Catalog

Material Insight: Motorcycle Seat Material

Motorcycle Seat Material: B2B Product Guide

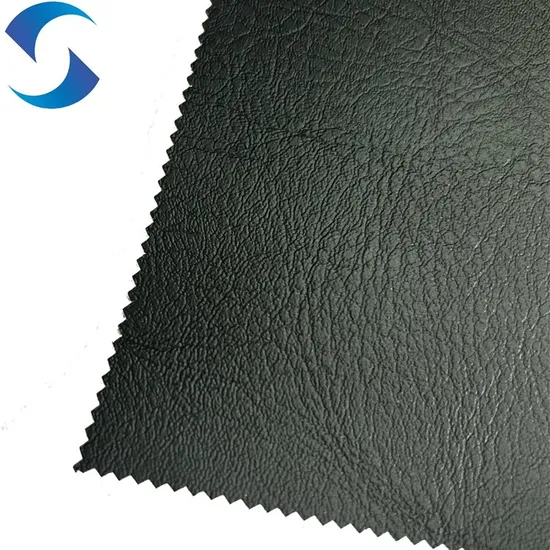

Selecting the right material for motorcycle seats is critical in balancing comfort, durability, and aesthetic appeal. With riders exposed to varying weather conditions, frequent friction, and prolonged use, the seat must withstand rigorous demands while maintaining its structural integrity and visual quality. Among the available options, faux leather—specifically high-performance synthetic leather—has emerged as the preferred choice for OEMs and aftermarket manufacturers alike.

Faux leather offers a compelling combination of advantages that make it ideal for motorcycle seat applications. Unlike natural leather, it provides consistent texture and thickness, ensuring uniform production quality across large batches. It is also highly resistant to UV degradation, preventing fading and cracking when exposed to sunlight—a common issue for motorcycles parked outdoors. Additionally, synthetic leather is engineered to be water-resistant, reducing the risk of moisture absorption, mold growth, and material breakdown over time.

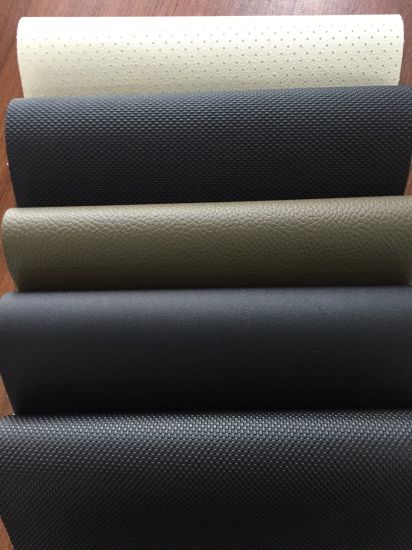

Another key benefit is design flexibility. Faux leather can be manufactured in a wide range of colors, textures, and finishes—from sleek matte surfaces to premium embossed patterns—allowing brands to differentiate their products in a competitive market. It also supports precise laser cutting and stitching, enabling complex seat designs and ergonomic contours.

From a sustainability and ethical standpoint, high-quality faux leather eliminates the environmental and animal welfare concerns associated with real leather, aligning with the growing demand for eco-conscious manufacturing practices in the automotive and powersports industries.

WINIW has been a trusted leader in synthetic leather innovation for over 20 years. Specializing in performance-driven faux leather solutions, WINIW serves global B2B clients in automotive, motorcycle, and specialty transportation sectors. Our materials are engineered to exceed industry standards for abrasion resistance, tensile strength, and long-term durability. With advanced coating technologies and a commitment to sustainable production, WINIW delivers motorcycle seat materials that combine superior performance, aesthetic precision, and environmental responsibility.

Technical Performance & Standards

WINIW Premium Synthetic Leather: Engineered for Motorcycle Seat Excellence

WINIW delivers high-performance synthetic leather solutions specifically engineered for motorcycle seating applications. Our material combines rigorous technical performance with sustainable manufacturing, providing OEMs and Tier-1 suppliers a competitive edge through reduced total cost of ownership, exceptional longevity, and seamless integration into eco-conscious production workflows.

Key Technical Advantages for Motorcycle Seating

-

Cost-Effective Performance

Achieve up to 30% lower total material cost versus premium genuine leather alternatives, without sacrificing quality. Optimized roll yield (min. 95%) and reduced cutting waste lower production costs. Enhanced processing efficiency (faster die-cutting, consistent thermoforming) minimizes downtime and labor expenses. -

Unmatched Durability for Demanding Use

Engineered to withstand extreme motorcycle-specific stressors: - Abrasion resistance: >100,000 cycles (Martindale, 9kPa, wool felt)

- Seam strength: >180 N (ASTM D4848) – critical for high-tension seat bolsters

- UV stability: >1,000 hrs (Xenon arc, ISO 105-B02) – prevents fading/cracking under prolonged sun exposure

- Cold flexibility: -30°C (ISO 1747) – maintains pliability in sub-zero conditions

-

Hydrolysis resistance: >5 years (70°C, 95% RH, ISO 1419) – combats moisture degradation

-

Precision Color Customization

WINIW’s digital color matching system (ΔE < 0.5 tolerance) ensures brand-perfect consistency across global production runs. Offer 1,000+ standard colors or develop bespoke shades (Pantone®/RAL) with batch-to-batch repeatability (ΔE < 1.0). Eco-friendly, solvent-free pigments maintain vibrancy through 5+ years of UV exposure. -

Guaranteed Regulatory Compliance

Fully REACH SVHC-compliant (Annex XIV) with zero use of DMF, AZO dyes, or heavy metals (Pb, Cd, Hg, Cr⁶⁺). All formulations exceed EU/EPA chemical restrictions. Traceable documentation provided for every shipment. -

Certified Quality Assurance

Manufactured under ISO 9001:2015-certified processes with 100% inline quality control. Batch-specific test reports for tensile strength, colorfastness, and dimensional stability ensure zero production line surprises.

Technical Specifications Overview

| Property | Especificación | Test Standard |

|---|---|---|

| Thickness | 1.0 – 1.8 mm (customizable) | ISO 2418 |

| Weight | 450 – 650 g/m² | ISO 2418 |

| Tensile Strength (MD) | ≥ 25 N/mm² | ISO 1766 |

| Tear Strength (Elmendorf) | ≥ 25 N | ISO 13937-3 |

| Colorfastness to Rubbing (Dry/Wet) | 4-5 / 4 | ISO 105-X12 |

| VOC Emissions | < 10 μg/g (after 28 days) | ISO 12219-4 |

| Roll Length | 30 – 50 m (standard) | Internal QC |

| Recyclability | 95%+ (mechanical recycling ready) | WINIW Eco-Standard |

WINIW’s motorcycle seat material delivers the optimal balance of performance economics, environmental responsibility, and manufacturing reliability. Our vertically integrated production – from polymer synthesis to finishing – ensures consistent quality while reducing supply chain complexity. Partner with WINIW to elevate your seat design with a material engineered for the open road and tomorrow’s sustainability standards.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs Real Leather for Motorcycle Seat Materials

When selecting materials for motorcycle seats, manufacturers must balance performance, cost, sustainability, and customer expectations. While real leather has long been considered a premium choice, advances in synthetic leather—particularly high-performance microfiber and PU-based materials—have positioned it as a competitive, and in many cases superior, alternative.

Both materials offer distinct advantages and limitations. Below is a comparative analysis focused on three critical factors: cost, durability, and eco-friendliness.

| Factor | Synthetic Leather (e.g., WINIW Microfiber) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; consistent pricing | Higher cost; subject to market and hide availability |

| Durabilidad | High abrasion resistance, UV stable, consistent thickness, no cracking | Prone to cracking, fading, and moisture damage over time; variable quality |

| Eco-friendliness | Recyclable options available; lower carbon footprint; no animal sourcing | Resource-intensive tanning; high water/chemical use; animal byproduct |

Key Advantages of Synthetic Leather for Motorcycle Seats

- Consistent Quality: Engineered for uniform thickness and texture, ensuring precision in manufacturing and superior fit.

- Weather Resistance: Resists UV degradation, moisture, and temperature fluctuations—critical for outdoor vehicle use.

- Customization: Offers a wide range of colors, textures, and finishes tailored to brand specifications.

- Sustainability Compliance: Supports ESG goals with cruelty-free, low-emission production; ideal for eco-conscious OEMs.

- Lower Total Cost of Ownership: Reduced material waste and longer service life in harsh conditions decrease long-term costs.

Considerations for Real Leather

- Aesthetic Appeal: Valued for its natural grain and aging characteristics, often associated with luxury.

- Breathability: Naturally more breathable than some early-generation synthetics (though modern microfibers have closed this gap).

- Market Perception: Some premium segments still associate real leather with higher status.

Conclusion

For B2B manufacturers focused on scalability, consistency, and sustainability, synthetic leather is increasingly the material of choice for motorcycle seating. With performance that meets or exceeds real leather in durability and environmental resilience—combined with lower costs and stronger eco-credentials—advanced synthetic leathers like WINIW’s microfiber solutions offer a future-forward alternative without compromising on quality or customer satisfaction.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global Business Excellence

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering premium performance materials trusted by leading brands worldwide. Our vertically integrated operations combine cutting-edge innovation with uncompromising environmental responsibility, ensuring your supply chain meets the highest global standards.

Core Manufacturing Capabilities

Our 100,000 sqm state-of-the-art facility in China represents one of Asia’s most advanced synthetic leather production hubs, engineered for scalability and precision:

– Mass Production Capacity: 30+ production lines supporting monthly output of 1.2 million meters, accommodating bulk orders with 15-20 day lead times

– Integrated Vertical Workflow: End-to-end control from polymer synthesis to finishing, eliminating third-party dependencies

– Eco-Optimized Infrastructure: Solar-powered energy systems and closed-loop water recycling reducing facility carbon footprint by 40% vs. industry average

Innovation Engine: R&D Excellence

WINIW’s 65-member technical team drives material science advancements through:

– Proprietary bio-based PU formulations (30%+ recycled content options) meeting EU Ecolabel criteria

– Collaborative partnerships with Tsinghua University and European textile institutes for next-gen material development

– Dedicated pilot lines enabling rapid prototyping (7-10 day sample turnaround) for custom performance requirements

Uncompromising Quality Assurance

Every meter undergoes rigorous validation against international benchmarks through our 7-stage QC protocol:

| Stage | Process | Compliance Standard |

|---|---|---|

| 1 | Raw Material Screening | ISO 9001:2015 |

| 2 | In-Process Thickness Testing | AATCC TM177 |

| 3 | Color Fastness Validation | ISO 105-B02 |

| 4 | Physical Property Verification | ASTM D751 |

| 5 | Eco-Toxicology Screening | OEKO-TEX® STANDARD 100 |

| 6 | Batch Traceability Logging | GS1 System |

| 7 | Final Certification Audit | REACH SVHC < 0.1% |

Global Market Readiness

WINIW supplies 50+ countries with full regulatory alignment for key markets:

– European Union: REACH, SCIP database compliance, and full material disclosure (S2023/01)

– United States: CPSIA, Prop 65 adherence, and FSC-certified packaging options

– Logistics Network: FCL/LCL shipping via strategic partners (DHL, Kuehne+Nagel) ensuring 25-30 day door-to-door delivery from order confirmation

WINIW’s manufacturing ecosystem delivers more than material supply – we provide risk-mitigated partnership through environmental accountability, technical agility, and certified quality. Our facility stands ready to support your brand’s sustainability goals while meeting the most demanding performance specifications. Partner with WINIW for synthetic leather solutions where ethical production meets industrial-scale excellence.

Contact Us for Samples

WINIW B2B Product Guide: High-Performance Synthetic Leather for Motorcycle Seat Applications

WINIW specializes in premium synthetic leather solutions engineered for durability, comfort, and sustainability. Our advanced microfiber materials are trusted by leading manufacturers in the motorcycle industry for their superior wear resistance, weather stability, and luxurious tactile qualities. Designed to meet rigorous performance standards, WINIW leather delivers long-term value without compromising environmental responsibility.

Our motorcycle seat materials are ideal for OEMs and aftermarket seat fabricators seeking a reliable, eco-conscious alternative to traditional leather and low-grade synthetics. With excellent abrasion resistance, UV stability, and cold crack performance, WINIW materials ensure consistent quality across diverse riding conditions.

Key Features of WINIW Motorcycle Seat Material:

- High tensile and tear strength for long-term structural integrity

- Excellent resistance to UV rays, preventing color fading and surface degradation

- Superior breathability and moisture management for enhanced rider comfort

- Cold crack resistant down to -30°C, suitable for all climate conditions

- Eco-friendly manufacturing process with low VOC emissions and REACH compliance

- Customizable textures, colors, and finishes to match brand-specific design requirements

- Lightweight construction contributes to overall vehicle efficiency

Technical Specifications:

| Property | Standard Performance |

|---|---|

| Thickness | 1.0 – 1.4 mm (customizable) |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness (UV) | Grade 4–5 (ISO 105-B02) |

| Cold Crack Resistance | Pass at -30°C |

| Tensile Strength | ≥30 N/mm² |

| Elongation at Break | ≥15% |

| Fire Resistance | Meets FMVSS 302 (optional) |

WINIW materials are produced using sustainable practices, including water-based coatings and recycled fiber content, aligning with global environmental standards and supporting your brand’s ESG goals.

Why Choose WINIW for Motorcycle Seating?

- Consistent roll-to-roll quality for seamless production integration

- Scalable manufacturing to support high-volume orders

- In-house R&D for custom material development and rapid prototyping

- Global logistics network with reliable lead times

Request Free Samples Today

Experience the performance and quality of WINIW synthetic leather firsthand. We offer free material samples tailored to motorcycle seat applications for qualified B2B partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your motorcycle seating design with a material that blends engineering excellence with environmental responsibility. Partner with WINIW—where innovation meets sustainability.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.