Introduction: Navigating the Global Market for leather for footwear

In an increasingly competitive global marketplace, sourcing high-quality leather for footwear presents a significant challenge for B2B buyers. With a diverse range of options from cow, goat, and pig leather to specialized materials like nubuck and suede, understanding which type best meets your needs is crucial. This comprehensive guide delves into the various types of leather available, their applications in different footwear segments, and essential considerations for supplier vetting and cost analysis.

By providing actionable insights into the leather sourcing process, this guide empowers international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Brazil—to make informed purchasing decisions. It addresses critical factors such as leather quality, durability, and processing methods, ensuring that your selections align with both product specifications and market demands.

Navigating the complexities of leather procurement becomes less daunting with a clear understanding of the materials at your disposal and a strategic approach to supplier partnerships. Whether you are focusing on fashion-forward designs or robust utility footwear, this guide serves as an essential resource for optimizing your supply chain and enhancing product offerings.

Table Of Contents

- Top 6 Leather For Footwear Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather for footwear

- Understanding leather for footwear Types and Variations

- Key Industrial Applications of leather for footwear

- 3 Common User Pain Points for ‘leather for footwear’ & Their Solutions

- Strategic Material Selection Guide for leather for footwear

- In-depth Look: Manufacturing Processes and Quality Assurance for leather for footwear

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for footwear’

- Comprehensive Cost and Pricing Analysis for leather for footwear Sourcing

- Alternatives Analysis: Comparing leather for footwear With Other Solutions

- Essential Technical Properties and Trade Terminology for leather for footwear

- Navigating Market Dynamics and Sourcing Trends in the leather for footwear Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather for footwear

- Strategic Sourcing Conclusion and Outlook for leather for footwear

- Important Disclaimer & Terms of Use

Understanding leather for footwear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains natural grain; highest quality; durable and ages well | Premium footwear, luxury brands | Pros: Aesthetic appeal, longevity. Cons: Higher cost, less water resistance. |

| Nubuck | Soft, velvety surface; requires maintenance for durability | Casual and fashion footwear | Pros: Soft touch, attractive appearance. Cons: Prone to staining, requires care. |

| Suede | Soft texture; available in various colors; less durable | Casual shoes, skate shoes | Pros: Versatile color options, comfortable. Cons: Sensitive to moisture, less durable. |

| Action Leather | Synthetic surface over split leather; durable and cost-effective | Sports shoes, casual footwear | Pros: Affordable, easy to maintain. Cons: Less premium feel, may not age well. |

| Corrected Grain Leather | Smooth surface; hides imperfections; often embossed | Work boots, service footwear | Pros: Resistant to wear, uniform appearance. Cons: Less breathable, can appear artificial. |

What Are the Key Characteristics of Full Grain Leather for Footwear?

Full grain leather is renowned for its natural grain and durability, making it the preferred choice for premium footwear and luxury brands. It retains the hide’s original texture, which enhances its aesthetic appeal and allows for unique aging characteristics. Buyers should consider its higher price point, but the investment pays off in longevity and quality. Full grain leather is less water-resistant compared to other types, so it may require additional treatments for outdoor applications.

Illustrative image related to leather for footwear

Why Choose Nubuck Leather for Casual Footwear?

Nubuck leather is celebrated for its soft, velvety texture, providing a luxurious feel that appeals to fashion-conscious consumers. It is often used in casual and fashion footwear, where comfort and aesthetics are paramount. However, it requires careful maintenance to protect against stains and moisture. B2B buyers should evaluate their target market’s willingness to invest in quality care products, as this can impact the long-term satisfaction of end consumers.

What Makes Suede a Popular Choice for Casual and Skate Shoes?

Suede is a versatile material available in a wide range of colors, making it popular for casual and skate shoes. Its soft texture offers comfort and a unique style, but it is less durable than full grain leather and more susceptible to moisture damage. B2B buyers should consider the demographics of their target market; younger consumers may favor suede for its trendy appeal, while those in rugged environments may require more durable options.

How Does Action Leather Provide Cost-Effective Solutions for Sports Shoes?

Action leather is a synthetic material that combines the durability of split leather with a protective coating, making it a cost-effective choice for sports and casual footwear. Its affordability and ease of maintenance make it attractive for high-volume production. However, it may lack the premium feel and aging characteristics of full grain leather. Buyers should assess their pricing strategies and target demographics to determine if action leather aligns with their product offerings.

Why Opt for Corrected Grain Leather in Work Boots?

Corrected grain leather features a smooth surface that masks imperfections, making it ideal for work boots and service footwear. It is often embossed for added texture and durability, providing a uniform appearance that appeals to businesses looking for reliable, professional-grade products. While it offers resistance to wear, B2B buyers should note that corrected grain leather may not provide the breathability of higher-quality leathers, which can affect comfort during prolonged wear.

Key Industrial Applications of leather for footwear

| Industry/Sector | Specific Application of leather for footwear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end luxury footwear | Enhances brand image and customer appeal | Focus on sourcing premium quality full-grain leather; consider ethical sourcing practices. |

| Sports and Recreation | Athletic shoes (e.g., soccer cleats) | Provides durability, flexibility, and performance | Ensure compliance with international safety standards; prioritize lightweight and breathable materials. |

| Safety and Workwear | Steel-toe boots for industrial workers | Offers protection and comfort for long working hours | Source water-resistant and blood-proof leather; check for certifications and durability ratings. |

| Military and Tactical | Combat boots for defense forces | Ensures safety and performance in harsh conditions | Look for leather that meets military specifications; prioritize waterproof and abrasion-resistant options. |

| Sustainable Fashion | Eco-friendly footwear made from recycled leather | Appeals to environmentally conscious consumers | Verify the sustainability of sourcing practices; consider certifications like Leather Working Group (LWG) approved leather. |

How is Leather Used in the Fashion Retail Sector for Footwear?

In the fashion retail sector, leather is primarily used for high-end luxury footwear, including designer shoes and boots. The use of premium quality full-grain leather enhances the aesthetic appeal and durability of the footwear, significantly boosting brand image. Buyers in this sector need to prioritize sourcing from reputable suppliers who adhere to ethical practices, ensuring that the leather is of the highest quality and free from defects. This focus on quality not only attracts discerning customers but also justifies higher price points.

What Role Does Leather Play in the Sports and Recreation Footwear Market?

In the sports and recreation industry, leather is utilized in athletic shoes, such as soccer cleats, to provide essential qualities like durability, flexibility, and performance. Buyers in this sector should look for lightweight, breathable leather that meets international safety standards, ensuring that the footwear can withstand rigorous activity while maintaining comfort. Sourcing from suppliers who specialize in sports-grade leather can help manufacturers create products that enhance athletic performance and cater to competitive markets.

How is Leather Essential for Safety and Workwear Footwear?

Leather is a critical component in the production of safety footwear, particularly steel-toe boots designed for industrial workers. These boots must provide both protection and comfort, as workers often spend long hours on their feet. Buyers should focus on sourcing water-resistant and blood-proof leather to ensure that the footwear meets safety regulations and withstands harsh working conditions. Certifications and durability ratings are essential considerations for sourcing, as they guarantee the reliability and longevity of the footwear.

Why is Leather Important in Military and Tactical Footwear?

In the military and tactical sectors, leather is used extensively in combat boots, where performance and safety are paramount. The leather must be robust enough to handle extreme conditions while providing comfort to the wearer. Buyers should seek leather that meets stringent military specifications, focusing on waterproof and abrasion-resistant options. Understanding the unique requirements of military footwear can guide sourcing decisions, ensuring that the final products are reliable and effective in the field.

How Can Sustainable Fashion Benefit from Leather Sourcing?

Sustainable fashion is increasingly incorporating eco-friendly footwear made from recycled leather. This application not only aligns with environmental concerns but also appeals to a growing consumer base that values sustainability. Buyers must verify the sustainability of their sourcing practices, ensuring that the leather is certified, such as through the Leather Working Group (LWG). This commitment to sustainability not only enhances brand reputation but also opens up new market opportunities for businesses looking to differentiate themselves in a competitive landscape.

3 Common User Pain Points for ‘leather for footwear’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Diverse Footwear Styles

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets the diverse requirements of various footwear styles. The challenge lies in identifying suppliers who can provide consistent quality, especially when dealing with different grades of leather like full grain, top grain, or corrected grain. Buyers may also face difficulties in ensuring the leather’s durability, aesthetics, and suitability for specific designs, which can lead to production delays or increased costs.

The Solution: To overcome this challenge, buyers should establish clear specifications for the types of leather required based on the intended footwear styles. Collaborating with suppliers who specialize in specific leather grades can enhance the quality assurance process. It is advisable to request samples and conduct thorough inspections for attributes such as thickness, texture, and color consistency. Additionally, developing long-term relationships with reputable tanneries can lead to better pricing, priority access to premium materials, and flexibility in meeting sudden demand changes. Buyers should also consider utilizing digital platforms that connect them with verified leather suppliers globally, ensuring a wider selection while maintaining quality control.

Illustrative image related to leather for footwear

Scenario 2: Navigating Leather Sustainability Concerns

The Problem: With increasing scrutiny on environmental impacts, B2B buyers face the challenge of sourcing leather that aligns with sustainability practices. Many buyers are uncertain about the ecological footprint of the tanning processes used and how to verify the environmental credentials of their suppliers. This concern is particularly relevant for companies looking to enhance their brand image and appeal to eco-conscious consumers, yet they often lack the necessary information to make informed decisions.

The Solution: To address sustainability concerns, buyers should prioritize sourcing leather from suppliers who adhere to recognized environmental standards, such as the Leather Working Group (LWG) certification. This certification assesses the environmental impact of leather manufacturing, including waste management and chemical usage. Buyers can request transparency in the supply chain, including details about the sourcing of animal hides and the tanning processes employed. Additionally, exploring alternative leather options, such as vegetable-tanned leather, can be beneficial as they tend to have a lower environmental impact. Engaging in dialogue with suppliers about their sustainability practices not only supports responsible sourcing but also enhances the brand’s commitment to environmental stewardship.

Scenario 3: Ensuring Compliance with International Quality Standards

The Problem: International B2B buyers frequently encounter issues related to compliance with different countries’ quality standards for leather used in footwear. Regulations may vary significantly, impacting product safety and marketability. Buyers may find it challenging to navigate these complexities, risking financial penalties or product recalls due to non-compliance, which can tarnish their brand reputation.

The Solution: To ensure compliance with international quality standards, buyers should familiarize themselves with the specific regulations governing leather products in their target markets. This includes understanding the requirements for chemical safety, durability, and labeling. Collaborating with legal experts or consultants specializing in international trade can provide valuable insights into compliance obligations. Additionally, buyers should work closely with suppliers to obtain documentation and certifications that verify compliance with relevant standards, such as REACH in Europe or the Consumer Product Safety Improvement Act (CPSIA) in the United States. Implementing a robust quality control program that includes regular testing of leather products can further mitigate risks and ensure that all footwear meets necessary safety and quality benchmarks before reaching consumers.

Strategic Material Selection Guide for leather for footwear

What Are the Key Properties of Common Leather Materials for Footwear?

When selecting leather for footwear, understanding the properties of various materials is crucial for ensuring product performance and meeting market demands. Below, we analyze four common types of leather used in footwear manufacturing: Full Grain Leather, Nubuck, Suede, and Action Leather. Each type has unique characteristics that affect its suitability for different applications.

What Are the Key Properties of Full Grain Leather?

Full Grain Leather is renowned for its durability and natural appearance. It retains the original grain of the hide, providing a robust surface that is resistant to wear and tear. This leather type has excellent breathability and moisture-wicking properties, making it suitable for various climates.

Pros: Full Grain Leather is extremely durable, ages beautifully, and develops a unique patina over time. It is ideal for high-end footwear that demands quality and longevity.

Cons: The cost is relatively high due to the quality of raw materials and the extensive processing required. Additionally, it can be less resistant to stains without proper treatment.

Impact on Application: Full Grain Leather is compatible with both casual and formal footwear. However, it may require additional care in humid environments to prevent mold growth.

Illustrative image related to leather for footwear

Considerations for International Buyers: Compliance with environmental regulations is essential, as tanning processes can vary significantly. Buyers should also consider the ASTM and DIN standards for leather quality and performance.

Why Choose Nubuck for Footwear Applications?

Nubuck is created by sanding the outer layer of full grain leather, resulting in a soft, velvety texture. It is often used in casual and fashion footwear due to its aesthetic appeal.

Pros: Nubuck is soft and comfortable, providing a luxurious feel. It also offers good breathability.

Cons: Its porous nature makes it susceptible to water and stains, requiring regular maintenance and waterproofing treatments.

Illustrative image related to leather for footwear

Impact on Application: Nubuck is well-suited for casual shoes but may not be ideal for environments where water exposure is frequent.

Considerations for International Buyers: Buyers from regions with high humidity or rainfall should be cautious, as Nubuck may not perform well in such climates. Compliance with local waterproofing standards is advisable.

What Makes Suede a Popular Choice for Footwear?

Suede, derived from the inner split of the hide, offers a softer texture compared to full grain leather. It is commonly used in fashion footwear, especially for its versatility in color and style.

Illustrative image related to leather for footwear

Pros: Suede is lightweight and provides a comfortable fit. It is available in a wide range of colors, enhancing design options.

Cons: Like Nubuck, Suede is prone to staining and water damage, requiring careful maintenance.

Impact on Application: Suede is ideal for casual and fashion-oriented footwear but may not withstand rigorous use or harsh weather conditions.

Considerations for International Buyers: Buyers should check for adherence to international standards for durability and stain resistance, particularly in markets with varying climate conditions.

What Are the Benefits of Using Action Leather?

Action Leather is a synthetic leather made from split leather coated with a plastic film. It mimics the appearance of full grain leather while providing enhanced durability.

Illustrative image related to leather for footwear

Pros: Action Leather is cost-effective, easy to maintain, and highly resistant to wear and tear. It is also waterproof, making it suitable for various applications.

Cons: While it looks like genuine leather, it may lack the breathability and natural feel of higher-quality leathers.

Impact on Application: Action Leather is often used in sports and casual footwear, where durability and cost are primary concerns.

Illustrative image related to leather for footwear

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding synthetic materials. Understanding the differences in quality standards across regions is essential.

Summary Table of Leather Materials for Footwear

| Material | Typical Use Case for leather for footwear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end formal and casual footwear | Extremely durable, develops unique patina | High cost, requires care against stains | Alta |

| Nubuck | Casual and fashion footwear | Soft, luxurious feel, good breathability | Susceptible to water and stains | Medium |

| Suede | Fashion-oriented and casual footwear | Lightweight, versatile color options | Prone to staining and water damage | Medium |

| Action Leather | Sports and casual footwear | Cost-effective, waterproof, highly durable | Lacks breathability compared to genuine leather | Low |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing leather for footwear, ensuring compliance with local standards and meeting market demands effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for leather for footwear

What Are the Main Stages of Leather Manufacturing for Footwear?

The manufacturing of leather for footwear is a complex process that involves multiple stages, each critical to the final product’s quality and performance. Understanding these stages can help B2B buyers make informed decisions when sourcing leather materials.

1. Material Preparation: How Are Raw Hides Processed?

The journey of leather begins with the selection of raw hides, predominantly from cows, due to their availability and durability. The first step involves cleaning the hides, which includes removing hair and any residual flesh or fat. This is typically achieved through a process known as liming, where the hides are treated with a lime solution to soften and prepare them for tanning.

Once cleaned, the hides undergo tanning, a pivotal process that alters the protein structure, making the leather resistant to decomposition. Tanning methods can be broadly categorized into vegetable and chrome tanning. Vegetable tanning uses natural tannins found in plants, resulting in a more environmentally friendly product, while chrome tanning is faster and produces softer leather, often preferred for footwear due to its flexibility.

2. Forming: What Techniques Are Used to Shape Leather?

After tanning, the leather is dried and conditioned. This is where the forming stage begins, which can involve several techniques depending on the desired end product.

- Cutting: Leather is cut into specific shapes using dies or lasers. This precision is crucial for ensuring that the pieces fit together correctly during assembly.

- Embossing and Texturing: To enhance aesthetics, manufacturers may emboss patterns or textures onto the leather. This can create a unique look and feel, appealing to different market segments.

- Dyeing: Color is added at this stage, with various methods available, such as aniline dyeing for a rich, transparent finish or pigmented dyeing for a more uniform look.

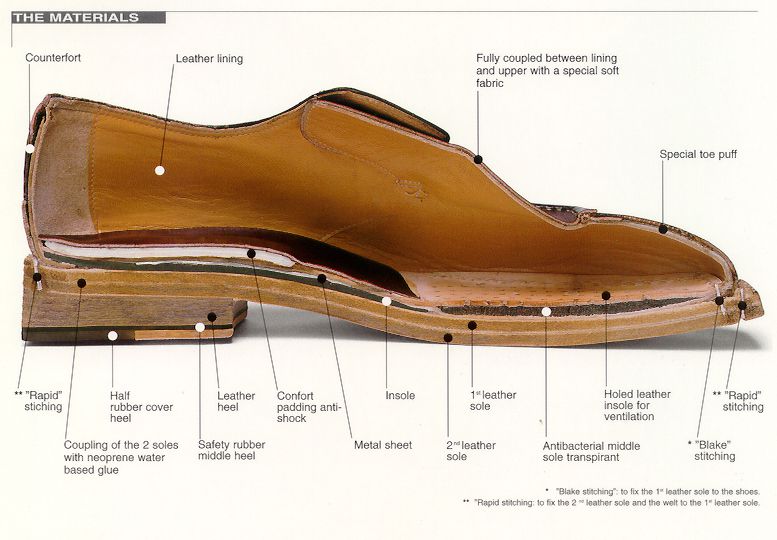

3. Assembly: How Are Leather Parts Joined Together?

The assembly process involves stitching, gluing, or bonding the cut leather pieces together. This stage requires skilled artisans who ensure that seams are strong and aesthetically pleasing. The assembly techniques can vary based on the shoe design:

- Goodyear Welting: A traditional method that provides durability and allows for resoling.

- Cementing: A more modern approach that involves gluing the upper and sole together, often used for mass-produced footwear.

Proper assembly is crucial, as it impacts the shoe’s comfort, longevity, and overall quality.

4. Finishing: What Steps Are Taken to Ensure Quality?

The finishing stage involves several processes aimed at enhancing the leather’s appearance and durability. This includes polishing, applying protective coatings, and conditioning the leather. Quality finishes not only improve aesthetics but also provide resistance to water and stains, which is essential for footwear.

What Are the Key Quality Assurance Standards for Leather Footwear?

Quality assurance (QA) is vital in the leather manufacturing process, ensuring that products meet specific standards and customer expectations. For international B2B buyers, understanding these standards can facilitate better sourcing decisions.

Relevant International Standards: What Should Buyers Know?

ISO 9001 is a widely recognized standard for quality management systems applicable across various industries, including leather manufacturing. Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality, customer satisfaction, and continuous improvement.

In addition, industry-specific certifications such as CE marking for safety and compliance with the API (American Petroleum Institute) standards for chemical safety can be crucial. These certifications assure buyers that the leather meets safety and environmental requirements, particularly important in regions with stringent regulations.

What Are the QC Checkpoints During Leather Manufacturing?

Quality control (QC) is integral to the leather manufacturing process, involving several checkpoints to ensure that each stage meets established standards.

Illustrative image related to leather for footwear

1. Incoming Quality Control (IQC): How Is Raw Material Quality Assessed?

IQC involves inspecting raw hides upon arrival at the facility. This includes assessing the quality of the hides for defects, thickness, and overall suitability for the intended use. Any subpar materials should be rejected at this stage to prevent issues down the line.

2. In-Process Quality Control (IPQC): How Are Processes Monitored?

During the manufacturing process, IPQC is employed to monitor critical stages, such as tanning, cutting, and assembly. This can involve sampling and testing materials at various points to ensure they meet specifications. Regular audits during these phases help identify and rectify potential issues early.

3. Final Quality Control (FQC): What Tests Are Conducted Before Shipping?

FQC is the last line of defense before products are shipped to buyers. This stage typically includes comprehensive testing for durability, flexibility, color fastness, and water resistance. Manufacturers may also perform visual inspections to check for defects in stitching and finishing.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is crucial to ensure that the leather products meet their standards and requirements.

1. Conducting Audits: What Should Buyers Look For?

Buyers should consider conducting on-site audits of potential suppliers. This allows them to assess the manufacturing processes, QC checkpoints, and overall facility conditions. During audits, buyers should inquire about the supplier’s adherence to international standards and their history of compliance.

2. Requesting Quality Reports: How Can Documentation Assist?

Buyers can request quality control reports from suppliers, detailing their QC processes, test results, and any certifications obtained. This documentation can provide valuable insights into the supplier’s commitment to quality.

3. Engaging Third-Party Inspectors: What Are the Benefits?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspectors can evaluate the manufacturing process, conduct tests, and ensure compliance with international standards, offering peace of mind to buyers.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances when dealing with international suppliers.

1. Understanding Regional Standards: What Variations Exist?

Different regions may have varying standards and expectations for leather quality. For instance, European buyers may prioritize sustainability and environmental impact, while buyers in the Middle East may focus more on durability and resistance to extreme conditions.

2. Navigating Tariffs and Regulations: How Can Buyers Prepare?

International trade can involve complex tariffs and regulations. Buyers should familiarize themselves with the import/export requirements specific to their countries to avoid unexpected costs or delays.

Illustrative image related to leather for footwear

By understanding the manufacturing processes and quality assurance measures in leather production, B2B buyers can make informed decisions that enhance their product offerings and ultimately satisfy their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for footwear’

Introducción

This sourcing guide provides a structured approach for B2B buyers seeking to procure leather specifically for footwear production. By following these steps, you can ensure that you select high-quality materials from reputable suppliers, ultimately enhancing the quality and durability of your footwear products.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the leather. Consider factors such as the type of leather (e.g., cow, goat, pig), thickness, grain type (full grain, top grain, suede), and any specific finishes required. Having well-defined specifications will help you communicate your needs effectively and streamline the sourcing process.

Illustrative image related to leather for footwear

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of leather for footwear. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay attention to their production capabilities, material offerings, and geographic location, as these factors can influence shipping costs and lead times.

Step 3: Evaluate Supplier Certifications

Ensure that your potential suppliers have the necessary certifications, such as ISO standards or environmental compliance (e.g., Leather Working Group certification). This is crucial for verifying their commitment to quality and sustainable practices. Ask for documentation that confirms their compliance and inspect their production processes if possible.

Step 4: Request Samples for Quality Assessment

Always request samples before making bulk purchases. Inspect the samples for quality, including texture, color consistency, and any defects. This step allows you to assess whether the leather meets your specifications and helps prevent costly mistakes in larger orders.

Illustrative image related to leather for footwear

Step 5: Understand Pricing Structures

Engage in discussions regarding pricing with potential suppliers. Understand the pricing structures, including any additional costs for customization, shipping, or bulk orders. Comparing prices across different suppliers will help you identify the best value for your investment, but remember that the cheapest option isn’t always the best in terms of quality.

Step 6: Check References and Reviews

Request references from other businesses that have sourced leather from the suppliers you are considering. Look for reviews or testimonials from clients in similar industries or regions. This feedback can provide insights into the supplier’s reliability, product quality, and customer service.

Step 7: Negotiate Terms and Conditions

Once you have identified a preferred supplier, negotiate the terms and conditions of your purchase. Pay attention to payment terms, delivery timelines, and return policies. Clear agreements will protect your interests and ensure a smooth transaction, reducing the risk of misunderstandings later on.

By following this checklist, B2B buyers can make informed decisions when sourcing leather for footwear, ensuring quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for leather for footwear Sourcing

What Are the Key Cost Components in Leather for Footwear Sourcing?

When sourcing leather for footwear, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of leather significantly affects pricing. Cow and calf leather are the most common, with costs varying based on quality, treatment, and finish. For instance, full-grain leather commands a premium price due to its durability and aesthetic appeal, while split leather and suede are generally more affordable.

-

Labor: Labor costs encompass the skilled work involved in tanning, finishing, and crafting the leather. Skilled artisans and labor-intensive processes can increase costs, particularly for high-quality leather products.

-

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, and utilities. Efficient production processes can mitigate overhead costs, but buyers should account for these when evaluating supplier pricing.

-

Tooling: Custom tooling for specific designs can add significant costs. This may include molds or dies for shoe components, which should be factored into the overall budget, especially for unique designs.

-

Quality Control (QC): Maintaining high-quality standards involves additional costs related to inspections and testing. Rigorous QC processes ensure that the leather meets industry standards, impacting the final price.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and customs duties can significantly impact the total cost of procurement.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on competition, demand, and the buyer’s negotiation leverage.

How Do Price Influencers Affect Leather for Footwear Sourcing?

Several factors can influence the pricing of leather for footwear, including:

-

Volume/MOQ: Higher order volumes often lead to discounts. Suppliers are more willing to negotiate when buyers commit to larger quantities, thus reducing per-unit costs.

-

Specifications and Customization: Custom specifications (e.g., specific colors or treatments) can lead to higher costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Premium materials and certified leathers (e.g., eco-friendly or ethically sourced) will typically incur higher prices. Buyers seeking specific certifications should be prepared to pay a premium.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is essential for international transactions. Different terms can dictate who bears the cost of freight, insurance, and duties, impacting the total landed cost.

What Are Some Essential Tips for Negotiating Leather Prices?

-

Leverage Total Cost of Ownership (TCO): Consider not just the initial purchase price but the TCO, which includes maintenance, durability, and potential resale value. A higher upfront cost for premium leather may offer better long-term value.

-

Negotiate on Volume: When possible, consolidate orders to negotiate better pricing. Suppliers are often more flexible with pricing for larger orders, which can lead to significant savings.

-

Research and Compare Suppliers: Conduct thorough market research to compare prices and terms from various suppliers. Understanding the market landscape will empower buyers during negotiations.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, labor costs, and material availability. Buyers should account for these factors when sourcing leather from different countries, especially in regions like Africa, South America, the Middle East, and Europe.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, preferential treatment, and improved service over time.

Disclaimer on Indicative Prices

Prices for leather can fluctuate based on market conditions, quality, and supplier negotiations. It is advisable for buyers to conduct their own market research and request quotes tailored to their specific needs to obtain accurate pricing.

Alternatives Analysis: Comparing leather for footwear With Other Solutions

Introduction to Alternative Footwear Materials

As global markets evolve, B2B buyers in the footwear industry are increasingly exploring alternatives to traditional leather. While leather offers unique benefits such as durability and aesthetic appeal, alternative materials can provide viable solutions that address cost, sustainability, and performance. Understanding these options enables manufacturers to make informed decisions that align with market demands and consumer preferences.

| Comparison Aspect | Leather For Footwear | Synthetic Leather (PU) | Natural Textiles (Cotton) |

|---|---|---|---|

| Performance | Highly durable, breathable | Durable, less breathable | Moderate durability, breathable |

| Cost | Higher initial investment | Lower initial cost | Lowest initial cost |

| Ease of Implementation | Requires specialized tanning processes | Easy to produce, versatile | Simple to manufacture |

| Maintenance | Requires regular conditioning | Easy to clean, less care needed | Requires washing, may fade |

| Best Use Case | High-end fashion, work boots | Everyday footwear, fashion | Casual wear, eco-friendly lines |

Detailed Breakdown of Alternatives

Synthetic Leather (PU)

Synthetic leather, often made from polyurethane (PU), serves as a popular alternative to traditional leather. It mimics the appearance and feel of leather while being more affordable and easier to maintain. Synthetic leather is particularly advantageous for mass production due to its versatility in design and color. However, it may not offer the same level of breathability as genuine leather, which can affect comfort during extended wear. Additionally, synthetic materials are often less durable over time compared to high-quality leather, leading to potential long-term costs in replacement.

Natural Textiles (Cotton)

Natural textiles, particularly cotton, present another alternative to leather footwear. Cotton is lightweight and breathable, making it ideal for casual and summer footwear. Its affordability and ease of production make it an attractive option for budget-conscious manufacturers. However, cotton lacks the durability and water resistance of leather, which may limit its use in certain applications, such as work boots or high-performance sports shoes. Furthermore, cotton requires regular washing and may fade with time, potentially affecting the overall aesthetic of the product.

Conclusion: How to Choose the Right Footwear Material

When selecting the right material for footwear, B2B buyers must consider their specific needs, target market, and production capabilities. Leather remains a premier choice for high-end and durable footwear, while synthetic options offer cost-effective solutions for mass-market appeal. Natural textiles, on the other hand, cater to eco-conscious consumers seeking comfort and affordability. Ultimately, the decision should align with brand positioning, customer expectations, and the overall sustainability goals of the business. By evaluating these factors, buyers can make informed choices that enhance their product offerings and meet market demands.

Essential Technical Properties and Trade Terminology for leather for footwear

What Are the Key Technical Properties of Leather for Footwear?

When sourcing leather for footwear, understanding critical technical specifications is essential for ensuring product quality and performance. Here are some key properties to consider:

-

Material Grade: Leather is categorized into various grades based on quality, such as full grain, top grain, and corrected grain. Full grain leather, which retains the animal hide’s natural texture, is the most durable and aesthetically pleasing. Understanding material grade helps buyers determine the suitability of leather for specific applications, balancing cost with desired performance characteristics.

-

Thickness: The thickness of leather typically ranges from 1.0 mm to 2.5 mm, depending on the type and intended use. For instance, casual shoes may require thinner leather for flexibility, while work boots need thicker leather for durability. Buyers should consider the end-use of the footwear to select an appropriate thickness that meets both comfort and durability requirements.

-

Tanning Method: Leather can be tanned using either vegetable or mineral methods, which significantly impacts its properties. Vegetable-tanned leather is known for its eco-friendliness and ability to age beautifully, while mineral-tanned leather offers greater water resistance and quicker production times. Understanding tanning methods can guide buyers in selecting leather that aligns with brand values and product lifecycle expectations.

-

Water Resistance: This property is crucial for footwear intended for outdoor or wet conditions. Leather can be treated with waterproofing agents or chosen based on its natural resistance. Buyers should assess the environmental conditions where the footwear will be used to ensure adequate protection against moisture.

-

Flexibility and Softness: The pliability of leather affects the comfort of the footwear. Leather can be softened through various treatments, impacting its feel and wearability. Buyers should evaluate the end-user’s comfort preferences to choose leather with the right balance of softness and structural support.

What Are Common Trade Terms in the Leather Footwear Industry?

In addition to technical specifications, understanding industry jargon is essential for effective communication and negotiation with suppliers. Here are some common terms used in the leather footwear sector:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products based on the specifications provided by another company, often a brand. In the footwear industry, an OEM partner may produce shoes according to a brand’s design and material requirements. For buyers, working with OEMs can lead to cost efficiencies and streamlined production processes.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of product a supplier is willing to sell. Understanding MOQ is vital for buyers to assess inventory needs and manage costs effectively. It allows them to plan purchases and negotiate terms that align with production schedules.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price quotes from suppliers for specific products or services. In the leather footwear industry, submitting an RFQ can help buyers compare prices, terms, and capabilities across multiple suppliers, facilitating informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is crucial for buyers to clarify shipping responsibilities, costs, and risk management when sourcing leather from different regions.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. In the leather footwear industry, lead times can vary significantly based on production schedules and material availability. Buyers should factor in lead times when planning launches and inventory replenishment to ensure product availability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance product quality, optimize supply chain efficiency, and align with market demands.

Navigating Market Dynamics and Sourcing Trends in the leather for footwear Sector

What Are the Current Market Dynamics and Key Trends in the Leather for Footwear Sector?

The leather for footwear sector is witnessing significant transformation driven by globalization, technological advancements, and evolving consumer preferences. A key trend is the increasing demand for high-quality, durable leather sourced from reputable suppliers. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing materials that not only meet aesthetic and functional needs but also align with their brand values. The rise of e-commerce platforms has facilitated easier access to diverse suppliers, enabling buyers to compare quality, pricing, and delivery options with unprecedented transparency.

Emerging technologies, such as digital supply chain management and blockchain, are playing a crucial role in enhancing traceability and efficiency in sourcing leather. Buyers are increasingly leveraging data analytics to identify trends, forecast demand, and optimize inventory, which is especially important in a competitive market where lead times and responsiveness can determine success. Additionally, the trend towards customization and personalization in footwear design is prompting suppliers to offer a wider range of leather types, colors, and finishes, allowing brands to differentiate their products in a crowded marketplace.

How Is Sustainability and Ethical Sourcing Shaping the Leather for Footwear Industry?

Sustainability and ethical sourcing have become paramount in the leather for footwear sector, driven by increasing consumer awareness and regulatory pressures. The environmental impact of leather production, particularly in terms of water usage and chemical waste, has led to a demand for more sustainable practices. International buyers are now prioritizing suppliers who implement eco-friendly tanning methods, such as vegetable tanning, which minimizes harmful chemical use and reduces pollution.

The importance of ethical supply chains cannot be overstated, as consumers are increasingly scrutinizing the origins of their products. Brands that can demonstrate transparency in their sourcing processes often enjoy a competitive advantage. Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers aiming to attract conscientious buyers. These certifications not only validate sustainable practices but also enhance brand reputation and consumer trust.

Moreover, the rise of alternative leathers, such as those made from recycled materials or plant-based sources, is reshaping the market. These innovations offer brands the opportunity to market themselves as environmentally friendly while appealing to a growing demographic that values sustainability. By embracing these trends, international B2B buyers can position themselves favorably in a market that increasingly values ethical considerations alongside quality.

What Is the Historical Context of the Leather for Footwear Sector and Its Relevance Today?

The leather for footwear sector has a rich history that dates back thousands of years, with its evolution closely tied to advancements in tanning and manufacturing techniques. Initially, leather was sourced primarily from local animals and processed using rudimentary methods. Over time, the introduction of industrial tanning processes in the 19th century revolutionized leather production, making it more accessible and affordable.

Today, this historical foundation is essential for understanding current market dynamics. The global leather industry has expanded beyond traditional sourcing regions, with countries like Brazil and Vietnam becoming key players due to their abundant livestock and established tanning industries. This globalization has led to a more competitive landscape, where buyers must navigate not only quality and cost but also ethical sourcing and sustainability issues. Understanding this evolution allows B2B buyers to appreciate the complexities of the leather supply chain and make informed decisions that align with both market demands and consumer expectations.

Illustrative image related to leather for footwear

Frequently Asked Questions (FAQs) for B2B Buyers of leather for footwear

-

How do I choose the right type of leather for my footwear production?

Choosing the right type of leather involves understanding your product’s requirements, such as durability, aesthetics, and cost. Common options include full grain, top grain, and suede. Full grain offers durability and a premium look but comes at a higher price, while suede provides softness and a unique texture but may require more maintenance. Assess your target market, intended use, and price point to make an informed decision. Consult with suppliers to explore available options and request samples for evaluation. -

What are the key factors to consider when vetting leather suppliers?

When vetting leather suppliers, consider their reputation, certifications, and compliance with international trade standards. Request references from previous clients and assess their production capabilities, quality control processes, and lead times. Evaluate their ability to customize products according to your specifications, and inquire about their sourcing practices to ensure ethical and sustainable leather production. Lastly, consider visiting their facilities if possible, or conducting a virtual inspection to gauge their operational standards. -

What are the minimum order quantities (MOQs) for leather materials?

Minimum order quantities can vary significantly among suppliers, influenced by the type of leather and the complexity of customization. Typically, MOQs range from 100 to 1,000 square feet, depending on the supplier’s production scale and capabilities. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms that align with your production plans. Smaller businesses may explore options with suppliers who offer flexible MOQs or consider joining a consortium to meet minimum order requirements collectively. -

How can I ensure quality assurance (QA) in my leather procurement process?

To ensure quality assurance in your leather procurement, establish clear specifications regarding thickness, texture, and finish before placing orders. Implement a quality control checklist that includes visual inspections and physical tests for durability and flexibility. Collaborate closely with your supplier throughout the production process and consider third-party inspections before shipment to verify compliance with your standards. Regular communication and feedback loops can also help maintain quality throughout your partnership. -

What payment terms should I negotiate with leather suppliers?

Payment terms can vary, but standard practices include a deposit of 30-50% upfront with the balance due upon delivery or prior to shipping. Depending on your relationship with the supplier, you may negotiate more favorable terms, such as extended payment periods or payment upon receipt. Ensure that payment methods are secure and that you understand any potential fees associated with international transactions. It’s advisable to document all terms clearly in a contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when sourcing leather internationally?

When sourcing leather internationally, consider shipping costs, delivery timelines, and customs regulations in your country. Work with suppliers who have experience in international shipping to facilitate smooth logistics. Be aware of import duties and taxes that may apply to leather products and factor these into your overall budget. Establish a reliable logistics partner to manage transportation and customs clearance, ensuring timely delivery of materials to avoid production delays. -

How can I customize leather products to meet my specific design needs?

Customization options for leather products may include altering color, texture, thickness, and finishes. Most suppliers can accommodate specific requests, so communicate your design requirements early in the negotiation process. Request samples of modified leather to assess quality and appearance before committing to larger orders. Additionally, consider collaborating with the supplier’s design team, if available, to leverage their expertise in achieving your desired look and functionality. -

What are the environmental considerations in leather sourcing?

Environmental considerations in leather sourcing include the ecological impact of tanning processes and animal husbandry. Opt for suppliers who use eco-friendly tanning methods, such as vegetable tanning, which minimizes harmful chemical usage. Additionally, inquire about the supplier’s sustainability practices, including animal welfare standards and waste management. As consumer demand for sustainable products grows, prioritizing environmentally responsible sourcing can enhance your brand’s reputation and appeal to eco-conscious markets.

Top 6 Leather For Footwear Manufacturers & Suppliers List

1. Hide & Leather House – Premium Footwear Hides

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: Leather for shoes, boots, and sandals from Hide & Leather House includes various types of hides such as goat, calf, sheep, bull, water buffalo, deer, cow, pig, moose, and bison. The footwear category features 102 different options. Hides are available in various finishes including oiled, aniline, foil, patent, pearlized, semi-aniline, waxy, nubuck, suede, pigmented, and hair on hide. Sizes range f…

2. Shoemaker’s Academy – The Designer’s Guide to Shoe Leather

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: The Designer’s Guide to Shoe Leather covers various types of shoe leather, focusing primarily on cow leather, which is the most common in footwear. Key details include:

1. **Types of Leather**: Cow, calf, pig, goat, sheep, kangaroo, alligator, ostrich.

2. **Processing**: Leather starts as animal hide, undergoes hair removal, flesh and fat removal, and tanning to preserve fibers. Tanning can be do…

3. Noble Shoe – Types of Leather

Domain: thenobleshoe.com

Registered: 2019 (6 years)

Introduction: Types of Shoe Leather: 1. Full Grain Leather – Top layer with all grain and pores intact; highest quality. 2. Top Grain Leather – Sanded grain, fewer imperfections. 3. Corrected Grain/Genuine Leather – Lower quality, may appear nice initially. 4. Calfskin – Smooth, durable, ages well; suitable for all shoe types. 5. Grain Leather – Textured, often embossed; hides creasing well. 6. Goat/Sheepskin -…

4. Buy Leather Online – Quality Leather for Footwear

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Leather for shoe making and footwear, suitable for various types of shoes including décolleté, boots, sneakers, and classical shoes. Types of leather include: 1. Full grain leather – retains original grain, can be opaque, shiny, printed, or embossed; 2. Corrected grain leather – resistant, uniform surface, easy maintenance; 3. Split leather – provides velour or suede effect. Subcategories include …

5. Secret Cobbler – Leather Types Guide

Domain: secretcobbler.com

Registered: 2017 (8 years)

Introduction: Choosing leather for shoes involves multiple types of leather beyond just the upper leather. Key types include: 1. Vegetable Tanned Leather: – Traditional tanning process, free from harmful chemicals. – Ages beautifully, durable, and takes dye easily. – Can be moistened, shaped, and stamped. – Drawbacks: absorbs water and is not heat resistant. 2. Chrome Tanned Leather: – Most commonly used for sh…

6. Shoegazing – Quality Leather Guide

Domain: shoegazing.com

Registered: 2019 (6 years)

Introduction: Calf leather: Soft, supple, durable; common in quality dress shoes; comes from animals under one year; smooth full-grain recognized by fine pores. Cow and ox leather: Thicker, sturdier; used for tougher boots; often split for cheaper shoes. Horse leather: Durable; used for jackets and accessories; shell cordovan is a famous type, very durable with a shiny surface. Pigskin: Soft, supple, easy to dy…

Strategic Sourcing Conclusion and Outlook for leather for footwear

As the global demand for high-quality leather for footwear continues to grow, strategic sourcing remains a critical component for B2B buyers in Africa, South America, the Middle East, and Europe. Understanding the diverse types of leather—ranging from cow and calf to specialized options like nubuck and action leather—allows businesses to tailor their offerings to meet specific market demands. By prioritizing quality and sustainability in sourcing, companies can enhance their product portfolios and improve customer satisfaction.

Moreover, leveraging regional advantages and establishing reliable supplier relationships can lead to cost-effective procurement and better supply chain resilience. Buyers should actively seek partnerships with tanneries that prioritize ethical practices and environmental stewardship, as consumer awareness around sustainability rises.

Looking ahead, the footwear industry is poised for innovation, with a growing emphasis on customization and performance materials. B2B buyers are encouraged to stay abreast of emerging trends and technologies in leather processing to maintain a competitive edge. By adopting a proactive approach to strategic sourcing, businesses can not only meet current market needs but also position themselves for future growth in a dynamic global landscape.

Illustrative image related to leather for footwear

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.