards, such as ASTM for durability, is crucial for ensuring product quality.

2. Split Leather

Key Properties:

Split leather is created from the lower layers of the hide, making it less durable than top grain leather. However, it can still offer reasonable temperature and pressure resistance for various applications.

Pros & Cons:

The cost-effectiveness of split leather is a significant advantage, making it accessible for budget-conscious projects. However, it is generally less durable and more prone to wear and tear compared to top grain leather, which limits its application in high-use environments.

Impact on Application:

Split leather is often used in lower-end furniture and accessories. Its compatibility with synthetic finishes allows for creative applications, though it may not suit high-end markets.

Illustrative image related to gray leather fabric

Considerations for International Buyers:

Buyers should ensure that split leather meets local standards for quality and durability. In regions like the Middle East, where humidity can affect leather, proper treatment and care are essential.

3. Nubuck Leather

Key Properties:

Nubuck leather is a type of top grain leather that has been sanded or buffed to create a soft, velvety surface. It offers good temperature regulation and is reasonably resistant to pressure.

Pros & Cons:

Nubuck’s luxurious feel and appearance make it a popular choice for upscale applications. However, it is more susceptible to staining and requires regular maintenance, which can be a drawback for some buyers.

Illustrative image related to gray leather fabric

Impact on Application:

Nubuck is often used in high-end furniture, fashion accessories, and automotive interiors, providing a sophisticated aesthetic. Its compatibility with various upholstery methods allows for versatile design options.

Considerations for International Buyers:

Buyers should consider the care requirements for nubuck, especially in regions with high humidity or dust, which may require additional maintenance efforts. Compliance with international leather standards is also essential.

4. Faux Leather (Synthetic Leather)

Key Properties:

Faux leather is made from synthetic materials, offering a wide range of textures and colors. It is generally resistant to moisture and easy to clean, making it suitable for various applications.

Pros & Cons:

The primary advantage of faux leather is its affordability and ethical appeal, as it does not involve animal products. However, it may lack the durability and breathability of genuine leather, which can limit its use in high-end applications.

Impact on Application:

Faux leather is widely used in budget-friendly furniture, automotive interiors, and fashion accessories. Its versatility allows for creative applications across different markets.

Considerations for International Buyers:

Buyers should verify the environmental impact of faux leather production and ensure compliance with local regulations regarding synthetic materials. Understanding regional preferences for materials can also guide purchasing decisions.

Summary Table of Material Selection for Gray Leather Fabric

| Material | Typical Use Case for gray leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Top Grain Leather | High-end furniture and automotive interiors | Durable and aesthetically pleasing | Higher cost; susceptible to scratches | Alta |

| Split Leather | Budget furniture and accessories | Cost-effective | Less durable; prone to wear | Low |

| Piel nobuk | Upscale furniture and fashion accessories | Luxurious feel | Requires regular maintenance; stains easily | Medium |

| Piel sintética | Budget-friendly furniture and automotive interiors | Affordable and ethical | Less durable; lacks breathability | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for gray leather fabric

What are the Key Stages in the Manufacturing Process of Gray Leather Fabric?

The manufacturing process of gray leather fabric is a detailed and multi-stage operation that transforms raw hides into high-quality materials suitable for various applications, such as upholstery, fashion, and automotive uses. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The journey begins with the selection of high-quality hides, primarily sourced from cattle. These hides undergo a rigorous inspection to assess their quality, thickness, and potential defects. Once selected, the hides are cleaned and preserved using methods like salting or tanning to prevent decomposition. The tanning process is critical as it transforms raw animal hides into durable leather. Techniques such as vegetable tanning and chrome tanning are common, each imparting distinct characteristics to the leather.

Forming

After tanning, the leather is shaped into the desired form. This stage may involve cutting the hides into specific sizes or shapes based on customer specifications or intended applications. Advanced cutting technologies, such as laser cutting, ensure precision and minimize waste. Additionally, embossing or other surface treatments may be applied at this stage to enhance the aesthetic appeal of the gray leather.

Assembly

In the assembly phase, various components of leather goods are stitched or bonded together. For upholstery applications, this might involve attaching leather to furniture frames or creating individual pieces for garments. Skilled artisans often oversee this process to ensure the craftsmanship meets high standards. Quality checks during this phase are crucial to identify any inconsistencies or defects before moving to the next stage.

Finishing

The final stage involves applying protective coatings, dyes, or finishes to enhance the leather’s durability and appearance. This may include processes like buffing, polishing, or applying water-resistant treatments. The finishing process is vital for achieving the desired texture and ensuring the leather maintains its integrity over time.

How is Quality Assurance Managed in Gray Leather Fabric Production?

Quality assurance (QA) is a cornerstone of the manufacturing process for gray leather fabric, ensuring that products meet international standards and customer expectations. Quality control practices are essential to identify and rectify potential issues throughout the production cycle.

What are the Relevant International Standards for Quality Assurance?

In the leather industry, compliance with international standards such as ISO 9001 is crucial. This standard outlines the requirements for a quality management system, focusing on customer satisfaction and continuous improvement. Other relevant certifications may include CE marking for products sold in Europe and API standards for leather used in automotive applications.

What are the Key Quality Control Checkpoints in Production?

Quality control checkpoints are integrated into the manufacturing process to ensure consistent quality. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Suppliers must provide documentation demonstrating that their hides meet specified quality criteria.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor processes and ensure adherence to quality standards. This may include assessing the precision of cuts and the quality of stitching.

-

Final Quality Control (FQC): Once the leather products are completed, a final inspection is carried out. This step includes checking for defects, measuring dimensions, and assessing the overall finish of the product.

What Common Testing Methods are Used for Quality Assurance?

To verify the quality of gray leather fabric, various testing methods are employed:

-

Physical Testing: This includes tensile strength tests, flexibility tests, and abrasion resistance tests to ensure the leather can withstand daily use.

-

Chemical Testing: Leather is often tested for resistance to water, oils, and other substances. This helps determine how the leather will perform in different environments.

-

Colorfastness Testing: This assesses how well the color holds up under exposure to light and washing, which is particularly important for upholstery applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure reliable products. Here are some actionable steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should look for suppliers with a track record of compliance with international standards.

-

Request Documentation: Buyers should request documentation regarding quality control processes, including inspection reports and test results for finished products. This documentation should detail the methodologies used for testing and the results achieved.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspectors can verify that the manufacturing processes adhere to agreed-upon standards.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control?

When dealing with suppliers across different regions, international buyers must be aware of certain nuances:

-

Cultural Differences: Understanding cultural attitudes toward quality and craftsmanship can influence supplier relationships. Building rapport and trust can lead to better outcomes in quality management.

-

Regulatory Compliance: Different regions may have varying regulations regarding leather production, environmental standards, and labor practices. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Supply Chain Transparency: Buyers should seek suppliers who are transparent about their sourcing and manufacturing processes. This transparency can help mitigate risks associated with unethical practices and subpar products.

In conclusion, understanding the manufacturing processes and quality assurance practices for gray leather fabric is vital for B2B buyers. By focusing on these key areas, buyers can ensure they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gray leather fabric’

This practical sourcing guide aims to assist B2B buyers in effectively procuring gray leather fabric, ensuring that each step is aligned with best practices for quality, cost-efficiency, and supplier reliability. By following this checklist, you can streamline your purchasing process and secure the best materials for your projects.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your gray leather fabric. This includes determining the type of leather (e.g., full-grain, top-grain), thickness, texture, and finish that best suits your needs. Having clear specifications helps in communicating effectively with suppliers and ensures that the materials you receive meet your quality standards.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify reputable suppliers who specialize in gray leather fabrics. Look for suppliers that have a strong presence in your target market regions, such as Africa, South America, the Middle East, and Europe. Utilize industry directories, trade shows, and online platforms to gather a list of potential vendors.

- Considerations:

- Supplier reputation and years of experience in the leather industry.

- Geographic location and logistics capabilities for timely delivery.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions. This evaluation process helps you gauge the supplier’s reliability and quality assurance practices.

Illustrative image related to gray leather fabric

- Look for:

- Certifications related to environmental standards and leather processing.

- Customer testimonials and reviews.

Step 4: Request Samples

Always ask for samples of the gray leather fabric before making a bulk purchase. This step allows you to assess the quality, texture, and color accuracy of the leather firsthand. Evaluating samples helps in making informed decisions and can prevent costly mistakes down the line.

- Things to note:

- Compare samples against your defined specifications.

- Evaluate the durability and finish of the leather.

Step 5: Verify Pricing and Terms

After narrowing down your suppliers, inquire about pricing and payment terms. Ensure you understand the total costs, including shipping, taxes, and any additional fees. Transparent pricing helps in budgeting and avoids unexpected expenses later in the procurement process.

- Key considerations:

- Compare quotes from multiple suppliers to ensure competitive pricing.

- Clarify payment terms, including deposits and credit options.

Step 6: Negotiate Contracts

Once you’ve selected a supplier, engage in negotiations to finalize the contract. Ensure all terms, including delivery timelines, quality standards, and return policies, are documented. A well-structured contract protects your interests and establishes clear expectations for both parties.

- Important elements to include:

- Quality assurance measures and inspection procedures.

- Penalties for late delivery or non-compliance with specifications.

Step 7: Establish a Communication Plan

After the order is placed, establish a communication plan with your supplier. Regular updates on production and shipping status can help mitigate any potential delays or issues. Open lines of communication foster a better working relationship and enhance collaboration.

- Recommended actions:

- Schedule regular check-ins to discuss progress.

- Use tracking tools for shipments to stay informed.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing gray leather fabric, ensuring high-quality procurement aligned with their business needs.

Illustrative image related to gray leather fabric

Comprehensive Cost and Pricing Analysis for gray leather fabric Sourcing

What Are the Key Cost Components in Sourcing Gray Leather Fabric?

When evaluating the total cost of sourcing gray leather fabric, several critical cost components come into play. The primary elements include:

-

Materials: The quality of the leather significantly influences the cost. High-grade, genuine leather sourced from reputable suppliers will generally command a higher price than synthetic alternatives. Prices can vary based on the type of leather (e.g., full-grain, top-grain, or split leather) and the specific tanning processes used.

-

Labor: Labor costs are affected by the region of production and the skill level required. Regions with lower labor costs might offer more competitive pricing, but this could impact the overall quality of craftsmanship.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, making it crucial to assess suppliers’ operational efficiency.

-

Tooling: If custom tooling is required for specific designs or patterns, this can add to initial costs. Buyers should consider whether the investment in tooling will be justified by the volume of production.

-

Quality Control (QC): Ensuring that the leather meets specific quality standards is essential, especially for international buyers who may face stricter regulations. The costs associated with quality control processes should be factored into the overall pricing.

-

Logistics: Shipping costs can vary greatly depending on the distance from the supplier to the buyer, the mode of transport, and any potential tariffs or duties. Efficient logistics planning can mitigate some of these expenses.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s reputation.

How Do Price Influencers Affect Gray Leather Fabric Sourcing?

Several factors can influence the pricing of gray leather fabric, particularly for B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often attract discounts, while smaller quantities may incur higher per-unit costs.

-

Specifications and Customization: Custom colors, textures, or finishes can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: High-quality leather often comes with certifications that ensure ethical sourcing and environmental compliance. Buyers should verify these certifications, as they may impact costs.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more due to their proven track record but can provide greater assurance in quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost of the leather.

What Buyer Tips Can Enhance Cost-Efficiency in Gray Leather Fabric Sourcing?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiate: Leverage your purchasing power when negotiating with suppliers. Discuss bulk orders or long-term contracts that could yield better pricing.

-

Consider Total Cost of Ownership: Beyond the initial purchase price, consider the total cost of ownership, including maintenance, durability, and potential resale value. Higher-quality materials may have a higher upfront cost but can result in lower overall expenses.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. This knowledge can empower you to make informed decisions about when to purchase.

-

Establish Relationships: Building strong relationships with suppliers can lead to better pricing, priority access to new products, and improved service.

Disclaimer on Indicative Prices

Prices for gray leather fabric can vary widely based on the factors mentioned above. It is essential for buyers to conduct thorough research and request quotes from multiple suppliers to ensure they are receiving competitive pricing. Always consider the context of the market and specific needs when evaluating quotes.

Alternatives Analysis: Comparing gray leather fabric With Other Solutions

Exploring Alternatives to Gray Leather Fabric for Upholstery Solutions

In the competitive landscape of upholstery materials, gray leather fabric stands out due to its durability and aesthetic appeal. However, businesses often seek alternatives that may offer different benefits or cost efficiencies. This section provides a comparative analysis of gray leather fabric against other viable solutions, enabling B2B buyers to make informed decisions tailored to their specific needs.

| Comparison Aspect | Gray Leather Fabric | Faux Leather (Vinyl) | Microfiber Fabric |

|---|---|---|---|

| Performance | Highly durable, resistant to wear | Less durable, prone to cracking | Durable, resistant to stains and fading |

| Cost | Higher initial investment | Generally lower cost | Moderate cost, often cheaper than leather |

| Ease of Implementation | Requires specialized skills for handling | Easy to cut and sew | Simple to handle, available in various widths |

| Maintenance | Requires regular conditioning | Easy to clean with soap and water | Machine washable, minimal upkeep needed |

| Best Use Case | Luxury furniture, automotive interiors | Budget-friendly furniture | High-traffic areas, family-friendly settings |

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather, often made from polyvinyl chloride (PVC) or polyurethane, offers a cost-effective alternative to gray leather fabric. Its primary advantage lies in affordability, making it accessible for budget-conscious projects. Faux leather is easy to clean, requiring only a damp cloth for maintenance, which is ideal for environments with high wear and tear. However, it may not match the durability or luxury feel of genuine leather, often cracking or peeling over time, especially in high-use scenarios.

How Does Microfiber Fabric Compare to Gray Leather Fabric?

Microfiber fabric is another alternative that provides a different set of benefits. This synthetic material is known for its stain resistance and ease of cleaning, making it suitable for family settings or commercial spaces where spills are common. Microfiber is also softer and more versatile in terms of color and texture, appealing to a broad range of design preferences. However, it does not offer the same level of durability as gray leather fabric and may wear out more quickly in high-traffic areas.

Conclusion: How Should B2B Buyers Choose the Right Upholstery Solution?

When selecting between gray leather fabric and its alternatives, B2B buyers must consider factors such as budget, application, and expected wear. Gray leather fabric is ideal for high-end applications where durability and aesthetics are paramount, while faux leather serves well in cost-sensitive projects that prioritize ease of maintenance. Microfiber offers a balance of affordability and practicality, especially in environments that require frequent cleaning. Ultimately, the best choice depends on the specific needs of the project, ensuring that the selected material aligns with both functional and aesthetic requirements.

Essential Technical Properties and Trade Terminology for gray leather fabric

What Are the Key Technical Properties of Gray Leather Fabric?

When sourcing gray leather fabric for B2B applications, it is essential to understand several critical technical properties that can influence product quality and suitability for specific projects. Below are key specifications to consider:

1. Material Grade

Material grade refers to the quality of leather, which can range from full-grain to corrected grain. Full-grain leather is the highest quality, showcasing natural imperfections, while corrected grain has been treated to remove flaws. Understanding the material grade is vital for buyers, as it directly impacts durability, aesthetic appeal, and pricing.

2. Thickness

Leather thickness, often measured in millimeters or ounces, plays a crucial role in determining the leather’s strength and application. Thicker leather is typically more durable and better suited for heavy-use items like furniture and automotive interiors, while thinner leather may be more appropriate for fashion accessories. Buyers should assess thickness based on the intended use to ensure optimal performance.

Illustrative image related to gray leather fabric

3. Finish Type

The finish of gray leather can vary, including aniline, semi-aniline, and pigmented finishes. Aniline leather is dyed with soluble dyes, preserving its natural look but requiring more care. Pigmented leather, on the other hand, has a protective coating that enhances durability and is easier to maintain. Selecting the right finish type is crucial for longevity and maintenance needs.

4. Tolerance

Tolerance refers to the allowable variation in the leather’s dimensions, such as width and length. This is particularly important for large-scale projects where uniformity is essential for production efficiency. Understanding tolerance levels helps buyers avoid costly errors in cutting and assembling leather pieces.

5. Weight

Leather weight, usually specified in ounces per square foot, affects its usability and application. Heavier leather is suitable for applications requiring durability, such as upholstery, while lighter weights are more versatile for fashion items. Evaluating weight in relation to the project requirements ensures compatibility and performance.

Illustrative image related to gray leather fabric

6. Colorfastness

Colorfastness measures a material’s resistance to fading or running when exposed to light, water, or other environmental factors. For gray leather, it is essential to ensure that the dye used is stable to maintain the aesthetic quality over time, especially in furniture or automotive applications where exposure is inevitable.

What Common Trade Terms Should B2B Buyers Know When Purchasing Gray Leather Fabric?

Familiarizing yourself with industry terminology can streamline the purchasing process and facilitate better negotiations. Here are several key terms commonly used in the leather trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather industry, this could relate to manufacturers who supply leather for furniture or automotive brands. Understanding OEM relationships can help buyers ensure quality and consistency in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost. Knowing the MOQ helps in budgeting and planning purchases effectively.

Illustrative image related to gray leather fabric

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers in the leather industry, sending an RFQ can help compare prices and terms from multiple suppliers, ensuring the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for managing shipping costs and responsibilities, especially when sourcing leather from global suppliers.

5. Lead Time

Lead time is the amount of time from placing an order to receiving it. For B2B buyers, understanding lead times is critical for project scheduling and inventory management. Longer lead times can affect production schedules, so it’s important to factor this into planning.

6. Certification

Certification refers to the process by which leather is verified for quality standards, such as environmental sustainability or compliance with industry regulations. Buyers should look for certified leather to ensure they meet legal and ethical standards in their products.

Illustrative image related to gray leather fabric

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ultimately leading to better procurement outcomes in their gray leather fabric sourcing efforts.

Navigating Market Dynamics and Sourcing Trends in the gray leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the Gray Leather Fabric Sector?

The global gray leather fabric market is experiencing significant transformation, driven by various factors including changing consumer preferences, advancements in manufacturing technology, and the increasing demand for sustainable materials. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly focused on high-quality, versatile leather that meets both aesthetic and functional requirements. The trend towards minimalistic and modern design has elevated gray leather as a favored choice for upholstery, automotive, and fashion applications.

Emerging technologies are revolutionizing the sourcing landscape. Digital platforms are enhancing transparency in the supply chain, allowing buyers to easily compare products and suppliers. This shift towards e-commerce in the leather industry facilitates quicker decision-making and reduces lead times. Additionally, innovations in leather treatment processes, such as eco-friendly tanning methods, are gaining traction, offering manufacturers the ability to produce durable and stylish gray leather without compromising environmental standards.

Another notable trend is the rise of personalized and customizable products. International buyers are increasingly seeking unique textures and finishes that can be tailored to specific project needs. This demand for customization is driving suppliers to expand their offerings and innovate in product development, ensuring that buyers have access to a diverse range of gray leather options.

How Is Sustainability and Ethical Sourcing Shaping the Gray Leather Fabric Market?

The environmental impact of leather production has become a focal point for both consumers and businesses, leading to a growing emphasis on sustainability and ethical sourcing in the gray leather fabric sector. International B2B buyers are increasingly scrutinizing the supply chains of their suppliers, looking for partners that prioritize sustainable practices and ethical treatment of animals. This shift is not only driven by regulatory pressures but also by consumer demand for products that align with environmental values.

Illustrative image related to gray leather fabric

Sustainable sourcing involves the use of environmentally friendly tanning processes, such as vegetable tanning, which minimizes chemical use and reduces water pollution. Buyers should look for certifications that demonstrate compliance with these practices, such as the Leather Working Group (LWG) certification, which assesses the environmental performance of leather manufacturers. Additionally, the use of recycled materials and biodegradable options is gaining popularity, further enhancing the appeal of gray leather as a sustainable choice.

Moreover, ethical supply chains that ensure fair labor practices and humane treatment of animals are increasingly important to B2B buyers. Establishing partnerships with suppliers who prioritize these values not only enhances brand reputation but also fosters loyalty among environmentally conscious consumers.

What Is the Historical Context of Gray Leather Fabric in the B2B Market?

Gray leather fabric has evolved significantly over the decades, transitioning from a utilitarian material to a stylish choice for various applications. Historically, leather was primarily used for functional purposes such as clothing and armor. However, as fashion and design trends evolved, so did the applications of leather, including upholstery and accessories.

In the late 20th century, the introduction of synthetic alternatives initially posed a challenge to the leather market. Nonetheless, the resurgence of natural materials in the 21st century has renewed interest in high-quality leather, particularly in neutral tones like gray. The adaptability of gray leather to various design aesthetics, from contemporary to rustic, has solidified its place in the B2B market, making it a staple choice for manufacturers and designers alike. As the industry continues to prioritize sustainability, the historical context of gray leather fabric underscores its enduring appeal and versatility.

Illustrative image related to gray leather fabric

Frequently Asked Questions (FAQs) for B2B Buyers of gray leather fabric

-

1. How do I choose the right gray leather fabric for my project?

Selecting the appropriate gray leather fabric involves considering several factors, including the intended use, desired texture, and finish. Assess the weight and thickness of the leather to ensure it suits your application, whether for upholstery, automotive, or fashion. Additionally, examine the tanning process used, as this affects durability and maintenance. It’s also wise to request samples from suppliers to evaluate color accuracy and material quality firsthand before making a bulk purchase. -

2. What is the best gray leather for upholstery applications?

The best gray leather for upholstery is typically full-grain or top-grain leather due to its durability and luxurious appearance. Full-grain leather retains the natural grain and imperfections, making it ideal for high-end furniture. Top-grain leather is slightly corrected and more affordable while still offering good quality. Consider the finish as well; aniline-dyed leather provides a rich color but may require more care, while pigmented leather is more resistant to stains and wear. -

3. What are the typical minimum order quantities (MOQs) for gray leather fabric?

Minimum order quantities for gray leather fabric vary by supplier and can range from a few hides to several hundred square feet. Generally, MOQs are influenced by the type of leather, the supplier’s manufacturing capabilities, and the specific order details. For international buyers, it’s advisable to discuss MOQs upfront and consider potential adjustments based on your project scale to ensure a satisfactory procurement process. -

4. How can I ensure the quality of gray leather fabric before purchase?

To ensure quality, always request samples before placing a bulk order. Evaluate the leather for consistency in color, texture, and thickness. It’s also beneficial to inquire about the tanning process and any certifications that guarantee the leather’s quality and ethical sourcing. Establishing a relationship with reliable suppliers who provide transparency regarding their quality assurance processes will further enhance your purchasing confidence. -

5. What payment terms should I expect when sourcing gray leather fabric internationally?

Payment terms can vary widely among suppliers, but common arrangements include upfront payments, deposits, and payment upon delivery. Many suppliers may offer net 30 or net 60 terms for established relationships. It’s crucial to negotiate favorable terms that align with your cash flow needs and to consider using secure payment methods, such as letters of credit or escrow services, to protect your transaction. -

6. What logistics considerations should I keep in mind when importing gray leather fabric?

When importing gray leather fabric, consider shipping costs, customs duties, and delivery timelines. Research the import regulations for your country, as leather may be subject to specific tariffs or restrictions. Partnering with a logistics provider experienced in handling textile imports can facilitate smoother customs clearance and ensure timely delivery. Be proactive in tracking your shipment to address any issues that may arise during transit. -

7. How can I customize gray leather fabric for my brand?

Customization options for gray leather fabric typically include selecting specific shades, textures, and finishes. Many suppliers offer embossing, stitching, or dyeing services to create unique designs that align with your brand identity. Discuss your customization requirements with potential suppliers to understand their capabilities and lead times. Be clear about your vision and provide samples or sketches to ensure accurate production. -

8. What are the most common uses for gray leather fabric in various industries?

Gray leather fabric is versatile and widely used across various industries. In furniture, it serves as upholstery for sofas, chairs, and ottomans, offering a modern aesthetic. In the automotive sector, it is often used for interior trim and seating due to its durability. Fashion brands incorporate gray leather into bags, jackets, and accessories, capitalizing on its timeless appeal. Understanding these applications can help you target your purchasing decisions effectively.

Top 6 Gray Leather Fabric Manufacturers & Suppliers List

1. Leather Hide Store – Grey Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Product: Grey Upholstery Leather

Supplier: Leather Hide Store

Availability: Closeouts (limited stock)

Purchase Method: Call 1-800-651-9521 (not available for online purchase)

Material: Cowhide

Average Size: 50 square feet (sq ft)

Usage: Furniture, automotive, general leathercraft

Notable Products: K1333 Italian Dream Cloud, K1294 Lambskin Anthracite, K1150 Gun Smoke, K1435 Tuscan Greystone, K1240 …

2. Barbarossa Leather – Custom Color Samples

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: This company, Barbarossa Leather – Custom Color Samples, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Kovi Fabrics – R9404 Medium Grey Leather

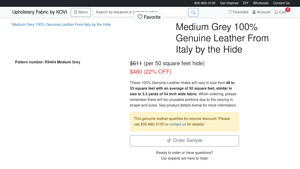

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: {“Pattern number”: “R9404 Medium Grey”, “Recommended Use”: “Upholstery, Automotive, Commercial, Residential”, “Collection”: “Premium European Hides”, “Origin”: “Italy”, “Color”: “Gray”, “Type”: “Genuine Leather, Performance Leather”, “Pattern”: “Leather Grain, Plain/Solid”, “Contents”: “100% Genuine Leather”, “Size”: “50 square feet on average”, “Finish”: “Tear, Water, Fade, Stain, Scratch Resista…

4. Online Fabric Store – Vinyl & Faux Leather Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, Online Fabric Store – Vinyl & Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

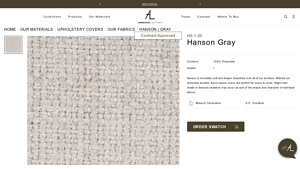

5. American Leather – Hanson Gray Fabric

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: {“name”: “Hanson Gray”, “type”: “Fabric”, “SKU”: “HS-1-20”, “UPC”: “”, “content”: “100% Polyester”, “grade”: “I”, “MSRP”: “”, “current_stock”: “”, “description”: “Hanson is incredibly soft and drapes beautifully over all of our furniture. Refined yet extremely durable, these classic colors are perfect for years to come. Slight color shade or textural variations may occur as part of the beauty and …

6. Decorative Fabrics Direct – Genuine Leather Hides

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Genuine Leather Hides for Upholstery, High Quality Genuine Leather Hides for Furniture Upholstery, Produced using premium cowhide and tanning methods, Soft and supple real leather upholstery fabrics, Ideal for furniture, garments, chaps, handbags, and other leather goods, In stock, ready to ship, wholesale priced, Special Order Only (1 Hide Minimum Order), Prices range from $7.69 to $14.97 per SqF…

Strategic Sourcing Conclusion and Outlook for gray leather fabric

In today’s competitive marketplace, strategic sourcing of gray leather fabric is essential for businesses aiming to enhance product quality while optimizing costs. By understanding the diverse range of gray leather options available—from various textures to finishes—international buyers can select materials that align with their specific project requirements. The ability to source high-quality leather closeouts and specialized hides can lead to significant savings, especially for businesses in emerging markets such as Nigeria and Brazil.

Furthermore, as consumer demand for sustainable and durable products grows, investing in genuine leather materials not only meets market expectations but also reinforces a brand’s commitment to quality. Buyers should consider leveraging relationships with reputable suppliers to ensure consistent access to premium materials, which can ultimately drive customer satisfaction and loyalty.

Looking ahead, the global demand for gray leather fabric is expected to rise, particularly in the upholstery and automotive sectors. As you explore sourcing opportunities, remember to prioritize suppliers who demonstrate transparency and ethical practices. Engage with your network, attend trade shows, and stay informed about market trends to position your business for success in the evolving landscape of leather sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to gray leather fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.