Introduction: Navigating the Global Market for motorcycle seat upholstery material

In the dynamic realm of motorcycle manufacturing, sourcing high-quality motorcycle seat upholstery material poses a significant challenge for international B2B buyers. The diverse range of materials—ranging from luxurious leather to robust vinyl—each presents unique attributes that cater to different market demands and consumer preferences. However, the decision-making process can be daunting, particularly when considering factors such as comfort, durability, aesthetic appeal, and cost-effectiveness.

This comprehensive guide aims to empower B2B buyers by providing a thorough exploration of the various types of upholstery materials available in the global market. We delve into the specific applications of each material, supplier vetting processes, and a detailed analysis of cost considerations. Furthermore, we highlight emerging trends that are shaping the motorcycle upholstery landscape, ensuring that buyers are well-equipped to make informed purchasing decisions.

By addressing the unique challenges faced by buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Germany and Vietnam—this guide serves as an essential resource. It not only aids in navigating the complexities of material selection but also ensures that your procurement strategy aligns with market expectations and consumer needs. With the insights provided, B2B buyers can confidently enhance their product offerings and gain a competitive edge in the motorcycle industry.

Table Of Contents

- Top 5 Motorcycle Seat Upholstery Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorcycle seat upholstery material

- Understanding motorcycle seat upholstery material Types and Variations

- Key Industrial Applications of motorcycle seat upholstery material

- 3 Common User Pain Points for ‘motorcycle seat upholstery material’ & Their Solutions

- Strategic Material Selection Guide for motorcycle seat upholstery material

- In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat upholstery material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat upholstery material’

- Comprehensive Cost and Pricing Analysis for motorcycle seat upholstery material Sourcing

- Alternatives Analysis: Comparing motorcycle seat upholstery material With Other Solutions

- Essential Technical Properties and Trade Terminology for motorcycle seat upholstery material

- Navigating Market Dynamics and Sourcing Trends in the motorcycle seat upholstery material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat upholstery material

- Strategic Sourcing Conclusion and Outlook for motorcycle seat upholstery material

- Important Disclaimer & Terms of Use

Understanding motorcycle seat upholstery material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather | Premium look, breathable, molds to body | High-end motorcycles, custom builds | Pros: Durable, comfortable, stylish. Cons: Expensive, requires maintenance. |

| Vinilo | Weather-resistant, easy to clean, affordable | Mass-produced motorcycles, OEM parts | Pros: Low-maintenance, cost-effective. Cons: Less luxurious feel, potential durability issues. |

| Marine-Grade Vinyl | Mildew-resistant, UV protection, designed for moisture | Boats, outdoor motorcycles | Pros: Excellent durability, weather-resistant. Cons: Can be pricier, less soft feel. |

| Memory Foam | Molds to body shape, superior comfort | Custom motorcycle seats | Pros: Enhanced comfort for long rides. Cons: Generally higher cost, may compress over time. |

| Standard Foam | Basic cushioning, decent for short rides | Stock motorcycle seats | Pros: Affordable, adequate for short trips. Cons: Lacks support for long-distance riding. |

What Are the Characteristics of Leather Upholstery for Motorcycle Seats?

Leather is often viewed as the premium choice for motorcycle seat upholstery due to its luxurious appearance and feel. It is naturally breathable, which helps to regulate temperature, providing comfort in various weather conditions. Leather molds to the rider’s body over time, enhancing comfort. However, B2B buyers should consider the higher upfront cost and the need for regular maintenance to prevent cracking and weather damage, particularly in harsher climates.

How Does Vinyl Compare as an Upholstery Material?

Vinyl offers a cost-effective alternative to leather, making it a popular choice for mass-produced motorcycles and OEM parts. This material is weather-resistant, easy to clean, and generally requires minimal maintenance. While it provides a solid balance between durability and affordability, buyers should be aware that vinyl may not deliver the same luxurious feel as leather, and its long-term durability can vary based on the quality of the product.

Why Choose Marine-Grade Vinyl for Motorcycle Seats?

Marine-grade vinyl is specifically designed to withstand extreme weather conditions, making it ideal for motorcycles used in humid or rainy environments. This material is mildew-resistant and provides UV protection, ensuring longevity and maintaining aesthetics even after prolonged exposure to the elements. However, B2B buyers should note that marine-grade vinyl can be more expensive than standard vinyl and may lack the soft feel of leather or high-quality vinyl options.

What Are the Benefits of Using Memory Foam in Motorcycle Seats?

Memory foam is an excellent choice for custom motorcycle seats, as it molds to the rider’s body shape, providing exceptional comfort during long rides. This type of foam significantly reduces pressure points, enhancing overall riding experience. While it typically comes at a higher cost than standard foam, the investment is justified for riders who prioritize comfort. Buyers should also consider that memory foam can compress over time, potentially affecting its supportive qualities.

How Does Standard Foam Perform in Motorcycle Seating?

Standard foam is commonly used in stock motorcycle seats and offers basic cushioning for short rides. It is an economical option for manufacturers looking to keep costs low. However, B2B buyers should be cautious, as this type of foam often lacks the necessary support for long-distance riding, leading to discomfort. While it is suitable for casual riders or those who do not prioritize comfort, investing in higher-quality foam options may be advisable for those seeking enhanced riding experiences.

Key Industrial Applications of motorcycle seat upholstery material

| Industry/Sector | Specific Application of Motorcycle Seat Upholstery Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Production of OEM motorcycle seats | Ensures high-quality, durable seating that enhances rider comfort and safety | Compliance with industry standards, material durability, and aesthetic appeal |

| Custom Upholstery | Tailored motorcycle seat designs for custom builds | Provides unique, personalized options that cater to specific customer preferences | Availability of diverse materials, customization capabilities, and turnaround time |

| Recreational Vehicle | Upholstery for ATV and snowmobile seats | Expands product offerings while maintaining comfort and style for off-road vehicles | Weather resistance, flexibility of materials, and ease of maintenance |

| Marine Industry | Seats for personal watercraft and boats | Durable, weather-resistant materials that withstand harsh marine conditions | UV resistance, mildew prevention, and compatibility with marine-grade standards |

| Hospitality | Motorcycle rental services and tour operators | Enhances customer experience through comfort and quality in rental motorcycles | Cost-effectiveness, ease of cleaning, and availability in bulk orders |

How is Motorcycle Seat Upholstery Material Used in the Motorcycle Manufacturing Sector?

In the motorcycle manufacturing sector, motorcycle seat upholstery material is integral to the production of Original Equipment Manufacturer (OEM) seats. Manufacturers prioritize high-quality materials that enhance rider comfort and safety, addressing issues like long-distance fatigue and seat durability. Buyers in this sector must consider compliance with industry standards, ensuring that the materials meet safety regulations and environmental requirements. Furthermore, aesthetic appeal is crucial, as design elements can significantly influence consumer purchasing decisions.

What Role Does Custom Upholstery Play in Tailored Motorcycle Seat Designs?

Custom upholstery is essential for businesses that specialize in tailored motorcycle seat designs. This application allows for personalized options that cater to specific rider preferences, enhancing the overall experience. Buyers in this segment seek materials that not only provide comfort but also allow for unique designs and branding opportunities. Key considerations include the availability of diverse material options, the ability to customize to specific dimensions, and the turnaround time for orders, which can impact customer satisfaction and business efficiency.

How is Motorcycle Seat Upholstery Material Applied in the Recreational Vehicle Industry?

In the recreational vehicle industry, motorcycle seat upholstery material is used to enhance seating for all-terrain vehicles (ATVs) and snowmobiles. This application ensures that riders enjoy comfort and support during off-road adventures. For international buyers, particularly in regions with rugged terrains, sourcing materials that are weather-resistant and flexible is critical. Additionally, ease of maintenance is a significant factor, as upholstery must withstand the elements while remaining visually appealing and functional.

What are the Benefits of Using Upholstery Material in the Marine Industry?

The marine industry utilizes motorcycle seat upholstery material for personal watercraft and boats, emphasizing durability and weather resistance. These materials must endure harsh marine conditions, including exposure to moisture and UV rays. Buyers in this sector should prioritize features such as mildew resistance and compatibility with marine-grade standards to ensure longevity and safety. By sourcing high-quality upholstery materials, businesses can enhance the comfort and appeal of their marine seating options, leading to increased customer satisfaction.

How Does Upholstery Material Enhance the Experience in the Hospitality Sector?

In the hospitality sector, motorcycle rental services and tour operators benefit significantly from high-quality motorcycle seat upholstery material. This application focuses on enhancing the customer experience, providing comfort and quality in rental motorcycles. Key considerations for buyers include cost-effectiveness, ease of cleaning, and the ability to procure materials in bulk to meet operational demands. By investing in superior upholstery materials, businesses can differentiate their offerings, attract more customers, and improve overall service quality.

3 Common User Pain Points for ‘motorcycle seat upholstery material’ & Their Solutions

Scenario 1: The Struggle with Comfort and Durability in Upholstery Selection

The Problem: B2B buyers often grapple with the dual challenge of ensuring comfort and durability in motorcycle seat upholstery materials. This is especially critical for manufacturers and retailers in regions with varying climates, such as Africa or South America, where extreme temperatures and humidity can significantly impact material performance. A common concern is that while some materials may offer initial comfort, they may degrade quickly under harsh environmental conditions, leading to increased returns and dissatisfied customers.

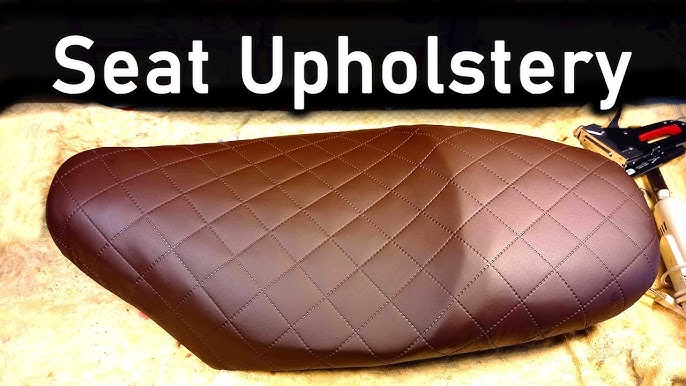

Illustrative image related to motorcycle seat upholstery material

The Solution: To address this pain point, buyers should prioritize sourcing upholstery materials that boast both comfort and weather resistance. Investing in high-quality vinyls or marine-grade materials can provide the necessary durability against moisture and UV exposure while maintaining comfort for riders. When specifying these materials, look for products that have been tested for cold-crack resistance and UV stability. Engaging with suppliers who offer warranties or guarantees on their upholstery can also provide added assurance. Conducting trials with samples in local conditions can help ensure that the chosen material meets both comfort and longevity needs, ultimately reducing returns and enhancing customer satisfaction.

Scenario 2: The Cost-Effectiveness Dilemma of Upholstery Options

The Problem: Many B2B buyers face budget constraints while trying to find upholstery materials that do not compromise on quality. In regions like the Middle East and Europe, where competition is fierce, the pressure to offer attractive pricing can lead to the temptation to opt for cheaper, lower-quality materials. This decision often results in increased maintenance costs and diminished customer satisfaction due to material failures or discomfort.

The Solution: To navigate this cost dilemma, it is essential to conduct a thorough cost-benefit analysis of upholstery materials. Buyers should consider the total lifecycle cost of materials rather than just the initial purchase price. For instance, while high-quality leather may come with a higher upfront cost, its longevity and minimal maintenance requirements can lead to lower overall costs. Establishing relationships with reputable suppliers who offer bulk purchasing options or loyalty discounts can also help manage costs effectively. Additionally, consider investing in training for staff on the benefits and selling points of premium materials to justify the higher price to customers, thereby enhancing the perceived value of the product.

Scenario 3: The Challenge of Customization for Diverse Market Needs

The Problem: Customization is increasingly demanded by customers who seek personalized motorcycle seat solutions tailored to their specific preferences. B2B buyers, particularly in diverse markets such as Europe and South America, often find it challenging to source upholstery materials that accommodate various custom designs, colors, and textures while still meeting performance standards.

Illustrative image related to motorcycle seat upholstery material

The Solution: To effectively address the customization challenge, buyers should partner with suppliers who specialize in flexible upholstery solutions and have a broad range of materials available. This includes sourcing materials that can be easily dyed or printed to meet specific design requirements. Additionally, investing in advanced inventory management systems can help streamline the ordering process for custom materials, ensuring timely delivery and reduced lead times. Collaborating with design teams to create a library of customizable options can also facilitate quicker decision-making for clients. Providing samples and swatches of various materials allows customers to visualize and feel the products, enhancing their confidence in the final choices. By prioritizing customization capabilities, buyers can differentiate their offerings in the market and cater to the evolving demands of consumers.

Strategic Material Selection Guide for motorcycle seat upholstery material

What Are the Key Properties of Common Motorcycle Seat Upholstery Materials?

When selecting upholstery materials for motorcycle seats, it is essential to consider their key properties, which directly affect performance and rider comfort. The most common materials include leather, vinyl, marine-grade materials, and memory foam. Each material has unique characteristics that cater to different market needs and preferences.

How Does Leather Perform as a Motorcycle Seat Upholstery Material?

Leather is often regarded as the premium choice for motorcycle seat upholstery. Its natural breathability helps regulate temperature, ensuring comfort in varying weather conditions. Leather also molds to the rider’s body over time, providing a personalized fit. However, it can be expensive and requires regular maintenance to prevent cracking and weather damage.

Pros and Cons of Leather:

– Pros: Durable, luxurious feel, molds to body shape, breathable.

– Cons: High cost, requires maintenance, vulnerable to weather damage.

For international buyers, particularly in regions like Europe and the Middle East, leather is often preferred for its aesthetic appeal and comfort. However, compliance with environmental regulations regarding leather sourcing and treatment processes is crucial.

What Are the Advantages of Using Vinyl for Motorcycle Seats?

Vinyl is a popular alternative to leather due to its affordability and durability. It is weather-resistant, making it suitable for motorcycles stored outdoors, and is easy to clean and maintain. Vinyl typically offers a decent level of comfort but may not provide the same luxurious feel as leather.

Pros and Cons of Vinyl:

– Pros: Cost-effective, low maintenance, weather-resistant.

– Cons: Less comfortable for long rides, may lack the premium feel.

For B2B buyers in regions like Africa and South America, vinyl can be an attractive option due to its lower cost and ease of maintenance, which is advantageous in markets where budget constraints are prevalent.

Why Choose Marine-Grade Materials for Motorcycle Seat Upholstery?

Marine-grade materials are designed to withstand harsh weather conditions, making them ideal for riders who frequently encounter rain or humidity. These materials are mildew-resistant and offer a balance of durability and comfort. However, they may not provide the same soft feel as leather or vinyl and can be more expensive.

Illustrative image related to motorcycle seat upholstery material

Pros and Cons of Marine-Grade Materials:

– Pros: Highly durable, mildew-resistant, suitable for extreme weather.

– Cons: Higher cost, less comfort than leather or vinyl.

International buyers in humid climates or regions with unpredictable weather, such as parts of Africa and South America, should consider marine-grade materials for their resilience and longevity.

How Does Foam Padding Impact Motorcycle Seat Comfort?

Foam padding is critical for comfort, with two primary types used in motorcycle seats: standard foam and memory foam. Memory foam, which molds to the rider’s shape, significantly enhances comfort during long rides. While standard foam is more affordable, it may not provide the same level of support.

Pros and Cons of Foam Padding:

– Pros: Enhances comfort, reduces pressure points, customizable.

– Cons: Quality varies, memory foam can be more expensive.

B2B buyers in Europe, particularly in Germany, may prioritize high-quality memory foam for its comfort benefits, especially for custom motorcycle seats designed for long-distance riding.

Summary Table of Motorcycle Seat Upholstery Materials

| Material | Typical Use Case for motorcycle seat upholstery material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium motorcycle seats for comfort and style | Durable and luxurious feel | High cost and maintenance needs | Alta |

| Vinilo | Budget-friendly motorcycle seats | Cost-effective and low maintenance | Less comfortable for long rides | Low |

| Marine-Grade | Seats for motorcycles in humid or wet conditions | Highly durable and mildew-resistant | Higher cost and less comfort | Medium |

| Memory Foam | Custom motorcycle seats for long-distance riding | Exceptional comfort and support | Quality varies, can be expensive | Medium |

This guide provides a comprehensive overview of the strategic selection of upholstery materials for motorcycle seats, helping international B2B buyers make informed decisions based on their specific market needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat upholstery material

What Are the Main Stages of Manufacturing Motorcycle Seat Upholstery Material?

Manufacturing motorcycle seat upholstery material involves a series of well-defined stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Motorcycle Seat Upholstery?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, such as vinyl, leather, or marine-grade fabrics. Suppliers must ensure that the materials are not only durable but also weather-resistant to withstand various environmental conditions.

Once the materials are sourced, they undergo a quality check to assess their integrity and suitability for upholstery. This can include tests for tensile strength, UV resistance, and colorfastness. After passing these checks, the materials are cut into specific patterns and dimensions required for different motorcycle models.

What Techniques Are Used in Forming Motorcycle Seat Upholstery?

After material preparation, the forming stage begins. This typically involves techniques such as die-cutting and molding. For vinyl and other synthetic materials, heat and pressure may be applied to mold the fabric into the desired shape, ensuring a snug fit on the seat frame.

In the case of leather, artisans may use traditional methods to shape and stitch the material, which often includes adding padding for comfort. This stage is crucial as it determines the overall fit and comfort of the seat.

Illustrative image related to motorcycle seat upholstery material

What Is Involved in the Assembly of Motorcycle Seats?

The assembly stage is where the formed components come together. This usually involves stitching the upholstery material to the seat’s foam padding and frame. Various stitching techniques are employed to ensure durability and aesthetic appeal, including double-stitched seams that can withstand wear and tear.

During assembly, quality control checkpoints are established to ensure that each component meets the specified standards. This can include verifying the accuracy of dimensions and inspecting the stitching for consistency and strength.

How Is Finishing Done in Motorcycle Seat Upholstery Production?

Finishing is the final stage of the manufacturing process. It involves adding any additional features such as logos, decorative elements, or protective coatings. For vinyl upholstery, a protective layer may be applied to enhance weather resistance and ease of cleaning.

Illustrative image related to motorcycle seat upholstery material

Quality checks during this stage include visual inspections for defects and ensuring that the upholstery is free from any flaws that could affect its performance. This comprehensive approach to finishing guarantees a polished and ready-to-use product.

What Quality Assurance Standards Are Relevant for Motorcycle Seat Upholstery Materials?

Quality assurance is critical in the manufacturing of motorcycle seat upholstery materials. International standards such as ISO 9001 provide a framework for maintaining quality management systems across organizations. Compliance with these standards ensures that manufacturers consistently meet customer and regulatory requirements.

Industry-specific certifications, such as CE marking for European markets, signify that products meet health, safety, and environmental protection standards. For manufacturers targeting international markets, understanding and adhering to these standards is essential for gaining credibility and market access.

What Are the Key Quality Control Checkpoints in Motorcycle Seat Upholstery Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the forming and assembly stages help identify any defects early in the process.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all quality standards before shipment.

Common testing methods include tensile strength tests, abrasion resistance tests, and colorfastness tests. These methods help verify the durability and performance of the upholstery materials.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are some effective strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality control systems and adherence to international standards.

- Quality Assurance Reports: Requesting detailed reports can provide insights into the supplier’s QC processes and any certifications they hold.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances. Differences in regulatory standards and market expectations can influence the selection of suppliers.

For instance, European buyers may prioritize CE certifications, while buyers in other regions may focus more on ISO compliance. Understanding these differences helps in selecting the right suppliers and negotiating contracts that align with regional standards.

Furthermore, cultural differences in business practices and quality expectations necessitate clear communication and thorough documentation. Establishing strong relationships with suppliers based on trust and transparency can significantly enhance the quality assurance process.

Conclusion: Ensuring Quality in Motorcycle Seat Upholstery Materials

In summary, the manufacturing processes and quality assurance measures for motorcycle seat upholstery materials are integral to delivering a reliable and comfortable product. By understanding the stages of production, relevant quality standards, and effective verification methods, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only ensures product quality but also helps build lasting partnerships in the competitive motorcycle upholstery market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat upholstery material’

Introducción

Sourcing high-quality motorcycle seat upholstery material is essential for manufacturers and retailers looking to provide durable and comfortable products. This guide offers a clear checklist to ensure you make informed decisions while procuring upholstery materials that meet your specific needs and standards.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s crucial to establish clear technical specifications for the upholstery material. Consider factors such as durability, weather resistance, and comfort level. Key aspects to define include:

– Material Type: Decide whether you need leather, vinyl, or marine-grade materials based on the intended use and environmental conditions.

– Thickness and Stretchability: Determine the required thickness and flexibility, as these influence the comfort and fit of the seat.

Illustrative image related to motorcycle seat upholstery material

Step 2: Research Industry Standards

Understanding the industry standards applicable to motorcycle upholstery materials will help you identify quality products. Familiarize yourself with regulations regarding safety, fire resistance, and environmental impact. Focus on:

– Safety Certifications: Ensure the materials comply with safety standards relevant to your region, such as ISO or ASTM certifications.

– Environmental Considerations: Look for eco-friendly options that align with sustainability goals, particularly if you’re targeting environmentally-conscious markets.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key evaluation criteria include:

– Reputation and Experience: Investigate how long the supplier has been in business and their expertise in motorcycle upholstery.

– Customer Feedback: Seek reviews or testimonials from other B2B buyers to gauge reliability and product quality.

Step 4: Request Samples

Requesting samples is a vital step in evaluating the quality and suitability of the materials. This will allow you to assess the texture, flexibility, and overall appearance. Consider the following:

– Material Performance: Examine how the material feels and behaves under different conditions, such as exposure to moisture and UV light.

– Color Matching: Ensure the samples match your desired aesthetic and consider how dye lots may vary.

Step 5: Compare Pricing and Terms

Pricing can significantly impact your procurement strategy. Compare costs across different suppliers but look beyond just the initial price. Key considerations include:

– Bulk Order Discounts: Inquire about pricing tiers for bulk purchases to optimize your budget.

– Payment and Delivery Terms: Ensure the terms align with your cash flow and project timelines, including lead times for delivery.

Illustrative image related to motorcycle seat upholstery material

Step 6: Verify Supplier Certifications

Ensuring that your suppliers have the necessary certifications is critical for maintaining quality and compliance. Certifications demonstrate a commitment to industry standards. Important certifications to check include:

– Quality Management Systems (e.g., ISO 9001): Indicates a supplier’s ability to consistently provide quality materials.

– Sustainability Certifications (e.g., GOTS for organic textiles): Important for meeting the growing demand for eco-friendly products.

Step 7: Establish a Communication Plan

Effective communication with your supplier is essential for a successful partnership. Create a plan that outlines how and when you will communicate regarding orders, quality concerns, or changes. Focus on:

– Regular Updates: Set up a schedule for regular check-ins to discuss order progress and any potential issues.

– Feedback Mechanisms: Establish channels for providing feedback on product quality and service, fostering a collaborative relationship.

By following this checklist, B2B buyers can confidently source motorcycle seat upholstery materials that meet their technical, aesthetic, and budgetary requirements.

Comprehensive Cost and Pricing Analysis for motorcycle seat upholstery material Sourcing

What Are the Key Cost Components in Sourcing Motorcycle Seat Upholstery Materials?

When sourcing motorcycle seat upholstery materials, understanding the comprehensive cost structure is crucial for effective budgeting and decision-making. The main cost components include:

-

Materials: The type of upholstery material significantly influences costs. Options range from high-end leather to durable vinyl and specialized marine-grade materials. Leather typically commands a premium price due to its durability and aesthetic appeal, while vinyl offers a more affordable yet functional alternative. Prices can vary widely based on quality and supplier, with leather often exceeding $50 per linear yard, whereas vinyl can range from $20 to $40 per linear yard.

-

Labor: Labor costs encompass the wages of skilled workers required for cutting, sewing, and finishing the upholstery. Depending on the complexity of the design and the skill level required, labor costs can vary. Custom jobs, which require more intricate craftsmanship, will naturally incur higher labor costs.

-

Manufacturing Overhead: This includes expenses related to the operation of the facility where the upholstery is produced, such as utilities, equipment maintenance, and administrative costs. These overheads are typically factored into the pricing per unit.

-

Tooling: Initial tooling costs for custom designs can be significant, especially if specific molds or sewing machines are required. This one-time cost should be considered when evaluating the overall price, particularly for custom orders.

-

Quality Control (QC): Ensuring that the upholstery meets industry standards requires investment in quality control processes. This can include testing materials for durability, colorfastness, and weather resistance, which adds to the overall cost.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. These costs can fluctuate based on distance, shipping methods, and the volume of materials ordered. Incoterms also play a vital role in determining who bears the shipping costs and risks.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market demand, competition, and the unique value proposition of their materials.

How Do Price Influencers Impact the Cost of Motorcycle Seat Upholstery Materials?

Several factors influence the pricing of motorcycle seat upholstery materials:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to bulk discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom designs and specifications can lead to increased costs. Buyers should clearly outline their requirements to ensure accurate pricing.

-

Material Quality and Certifications: Materials that meet specific industry standards or certifications may come at a premium. For instance, marine-grade materials often cost more due to their enhanced durability and weather resistance.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their products due to perceived quality and service.

-

Incoterms: Understanding the shipping terms is essential for budgeting. Different Incoterms can shift the responsibility and cost of shipping, affecting the total landed cost of the materials.

What Are Effective Buyer Tips for Negotiating Motorcycle Seat Upholstery Material Prices?

B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

Illustrative image related to motorcycle seat upholstery material

-

Negotiate Bulk Orders: Leverage volume purchasing to negotiate better rates. Suppliers are often willing to provide discounts for larger orders.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance and durability. Higher upfront costs for premium materials can yield savings over time due to reduced replacement and maintenance needs.

-

Explore Multiple Suppliers: Obtaining quotes from multiple suppliers can provide leverage in negotiations. It allows buyers to compare quality, price, and service.

-

Be Aware of Pricing Nuances for International Purchases: Currency fluctuations, import duties, and local taxes can significantly impact the final cost. Buyers should factor these into their budgeting process.

Disclaimer on Indicative Prices

Prices mentioned are indicative and subject to change based on market conditions, material availability, and specific supplier pricing strategies. Buyers are encouraged to request updated quotes and verify specifications to ensure accurate budgeting and procurement planning.

Alternatives Analysis: Comparing motorcycle seat upholstery material With Other Solutions

Exploring Alternatives to Motorcycle Seat Upholstery Material

In the realm of motorcycle seat construction, selecting the right upholstery material is crucial for ensuring rider comfort, durability, and aesthetic appeal. However, businesses may also consider alternative solutions that can either supplement or replace traditional upholstery materials. This analysis compares motorcycle seat upholstery materials with two viable alternatives: gel seat pads and custom foam inserts.

| Comparison Aspect | Motorcycle Seat Upholstery Material | Gel Seat Pads | Custom Foam Inserts |

|---|---|---|---|

| Performance | High durability, comfort varies by material choice (e.g., leather vs. vinyl) | Excellent pressure distribution, may be less durable | Exceptional comfort tailored to body shape |

| Cost | Varies widely ($20-$100+ per yard) | Moderate ($30-$100 per pad) | Higher upfront cost ($100-$300) |

| Ease of Implementation | Requires sewing and fitting skills | Easy to install, no special tools needed | Requires professional fitting or custom order |

| Maintenance | Moderate, depends on material (e.g., leather needs conditioning) | Low, easy to clean | Low, but replacement may be necessary over time |

| Best Use Case | Ideal for custom and OEM seats, aesthetic variety | Great for added comfort on existing seats | Best for high-mileage riders needing tailored support |

What Are the Advantages and Disadvantages of Gel Seat Pads?

Gel seat pads are a popular alternative for enhancing comfort without completely replacing existing upholstery. They are designed to distribute weight evenly, significantly reducing pressure points during long rides. Gel pads are generally easy to install and can be removed or adjusted as needed, making them a flexible option for riders looking to improve comfort on the go. However, they may not offer the same level of durability as traditional upholstery materials, and over time, the gel can degrade, affecting performance.

How Do Custom Foam Inserts Compare to Traditional Upholstery?

Custom foam inserts provide a tailored solution, molded specifically to the rider’s body shape, which can enhance comfort during long rides. They can be integrated into existing motorcycle seats, offering significant ergonomic advantages, especially for riders who spend extended periods on their bikes. While the initial investment is typically higher compared to standard upholstery materials, the long-term comfort and support can justify the cost for serious riders. The downside is that they often require professional fitting, which can delay the implementation process.

Conclusion: Choosing the Right Solution for Your Motorcycle Seat Needs

When selecting the appropriate motorcycle seat solution, B2B buyers should weigh the specific needs of their target market. For businesses focused on aesthetics and versatility, traditional upholstery materials may remain the best choice. However, for those targeting comfort-focused riders or those who frequently ride long distances, gel seat pads or custom foam inserts could provide significant advantages. Ultimately, understanding the nuances of each option will enable businesses to align their product offerings with the preferences of their clientele, ensuring satisfaction and loyalty in competitive markets.

Essential Technical Properties and Trade Terminology for motorcycle seat upholstery material

What Are the Key Technical Properties of Motorcycle Seat Upholstery Materials?

When sourcing motorcycle seat upholstery materials, understanding critical technical properties is essential for ensuring quality and performance. Here are some key specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality classification of the upholstery material, which impacts durability, aesthetics, and comfort. High-grade materials, such as premium vinyl or leather, offer enhanced resistance to wear and tear, UV exposure, and moisture. For international buyers, especially in regions with diverse climates, selecting the right material grade can significantly affect product longevity and customer satisfaction.

2. Tolerance

Tolerance indicates the permissible variation in material dimensions and properties during manufacturing. It is crucial for ensuring that upholstery fits perfectly on motorcycle seats, contributing to both aesthetics and functionality. Tight tolerances are particularly important when dealing with custom designs, as they ensure a seamless fit and reduce the likelihood of defects, which can lead to costly reworks.

3. Abrasion Resistance

Abrasion resistance measures the material’s ability to withstand wear caused by friction. This property is vital for motorcycle seats, which experience constant contact with riders and the elements. A higher abrasion resistance rating translates to longer-lasting upholstery, making it a key consideration for B2B buyers focused on quality and durability.

4. UV Resistance

UV resistance indicates how well the material can withstand prolonged exposure to sunlight without degrading. For buyers in sunny climates or regions with high UV exposure, this property is crucial. Upholstery that fails to resist UV light can fade, crack, or deteriorate quickly, impacting the overall quality and appearance of the motorcycle.

5. Water Resistance

Water resistance refers to the material’s ability to repel water, preventing moisture penetration that can lead to mold and mildew growth. This property is essential for motorcycle upholstery, especially for bikes used in rainy or humid environments. B2B buyers should prioritize materials with high water resistance to ensure longevity and maintain the integrity of the seat.

What Are Common Trade Terms in Motorcycle Seat Upholstery Material Sourcing?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are several essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of motorcycle seats, working with OEMs can ensure that the upholstery materials meet the original specifications and quality standards of the motorcycle manufacturer, providing assurance of compatibility and performance.

Illustrative image related to motorcycle seat upholstery material

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs and supplier relationships. When negotiating with suppliers, knowing the MOQ can help buyers align their purchasing strategy with production needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. When sourcing motorcycle seat upholstery, submitting an RFQ allows buyers to obtain detailed pricing and terms from multiple suppliers, fostering competitive pricing and informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is crucial for B2B transactions, as they clarify who bears the costs and risks associated with shipping, insurance, and delivery of upholstery materials.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is essential for inventory management and planning production schedules. Shorter lead times can enhance responsiveness to market demands, while longer lead times may necessitate more strategic inventory planning.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their product offerings and meet customer expectations in the competitive motorcycle market.

Navigating Market Dynamics and Sourcing Trends in the motorcycle seat upholstery material Sector

What Are the Key Market Trends in Motorcycle Seat Upholstery Material?

The motorcycle seat upholstery material sector is experiencing significant growth, driven by a combination of factors including rising motorcycle ownership, increased demand for customization, and a shift towards more durable and comfortable materials. Global markets, particularly in Africa, South America, the Middle East, and Europe, are seeing a surge in motorcycle use for both commuting and leisure, which necessitates high-quality upholstery materials. As manufacturers and suppliers cater to these regions, they must remain agile and responsive to local preferences and market dynamics.

Current trends indicate a strong move towards synthetic materials, such as vinyl and marine-grade fabrics, which are not only cost-effective but also offer weather resistance and ease of maintenance. Technological advancements in manufacturing processes are enhancing the durability and comfort of these materials, making them attractive options for B2B buyers. Additionally, the rise of e-commerce platforms is enabling international buyers to source materials more efficiently, providing access to a broader range of suppliers and competitive pricing. Emerging markets are also witnessing an increase in demand for custom upholstery solutions, prompting suppliers to invest in innovative designs and materials that cater to specific customer needs.

How Is Sustainability Influencing the Sourcing of Motorcycle Seat Upholstery Materials?

The environmental impact of production processes and the growing demand for sustainable practices are reshaping the motorcycle seat upholstery material landscape. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability, reflecting a broader global trend towards corporate social responsibility. This shift is particularly pronounced in Europe, where regulatory frameworks are more stringent regarding environmental standards.

Sustainable materials, such as recycled fabrics and eco-friendly vinyl, are gaining traction in the market. These options not only reduce waste but also appeal to environmentally conscious consumers, thereby enhancing brand reputation. Certifications such as OEKO-TEX and GOTS (Global Organic Textile Standard) are becoming crucial for suppliers looking to differentiate themselves in a competitive market. By sourcing upholstery materials that meet these green standards, B2B buyers can not only fulfill their corporate sustainability goals but also tap into a growing consumer base that values ethical practices.

Illustrative image related to motorcycle seat upholstery material

How Has the Motorcycle Seat Upholstery Material Market Evolved Over Time?

The evolution of motorcycle seat upholstery materials can be traced back to the early days of motorcycling, where leather was the predominant choice due to its durability and aesthetic appeal. However, as the motorcycle industry expanded and diversified, so did the materials used for seats. The introduction of synthetic materials in the late 20th century revolutionized the market, offering alternatives that were more affordable and resistant to weather conditions.

Over the past two decades, advancements in textile technology have led to the development of high-performance materials that combine comfort, durability, and style. The integration of memory foam and specialized padding has further enhanced the riding experience, catering to the needs of long-distance riders. Today, the market is characterized by a blend of traditional and modern materials, with a clear trend towards customization and sustainability, reflecting the evolving preferences of consumers and the demands of the global marketplace.

In conclusion, the motorcycle seat upholstery material sector is poised for continued growth, driven by market dynamics that favor innovation, sustainability, and customization. B2B buyers must stay informed about emerging trends and prioritize partnerships with suppliers that align with their sustainability goals while offering high-quality, durable materials.

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat upholstery material

-

How do I choose the right upholstery material for motorcycle seats?

Selecting the right upholstery material involves considering factors such as durability, comfort, and maintenance. Leather offers a premium feel and breathability but requires regular upkeep. Vinyl is more affordable, weather-resistant, and low-maintenance, making it ideal for various climates. For extreme weather conditions, marine-grade materials provide superior durability and mildew resistance. Ultimately, assess your target market’s preferences and riding conditions to make an informed choice. -

What is the best upholstery material for long-distance motorcycle rides?

For long-distance comfort, memory foam combined with high-quality vinyl or leather is recommended. Memory foam molds to the rider’s body, reducing pressure points and enhancing comfort over extended periods. Leather provides a luxurious feel and breathability, while durable vinyl is more affordable and easier to maintain. Evaluate the specific needs of your customers, including climate and riding habits, to select the best option. -

What are the minimum order quantities (MOQ) for motorcycle seat upholstery materials?

MOQs vary by supplier and the type of material. Typically, MOQs for upholstery materials can range from 50 to 500 yards, depending on the manufacturer’s production capabilities and the material’s popularity. It’s essential to communicate your needs clearly with potential suppliers to determine if they can accommodate your order size. Negotiating MOQs can also be possible, especially for long-term partnerships. -

How can I vet suppliers of motorcycle seat upholstery materials?

To effectively vet suppliers, start by researching their reputation in the industry through reviews and testimonials. Request samples to evaluate the quality of their materials firsthand. Additionally, inquire about their production processes, lead times, and compliance with international standards. Establishing a relationship with suppliers who have experience in international trade can also help mitigate risks associated with sourcing. -

What payment terms should I expect when sourcing upholstery materials internationally?

Payment terms can vary widely based on supplier policies and your negotiation. Common terms include advance payment, a 30% deposit with the balance upon shipment, or net 30-60 days after delivery. It’s advisable to use secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing contracts to avoid misunderstandings. -

What quality assurance measures should I consider when sourcing upholstery materials?

Quality assurance is crucial in ensuring that the upholstery materials meet your specifications. Request certifications from suppliers that demonstrate compliance with industry standards, such as ISO or ASTM. Implement a thorough inspection process upon receipt of materials, including checking for defects in texture, color, and durability. Establishing a quality control agreement with your supplier can also help maintain consistent quality. -

How do logistics and shipping impact sourcing upholstery materials?

Logistics and shipping are vital components of the sourcing process. Consider the supplier’s location, shipping methods, and lead times when planning your orders. International shipping can introduce delays and additional costs, such as tariffs and customs duties. Collaborating with experienced freight forwarders can streamline the process, helping you navigate regulations and optimize shipping routes for timely delivery. -

Can I customize motorcycle seat upholstery materials to meet specific design requirements?

Yes, many suppliers offer customization options for upholstery materials, including color, texture, and branding. Discuss your specific design requirements with potential suppliers to determine their capabilities. Customization may require higher MOQs and longer lead times, so it’s essential to plan ahead. Additionally, ensure that the supplier provides samples for approval before full production to ensure the final product meets your expectations.

Top 5 Motorcycle Seat Upholstery Material Manufacturers & Suppliers List

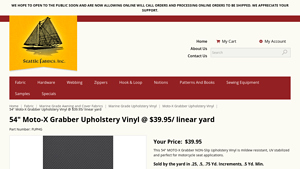

1. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: Product Name: 54″ Moto-X Grabber Upholstery Vinyl

Price: $39.95 per linear yard

Part Number: FUPHG

Width: 54 inches

Material Type: NON-Slip Upholstery Vinyl

Features: Mildew resistant, UV stabilized

Applications: Ideal for motorcycle seat upholstery

Availability: Sold by the yard in .25, .5, .75 yard increments, with a .5 yard minimum

Color: Black

Weight Per Linear Yard: 30.0 Oz

Abrasion Resistanc…

2. All Sport – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

Introduction: Product Name: Motorcycle Vinyl

Brand: All Sport

Description: Best upholstery vinyl for stretchable, pliable applications. Suitable for gaming rails, marine applications, ATVs, snow machines, and motorcycles.

Features: -60° cold crack, 360° stretch, flame retardant.

Color Options: Black, High-Tac Black, Chalk, Nu Bright Yellow, Bright Red, Silver Met, Royal Blue, Electric Blue, Marine Green, Bright…

3. Advrider – Premium Outdoor Fabrics

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 1. **Fabric Options:** Sunbrella outdoor fabric, high-grade leather-look grain black vinyl, 4-way stretch vinyl, hospital/industrial grade vinyl, motorcycle seat vinyl.

2. **Key Features:**

– Sunbrella: Fade and stain resistant, waterproof, wear resistant, available in various colors and textures.

– Vinyl: Durable, holds up well over time, can last for decades if done correctly.

-…

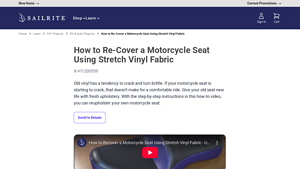

4. Sailrite – Morbern™ Allsport Stretch Vinyl & Accessories

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

5. VTX Mods – Modified Seat Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: VTX Mods, modified seat, shaved foam, narrowed seat, wrapped in material

Strategic Sourcing Conclusion and Outlook for motorcycle seat upholstery material

In conclusion, strategic sourcing of motorcycle seat upholstery materials is crucial for optimizing cost, quality, and performance in a competitive market. By selecting the right materials—whether premium leather, durable vinyl, or marine-grade options—international B2B buyers can enhance their product offerings and meet diverse consumer needs. Understanding the specific advantages and drawbacks of each material type is vital for making informed decisions that can lead to greater customer satisfaction and brand loyalty.

Illustrative image related to motorcycle seat upholstery material

As the motorcycle industry continues to evolve, buyers should remain vigilant about emerging trends and innovations in upholstery materials. This proactive approach will enable businesses to capitalize on new opportunities and maintain a competitive edge in their respective markets.

For stakeholders in Africa, South America, the Middle East, and Europe, now is the time to evaluate your sourcing strategies and consider partnerships with reliable suppliers who prioritize quality and sustainability. Embrace the future of motorcycle seat upholstery by investing in materials that not only enhance comfort and aesthetics but also align with your brand’s values. Engage with suppliers today to secure the best options for your business and drive your success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to motorcycle seat upholstery material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.