Introduction: Navigating the Global Market for motorbike seat cover material

In an increasingly competitive landscape, sourcing high-quality motorbike seat cover materials presents a significant challenge for international B2B buyers. With diverse market demands and varying regional preferences, it is essential to navigate the complexities of material selection, comfort, durability, and aesthetic appeal. This comprehensive guide aims to empower businesses from Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—by providing in-depth insights into the types of motorbike seat cover materials available, their applications, and best practices for supplier vetting.

Throughout this guide, we will explore various materials, including leather, marine-grade vinyl, and advanced foam technologies, while assessing their suitability for different riding conditions. Additionally, we will discuss the importance of evaluating suppliers based on quality, reliability, and compliance with international standards. Understanding the cost implications and potential return on investment for each material will also be covered, ensuring that buyers can make informed decisions that align with their business goals.

By equipping B2B buyers with essential knowledge and actionable insights, this guide aims to facilitate strategic sourcing, enhance product offerings, and ultimately drive customer satisfaction in the motorbike seat cover market. As we delve into the intricacies of material selection and supplier relationships, businesses will be better positioned to meet the evolving needs of their customers while maintaining a competitive edge in the global marketplace.

Table Of Contents

- Top 5 Motorbike Seat Cover Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorbike seat cover material

- Understanding motorbike seat cover material Types and Variations

- Key Industrial Applications of motorbike seat cover material

- 3 Common User Pain Points for ‘motorbike seat cover material’ & Their Solutions

- Strategic Material Selection Guide for motorbike seat cover material

- In-depth Look: Manufacturing Processes and Quality Assurance for motorbike seat cover material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorbike seat cover material’

- Comprehensive Cost and Pricing Analysis for motorbike seat cover material Sourcing

- Alternatives Analysis: Comparing motorbike seat cover material With Other Solutions

- Essential Technical Properties and Trade Terminology for motorbike seat cover material

- Navigating Market Dynamics and Sourcing Trends in the motorbike seat cover material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorbike seat cover material

- Strategic Sourcing Conclusion and Outlook for motorbike seat cover material

- Important Disclaimer & Terms of Use

Understanding motorbike seat cover material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather | Durable, high-quality, and luxurious appearance | Premium motorcycles, custom builds | Pros: Long-lasting, elegant look. Cons: Higher cost, requires maintenance. |

| Marine-grade Vinyl | Water-resistant, UV-protected, and easy to clean | Standard motorcycles, outdoor use | Pros: Affordable, durable against elements. Cons: Less premium feel than leather. |

| Foam Padding | Offers comfort and support through various densities | Custom seat manufacturing | Pros: Customizable, lightweight. Cons: May compress over time, varying comfort levels. |

| Gel Inserts | Enhanced comfort through pressure distribution | Long-distance riding, touring bikes | Pros: Reduces pressure points, great for extended use. Cons: Can add weight, requires proper installation. |

| Synthetic Fabrics | Cost-effective, varied designs, and easy maintenance | Budget motorcycles, mass production | Pros: Versatile, affordable. Cons: Less durable than leather or vinyl, can wear out quickly. |

What Are the Characteristics of Leather as a Motorbike Seat Cover Material?

Leather is a premier choice for motorbike seat covers, prized for its durability and luxurious appearance. It provides a sophisticated look that appeals to high-end motorcycle manufacturers and custom builders. When considering leather, B2B buyers should evaluate the type of leather (genuine vs. synthetic) and its treatment for weather resistance. While it offers longevity and aesthetic appeal, leather requires maintenance to preserve its quality and can come with a higher price tag.

How Does Marine-grade Vinyl Stand Out in the Market?

Marine-grade vinyl is engineered to withstand harsh environmental conditions, making it ideal for motorcycles that are frequently exposed to moisture and UV rays. This material is often used in standard motorcycles and outdoor applications due to its affordability and ease of cleaning. B2B buyers should consider the quality of the vinyl, as it varies widely. While it offers good durability and a practical solution for budget-conscious buyers, it may lack the premium feel that leather provides.

Why Choose Foam Padding for Comfort in Motorbike Seats?

Foam padding is a versatile option used in motorbike seats, available in various densities to suit different riding preferences. It is often utilized in custom seat manufacturing, allowing for tailored comfort levels. B2B buyers should pay attention to the foam type, as open-cell foam offers softness while closed-cell foam provides firmness and durability. While foam is lightweight and customizable, it can compress over time, impacting long-term comfort.

What Are the Benefits of Using Gel Inserts in Motorcycle Seats?

Gel inserts are designed to enhance comfort by distributing pressure more evenly across the seat. They are particularly beneficial for long-distance riders and touring bikes, as they help alleviate discomfort during extended periods of use. B2B buyers should assess the quality of the gel material and its compatibility with existing seat structures. While gel inserts significantly improve comfort, they can add weight and may require precise installation to ensure effectiveness.

How Do Synthetic Fabrics Compare to Other Materials?

Synthetic fabrics offer a cost-effective solution for motorbike seat covers, appealing to budget motorcycles and mass production. They come in a variety of designs and colors, providing versatility for manufacturers. B2B buyers should be aware that while synthetic options are affordable and easy to maintain, they may not be as durable as leather or marine-grade vinyl. Over time, synthetic fabrics can wear out quickly, so it’s crucial to balance cost with expected longevity in purchasing decisions.

Key Industrial Applications of motorbike seat cover material

| Industry/Sector | Specific Application of motorbike seat cover material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Custom seat covers for OEM bikes | Enhances product appeal and customer satisfaction | Quality of materials, customization options, lead times |

| Aftermarket Accessories | Replacement seat covers for aftermarket sales | Increases sales and brand loyalty | Compatibility with various models, pricing, material durability |

| Delivery Services | Protective seat covers for delivery motorcycles | Extends seat life and reduces maintenance costs | Weather resistance, ease of cleaning, comfort features |

| Tourism & Rentals | Seat covers for rental motorcycles | Improves rider comfort and enhances user experience | Custom branding, durability, and ease of maintenance |

| Sports & Racing | Specialized seat covers for racing bikes | Enhances performance and rider comfort | Lightweight materials, grip features, and safety standards |

How is motorbike seat cover material used in motorcycle manufacturing?

In the motorcycle manufacturing sector, motorbike seat cover material is crucial for creating custom seat covers that meet both aesthetic and functional requirements. Manufacturers seek durable materials that can withstand various weather conditions while offering comfort to riders. By providing high-quality seat covers, manufacturers enhance product appeal, potentially increasing customer satisfaction and loyalty. Key considerations include the quality of the fabric, customization options, and lead times for production, especially for B2B buyers in regions with varying climates like Africa and South America.

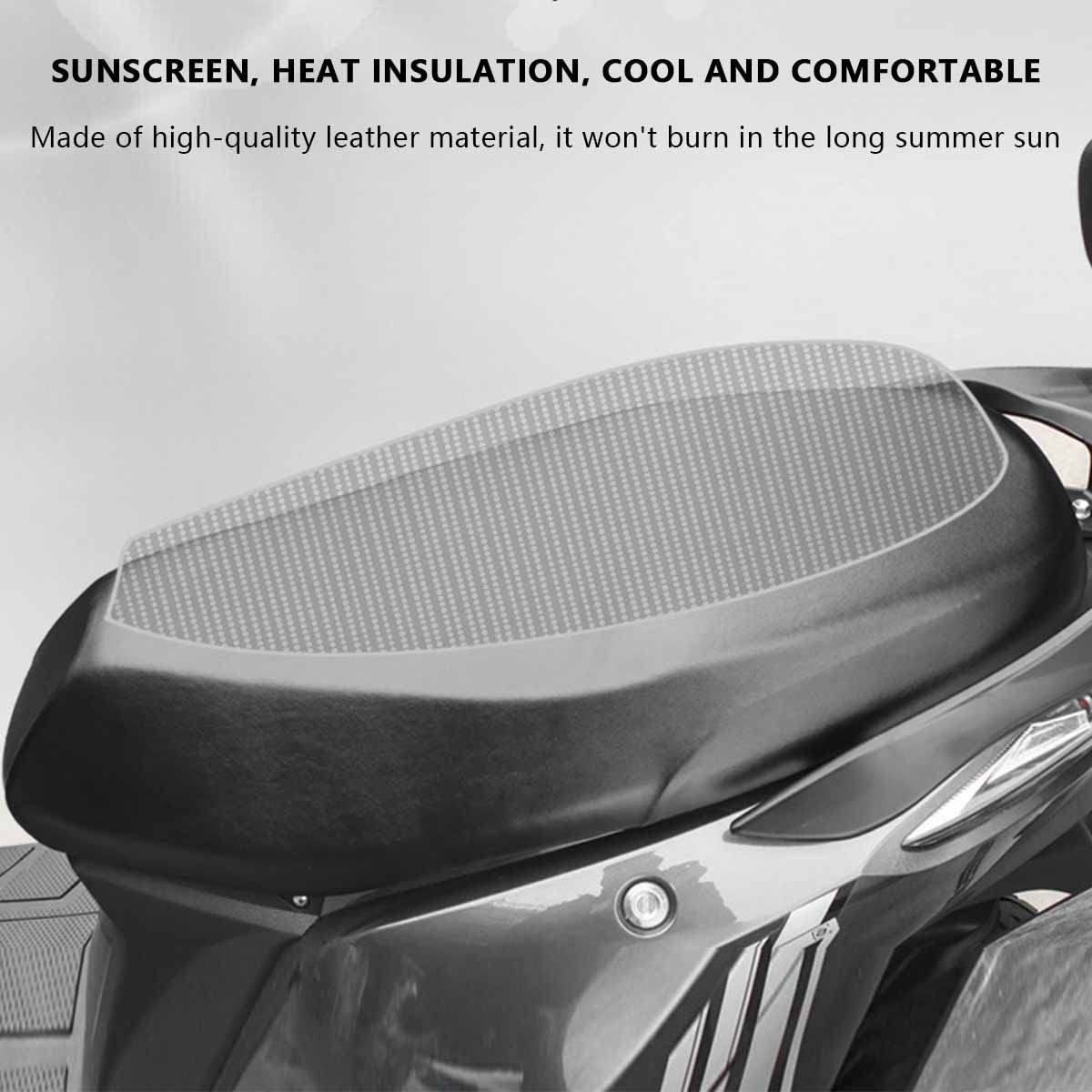

Illustrative image related to motorbike seat cover material

What role does motorbike seat cover material play in aftermarket accessories?

In the aftermarket accessories industry, seat cover materials are used for replacement parts that cater to a wide range of motorcycle models. This application allows businesses to tap into a growing market of motorcycle enthusiasts who seek personalized or upgraded riding experiences. The value lies in the ability to increase sales and foster brand loyalty through high-quality, customizable options. Buyers should prioritize compatibility with various motorcycle models, competitive pricing, and the durability of materials to ensure long-lasting performance, particularly in competitive markets in Europe and the Middle East.

How do delivery services benefit from motorbike seat cover materials?

Delivery services utilize motorbike seat cover materials to create protective covers for their delivery motorcycles. These covers help extend the life of the seats, reducing maintenance costs and ensuring that the vehicles remain in good condition despite daily wear and tear. Businesses benefit from investing in weather-resistant materials that are also easy to clean, enhancing the overall operational efficiency. B2B buyers in this sector should consider the comfort features of the seat covers, as well as their ability to withstand various environmental conditions, especially in regions with extreme weather.

Why are motorbike seat cover materials important for tourism and rentals?

In the tourism and rentals sector, high-quality seat covers are essential for enhancing the riding experience for customers using rental motorcycles. Comfortable and visually appealing seat covers can significantly improve user satisfaction, leading to repeat business and positive reviews. Key sourcing considerations include the ability to customize covers with branding, ensuring durability against wear, and ease of maintenance. Buyers from regions with a thriving tourism industry, such as South America and Europe, should focus on materials that offer both comfort and aesthetic appeal to attract a diverse clientele.

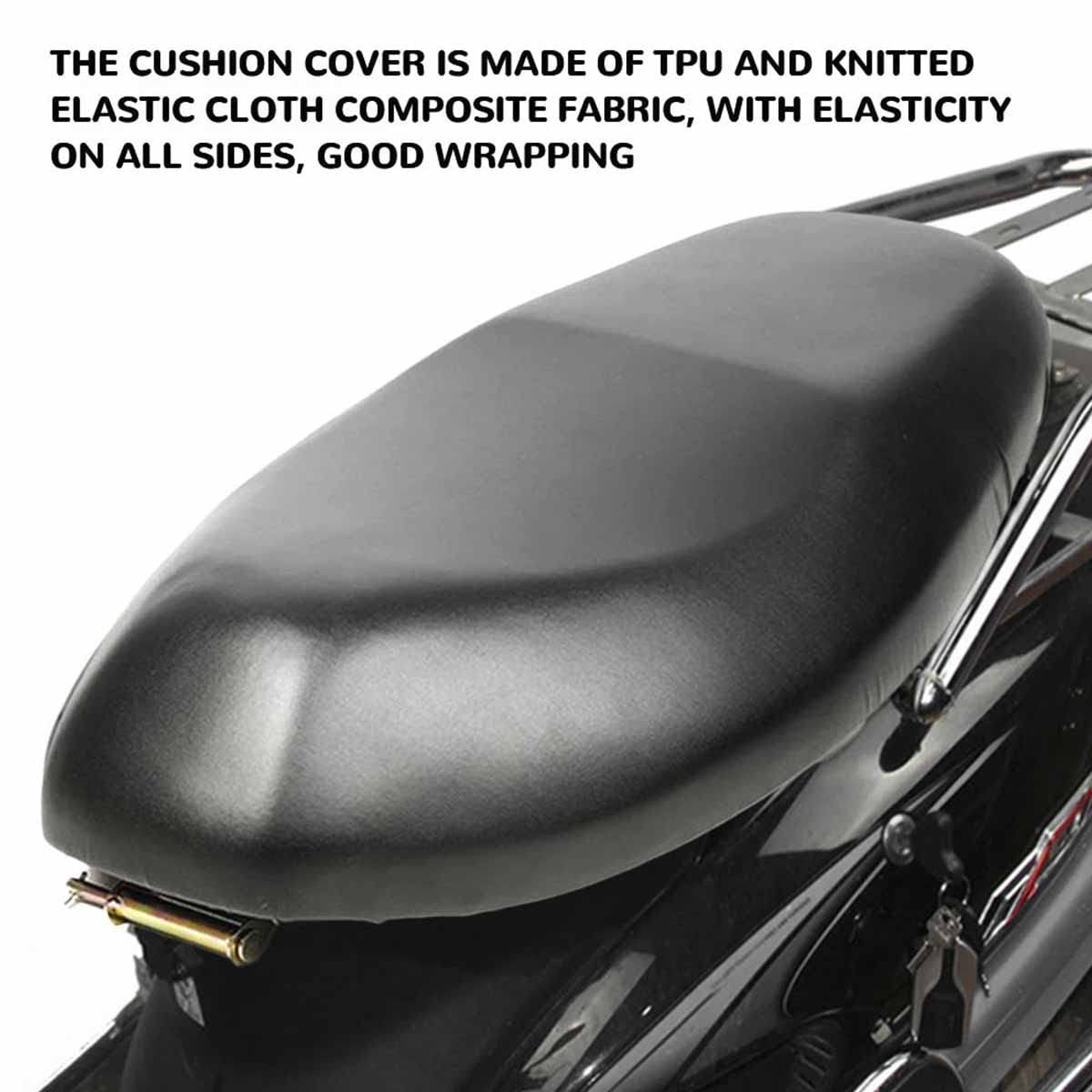

Illustrative image related to motorbike seat cover material

How do sports and racing applications benefit from specialized seat cover materials?

In the sports and racing industry, specialized motorbike seat cover materials are designed to enhance both performance and rider comfort. These covers often incorporate lightweight materials that provide grip and support during high-speed maneuvers, addressing the specific needs of competitive riders. The value lies in the combination of safety and comfort, which can significantly impact performance outcomes. B2B buyers in this sector must prioritize materials that meet safety standards while offering superior grip features, particularly in markets like Germany and Vietnam, where racing culture is prominent.

3 Common User Pain Points for ‘motorbike seat cover material’ & Their Solutions

Scenario 1: The Challenge of Durability in Harsh Climates

The Problem: Many B2B buyers, particularly those in regions with extreme weather conditions like Africa or the Middle East, face significant challenges with the durability of motorbike seat cover materials. High temperatures, intense UV exposure, and humidity can rapidly degrade lower-quality materials, leading to frequent replacements and increased operational costs. This scenario is especially frustrating for businesses that rely on motorcycles for logistics or transportation, as they need reliable equipment that can withstand tough environments.

The Solution: To ensure durability, it’s essential to source seat cover materials specifically designed for harsh climates. Look for marine-grade vinyl or high-quality leather that has been treated for UV resistance and waterproofing. When specifying materials, ask suppliers for performance certifications that demonstrate the material’s resilience against fading and cracking. Additionally, consider integrating breathable materials that promote airflow and reduce moisture accumulation, which can prolong the lifespan of the seat cover. Establish relationships with manufacturers who offer samples or small batches so that you can test materials under real conditions before committing to bulk orders.

Scenario 2: Comfort vs. Cost—Finding the Right Balance

The Problem: B2B buyers often struggle with the trade-off between comfort and cost when selecting motorbike seat cover materials. While high-quality, comfortable materials such as gel pads or specialized foams can enhance the riding experience, they often come at a premium price. This dilemma can lead to decisions that compromise rider comfort, resulting in decreased productivity and potential safety risks, especially for businesses involved in long-distance travel or logistics.

The Solution: To navigate this challenge, conduct a thorough cost-benefit analysis that weighs the long-term benefits of investing in higher-quality materials against immediate budget constraints. Engage in dialogue with manufacturers about bulk purchasing options or loyalty programs that can reduce costs. Additionally, consider hybrid solutions that combine different materials—for instance, using a high-density foam for the base layer paired with a gel insert for comfort. This approach can provide the necessary support and comfort without significantly increasing costs. Request samples and conduct trials to find the optimal balance that meets your needs without compromising on quality.

Scenario 3: Customization Needs for Diverse Clientele

The Problem: In diverse markets like South America and Europe, B2B buyers often encounter the challenge of meeting varying customer preferences and requirements for motorbike seat covers. Different riders may have distinct needs based on their riding style, body type, or aesthetic preferences, making it difficult for suppliers to stock a one-size-fits-all solution. This can lead to lost sales and dissatisfied customers if buyers cannot find the right fit or style.

The Solution: To effectively address customization needs, develop partnerships with manufacturers that offer bespoke services. This allows for the production of tailored seat covers that align with specific customer preferences, including color, texture, and material type. When placing orders, provide detailed specifications and encourage customer feedback to refine offerings continually. Additionally, consider implementing a modular design approach where customers can choose components—such as padding thickness, cover material, and design features—allowing them to create a seat cover that perfectly meets their requirements. This not only enhances customer satisfaction but also positions your business as a leader in providing personalized solutions in the market.

Strategic Material Selection Guide for motorbike seat cover material

What Are the Key Properties of Common Motorbike Seat Cover Materials?

When selecting materials for motorbike seat covers, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials: leather, marine-grade vinyl, neoprene, and synthetic leather, focusing on their relevance to B2B buyers across diverse markets.

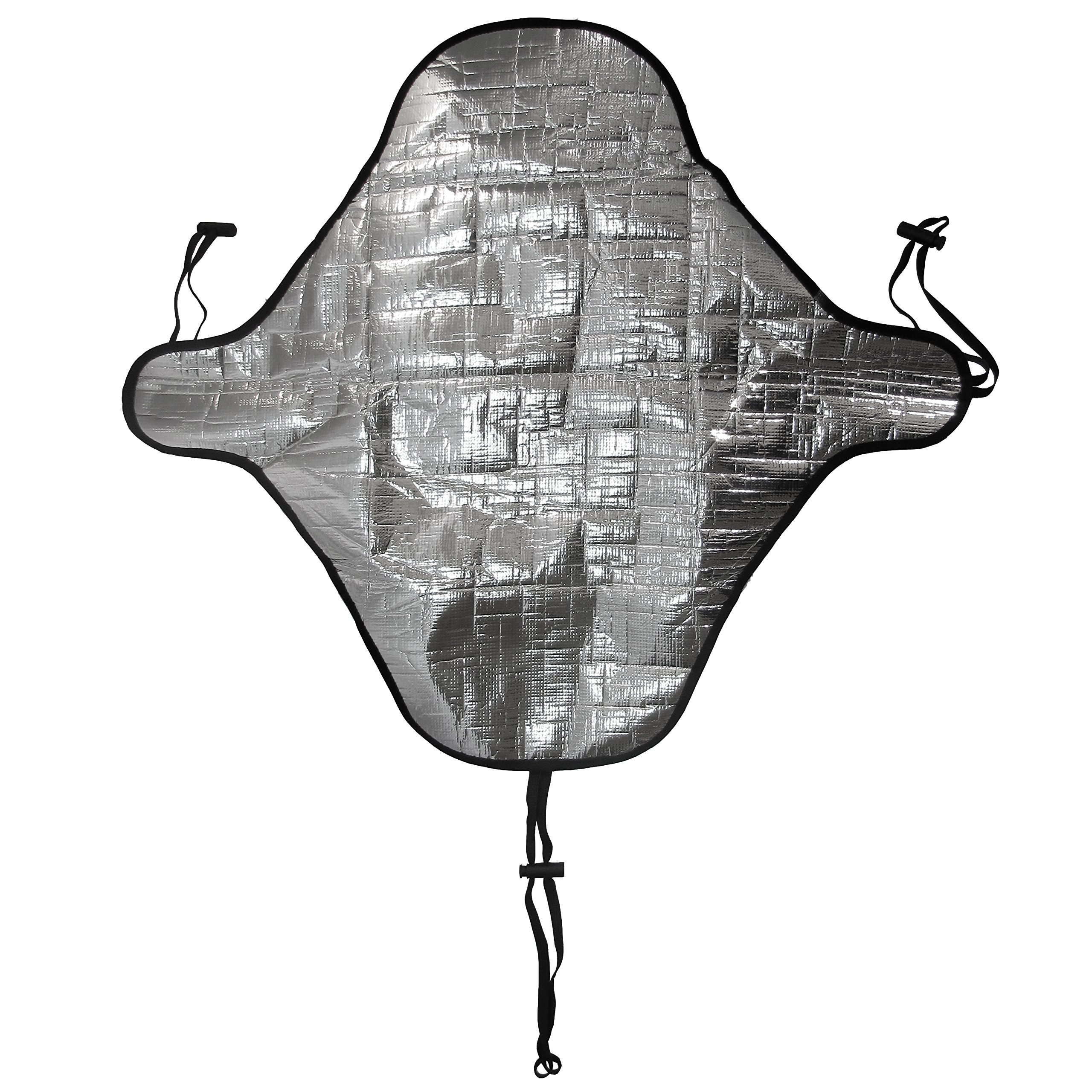

Illustrative image related to motorbike seat cover material

How Does Leather Perform as a Motorbike Seat Cover Material?

Leather is a traditional choice for motorbike seat covers, renowned for its aesthetic appeal and comfort. It has excellent temperature resistance, maintaining its integrity in both hot and cold conditions. Leather is also breathable, which enhances comfort during long rides. However, it requires regular maintenance to prevent cracking and fading, particularly in harsh climates.

Pros: Leather offers superior durability and a luxurious appearance. It is also resistant to wear and tear, making it suitable for high-end motorcycles.

Cons: The cost of high-quality leather can be substantial, and its manufacturing process is complex, requiring skilled labor. Additionally, leather may not be the best option in extremely wet conditions unless treated.

Impact on Application: Leather is compatible with various riding styles but is best suited for premium motorcycle models.

Considerations for International Buyers: Buyers from regions like Europe may prefer leather for its prestige, while those in hotter climates, such as Africa and the Middle East, should consider the need for UV protection and moisture resistance.

Illustrative image related to motorbike seat cover material

What Are the Advantages of Marine-Grade Vinyl?

Marine-grade vinyl is another popular choice for motorbike seat covers, particularly due to its water resistance and durability. This material is designed to withstand extreme weather conditions, making it ideal for outdoor use. It is also easy to clean and maintain, which is a significant advantage for riders who frequently encounter dirt and grime.

Pros: The primary advantage of marine-grade vinyl is its resilience against moisture and UV rays, which prolongs its lifespan. It is also relatively cost-effective compared to leather.

Cons: While durable, marine-grade vinyl may not provide the same level of comfort as leather, particularly for long-distance rides. It can also become hot in direct sunlight, affecting rider comfort.

Impact on Application: This material is suitable for various motorcycle types, especially those used in rugged environments or for off-road riding.

Considerations for International Buyers: Compliance with local standards, such as ASTM for fire resistance, is crucial, particularly in regions with stringent regulations like Europe.

Illustrative image related to motorbike seat cover material

How Does Neoprene Compare in Terms of Performance?

Neoprene is a synthetic rubber material known for its flexibility and comfort. It offers good cushioning and is resistant to water, making it a viable option for motorbike seat covers. Neoprene can also withstand a range of temperatures, although it may not be as durable as leather or marine-grade vinyl.

Pros: Neoprene’s flexibility provides excellent comfort, and its water resistance makes it suitable for various weather conditions.

Cons: The main drawback is its susceptibility to UV damage over time, which can lead to degradation. Additionally, neoprene can be more expensive than vinyl options.

Impact on Application: Neoprene is particularly well-suited for riders who prioritize comfort and ride in variable weather conditions.

Illustrative image related to motorbike seat cover material

Considerations for International Buyers: Buyers should ensure that the neoprene used meets international quality standards, especially in regions like South America and Europe where product quality is closely scrutinized.

What Are the Key Features of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to natural leather. It is designed to mimic the look and feel of leather while providing enhanced durability and ease of maintenance. Synthetic leather is resistant to fading and cracking, making it suitable for various applications.

Pros: The primary advantage is its affordability and low maintenance requirements. It also offers a wide range of colors and styles, appealing to diverse consumer preferences.

Cons: Synthetic leather may not breathe as well as natural leather, which can lead to discomfort during long rides. It may also lack the prestige associated with genuine leather.

Illustrative image related to motorbike seat cover material

Impact on Application: This material is suitable for budget-conscious consumers and is commonly used in entry-level motorcycles.

Considerations for International Buyers: Compliance with environmental regulations is critical, particularly in Europe, where there is a strong emphasis on sustainable materials.

Summary Table of Motorbike Seat Cover Materials

| Material | Typical Use Case for motorbike seat cover material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium motorcycles, long-distance riding | Superior durability and comfort | High cost and requires maintenance | Alta |

| Marine-Grade Vinyl | Off-road and outdoor motorcycles | Water and UV resistance | Can be hot and less comfortable | Medium |

| Neoprene | Variable weather conditions | Flexible and comfortable | Susceptible to UV damage | Medium |

| Piel sintética | Budget motorcycles and entry-level models | Cost-effective and low maintenance | Less breathable than natural leather | Low |

This strategic material selection guide provides a comprehensive overview of the key materials used in motorbike seat covers, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

Illustrative image related to motorbike seat cover material

In-depth Look: Manufacturing Processes and Quality Assurance for motorbike seat cover material

What Are the Main Stages in the Manufacturing Process of Motorbike Seat Cover Material?

The manufacturing process for motorbike seat cover material typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the quality expectations of B2B buyers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing motorbike seat cover materials is the selection and preparation of raw materials. Manufacturers often choose durable fabrics such as marine-grade vinyl, leather, or specialized synthetic materials designed to withstand harsh weather conditions.

Materials are inspected for quality and consistency, and any defects are identified before production begins. This stage may include cutting the fabrics into specific shapes or sizes, treating them with water-resistant or UV-protective coatings, and ensuring they meet the required specifications for durability and comfort.

Forming: What Techniques Are Used to Shape the Material?

Once the materials are prepared, the next stage is forming. This involves cutting and shaping the fabric to fit the seat design. Advanced techniques such as laser cutting may be employed to ensure precision and minimize waste.

Sewing is a critical part of this process, where skilled operators use industrial sewing machines to stitch together the cut pieces. Different stitching techniques, such as double-stitched seams, are utilized to enhance the durability of the seat covers, ensuring they can withstand the rigors of daily use.

How Is the Assembly Process Conducted for Motorbike Seat Covers?

The assembly stage involves combining the formed pieces into a complete seat cover. This process often includes the integration of additional features such as gel pads or foam padding for enhanced comfort.

Quality control checks are implemented at this stage to ensure that all components fit correctly and that there are no defects in the assembly. Proper alignment and secure fastening are essential to provide a finished product that not only looks good but also performs well under various riding conditions.

What Finishing Techniques Are Applied to Motorbike Seat Covers?

Finishing touches are applied after the assembly process. This includes trimming excess material, applying final coatings, and ensuring that the aesthetics of the seat cover meet the buyer’s specifications.

Illustrative image related to motorbike seat cover material

Finishing techniques may also involve heat sealing, which enhances the waterproof properties of the seat cover, or the addition of branding elements such as embroidered logos. The goal is to create a visually appealing product that meets the functional requirements of motorbike riders.

What Quality Control Standards Are Relevant for Motorbike Seat Cover Manufacturing?

Quality assurance is critical in the manufacturing process of motorbike seat covers. International standards such as ISO 9001 set the framework for quality management systems, ensuring that products are consistently produced to meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, particularly for materials that need to comply with safety and environmental regulations. These certifications demonstrate a commitment to quality and safety in manufacturing processes.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control is implemented at various checkpoints throughout the manufacturing process. These include:

Illustrative image related to motorbike seat cover material

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Any defective materials are rejected to prevent issues later on.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections ensure that processes are followed correctly and that the product meets quality standards at every step.

-

Final Quality Control (FQC): Once the seat covers are fully assembled, a comprehensive inspection is conducted to check for defects, ensure proper assembly, and verify that the product meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to ensure the quality of their suppliers should consider several methods for verification. Conducting on-site audits is one of the most effective ways to evaluate a supplier’s quality control processes. During an audit, buyers can assess the manufacturing environment, review documentation, and observe production techniques firsthand.

Additionally, requesting detailed quality reports can provide insight into a supplier’s performance over time. These reports should outline testing methods, compliance with standards, and results from various quality checkpoints.

Third-party inspections can also serve as an independent verification method. Engaging a reputable inspection agency to evaluate the production process can provide an unbiased assessment of the supplier’s quality practices.

What Testing Methods Are Commonly Used in the Quality Control Process?

Several testing methods are employed to ensure that the motorbike seat covers meet required standards. Common tests include:

-

Durability Testing: This assesses the material’s resistance to wear, tear, and environmental factors. Tests may include abrasion resistance and UV exposure tests.

-

Comfort Testing: Evaluates how the seat covers perform under typical riding conditions, focusing on pressure distribution and temperature control.

-

Water Resistance Testing: Ensures that the materials can withstand exposure to moisture without degrading.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control across different regions is essential. Variations in regulations, standards, and consumer expectations can impact the quality assurance processes of manufacturers in different countries.

For example, European manufacturers may have stringent environmental regulations compared to those in other regions. Buyers should familiarize themselves with local standards and certifications to ensure that the products they source comply with their market’s requirements.

Additionally, effective communication with suppliers about quality expectations and standards is vital. Establishing clear criteria for quality and performance can help mitigate risks associated with sourcing from international suppliers.

In conclusion, the manufacturing processes and quality assurance practices for motorbike seat cover materials are intricate and multifaceted. B2B buyers must be diligent in their evaluation of suppliers, focusing on manufacturing techniques, quality control measures, and relevant certifications to ensure they receive high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorbike seat cover material’

In the competitive landscape of motorbike seat cover material procurement, a structured approach can enhance decision-making and ensure the selection of quality materials. This guide offers a practical checklist for B2B buyers to navigate the sourcing process effectively.

Illustrative image related to motorbike seat cover material

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the motorbike seat cover materials. Consider factors such as durability, weather resistance, and comfort levels. These specifications will guide your search for suitable materials and help communicate your needs to suppliers.

- Material Types: Decide between leather, vinyl, or other synthetic materials based on the intended use and environmental factors.

- Performance Requirements: Assess if the material needs to withstand UV rays, moisture, and temperature fluctuations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in motorbike seat cover materials. This step is vital to ensure quality and reliability.

- Supplier Credentials: Look for suppliers with industry certifications and a strong track record in manufacturing motorbike accessories.

- Client Testimonials: Seek feedback from previous clients, especially those from your target regions (Africa, South America, Middle East, Europe).

Step 3: Request Material Samples

Before making a large order, request samples of the materials you are considering. This allows you to evaluate the quality firsthand.

- Quality Assessment: Inspect the samples for durability, texture, and overall finish.

- Compatibility Testing: Ensure that the material aligns with your design and technical requirements.

Step 4: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications for quality and safety standards relevant to your market. This ensures compliance and reduces the risk of sourcing subpar materials.

Illustrative image related to motorbike seat cover material

- ISO Certifications: Check if the supplier is ISO-certified, which indicates adherence to international quality standards.

- Environmental Compliance: Ensure that the materials meet environmental regulations, especially if your business emphasizes sustainability.

Step 5: Negotiate Pricing and Terms

Once you have selected a few potential suppliers, initiate discussions on pricing, minimum order quantities, and payment terms. This step is critical for managing your budget and financial commitments.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly affect your overall costs.

- Payment Flexibility: Discuss payment terms that align with your financial strategy, such as net 30 or net 60 terms.

Step 6: Assess Logistics and Delivery Capabilities

Understand the logistics involved in the procurement process, including delivery times and shipping options. This is essential for planning your inventory and meeting customer demands.

- Shipping Options: Evaluate the supplier’s shipping methods and their ability to deliver to your location efficiently.

- Lead Times: Confirm lead times for production and delivery to ensure they align with your project timelines.

Step 7: Establish a Quality Control Process

Implement a quality control process for the materials upon delivery. This ensures that what you receive meets your initial specifications and standards.

- Inspection Protocols: Develop clear inspection criteria for assessing the quality of received materials.

- Feedback Loop: Establish a system for providing feedback to suppliers to foster continuous improvement.

By following these steps, B2B buyers can streamline their sourcing process for motorbike seat cover materials, ensuring they select high-quality options that meet their technical requirements and business goals.

Illustrative image related to motorbike seat cover material

Comprehensive Cost and Pricing Analysis for motorbike seat cover material Sourcing

What Are the Key Cost Components in Sourcing Motorbike Seat Cover Materials?

When sourcing materials for motorbike seat covers, a clear understanding of the cost structure is essential for B2B buyers. The total cost encompasses several components:

-

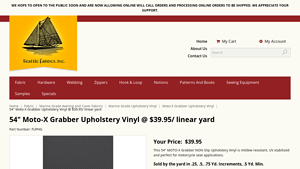

Materials: The choice of materials significantly influences the overall cost. High-quality leather, marine-grade vinyl, and advanced foam or gel padding are more expensive but offer superior durability and comfort. As per recent market data, materials like Moto-X Grabber Upholstery Vinyl can cost around $39.95 per linear yard, reflecting the premium associated with specialized fabrics.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but be cautious about potential trade-offs in quality. Skilled labor is essential for ensuring high-quality stitching and finishing, which are critical for the durability of seat covers.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer better pricing to buyers.

-

Tooling: Custom tooling for specific designs can be a significant upfront cost. Buyers requiring unique seat shapes or custom features should factor in these costs, which can vary widely based on complexity and volume.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the final product meets required standards. While this incurs additional costs, it ultimately protects against returns and enhances customer satisfaction.

-

Logistics: Transporting materials and finished products involves freight charges, customs duties, and insurance. These costs fluctuate based on distance and trade agreements, which can impact pricing, especially for international buyers.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect Motorbike Seat Cover Material Costs?

Several factors can influence the pricing of motorbike seat cover materials:

-

Volume/MOQ: Bulk orders often lead to discounts, so understanding the minimum order quantity (MOQ) can help negotiate better terms. Suppliers are usually more willing to offer lower prices for larger orders.

-

Specifications and Customization: Customization requests, such as specific dimensions, colors, or branding, can increase costs. Be prepared for potential price hikes when specifying unique features.

-

Quality and Certifications: Materials that meet certain industry standards or certifications may come at a premium. Ensure that the materials chosen align with expected quality benchmarks, especially for markets with stringent regulations.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers with proven track records may command higher prices but often deliver better quality and service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms (like FOB, CIF, etc.) dictate who bears the responsibility for shipping and customs, impacting the total landed cost.

What Are the Best Negotiation Strategies for B2B Buyers in the Motorbike Seat Cover Market?

When negotiating prices, consider the following strategies:

-

Research and Benchmarking: Gather data on market prices and supplier offerings to establish a baseline for negotiations. Being informed about competitors’ pricing can strengthen your bargaining position.

-

Emphasize Long-Term Relationships: Suppliers are often willing to provide better pricing for buyers who commit to long-term partnerships. Highlight potential future orders during negotiations.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the upfront cost but also the long-term implications, including durability, maintenance, and potential return on investment. A higher initial price may be justified if the material lasts significantly longer.

-

Be Culturally Aware: When dealing with international suppliers, understanding cultural nuances can aid negotiations. Different regions may have varying expectations regarding communication, pricing, and contract terms.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of pricing nuances such as:

-

Currency Fluctuations: Exchange rates can impact costs, especially for buyers purchasing in foreign currencies. Consider locking in rates or using hedging strategies.

-

Import Duties and Taxes: These can significantly affect the total cost. Familiarize yourself with local regulations to avoid unexpected expenses.

-

Cultural Differences in Pricing: Some regions may have different pricing strategies, including the use of discounts or promotional pricing. Understanding these can provide leverage during negotiations.

Disclaimer

The prices and cost structures mentioned herein are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and engage directly with suppliers for the most accurate pricing.

Illustrative image related to motorbike seat cover material

Alternatives Analysis: Comparing motorbike seat cover material With Other Solutions

Introduction: Understanding Alternatives in Motorbike Seat Solutions

When considering motorbike seat cover materials, it’s essential to evaluate viable alternatives that could provide similar benefits or address specific needs. The right choice can enhance rider comfort, improve durability, and meet aesthetic preferences. This analysis will compare traditional motorbike seat cover materials with two alternative solutions: aftermarket seat replacements and gel seat pads.

Comparison Table

| Comparison Aspect | Motorbike Seat Cover Material | Aftermarket Seat Replacement | Gel Seat Pads |

|---|---|---|---|

| Performance | High durability and comfort; tailored fit for various models | Excellent comfort and often superior ergonomics; may require installation | Provides additional cushioning; can alleviate pressure points |

| Cost | Moderate to high, depending on material and customization | Higher initial investment; varies significantly by brand and model | Generally low-cost; easy to replace or upgrade |

| Ease of Implementation | Moderate; requires removal of old cover and fitting new one | High; often needs professional installation | Very easy; simply place over existing seat |

| Maintenance | Requires occasional cleaning; may need replacement after wear | Minimal maintenance; depends on material | Low maintenance; easy to clean and replace |

| Best Use Case | Ideal for customizing aesthetics and comfort for specific riding styles | Best for riders seeking significant upgrades in comfort and support | Suitable for occasional riders or those looking for a temporary solution |

Detailed Breakdown of Alternatives

Aftermarket Seat Replacement

Aftermarket seats provide an entirely new seating solution, often designed with improved ergonomics and comfort features. They can enhance the riding experience, especially on long trips, by providing better support and reducing fatigue. However, the cost can be substantial, and installation may require professional help, which could deter some buyers. For businesses catering to serious riders or those seeking performance enhancements, offering a range of aftermarket seats could be a lucrative option.

Gel Seat Pads

Gel seat pads are an economical alternative that can significantly improve comfort without the commitment of a full seat replacement. These pads are designed to conform to the rider’s shape, distributing weight evenly and alleviating pressure points during rides. While they are easy to use and maintain, gel pads may not provide the same level of support as a high-quality aftermarket seat or customized cover. They are best suited for riders who want a quick and affordable comfort upgrade, making them an attractive option for budget-conscious buyers.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate motorbike seating solution requires a clear understanding of the rider’s preferences, budget constraints, and intended use. Motorbike seat cover materials offer customization and durability, while aftermarket seat replacements deliver superior comfort and support at a higher cost. Gel seat pads provide a practical, low-cost solution for temporary comfort improvements. B2B buyers should consider these factors carefully, aligning their choice with the specific needs of their customers to ensure satisfaction and enhance the riding experience.

Essential Technical Properties and Trade Terminology for motorbike seat cover material

What Are the Key Technical Properties of Motorbike Seat Cover Materials?

When sourcing motorbike seat cover materials, understanding the technical specifications is essential for making informed purchasing decisions. Here are some critical properties to consider:

-

Material Grade

The grade of material indicates its quality and performance characteristics. Common materials include high-quality leather, marine-grade vinyl, and synthetic fabrics. A higher material grade typically translates to better durability, resistance to UV rays, and overall longevity, which is crucial for B2B buyers looking to maintain competitive product offerings. -

Abrasion Resistance

This property measures how well a material can withstand wear and tear. For motorbike seat covers, abrasion resistance is vital due to the friction created during rides. Materials with high abrasion resistance reduce the frequency of replacements, thereby lowering costs and enhancing customer satisfaction. -

Water Resistance

The ability of a material to repel water is critical, particularly for riders in regions prone to rain. Water-resistant materials prevent the degradation of seat covers, thus extending their lifespan. B2B buyers should prioritize this property to ensure their products can meet diverse climate conditions. -

Temperature Tolerance

Different materials react differently to temperature changes. For instance, some may become brittle in extreme cold or overly soft in high heat. Understanding the temperature tolerance of seat cover materials allows buyers to select products that maintain performance and comfort across various environmental conditions. -

Weight Capacity

Knowing the weight capacity of the seat cover material is essential for ensuring safety and comfort for riders of different sizes. Materials that can support heavier weights without compromising structural integrity are more appealing to B2B buyers, as they can cater to a broader customer base. -

Customization Options

The ability to customize seat covers can greatly enhance their appeal. This includes options for colors, patterns, and stitching styles. Buyers should consider materials that allow for customization to meet specific market demands, as personalized products often lead to higher customer satisfaction and loyalty.

What Are Common Trade Terms in the Motorbike Seat Cover Industry?

Understanding industry jargon can facilitate smoother negotiations and transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of motorbike seat covers, OEM materials are often preferred for their compatibility and quality, making it essential for B2B buyers to inquire about OEM options when sourcing materials. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For motorbike seat cover materials, understanding MOQ helps buyers plan their inventory and budget effectively. It is crucial to negotiate this term to ensure it aligns with production needs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing information from suppliers. It is a standard procedure in B2B transactions, allowing buyers to compare costs and select the most competitive offers for motorbike seat cover materials. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, risk transfer, and delivery obligations associated with motorbike seat cover materials. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the motorbike seat cover industry, knowing the lead time is critical for inventory management and meeting customer demands promptly. -

Surface Finish

This term describes the final texture and appearance of the material’s surface. Surface finishes can affect both aesthetics and functionality, including grip and comfort levels. Buyers should be aware of the available finishes to ensure they meet their product specifications and customer expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they choose the right motorbike seat cover materials that align with their business needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the motorbike seat cover material Sector

What Are the Key Market Dynamics and Trends in the Motorbike Seat Cover Material Sector?

The motorbike seat cover material sector is experiencing significant growth, driven by several global factors. Increasing motorcycle ownership, particularly in emerging markets such as Africa and South America, is propelling demand for high-quality aftermarket products. As urbanization continues to rise, the need for durable and comfortable seating solutions for both commuting and recreational riding is becoming paramount. International B2B buyers are particularly interested in sourcing innovative materials that enhance comfort and performance, such as gel inserts and advanced foam technologies, which cater to diverse riding styles and preferences.

Illustrative image related to motorbike seat cover material

Emerging technologies are also reshaping the landscape of motorbike seat cover materials. Digital manufacturing techniques, including 3D printing, allow for customization and rapid prototyping, enabling suppliers to meet specific buyer requirements efficiently. Additionally, the integration of smart materials that adapt to temperature and pressure changes is gaining traction, offering enhanced comfort and user experience. This trend is especially appealing to buyers in regions like Europe, where consumer expectations for product performance are high.

Moreover, the ongoing shift towards personalization in the motorcycle market is influencing sourcing strategies. Buyers are increasingly seeking suppliers who can provide customization options, from fabric color and texture to unique stitching patterns. This demand for tailored solutions is particularly prevalent among premium motorcycle brands, which emphasize aesthetics alongside functionality.

How Is Sustainability Shaping the Sourcing Strategies for Motorbike Seat Cover Materials?

Sustainability is becoming a critical consideration for B2B buyers in the motorbike seat cover material sector. As environmental concerns gain prominence globally, companies are increasingly prioritizing ethical sourcing and sustainable practices. This shift is driven not only by regulatory pressures but also by growing consumer awareness regarding the environmental impact of products. For instance, the use of eco-friendly materials, such as recycled plastics and organic textiles, is gaining traction among suppliers looking to align with sustainable practices.

Buyers are also focusing on the traceability of their supply chains. Ensuring that materials are sourced from ethical suppliers who adhere to labor and environmental standards is crucial. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can enhance a supplier’s credibility and appeal to conscious buyers. These certifications assure that the materials used not only minimize environmental impact but also promote fair labor practices.

Furthermore, sustainable innovations, such as biodegradable seat covers and production processes that minimize waste, are becoming increasingly important. Buyers in markets like the Middle East and Europe are particularly keen on sourcing from suppliers who are committed to reducing their carbon footprint. This trend not only satisfies consumer demands but also fosters brand loyalty and enhances the overall market reputation.

How Has the Motorbike Seat Cover Material Sector Evolved Over Time?

The evolution of motorbike seat cover materials reflects broader trends in the automotive and textile industries. Initially dominated by basic leather and vinyl options, the market has transitioned towards a more diverse range of materials tailored for comfort, durability, and performance. The introduction of advanced cushioning technologies, such as gel and memory foam, has transformed the riding experience, allowing for longer journeys without discomfort.

In recent years, the focus on customization has surged, with aftermarket manufacturers offering bespoke solutions that cater to individual rider preferences. This evolution has been fueled by technological advancements in material science and manufacturing processes, enabling suppliers to create products that not only meet functional requirements but also appeal to aesthetic sensibilities.

As the market continues to mature, the integration of sustainability into product development is set to shape the future of motorbike seat cover materials. Buyers are increasingly recognizing the importance of sustainable sourcing, which will likely drive innovation and influence purchasing decisions in the coming years.

Frequently Asked Questions (FAQs) for B2B Buyers of motorbike seat cover material

-

How do I choose the right material for motorbike seat covers?

Selecting the appropriate material for motorbike seat covers involves considering several factors, including comfort, durability, and climate. For long-distance riding, look for materials that offer excellent cushioning, like gel inserts or high-density foam. In contrast, if you frequently ride in wet or hot conditions, marine-grade vinyl or high-quality leather may be ideal due to their resistance to moisture and UV damage. Additionally, consider the aesthetic appeal and customization options available to match your brand identity. -

What is the best padding material for motorbike seats?

The best padding material for motorbike seats typically includes foam and gel options. Open-cell foam provides comfort and breathability for leisure rides, while closed-cell foam is better suited for racing due to its firmness and water resistance. Gel pads are excellent for long rides, as they conform to the rider’s body and relieve pressure points. A combination of these materials can be utilized for a more customized solution, catering to specific riding needs and preferences. -

What customization options are available for motorbike seat covers?

Customization options for motorbike seat covers can include varied colors, stitching patterns, and personalized embroidery. Many suppliers also offer the ability to select different materials for both the cover and padding. When placing a bulk order, inquire about the minimum order quantities (MOQs) for custom designs, as these can differ among manufacturers. Customization not only enhances branding but also allows you to meet specific customer preferences in different regions. -

How can I verify the reliability of a motorbike seat cover supplier?

To ensure the reliability of a motorbike seat cover supplier, conduct thorough background checks by reviewing their business history, customer testimonials, and industry certifications. Request samples to evaluate the quality of materials and craftsmanship. Additionally, consider reaching out to other businesses that have worked with the supplier to gather insights on their experiences. Transparency in communication and willingness to accommodate your specific needs are also good indicators of a dependable supplier. -

What are the typical payment terms for international orders of motorbike seat cover materials?

Payment terms for international orders can vary widely but generally include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss and agree upon payment terms before placing an order to avoid misunderstandings. Many suppliers require a deposit, often ranging from 30% to 50% of the total order value, with the balance due upon shipment. Ensure that all payment terms are clearly outlined in the contract to protect both parties. -

What are the common logistics challenges in sourcing motorbike seat cover materials internationally?

Sourcing motorbike seat cover materials internationally can present logistical challenges, such as customs clearance delays, varying shipping costs, and potential tariffs. To mitigate these issues, collaborate with logistics providers experienced in international shipping and familiarize yourself with the import regulations of your destination country. Establishing a reliable supply chain and maintaining open communication with your supplier can also help address any unforeseen delays or complications during transit. -

What quality assurance measures should I look for in motorbike seat cover materials?

When sourcing motorbike seat cover materials, look for suppliers who implement strict quality assurance measures, such as regular inspections and testing of materials. Certifications from recognized industry standards, such as ISO or specific automotive quality standards, can also indicate a commitment to quality. Requesting samples and conducting your own testing for durability, comfort, and resistance to environmental factors will further ensure that the materials meet your specifications and customer expectations. -

What is the minimum order quantity (MOQ) for motorbike seat cover materials?

The minimum order quantity (MOQ) for motorbike seat cover materials varies by supplier and can depend on factors like material type and customization requirements. Typically, MOQs can range from a few hundred to several thousand units. It’s advisable to discuss MOQs early in negotiations to align your purchasing needs with the supplier’s capabilities. Some suppliers may offer flexibility on MOQs for first-time orders or during promotional periods, so it’s worth inquiring about potential options.

Top 5 Motorbike Seat Cover Material Manufacturers & Suppliers List

1. Luimoto – Motorcycle Seat Covers & Accessories

Domain: luimoto.com

Registered: 2004 (21 years)

Introduction: Motorcycle Seat Covers, Tank Grips & More – Luimoto

1. Rider Seat Covers: Premium aftermarket covers designed for comfort and style, made from marine-grade materials, tailored for various motorcycles, providing protection and aesthetic upgrade.

2. Passenger Seat Covers: High-quality marine-grade aftermarket covers that enhance grip and styling for two-up seating, outperforming OEM covers in dura…

2. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: Product Name: 54″ Moto-X Grabber Upholstery Vinyl

Price: $39.95 per linear yard

Part Number: FUPHG

Width: 54 inches

Material Type: NON-Slip Upholstery Vinyl

Features: Mildew resistant, UV stabilized

Applications: Ideal for motorcycle seat upholstery

Availability: Sold by the yard in .25, .5, .75 yard increments, with a .5 yard minimum

Color: Black (remnants available at 30% off)

Weight Per Linear …

3. MotoDeal – Motorcycle Seats

Domain: motodeal.com.ph

Introduction: Motorcycle seats typically consist of three layers: a backing plate (plastic or fiberglass/carbon fiber for super sportbikes), a foam layer (usually open-cell polyurethane for comfort, or closed-cell polyurethane for racing), and a seat cover (vinyl, leather, or synthetic). Vinyl is affordable and durable but can crack if low quality; leather offers premium comfort but requires maintenance and is …

4. Sailrite – Morbern™ Allsport 360º Stretch Vinyl Fabric

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

5. Wild-Ass – Motorcycle Seat Cushions Guide

Domain: wild-ass.com

Registered: 2015 (10 years)

Introduction: Motorcycle Seat Cushions: A Guide to the Most Comfortable Materials – Key Materials: 1. Neoprene Rubber – Flexible, durable, waterproof, often used in medical-grade seat pads for ergonomic support. 2. Polyurethane – Used in flexible cushioning foams, can be combined with gel pads for added comfort. 3. Gel Pads – Made from silicon, latex, soy, or polyurethane, they provide shock absorption and supp…

Strategic Sourcing Conclusion and Outlook for motorbike seat cover material

In summary, strategic sourcing of motorbike seat cover materials plays a pivotal role in enhancing product quality and customer satisfaction in the motorcycle industry. By prioritizing durable and comfortable materials—such as high-grade leather and marine-grade vinyl—businesses can cater to the diverse needs of riders across various terrains and climates. Additionally, understanding the importance of seat padding options, like foam and gel inserts, allows manufacturers to innovate and offer customized solutions that enhance riding experiences.

Illustrative image related to motorbike seat cover material

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate this competitive landscape, it is crucial to align sourcing strategies with emerging trends in material technology and consumer preferences. Building strong relationships with suppliers who prioritize quality and sustainability will not only streamline operations but also improve brand loyalty.

Looking ahead, the motorcycle market is poised for growth, driven by increasing demand for personalized and high-performance products. Now is the time to seize opportunities in sourcing innovative materials that resonate with today’s riders. Engage with reliable suppliers, explore customization options, and invest in quality to stay ahead in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to motorbike seat cover material

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.