Catalog

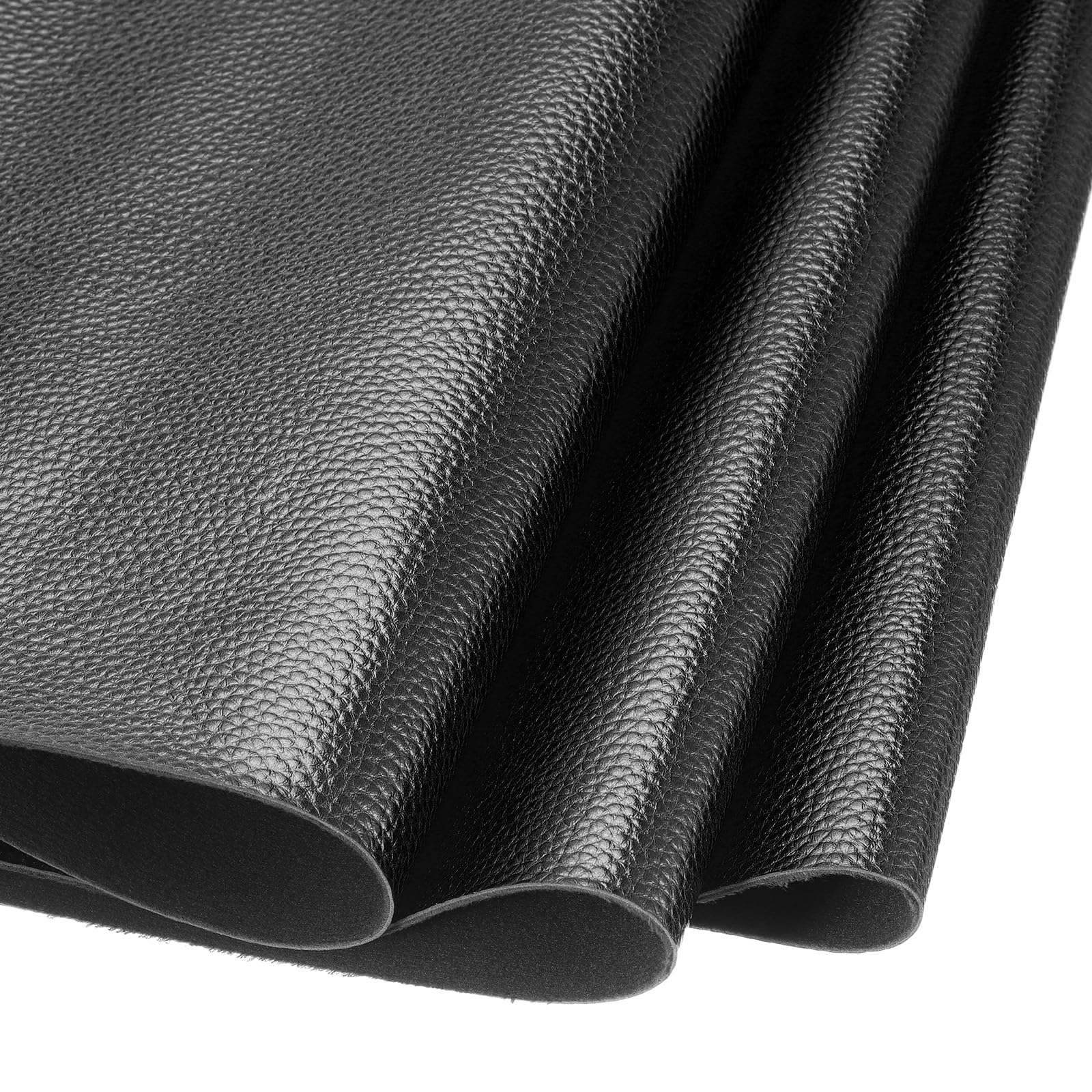

Material Insight: Vinyl Synthetic Leather

B2B Product Guide: Vinyl Synthetic Leather

Vinyl synthetic leather is a durable, cost-effective, and versatile alternative to genuine leather, widely used across industries such as automotive, furniture, footwear, and retail fixtures. Composed of a polyvinyl chloride (PVC) coating applied to a textile backing—typically polyester—vinyl leather offers excellent resistance to abrasion, moisture, and UV exposure, making it ideal for high-traffic and demanding environments. Its consistent texture, wide range of colors and finishes, and low maintenance requirements further enhance its appeal for commercial and industrial applications.

- High durability and long service life in heavy-use settings

- Resistant to spills, stains, and microbial growth—ideal for hygiene-sensitive environments

- Available in customizable textures, thicknesses, and colors to meet specific design and functional needs

- More affordable than genuine leather without sacrificing aesthetic quality

- Suitable for indoor applications where breathability is less critical

Why Faux Leather Is the Best Choice for This Application

Faux leather, particularly vinyl synthetic leather, is the optimal choice for B2B applications where performance, consistency, and sustainability matter. Unlike genuine leather, faux leather production is more controlled, resulting in uniform quality across batches—critical for large-scale manufacturing. It also supports eco-conscious business goals by reducing reliance on animal products and minimizing environmental impact through efficient production processes. With advancements in material science, modern vinyl leather closely mimics the look and feel of natural leather while offering superior resistance to wear, fading, and environmental stressors.

About WINIW

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-performance faux leather materials, we serve global clients across automotive, furniture, fashion, and technical textiles. Our commitment to R&D, sustainability, and customization enables us to deliver premium vinyl and polyurethane (PU) leathers that meet rigorous international standards.

- ISO-certified manufacturing with a focus on environmental responsibility

- In-house design and engineering teams for rapid prototyping and custom development

- Sustainable practices, including low-VOC emissions and recyclable material options

- Trusted partner for OEMs and brands seeking durable, ethical, and scalable leather alternatives

With a proven track record in quality and innovation, WINIW empowers businesses to elevate their products with synthetic leather solutions that perform, endure, and align with modern environmental expectations.

Technical Performance & Standards

WINIW Vinyl Synthetic Leather: Technical Product Guide for B2B Applications

WINIW Vinyl Synthetic Leather delivers a precision-engineered solution for manufacturers demanding reliable performance, operational efficiency, and regulatory adherence. Engineered for high-volume industrial use, our PVC-based synthetic leather minimizes total cost of ownership while meeting stringent global compliance standards. Ideal for furniture, automotive interiors, mass transit, and commercial upholstery, WINIW provides consistent quality without compromising on sustainability or design flexibility.

Core Technical Advantages

- Cost-Effective Production: Optimized thickness tolerance (±0.05mm) reduces material waste during cutting by up to 15% compared to standard vinyl leathers. High yield per roll (maximized usable surface area) lowers unit costs in high-volume manufacturing.

- Enhanced Durability: 50,000+ double-rub abrasion resistance (Martindale ASTM D4157) ensures longevity in high-traffic applications. Resists cracking at -20°C (ASTM D2196) and maintains integrity under UV exposure (500+ hrs Xenon arc testing per ISO 4892-2).

- Precision Color Customization: Pantone®-matched color consistency (ΔE <1.0) across batches. Capable of complex multi-layer embossing and custom surface textures (e.g., pebble, cross-hatch) without compromising wear resistance.

- REACH Compliance Guaranteed: Fully compliant with EU REACH Regulation (EC 1907/2006), including SVHC screening. Phthalate-free plasticizer options available (DEHP, BBP, DBP <0.1% w/w per Annex XVII). Certificates provided with every shipment.

- ISO 9001-Certified Quality Control: Rigorous in-line testing at all production stages (thickness, color fastness, peel strength) ensures batch-to-batch uniformity. Traceability from raw material to finished roll via unique batch coding.

Technical Specifications Overview

| Property | Especificación | Test Standard |

|---|---|---|

| Base Material | PVC Resin (Phthalate-free options) | ISO 10545-13 |

| Thickness Range | 0.6mm – 1.2mm (custom up to 1.8mm) | ASTM D2240 |

| Width | 137cm ± 1cm (custom rolls available) | ISO 2286-1 |

| Weight | 450g/m² – 950g/m² | ISO 9073-3 |

| Abrasion Resistance | ≥50,000 cycles | ASTM D4157 (Martindale) |

| Color Fastness to Light | ≥6 (Gray Scale) | ISO 105-B02 |

| Cold Crack Resistance | Passes at -20°C | ASTM D2196 |

| Peel Strength | ≥4.0 N/mm | ISO 1764 |

| REACH Status | Compliant (Full SVHC report) | EC 1907/2006 |

| Quality Management | ISO 9001:2015 Certified | Certificate WINIW-QM-021 |

WINIW’s vinyl synthetic leather eliminates supply chain uncertainty through documented compliance and repeatable performance. Our technical team collaborates with clients to optimize material specifications for specific production processes—from die-cutting efficiency to thermal forming parameters—ensuring seamless integration into your manufacturing workflow. Request a custom sample kit with full compliance documentation to validate performance against your application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Vinyl Synthetic Leather vs. Real Leather

In commercial and industrial applications such as furniture manufacturing, automotive interiors, and fashion accessories, selecting the right leather material is critical for balancing performance, cost, and sustainability. Two of the most common materials considered are vinyl synthetic leather and real leather. Each offers distinct advantages and trade-offs depending on the intended application and business priorities.

Vinyl synthetic leather, often referred to as PVC leather, is a man-made material composed of a fabric backing coated with polyvinyl chloride. It is engineered to replicate the appearance and texture of real leather at a lower cost. Real leather, by contrast, is derived from animal hides—typically bovine—and undergoes extensive tanning and finishing processes to achieve its final form.

While real leather is traditionally valued for its natural aesthetics and long-term durability, vinyl synthetic leather offers consistent quality, lower production costs, and greater control over physical properties. Additionally, synthetic options support more predictable supply chains and can align with eco-conscious manufacturing goals when produced responsibly.

Key considerations when choosing between these materials include cost efficiency, product lifespan, and environmental impact. Below is a comparative overview based on these critical factors:

| Factor | Vinyl Synthetic Leather | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher upfront cost |

| Durabilidad | Moderate; prone to cracking over time, especially with UV and heat exposure | High; develops a patina and can last decades with proper care |

| Eco-Friendliness | Moderate to low; PVC production involves chlorine and can release harmful dioxins; however, newer production methods are improving sustainability | Mixed; uses animal byproducts but tanning (especially chrome tanning) can pollute waterways; biodegradable but resource-intensive |

Additional considerations for B2B decision-makers:

- Vinyl synthetic leather is highly customizable in color, texture, and thickness, making it ideal for mass production and design consistency.

- Real leather offers superior breathability and tactile comfort, often preferred in premium automotive and luxury furniture markets.

- Maintenance requirements differ significantly: vinyl is easy to clean and resistant to spills, while real leather requires conditioning and protection from moisture and sunlight.

- Ethical sourcing is a growing concern; synthetic leather avoids animal use, appealing to vegan and cruelty-free markets.

For businesses focused on cost control, design flexibility, and scalable production, vinyl synthetic leather presents a compelling option—especially when enhanced with modern eco-improvements. However, for brands emphasizing longevity, natural aesthetics, and premium market positioning, real leather may remain the preferred choice despite its environmental and cost challenges.

WINIW supports sustainable innovation in synthetic leather, offering advanced microfiber and PVC-free alternatives that improve both performance and environmental outcomes—helping B2B partners meet market demands responsibly.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Excellence for Global Partners

WINIW stands as a premier manufacturer of high-performance synthetic leather, delivering innovative, eco-conscious materials to discerning B2B clients worldwide. Our vertically integrated operations, anchored by significant manufacturing scale and technical expertise, ensure consistent quality, sustainability, and reliability for brands committed to excellence.

Core Manufacturing Strengths

- 100,000 sqm Advanced Production Facility: Our state-of-the-art campus in China integrates every stage of production—from polymer synthesis and substrate engineering to coating, embossing, and finishing—under one roof. This scale enables agile large-volume production while maintaining meticulous process control.

- Dedicated R&D Innovation Hub: A 150+ member technical team, including material scientists and chemical engineers, drives continuous advancement. We specialize in developing customized solutions (e.g., ultra-microfiber, PU/TPU hybrids, recycled-content formulations) aligned with client performance and sustainability targets.

- Rigorous Multi-Stage Quality Control: Every meter undergoes 12+ inspection points, exceeding ISO 9001 standards. Our QC protocol ensures compliance with global safety and durability benchmarks for automotive, footwear, and upholstery sectors.

Global Compliance & Export Leadership

WINIW materials are certified for seamless market access across key regions, with 70% of output shipped to Europe and North America. Our adherence to stringent international regulations eliminates supply chain barriers for partners:

| Certification | Region | Key Standards Met | Client Benefit |

|---|---|---|---|

| REACH | Europe | SVHC-free formulations, full chemical tracing | Duty-free entry; meets EU Ecodesign requirements |

| CPSIA | USA | Phthalate-free, heavy metal compliance | Accelerated customs clearance; retail compliance |

| OEKO-TEX® STANDARD 100 | Global | Class I (baby articles) safety | Brand trust; premium market eligibility |

Why Partner with WINIW?

- Eco-Engineered Production: 92% of our lines utilize water-based, solvent-free processes with closed-loop recycling, reducing VOC emissions by 85% vs. industry average.

- Supply Chain Resilience: 30-day guaranteed lead times for standard grades; dedicated logistics partnerships ensure on-time delivery to EU/US ports.

- Collaborative Development: Co-engineer materials with our R&D team to solve specific challenges—abrasion resistance, breathability, or bio-based content—without minimum order constraints.

WINIW merges industrial scale with precision craftsmanship, empowering global brands to achieve uncompromised quality and sustainability. Partner with us to transform your material vision into market-ready reality.

Contact Us for Samples

B2B Product Guide: Vinyl Synthetic Leather by WINIW

WINIW is a trusted global supplier of high-performance synthetic leather solutions, serving industries ranging from furniture and automotive to fashion and upholstery. Our vinyl synthetic leather is engineered to meet the rigorous demands of commercial applications, combining durability, aesthetic versatility, and environmental responsibility.

Designed for manufacturers, designers, and procurement specialists, this guide provides essential information about our vinyl synthetic leather offerings—highlighting technical advantages, applications, and sustainability features.

Key Features of WINIW Vinyl Synthetic Leather

- Durable, abrasion-resistant surface ideal for high-traffic environments

- Excellent color fastness and UV resistance for long-term visual integrity

- Available in a wide range of textures, finishes, and custom colors

- Easy to clean and maintain—suitable for commercial and residential use

- Cost-effective alternative to genuine leather without compromising aesthetics

- Consistent roll-to-roll quality ensures minimal waste in production

Technical Specifications

| Property | Standard Performance |

|---|---|

| Thickness Range | 0.6 mm – 1.2 mm |

| Width per Roll | 54” (137 cm), 60” (152 cm) |

| Weight | 200 – 350 g/m² |

| Backing Material | Knit or woven polyester |

| Abrasion Resistance | >20,000 cycles (Martindale) |

| Cold Crack Resistance | Passes at -20°C |

| Fire Retardancy | Available (compliant with CA117, BS5852) |

Sustainability Commitment

WINIW prioritizes eco-conscious manufacturing:

– PVC base formulations with reduced heavy metal content

– Compliant with REACH, RoHS, and other international safety standards

– Low-VOC emissions for improved indoor air quality

– Recyclable at end of life in appropriate waste streams

Our production process emphasizes water and energy efficiency, aligning with global sustainability goals and supporting your brand’s ESG initiatives.

Common Applications

- Office and residential furniture upholstery

- Hospitality seating and headboards

- Automotive interiors (door panels, armrests)

- Retail display fixtures and decorative elements

- Healthcare and senior living facilities (easy-clean surfaces)

Why Partner with WINIW?

- Scalable production capacity for bulk B2B orders

- OEM and ODM support with custom development

- Global logistics network with reliable lead times

- Dedicated technical and design assistance

- Free sample program to support your prototyping and sourcing

Request Free Samples Today

Evaluate the quality and performance of WINIW vinyl synthetic leather with no obligation. Our team provides complimentary samples to qualified business partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.