Introduction: Navigating the Global Market for brown faux leather fabric

In an increasingly competitive landscape, sourcing high-quality brown faux leather fabric can pose a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek sustainable and cost-effective alternatives to genuine leather, understanding the intricacies of faux leather becomes paramount. This guide provides a comprehensive overview of brown faux leather fabric, addressing various types, applications, and supplier vetting processes essential for informed purchasing decisions.

From upholstery in commercial and residential settings to automotive interiors and fashion accessories, brown faux leather fabric serves multiple markets, delivering both aesthetic appeal and durability. Buyers will gain insights into the different materials available, including PVC and PU leather, each with distinct qualities and applications. Additionally, the guide explores critical factors such as pricing strategies, shipping logistics, and quality assurance measures to help buyers navigate the complexities of sourcing.

With this resource, B2B buyers can confidently make choices that align with their business needs and sustainability goals. By equipping decision-makers with actionable insights and best practices, this guide empowers them to enhance their supply chain and ultimately improve their bottom line. Embrace the opportunity to leverage brown faux leather fabric in your business offerings and stay ahead in the dynamic global market.

Table Of Contents

- Top 6 Brown Faux Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for brown faux leather fabric

- Understanding brown faux leather fabric Types and Variations

- Key Industrial Applications of brown faux leather fabric

- 3 Common User Pain Points for ‘brown faux leather fabric’ & Their Solutions

- Strategic Material Selection Guide for brown faux leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for brown faux leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown faux leather fabric’

- Comprehensive Cost and Pricing Analysis for brown faux leather fabric Sourcing

- Alternatives Analysis: Comparing brown faux leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for brown faux leather fabric

- Navigating Market Dynamics and Sourcing Trends in the brown faux leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of brown faux leather fabric

- Strategic Sourcing Conclusion and Outlook for brown faux leather fabric

- Important Disclaimer & Terms of Use

Understanding brown faux leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cuero PU | Softer, more breathable, eco-friendly | Upholstery, fashion accessories | Pros: More sustainable, resembles genuine leather; Cons: Can be less durable than PVC. |

| Cuero PVC | Waterproof, stain-resistant, non-porous | Automotive, marine applications | Pros: Affordable, durable; Cons: Less breathable, environmental concerns. |

| Heavy-Duty Vinyl | Extra-heavyweight, high durability, often water-resistant | Commercial upholstery, hospitality | Pros: Long-lasting, withstands heavy use; Cons: Can be less aesthetically appealing. |

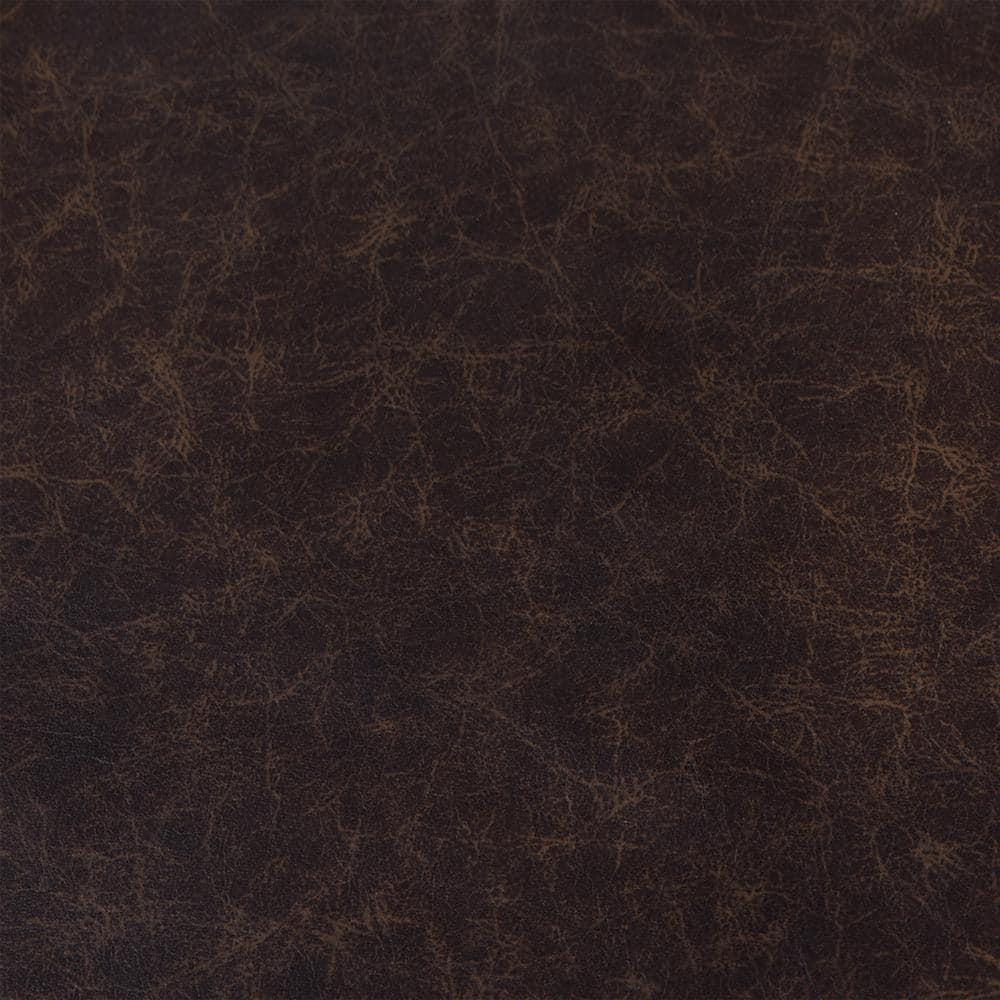

| Distressed Faux Leather | Textured appearance mimicking aged leather | Furniture, décor items | Pros: Unique look, trendy; Cons: May require more care to maintain appearance. |

| Breathable Polyurethane | Feels like leather, excellent breathability, eco-friendly | High-end upholstery, automotive | Pros: Comfortable, luxurious feel; Cons: Higher cost compared to other options. |

What Are the Key Characteristics of PU Leather?

PU leather, or polyurethane leather, is distinguished by its soft texture and breathability. This eco-friendly option is made by coating a base fabric with polyurethane, making it more similar to genuine leather in appearance and feel. B2B buyers should consider PU leather for applications in upholstery and fashion accessories, especially where sustainability is a priority. While it offers a luxurious feel, it may not be as durable as PVC leather, making it essential to assess the intended use and expected wear.

How Does PVC Leather Compare in Terms of Functionality?

PVC leather is known for its waterproof and stain-resistant properties, making it a popular choice in the automotive and marine industries. This type of faux leather is created by coating strong polyester fibers with melted vinyl, resulting in a durable yet less breathable material. B2B buyers should weigh the affordability and resilience of PVC leather against its environmental impact. While it is suitable for high-traffic areas, the lack of breathability can lead to discomfort in certain applications.

What Makes Heavy-Duty Vinyl a Preferred Option for Commercial Use?

Heavy-duty vinyl is characterized by its extra-heavyweight construction and high durability, often exceeding 250,000 double rubs. This makes it ideal for commercial upholstery and hospitality settings where furniture must withstand significant wear and tear. Buyers should consider heavy-duty vinyl for its longevity and ease of maintenance, though it may lack the aesthetic appeal of softer materials. Its water-resistant nature also adds to its practicality in various environments.

Why Choose Distressed Faux Leather for Unique Aesthetics?

Distressed faux leather provides a textured appearance that mimics aged leather, making it a stylish choice for furniture and decorative items. This type of fabric appeals to buyers looking for trendy designs that stand out. However, it may require more care to maintain its appearance over time. B2B purchasers should evaluate the market demand for unique designs when considering distressed faux leather, as it can enhance the overall aesthetic of a product line.

What Are the Advantages of Breathable Polyurethane in Upholstery?

Breathable polyurethane combines the luxurious feel of leather with excellent breathability, making it suitable for high-end upholstery and automotive applications. This eco-friendly option often comes at a higher price point but offers superior comfort and durability. B2B buyers should consider the long-term value of investing in breathable polyurethane, particularly in markets where comfort and quality are paramount. Its ability to closely mimic genuine leather makes it an attractive option for discerning consumers.

Key Industrial Applications of brown faux leather fabric

| Industry/Sector | Specific Application of brown faux leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Durable, cost-effective alternative to genuine leather | Supplier reliability, quality certifications, and local regulations |

| Automotive | Interior seating and trims | Aesthetic appeal and easy maintenance | Compliance with safety standards, color consistency, and durability testing |

| Hospitality | Restaurant and hotel furnishings | Enhances ambiance and provides easy-to-clean surfaces | Bulk purchasing options, customization capabilities, and fabric longevity |

| Fashion and Accessories | Bags, belts, and apparel | Versatile design options and cruelty-free materials | Trend alignment, material sourcing ethics, and price competitiveness |

| Marine and Outdoor | Boat upholstery and outdoor furniture | Water-resistant and UV-protected for long-lasting use | Weather resistance specifications, weight considerations, and shipping logistics |

How is Brown Faux Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, brown faux leather fabric is extensively used for upholstery on sofas, chairs, and other seating solutions. Its durability and cost-effectiveness make it an attractive alternative to genuine leather, particularly for businesses looking to offer stylish yet affordable furniture. International buyers from regions like Africa and South America should focus on suppliers that can provide consistent quality and adhere to local regulations regarding materials. Additionally, understanding the environmental impact of sourcing practices is essential for aligning with ethical consumer trends.

What Are the Benefits of Brown Faux Leather in Automotive Applications?

In the automotive industry, brown faux leather fabric is used for interior seating and trims, providing both aesthetic appeal and practicality. Its resistance to wear and ease of maintenance are crucial for automotive applications, where durability is paramount. Buyers must ensure that their suppliers comply with safety standards and offer materials that withstand rigorous testing for color consistency and durability, especially in extreme climates found in regions like the Middle East and parts of Africa.

How Does Brown Faux Leather Enhance Hospitality Furnishings?

Brown faux leather fabric is increasingly popular in the hospitality sector, where it is used for restaurant and hotel furnishings. It not only enhances the ambiance with its rich, warm tones but also offers easy-to-clean surfaces that can withstand high traffic. Businesses in this sector should consider suppliers that can provide bulk purchasing options and customization capabilities to meet specific design needs. Additionally, the longevity of the fabric is a critical factor, ensuring that the investment pays off over time.

Illustrative image related to brown faux leather fabric

Why Choose Brown Faux Leather for Fashion and Accessories?

In fashion and accessories, brown faux leather fabric is versatile, used in items such as bags, belts, and clothing. Its ability to mimic the look of genuine leather while being cruelty-free appeals to a growing demographic of environmentally conscious consumers. B2B buyers in this industry should focus on sourcing from suppliers that align with current trends and ethical standards. Competitive pricing and the ability to meet design specifications are also essential for success in this fast-paced market.

How is Brown Faux Leather Beneficial for Marine and Outdoor Applications?

Brown faux leather fabric finds significant application in marine and outdoor settings, particularly for boat upholstery and outdoor furniture. Its water-resistant properties and UV protection make it ideal for environments exposed to harsh weather conditions. Businesses looking to source this material should prioritize suppliers who can guarantee weather resistance specifications and adequate weight considerations. Additionally, understanding shipping logistics is crucial for timely delivery, especially for international buyers in remote locations.

3 Common User Pain Points for ‘brown faux leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Brown Faux Leather Fabric for Diverse Applications

The Problem: B2B buyers often struggle with sourcing high-quality brown faux leather fabric that meets their specific requirements for various applications, such as upholstery for furniture, automotive interiors, or fashion accessories. The market is flooded with options, but not all products are created equal. This leads to uncertainty about durability, texture, and overall performance, resulting in potential financial loss if the fabric does not meet the expected standards. Buyers may also face issues related to inconsistent quality and color variations, which can affect the final product’s appearance and appeal.

The Solution: To ensure the procurement of quality brown faux leather fabric, buyers should establish strong relationships with reputable suppliers who have a proven track record in the industry. Request samples before making bulk purchases to assess the texture, weight, and finish. It’s essential to look for certifications that indicate the fabric meets industry standards for durability, such as Wyzenbeek rub counts for abrasion resistance. Additionally, specifying the intended application clearly to the supplier can help them recommend the most suitable type of faux leather, whether it’s a heavy-duty vinyl for commercial use or a softer PU leather for fashion items. Regular communication with suppliers about quality control can further mitigate risks.

Scenario 2: Ensuring Color Consistency Across Different Batches

The Problem: One of the major pain points for B2B buyers of brown faux leather fabric is the challenge of color consistency. When ordering from different batches, variations in shade can occur due to manufacturing processes or dye lots. This inconsistency can be particularly problematic for businesses producing items where uniformity is crucial, such as furniture lines or fashion collections. Discrepancies in color can lead to customer dissatisfaction, increased returns, and damage to brand reputation.

The Solution: To tackle color consistency issues, buyers should establish clear specifications regarding color matching and request that suppliers adhere to a Pantone or RAL color system. This standardized approach helps to ensure that all fabric orders maintain the same hue, regardless of when they are produced. Additionally, buyers should consider using a single supplier for all orders to minimize discrepancies. If sourcing from multiple suppliers is unavoidable, it is advisable to conduct a thorough color matching process before finalizing bulk orders. Using a lightbox for accurate color assessment under controlled lighting conditions can also help in identifying and addressing any color variations early in the process.

Scenario 3: Managing Maintenance and Longevity of Brown Faux Leather Upholstery

The Problem: Many businesses underestimate the maintenance requirements of brown faux leather upholstery, leading to premature wear and tear. Issues such as fading, cracking, or staining can arise if proper care guidelines are not followed, which ultimately affects the longevity of the product. B2B buyers may feel overwhelmed by the lack of clear maintenance instructions, leading to costly replacements and unsatisfied customers.

The Solution: To manage the maintenance of brown faux leather upholstery effectively, buyers should implement a comprehensive care plan. This includes educating staff on the proper cleaning methods, such as using a damp cloth with mild soap for routine cleaning and avoiding harsh chemicals that can damage the finish. Providing customers with care instructions at the point of sale can also enhance their experience and encourage them to take better care of their purchases. Additionally, selecting a faux leather fabric that has been treated for stain resistance or easy cleanability can significantly reduce maintenance efforts and extend the product’s lifespan. Regular checks for any signs of wear can help address issues proactively, preventing larger problems down the line.

Strategic Material Selection Guide for brown faux leather fabric

What Are the Key Materials for Brown Faux Leather Fabric?

When selecting brown faux leather fabric for various applications, understanding the materials used is crucial for B2B buyers. Here, we analyze four common materials: Polyurethane (PU), Polyvinyl Chloride (PVC), Microfiber, and Eco-Leather. Each material has distinct properties, advantages, and limitations that can significantly influence the performance and suitability of the final product.

Illustrative image related to brown faux leather fabric

How Does Polyurethane (PU) Perform in Brown Faux Leather Applications?

Polyurethane (PU) is a popular choice for brown faux leather due to its soft texture and breathability. PU faux leather typically exhibits a high resistance to wear and tear, making it suitable for heavy-duty applications. It can withstand around 50,000 to 100,000 double rubs, indicating its durability. Additionally, PU is more environmentally friendly compared to PVC, as it does not require harmful plasticizers.

Pros: PU leather is soft, breathable, and has a more natural appearance. It is also easier to clean and maintain, making it ideal for upholstery in residential and commercial settings.

Cons: The primary drawback is its cost, which can be higher than PVC. PU is also less resistant to harsh chemicals, which may limit its use in certain industrial applications.

Impact on Application: PU is well-suited for high-end furniture, automotive interiors, and fashion accessories. Its aesthetic appeal makes it a preferred choice for upscale markets.

What Are the Characteristics of Polyvinyl Chloride (PVC) in Faux Leather?

Polyvinyl Chloride (PVC) is another widely used material for brown faux leather. It is known for its waterproof and stain-resistant properties, making it ideal for environments where spills are common. PVC can endure high-pressure applications and is often used in automotive and marine upholstery.

Pros: PVC is generally less expensive than PU, making it accessible for budget-conscious projects. Its durability and resistance to moisture make it suitable for outdoor and industrial applications.

Cons: However, PVC is less breathable, which can lead to discomfort in applications like clothing. It is also associated with environmental concerns due to the release of harmful chemicals during production and disposal.

Impact on Application: PVC is commonly used in automotive interiors, outdoor furniture, and low-cost upholstery solutions, where durability and cost are prioritized over aesthetics.

Illustrative image related to brown faux leather fabric

How Does Microfiber Compare as a Faux Leather Material?

Microfiber is a synthetic material made from ultra-fine polyester fibers. When used as brown faux leather, it offers a soft, suede-like texture that mimics the look and feel of genuine leather. Microfiber is highly durable, with resistance to stains and fading.

Pros: Its lightweight nature and ease of cleaning make microfiber a practical choice for a variety of applications, including upholstery and fashion items. It is also hypoallergenic, appealing to health-conscious consumers.

Cons: The main limitation is its lower resistance to high temperatures, which can affect its performance in certain applications. Additionally, it may not provide the same luxurious feel as PU.

Impact on Application: Microfiber is ideal for residential furniture, automotive interiors, and fashion accessories, particularly in markets focused on comfort and ease of maintenance.

What Is Eco-Leather and Its Role in Faux Leather Fabric?

Eco-leather is a term that refers to faux leather made from recycled materials or sustainable processes. It typically combines polyurethane with recycled fibers, offering a more environmentally friendly alternative to traditional faux leather.

Pros: Eco-leather is a sustainable choice that appeals to environmentally conscious buyers. It retains many of the advantages of PU, such as breathability and durability, while reducing environmental impact.

Cons: The production process can be more complex and costly, potentially leading to higher prices. Additionally, availability may be limited compared to more conventional materials.

Impact on Application: Eco-leather is suitable for high-end furniture, fashion items, and automotive interiors targeting eco-conscious consumers.

Summary Table of Material Properties

| Material | Typical Use Case for brown faux leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | High-end furniture, automotive interiors | Soft, breathable, natural look | Higher cost, less chemical resistance | Alta |

| Polyvinyl Chloride (PVC) | Automotive interiors, outdoor furniture | Waterproof, stain-resistant | Less breathable, environmental concerns | Low |

| Microfibra | Residential furniture, fashion accessories | Lightweight, easy to clean | Lower heat resistance | Medium |

| Eco-Leather | High-end furniture, eco-friendly products | Sustainable, retains PU benefits | Higher cost, limited availability | Alta |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used in brown faux leather fabric, allowing for informed decisions tailored to specific applications and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for brown faux leather fabric

What Are the Main Stages in the Manufacturing Process of Brown Faux Leather Fabric?

The manufacturing of brown faux leather fabric involves several critical stages, each designed to ensure the final product meets the necessary quality and performance standards. Here’s a breakdown of the main stages:

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. Manufacturers typically begin with a base fabric, which can be made from polyester, cotton, or a blend of textiles. This base is then coated with a synthetic material to create the leather-like texture. Two common types of coatings are:

Illustrative image related to brown faux leather fabric

- Polyvinyl Chloride (PVC): Known for its durability and water resistance, PVC is often used in applications where longevity is crucial, such as in automotive upholstery.

- Polyurethane (PU): This is more eco-friendly than PVC and provides a softer, more breathable finish, making it a popular choice for furniture and fashion applications.

Forming: How Is the Faux Leather Fabric Created?

The forming stage involves applying the chosen synthetic coating to the base fabric. This can be achieved through several techniques:

- Coating: A liquid form of PVC or PU is applied to the fabric, often using a process called knife-over-roll coating, where a knife blade spreads the material evenly across the fabric.

- Foaming: This technique introduces air into the synthetic material, creating a thicker, cushioned texture that mimics genuine leather.

- Calendering: The coated fabric is passed through heated rollers to achieve a specific thickness and finish. This process also allows for the creation of textures and patterns that enhance the aesthetic appeal of the faux leather.

Assembly: What Are the Key Techniques in Assembly?

Once the faux leather is formed, it is cut and assembled into final products. This assembly can include:

- Cutting: Large rolls of faux leather are cut into specific dimensions required for upholstery, clothing, or other applications.

- Sewing: The cut pieces are stitched together using industrial sewing machines. This process may involve various stitching techniques to ensure durability and aesthetic appeal.

- Finishing: The final stage of assembly includes adding any additional features, such as zippers or embellishments, and applying surface treatments to enhance the fabric’s performance, such as water repellents or UV protection.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is critical in the manufacturing of brown faux leather fabric. To maintain high standards, manufacturers often adhere to international and industry-specific quality standards.

What International Standards Should B2B Buyers Be Aware Of?

- ISO 9001: This international standard focuses on quality management systems and is essential for manufacturers looking to establish credibility and ensure consistent quality.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) sets standards for materials used in oil and gas industries, which can be applicable for specific faux leather applications.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to catch any defects early. Common checkpoints include:

Illustrative image related to brown faux leather fabric

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks are performed during the manufacturing process to identify and rectify issues as they arise.

- Final Quality Control (FQC): The finished product undergoes a thorough inspection to ensure it meets all quality and performance standards before shipment.

What Common Testing Methods Are Used for Quality Assurance?

Manufacturers utilize various testing methods to ensure the faux leather fabric meets performance criteria:

- Abrasion Resistance Testing: This assesses how well the fabric withstands wear and tear, often measured in double rubs (e.g., 55,000 double rubs for heavy-duty fabrics).

- Flammability Testing: Fabrics must meet specific flammability standards to ensure safety, particularly for applications in residential or commercial settings.

- Colorfastness Testing: This evaluates how well the color holds up against washing, light exposure, and rubbing, ensuring that the fabric maintains its aesthetic appeal over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, ensuring that suppliers maintain rigorous quality control is paramount. Here are actionable steps buyers can take:

Conducting Supplier Audits

Buyers should consider conducting on-site audits of suppliers to assess their quality control processes directly. This allows buyers to verify compliance with international standards and evaluate the manufacturing environment.

Requesting Quality Control Reports

Buyers can request detailed quality control reports from suppliers, including results from testing methods and any certifications obtained. This documentation provides transparency and assurance regarding product quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These firms can conduct inspections at various stages of production, ensuring compliance with agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers need to be aware of specific nuances that can affect quality control:

- Cultural Differences: Understanding cultural practices regarding quality assurance can impact communication and expectations. Buyers should establish clear quality criteria and maintain open dialogue with suppliers.

- Regulatory Compliance: Different regions may have varying regulations regarding materials and safety standards. Buyers should ensure that suppliers are compliant with local laws to avoid potential liabilities.

- Logistics and Supply Chain Management: Delays and inconsistencies in supply chains can affect quality. Buyers should work closely with suppliers to establish reliable logistics and ensure timely delivery of quality materials.

By understanding the manufacturing processes and quality assurance measures for brown faux leather fabric, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown faux leather fabric’

Introducción

Sourcing brown faux leather fabric effectively requires a structured approach to ensure quality, cost-effectiveness, and supplier reliability. This checklist serves as a practical guide for B2B buyers, particularly in Africa, South America, the Middle East, and Europe, helping you navigate the complexities of procurement in this niche market.

1. Identify Your Specific Needs

Understanding your requirements is the first crucial step. Determine the intended application—whether for upholstery, fashion, or automotive uses—as this will influence the type of faux leather you select. Consider factors such as texture, durability, and environmental resistance that align with your project specifications.

2. Define Technical Specifications

Clearly outline the technical specifications for the faux leather you need. This includes factors like material composition (e.g., PU vs. PVC), weight, width, and flammability ratings. Having precise specifications will help you communicate effectively with suppliers and ensure that the materials meet your quality standards.

Illustrative image related to brown faux leather fabric

3. Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in brown faux leather fabric. Look for companies with a strong reputation in your target regions, and verify their industry certifications. Online reviews, case studies, and customer testimonials can provide insights into supplier reliability and product quality.

4. Request Samples for Evaluation

Before placing a large order, request samples of the brown faux leather fabric. This allows you to assess the material’s texture, color accuracy, and durability firsthand. Make sure to evaluate samples under the conditions they will be used to ensure they meet your performance expectations.

5. Assess Supplier Capabilities

Evaluate each supplier’s manufacturing capabilities and capacity to meet your order volume. Inquire about their lead times, production processes, and quality control measures. Understanding their operational efficiency can prevent delays and ensure you receive your materials on time.

6. Negotiate Pricing and Terms

Once you have shortlisted suppliers, initiate discussions on pricing and payment terms. Be sure to consider not only the unit price but also shipping costs, minimum order quantities, and payment schedules. A well-negotiated agreement can significantly impact your bottom line.

Illustrative image related to brown faux leather fabric

7. Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Ensure that you have established clear lines of communication with your chosen supplier. Regular updates and feedback loops can help mitigate misunderstandings and ensure that your order specifications are met accurately.

By following this checklist, B2B buyers can streamline their sourcing process for brown faux leather fabric, ensuring that they select the best materials for their projects while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for brown faux leather fabric Sourcing

What Are the Key Cost Components in Sourcing Brown Faux Leather Fabric?

When sourcing brown faux leather fabric, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The base fabric, typically polyester or polyurethane, is treated to mimic leather. The choice of materials directly impacts the price, with PU leather generally being more expensive than PVC due to its superior quality and environmental considerations.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs can offer competitive pricing, but quality and craftsmanship should not be compromised.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can lower overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Depending on the complexity of the designs and patterns, tooling costs can be substantial. Custom molds and equipment for specific patterns can increase initial costs but may be offset by economies of scale for larger orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the fabric meets specified standards, which can add to costs but is essential for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping costs can vary based on the distance from the manufacturing site to the buyer, as well as the chosen shipping method. Understanding Incoterms is critical for clarifying who bears responsibility for shipping costs and risks.

-

Margin: Suppliers typically include a margin that reflects their business model and market positioning. This can vary widely based on the supplier’s reputation and the perceived value of the product.

How Do Price Influencers Affect the Cost of Brown Faux Leather Fabric?

Several factors influence the pricing of brown faux leather fabric, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often results in reduced per-unit costs. Buyers should assess their needs and negotiate for better pricing based on anticipated order volumes.

-

Specifications and Customization: Custom orders, such as specific textures or colors, can increase costs. Buyers should evaluate whether custom features are necessary or if standard options would suffice.

-

Quality and Certifications: Fabrics that meet specific quality standards or certifications (e.g., fire resistance, eco-friendliness) may command higher prices. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge premium prices but often provide better service and assurance of quality.

-

Incoterms: Understanding the implications of Incoterms can help buyers manage costs effectively. For instance, choosing an FOB (Free on Board) term can minimize risk and clarify who is responsible for shipping and insurance.

What Buyer Tips Can Help Achieve Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing brown faux leather fabric, buyers should consider the following strategies:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing. Emphasize long-term relationships and potential future orders to leverage better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider additional costs such as shipping, handling, and potential waste. A lower initial price may not always equate to better value.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing.

-

Research Local Market Trends: Awareness of local demand and competition can provide insights into fair pricing and help in negotiations.

Disclaimer on Indicative Prices

Prices for brown faux leather fabric can vary significantly based on the factors discussed. It is essential for buyers to obtain quotes from multiple suppliers and consider all associated costs to make informed purchasing decisions.

Alternatives Analysis: Comparing brown faux leather fabric With Other Solutions

Introduction to Alternative Solutions for Brown Faux Leather Fabric

In the upholstery and fashion industries, brown faux leather fabric is a popular choice due to its aesthetic appeal and practicality. However, there are several alternative solutions that offer various benefits depending on the specific needs of B2B buyers. Understanding these alternatives can help businesses make informed decisions tailored to their operational requirements and target markets.

Comparison Table

| Comparison Aspect | Brown Faux Leather Fabric | Cuero PU | Genuine Leather |

|---|---|---|---|

| Performance | Durable, resistant to wear (up to 55,000 double rubs) | Soft, breathable, and more similar to genuine leather | Extremely durable, ages well, high tensile strength |

| Cost | Generally affordable, wholesale pricing available | Moderate, typically more expensive than faux leather | High cost, varies significantly based on quality |

| Ease of Implementation | Easy to cut and sew, widely available | Requires skilled labor for high-quality results | Labor-intensive production and sourcing |

| Maintenance | Low maintenance, easy to clean with mild soap | Moderate maintenance, requires special cleaners | High maintenance, needs conditioning and regular care |

| Best Use Case | Ideal for upholstery, automotive, and fashion | Suitable for high-end fashion and upholstery | Best for luxury items and long-lasting furniture |

Detailed Breakdown of Alternatives

Cuero PU

PU (polyurethane) leather is a synthetic alternative that is often regarded as more eco-friendly compared to traditional faux leather. It is softer, more breathable, and mimics the texture and feel of genuine leather more closely. This material is highly versatile, making it suitable for various applications, including high-end fashion and upholstery. However, it tends to be more expensive than brown faux leather fabric, which may be a consideration for budget-conscious buyers. Additionally, while PU leather requires moderate maintenance and specific cleaning products, it does not demand the same level of upkeep as genuine leather.

Genuine Leather

Genuine leather is a natural product known for its durability and luxurious appearance. It ages beautifully and develops a unique character over time, making it a favored choice for high-end furniture and accessories. While genuine leather offers superior performance and a timeless aesthetic, its cost can be prohibitively high for many businesses. Furthermore, the sourcing and production process can be labor-intensive and may involve ethical considerations regarding animal welfare. Maintenance is another factor; genuine leather requires regular conditioning to prevent drying and cracking, which can increase overall ownership costs.

Illustrative image related to brown faux leather fabric

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between brown faux leather fabric and its alternatives, B2B buyers should carefully evaluate their specific needs, including budget, intended use, and maintenance capabilities. For businesses focused on cost-effectiveness and low maintenance, brown faux leather fabric remains an excellent choice. In contrast, those aiming for a premium product that combines aesthetics with functionality may lean towards PU leather or genuine leather, despite the higher costs and maintenance requirements. By understanding the strengths and weaknesses of each option, buyers can make more informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for brown faux leather fabric

What Are the Key Technical Properties of Brown Faux Leather Fabric?

When considering brown faux leather fabric for various applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

Brown faux leather is primarily made from two materials: polyurethane (PU) and polyvinyl chloride (PVC). PU offers a softer, more breathable alternative, making it ideal for upholstery in residential and commercial settings. PVC, while more durable and waterproof, may lack the same comfort level. Buyers should assess the intended use to determine which material best suits their needs. -

Weight and Thickness

The weight of faux leather fabric is typically measured in ounces per yard, with heavier fabrics often being more durable and suitable for high-traffic areas. A common weight for upholstery-grade faux leather is between 14 to 26 ounces. Thickness can affect both the look and feel of the material; thicker fabrics may provide a more premium appearance but can also be less flexible. -

Durability Rating (Double Rubs)

Durability is often quantified using the double rubs test, which measures how many times a fabric can withstand being rubbed before showing signs of wear. A rating of 30,000 to 50,000 double rubs is considered suitable for residential use, while commercial applications may require fabrics exceeding 100,000 double rubs. Understanding this metric helps buyers select fabrics that will withstand their specific use cases. -

Flammability Standards

Faux leather fabrics must meet certain flammability standards, which vary by region and application. For example, in the U.S., the UFAC Class 1 standard is commonly referenced. Buyers should ensure that the chosen fabric complies with local regulations, particularly for use in public spaces or residential applications where safety is a concern. -

Cleanability and Maintenance

Faux leather is generally easy to maintain, but specific cleaning requirements can vary. Many fabrics can be cleaned with mild soap and water, while others may require specialized cleaners. Understanding the care instructions will help buyers ensure the longevity of their investment.

What Are Common Trade Terms Related to Brown Faux Leather Fabric?

Familiarity with industry terminology is crucial for B2B buyers to navigate the purchasing process efficiently. Here are some key terms to know:

Illustrative image related to brown faux leather fabric

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of faux leather, an OEM may create fabric materials that are branded and sold by furniture or automotive companies. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for buyers to ensure they meet supplier requirements, which can affect pricing and availability. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. Buyers should prepare a detailed RFQ that includes specifications for brown faux leather fabric, such as material type, weight, and quantity, to receive accurate pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarizing oneself with Incoterms can help buyers understand their obligations and risks during international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times for brown faux leather fabric is crucial for supply chain management and planning. -

Certification Standards

Certification standards indicate that the material meets specific quality or safety benchmarks. Familiarity with relevant certifications can assure buyers of the quality and compliance of the faux leather fabric with industry standards.

By understanding these properties and terminology, B2B buyers can make more informed decisions and engage effectively with suppliers in the global market for brown faux leather fabric.

Navigating Market Dynamics and Sourcing Trends in the brown faux leather fabric Sector

What Are the Key Market Trends Affecting Brown Faux Leather Fabric?

The brown faux leather fabric market is experiencing dynamic changes influenced by various global drivers. As consumer preferences shift towards sustainable and cruelty-free products, the demand for faux leather is surging, particularly among B2B buyers from regions like Africa, South America, the Middle East, and Europe. The growing middle class in emerging markets such as Nigeria and Vietnam is driving demand for affordable yet stylish upholstery solutions in residential and commercial settings.

Technological advancements in fabric production are also noteworthy, with innovations in manufacturing processes leading to higher quality and more durable products. Suppliers are increasingly adopting digital platforms for sourcing, enabling international buyers to streamline their procurement processes and access a broader range of options. Furthermore, the rise of e-commerce has made it easier for businesses to explore various suppliers and materials, enhancing competition and fostering innovation in design and functionality.

Illustrative image related to brown faux leather fabric

Additionally, the focus on customization is becoming more pronounced. B2B buyers are looking for suppliers who can offer tailored solutions, such as specific textures, colors, and patterns that align with their branding and consumer demands. This trend is particularly relevant in the hospitality and automotive sectors, where faux leather is frequently utilized for upholstery, offering a blend of aesthetics and practicality.

How Important Is Sustainability and Ethical Sourcing in the Brown Faux Leather Fabric Industry?

Sustainability and ethical sourcing have become critical considerations for international B2B buyers in the brown faux leather fabric sector. The environmental impact of traditional leather production, including high water usage and toxic chemical runoff, has prompted many companies to pivot towards more sustainable alternatives. Faux leather, particularly when made from polyurethane (PU) rather than polyvinyl chloride (PVC), offers a more eco-friendly option. PU leather is not only more breathable but also involves fewer harmful chemicals in its production.

For B2B buyers, establishing ethical supply chains is essential. This includes partnering with manufacturers who prioritize sustainable practices and adhere to certifications such as Global Recycled Standard (GRS) or OEKO-TEX® Standard 100. These certifications ensure that the materials used in the production of brown faux leather are safe, responsibly sourced, and environmentally friendly.

Illustrative image related to brown faux leather fabric

Moreover, consumers are increasingly scrutinizing brands for their sustainability efforts. B2B buyers that prioritize ethical sourcing can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers. As a result, integrating sustainability into the sourcing strategy not only aligns with ethical considerations but also positions businesses favorably in competitive markets.

How Has the Brown Faux Leather Fabric Market Evolved Over Time?

The evolution of brown faux leather fabric can be traced back to the mid-20th century when synthetic materials began to gain popularity as alternatives to genuine leather. Initially, the focus was on affordability and practicality; however, advancements in technology have significantly improved the aesthetics and functionality of faux leather.

In the past two decades, the rise of ethical consumerism has further transformed the market. Today, faux leather is not merely seen as a budget option but as a stylish, sustainable choice that meets the demands of modern consumers. Innovations such as eco-friendly manufacturing processes and enhanced durability have established faux leather as a competitive alternative to traditional leather, particularly in applications like upholstery, fashion, and automotive industries.

As B2B buyers navigate this evolving landscape, understanding the historical context and current trends is essential for making informed sourcing decisions that align with both market demands and ethical standards.

Illustrative image related to brown faux leather fabric

Frequently Asked Questions (FAQs) for B2B Buyers of brown faux leather fabric

-

How do I choose the right supplier for brown faux leather fabric?

Selecting the right supplier involves thorough research and vetting. Look for manufacturers with a proven track record in quality and reliability. Check for certifications, such as ISO or OEKO-TEX, which ensure adherence to international quality standards. Request samples to assess the material’s quality and durability. Additionally, consider suppliers who have experience in your target market, as they will better understand regional preferences and regulations. -

What is the best type of faux leather for upholstery applications?

For upholstery, PU (polyurethane) faux leather is often the best choice due to its softness, breathability, and eco-friendliness. It mimics the look and feel of genuine leather while being more affordable and easier to maintain. PVC leather, while durable and waterproof, is less breathable and may not be suitable for all upholstery needs. Consider the intended use and environment when selecting the type of faux leather. -

What are the typical minimum order quantities (MOQs) for brown faux leather fabric?

MOQs can vary significantly among suppliers, typically ranging from 50 to 500 yards, depending on the manufacturer and material type. Some suppliers may offer lower MOQs for certain products to attract smaller businesses. Always confirm the MOQ before placing an order, as this can impact your inventory management and cash flow, especially when entering new markets. -

What payment terms should I expect when sourcing faux leather internationally?

Payment terms can vary widely, but most suppliers require a deposit (usually 30%) upfront, with the balance due before shipment. Some may offer more flexible terms, such as payment upon delivery or after inspection. It’s crucial to negotiate terms that align with your cash flow needs and to ensure clarity on accepted payment methods, including bank transfers and letters of credit. -

How can I ensure quality assurance (QA) for my faux leather orders?

To ensure quality, establish clear specifications with your supplier, including material composition, weight, color, and finish. Request samples prior to full production and consider third-party inspection services to evaluate quality before shipment. Additionally, implementing a quality control checklist can help ensure that the final product meets your standards and reduces the risk of returns or disputes. -

What logistics considerations should I take into account when importing faux leather?

When importing faux leather, consider shipping methods, costs, and lead times. Choose between air freight for speed or sea freight for cost-effectiveness. Be aware of customs regulations in your destination country and ensure all necessary documentation is in order to avoid delays. Collaborating with a freight forwarder can streamline the logistics process and help navigate any potential challenges. -

Are there customization options available for brown faux leather fabric?

Many suppliers offer customization options, including color, texture, and pattern modifications. This allows you to create unique products that meet your branding and design requirements. Be sure to discuss your specific needs with the supplier and inquire about additional costs and lead times associated with custom orders. -

What are the common applications for brown faux leather fabric?

Brown faux leather fabric is versatile and commonly used in various applications, including furniture upholstery, automotive interiors, fashion accessories, and home décor. Its durability and aesthetic appeal make it suitable for both residential and commercial settings. Understanding the specific application will help you choose the right type of faux leather that meets your performance and design needs.

Top 6 Brown Faux Leather Fabric Manufacturers & Suppliers List

1. Faux Leather Upholstery Vinyl – Brown

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Brown Faux Leather Upholstery Vinyl

– Available Brands: Naugahyde, Boltaflex, Omnova, Spradling, Nassimi, Morbern

– Price Range: $8.95 – $33.95 per yard

– Stock Availability: Various products with yardage ranging from 5 to 54 yards

– Uses: Automotive, Furniture, Marine

– Product Types: Faux Leather, Vinyl (PVC), Urethane

– Notable Products:

– LDR14 LANDERS BROWN: $14.95 per yard, 41 yards in sto…

2. Hobby Lobby – Brown Saddle Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘SKU’: ‘1533801’, ‘Original Price’: ‘$17.99’, ‘Description’: ‘Brown Saddle Faux Leather Fabric boasts a warm, medium brown color with a sleek design and a leather-like texture.’, ‘Available Increments’: ‘1-yard increments’, ‘Average Bolt Size’: ‘approximately 9 yards’, ‘Width’: ’55 inches’, ‘Vertical Repeat’: ‘29.13 inches’, ‘Horizontal Repeat’: ‘8.25 inches’, ‘Color’: ‘Brown’, ‘Weight’: ‘Extra-H…

3. Kovi Fabrics – Faux Leather Solutions

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Faux leather fabric is an alternative to genuine leather, made from synthetic materials like polyester, polyurethane (PU), and polyvinyl chloride (PVC). It is soft, easy to clean, water-resistant, and stain-resistant. There are two main types: PVC leather, which is waterproof and non-porous but less sustainable, and PU leather, which is more eco-friendly and resembles genuine leather in texture. F…

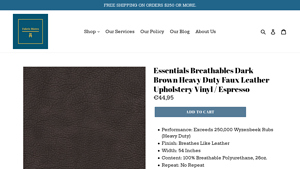

4. Fabric Bistro – Essentials Breathables Dark Brown Faux Leather

Domain: fabricbistro.com

Registered: 2015 (10 years)

Introduction: {‘name’: ‘Essentials Breathables Dark Brown Heavy Duty Faux Leather Upholstery Vinyl’, ‘price’: ‘$49.90’, ‘performance’: ‘Exceeds 250,000 Wyzenbeek Rubs (Heavy Duty)’, ‘finish’: ‘Breathes Like Leather’, ‘width’: ’54 Inches’, ‘content’: ‘100% Breathable Polyurethane, 26oz.’, ‘repeat’: ‘No Repeat’, ‘pattern_direction’: ‘Non-Directional’, ‘cleanability’: ‘Water Based Cleaner’, ‘flammability’: ‘UFAC C…

5. OnlineFabricStore – Vinyl & Faux Leather Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, OnlineFabricStore – Vinyl & Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Sailrite – Faux Leather Upholstery

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Faux Leather, Vinyl Leather; Quality faux leather available in a variety of natural and bright colors; Suitable for upholstery applications like couches; Durable; All faux leather is in stock and ready to ship; Fabric samples available.

Strategic Sourcing Conclusion and Outlook for brown faux leather fabric

As the demand for sustainable and cost-effective materials continues to rise globally, brown faux leather fabric emerges as a versatile solution for various industries, including upholstery, automotive, and home décor. Its appeal lies in its ethical production, affordability, and extensive design options, making it an attractive alternative to genuine leather. B2B buyers can leverage strategic sourcing to access high-quality brown faux leather from reputable manufacturers, ensuring consistency and reliability in their supply chains.

Investing in brown faux leather also aligns with current market trends that prioritize sustainability and animal welfare. By choosing this material, businesses not only enhance their product offerings but also appeal to a growing consumer base that values ethical consumption.

Looking ahead, international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are encouraged to explore strategic partnerships with suppliers who can provide innovative faux leather solutions tailored to their specific needs. Engaging with industry-leading brands can facilitate access to the latest developments and trends, ensuring your business remains competitive in the evolving marketplace. Take the next step today and invest in brown faux leather fabric to elevate your product line and meet consumer demands.

Illustrative image related to brown faux leather fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.