Introduction: Navigating the Global Market for hot leather stamp

In the dynamic world of leather craftsmanship, sourcing the right hot leather stamp can be a pivotal challenge for B2B buyers. Whether you’re a manufacturer in South America looking to add a unique branding touch to your products or a retailer in Europe seeking to enhance your offerings, understanding the intricacies of hot leather stamps is essential. This guide serves as a comprehensive resource, detailing various types of hot leather stamps, their applications, and the technical specifications that can significantly impact your production processes.

From custom brass stamps designed for intricate designs to powerful electric branding irons capable of hot stamping on various leather types, we cover the essential tools and techniques that can elevate your brand’s identity. Additionally, we provide insights on supplier vetting, ensuring that you select reliable manufacturers who meet international quality standards. Cost considerations are also analyzed, allowing you to make informed budgetary decisions while maximizing your return on investment.

By empowering international B2B buyers from regions like Africa, the Middle East, and Europe, this guide will help you navigate the global market for hot leather stamps. With actionable insights and expert recommendations, you will be better equipped to make strategic purchasing decisions that enhance your product offerings and drive your business forward.

Table Of Contents

- Top 5 Hot Leather Stamp Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hot leather stamp

- Understanding hot leather stamp Types and Variations

- Key Industrial Applications of hot leather stamp

- 3 Common User Pain Points for ‘hot leather stamp’ & Their Solutions

- Strategic Material Selection Guide for hot leather stamp

- In-depth Look: Manufacturing Processes and Quality Assurance for hot leather stamp

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot leather stamp’

- Comprehensive Cost and Pricing Analysis for hot leather stamp Sourcing

- Alternatives Analysis: Comparing hot leather stamp With Other Solutions

- Essential Technical Properties and Trade Terminology for hot leather stamp

- Navigating Market Dynamics and Sourcing Trends in the hot leather stamp Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot leather stamp

- Strategic Sourcing Conclusion and Outlook for hot leather stamp

- Important Disclaimer & Terms of Use

Understanding hot leather stamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Stamps | Durable, high precision, CNC machined | Branding leather goods, custom logos | Pros: Long-lasting, crisp impressions. Cons: Higher initial cost. |

| Electric Branding Irons | Adjustable temperature settings, fast operation | Mass production of branded items | Pros: Versatile, consistent results. Cons: Requires power source. |

| Handheld Steel Stamps | Manual operation, traditional imprinting technique | Small batch production, artisanal products | Pros: Affordable, portable. Cons: Labor-intensive, less uniform results. |

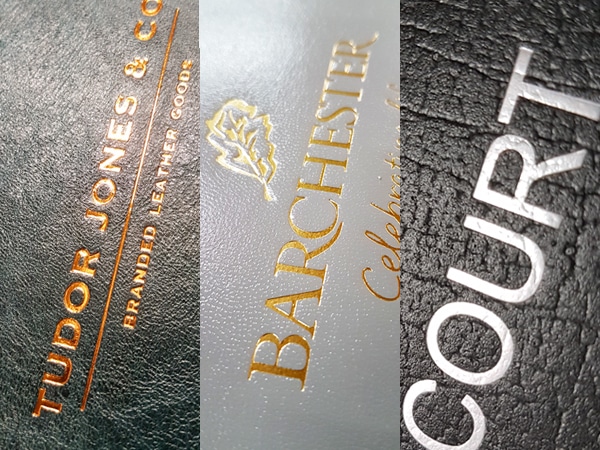

| Hot Foil Stamps | Uses foils for metallic impressions | High-end leather goods, luxury branding | Pros: Eye-catching designs, unique finishes. Cons: Limited to specific applications. |

| Heat Embossers | Combines heat and pressure for deep impressions | Custom designs on various leather types | Pros: Versatile, quick setup. Cons: Potential for heat damage if misused. |

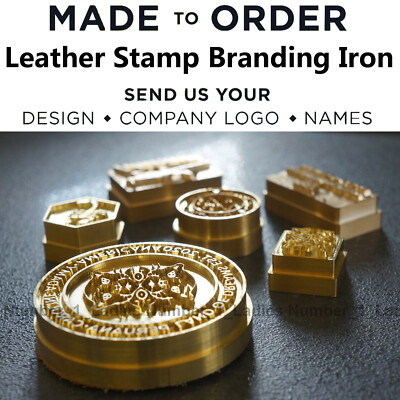

What are the characteristics of Custom Brass Stamps?

Custom brass stamps are renowned for their durability and precision, often produced using CNC machining. This method ensures that the designs are crisp and detailed, making them ideal for branding leather goods with logos and unique designs. These stamps are particularly suited for businesses that prioritize quality and longevity in their branding efforts. When purchasing, buyers should consider the size of the stamp, the intricacy of the design, and the long-term investment value as they typically come at a higher initial cost.

How do Electric Branding Irons enhance production efficiency?

Electric branding irons are designed with adjustable temperature settings, allowing for quick and effective branding across various types of leather. They are particularly beneficial for businesses engaged in mass production, as they provide consistent results and can handle larger logos and designs. Buyers should consider the power requirements and temperature control features when purchasing, as these factors will impact operational efficiency and the quality of the imprint on different leather types.

Why choose Handheld Steel Stamps for artisanal products?

Handheld steel stamps are ideal for small batch production and artisanal leather goods. They operate manually, allowing artisans to have more control over the stamping process. This type of stamp is often more affordable and portable, making it suitable for businesses that require flexibility in their operations. However, buyers should be aware that the manual nature of these stamps can lead to less uniform results, which may not meet the standards of larger-scale manufacturers.

What are the advantages of using Hot Foil Stamps in branding?

Hot foil stamps are specialized for creating metallic impressions on leather, which can significantly enhance the aesthetic appeal of high-end leather products. This technique is commonly used in luxury branding, where a unique and eye-catching finish is desired. While hot foil stamping can attract premium customers, buyers must consider the specific applications and limitations of this method, as it may not be suitable for all types of leather.

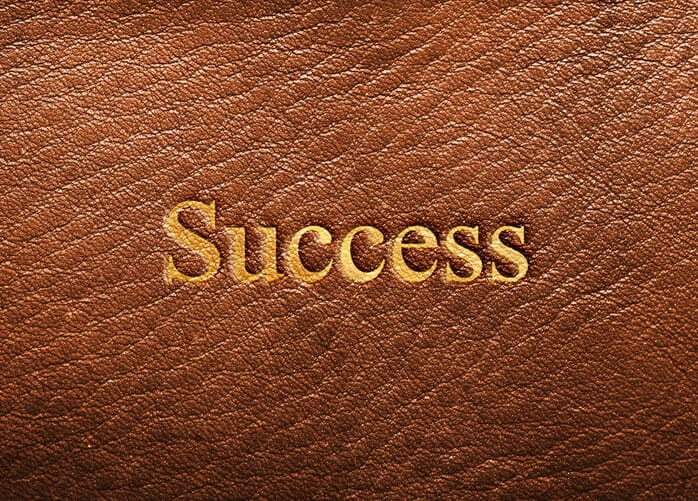

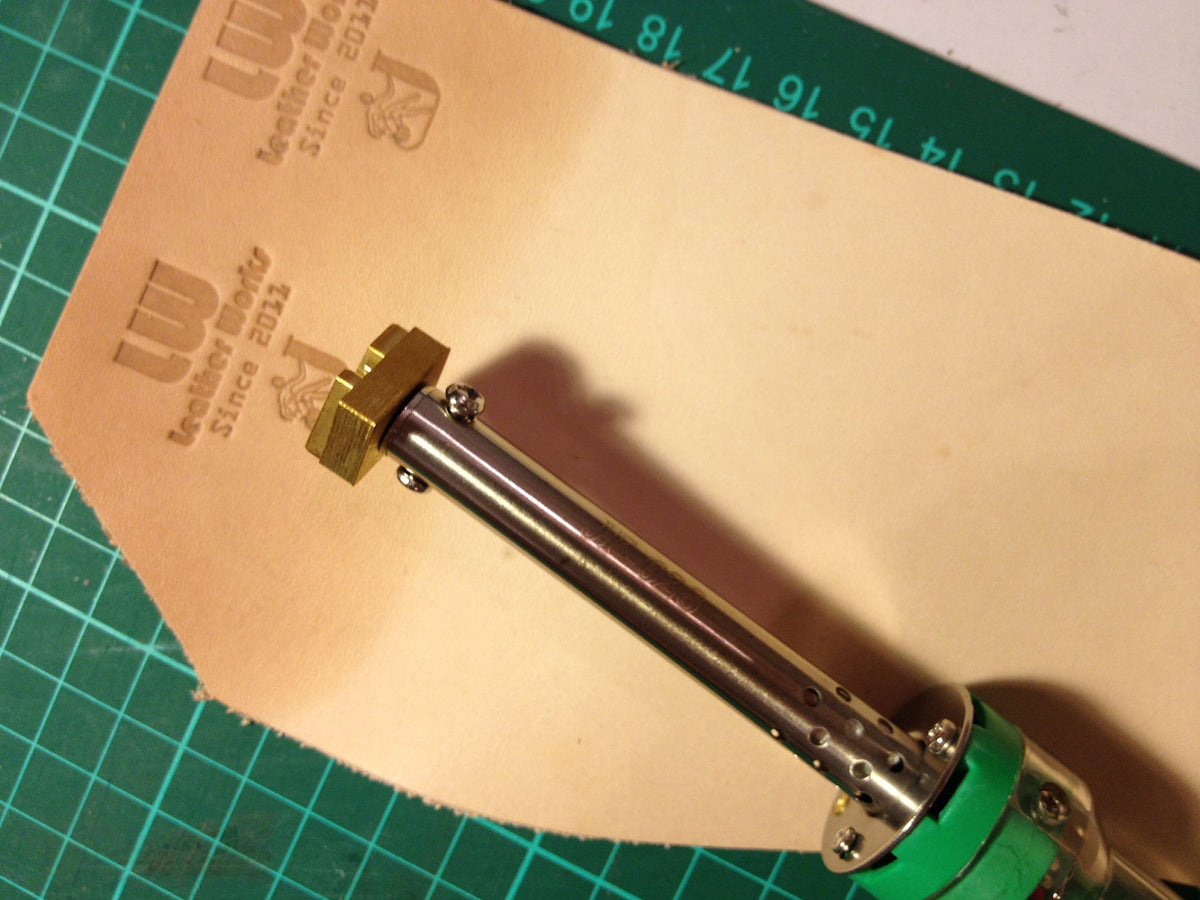

Illustrative image related to hot leather stamp

How do Heat Embossers provide versatility in leather stamping?

Heat embossers utilize a combination of heat and pressure to create deep impressions in leather, making them versatile tools for various stamping needs. They can be used on different leather types, including vegetable-tanned and suede, and are ideal for custom designs. Buyers should focus on the ease of use and the potential for heat damage when selecting a heat embosser, as improper settings can compromise the quality of the leather.

Key Industrial Applications of hot leather stamp

| Industry/Sector | Specific Application of hot leather stamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Custom branding on leather goods like handbags and belts | Enhances brand identity and adds a premium touch | Need for high-quality, durable stamps that can handle various leathers. |

| Automotive | Embossing leather interiors and custom seat covers | Creates a luxurious feel and personalization for clients | Consideration for temperature control and compatibility with different leather types. |

| Home Decor | Stamping on leather furniture and decor items | Differentiates products in a competitive market | Sourcing of stamps that can handle larger designs for furniture applications. |

| Sports and Outdoor Gear | Branding on leather sporting goods and outdoor equipment | Builds brand loyalty and recognition among users | Importance of stamps that can withstand outdoor conditions and frequent use. |

| Craft and DIY | Personalized leather items for hobbyists and crafters | Allows for creativity and customization, increasing sales | Availability of customizable stamps and ease of use for non-professionals. |

How is ‘hot leather stamp’ used in the fashion and accessories industry?

In the fashion and accessories sector, hot leather stamps are utilized for custom branding on products such as handbags, belts, and wallets. This method not only enhances brand identity but also adds a premium touch to items, making them more appealing to consumers. Buyers in this sector must consider the durability of the stamps and their ability to handle various leather types, including chrome and vegetable-tanned leather. Additionally, the ability to produce intricate designs quickly is crucial for keeping up with fashion trends.

What role does hot leather stamping play in the automotive industry?

In the automotive industry, hot leather stamping is employed to emboss leather interiors and custom seat covers, providing a luxurious feel that enhances the overall aesthetics of vehicles. This application is particularly important for high-end car manufacturers aiming to offer personalized options to their clients. Buyers should focus on sourcing stamps with adjustable temperature controls to accommodate different leather materials and thicknesses, ensuring a consistent and high-quality finish.

Illustrative image related to hot leather stamp

How does hot leather stamping enhance home decor products?

Hot leather stamping is increasingly used in the home decor industry for branding on leather furniture and decorative items. This technique allows manufacturers to differentiate their products in a competitive market, adding a unique touch that appeals to consumers. When sourcing hot leather stamps for this application, businesses should prioritize stamps that can accommodate larger designs, as well as those that are robust enough to withstand the rigors of furniture production.

Why is hot leather stamping valuable for sports and outdoor gear?

In the sports and outdoor gear sector, hot leather stamping is applied to brand leather sporting goods and outdoor equipment. This method not only builds brand loyalty but also reinforces recognition among users who value quality and craftsmanship. Buyers in this industry should seek stamps that are durable and can withstand outdoor conditions, ensuring that the branding remains intact despite exposure to the elements.

How does hot leather stamping benefit the craft and DIY market?

For hobbyists and crafters, hot leather stamping offers a means to personalize leather items, allowing for creativity and customization. This application can significantly increase sales by providing unique, one-of-a-kind products. Buyers in this market need to consider the availability of customizable stamps that are easy to use, enabling both professionals and non-professionals to achieve high-quality results in their crafting projects.

Illustrative image related to hot leather stamp

3 Common User Pain Points for ‘hot leather stamp’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Quality Across Different Leather Types

The Problem: B2B buyers often encounter challenges when trying to achieve uniform quality in their hot stamping process, especially when working with various leather types such as chrome-tanned, vegetable-tanned, and suede. Each leather type has unique properties that affect how heat is absorbed and retained, leading to inconsistent results. Buyers may find that their branding looks perfect on one type of leather but fails to impress on another, resulting in wasted materials and a tarnished brand reputation.

The Solution: To ensure consistent quality, buyers should invest in a hot leather stamp with adjustable temperature settings. This feature allows users to modify the heat according to the specific type of leather being used. For instance, vegetable-tanned leather typically requires lower temperatures, while chrome-tanned leather may need higher heat for optimal results. Before starting production, conduct small test runs on each leather type to determine the ideal temperature settings. Additionally, sourcing stamps made from high-quality materials, such as solid brass, can enhance durability and ensure that the design remains crisp across multiple uses. Providing training for staff on the nuances of different leather types can further mitigate quality issues.

Scenario 2: Long Lead Times for Custom Stamps

The Problem: Many B2B buyers experience significant delays when ordering custom hot leather stamps, which can lead to missed deadlines and frustrated customers. These delays often stem from the lengthy design and manufacturing processes that some suppliers employ, resulting in a negative impact on production schedules, especially for businesses with seasonal demands or promotional events.

Illustrative image related to hot leather stamp

The Solution: To overcome this challenge, buyers should seek suppliers who offer rapid turnaround times for custom orders. Look for companies that utilize CNC machining for their stamps, as this technology typically allows for faster production without sacrificing quality. Inquire about expedited shipping options for urgent orders. Additionally, having a well-prepared design file ready for submission—preferably in vector format—can streamline the process. Establishing a long-term relationship with a reliable supplier can also lead to improved lead times, as they will become familiar with your specific needs and preferences.

Scenario 3: Inefficient Use of Resources and Energy Costs

The Problem: B2B buyers may find that their hot stamping operations are not energy-efficient, leading to higher operational costs. Inefficient heating methods or poorly designed equipment can waste energy, resulting in increased expenses that affect the overall profitability of their leather goods business. Moreover, inefficient stamping processes can lead to defects, requiring additional resources for corrections.

The Solution: Buyers should evaluate their current hot stamping equipment and consider investing in energy-efficient models with digital temperature controls. These units not only provide precise temperature settings for different leather types but also reduce energy consumption by maintaining optimal heat levels without excessive fluctuation. Additionally, implementing a proactive maintenance schedule for the stamping equipment can prevent breakdowns and inefficiencies. Finally, conducting a thorough analysis of the stamping process can identify bottlenecks or redundancies, allowing buyers to streamline operations and better allocate resources. By focusing on efficiency, businesses can significantly reduce costs while maintaining high-quality standards in their products.

Strategic Material Selection Guide for hot leather stamp

What Are the Key Materials for Hot Leather Stamps?

When selecting materials for hot leather stamps, it is essential to consider their properties, advantages, and limitations. The choice of material directly impacts the performance, durability, and suitability of the stamps for various leather types. Below are analyses of four common materials used in hot leather stamping.

How Does Brass Perform as a Material for Hot Leather Stamps?

Brass is a popular choice for hot leather stamps due to its excellent thermal conductivity and durability. It can withstand high temperatures (up to 450°C) without deforming, making it suitable for various leather types, including vegetable-tanned and chrome-tanned leather.

Illustrative image related to hot leather stamp

Pros: Brass stamps are highly durable and resistant to corrosion, ensuring longevity even with frequent use. They also provide a crisp, clean impression, which is essential for branding.

Cons: The initial cost of brass can be higher than other materials like aluminum, and it may require more complex manufacturing processes, especially for custom designs.

Impact on Application: Brass is compatible with a wide range of leather media, ensuring that the quality of the stamp remains high across different applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure that brass stamps comply with local regulations regarding metal content and environmental standards.

What Are the Benefits of Aluminum for Hot Leather Stamps?

Aluminum is another common material used in hot leather stamps. It is lightweight and can be produced at a lower cost than brass, making it an attractive option for budget-conscious buyers.

Illustrative image related to hot leather stamp

Pros: Aluminum stamps are easier and cheaper to manufacture, allowing for quick turnaround times on custom orders. They are also suitable for smaller-scale operations where cost efficiency is crucial.

Cons: While aluminum is less expensive, it is not as durable as brass and may suffer from wear and tear more quickly, especially under high-temperature conditions.

Impact on Application: Aluminum is best suited for lighter applications and may not perform well with thicker or tougher leather types, limiting its versatility.

Considerations for International Buyers: Buyers should be aware of the potential for aluminum to corrode over time, especially in humid environments, which is a common concern in regions like Africa and South America.

How Does Steel Compare for Hot Leather Stamps?

Steel, particularly stainless steel, is another viable option for hot leather stamps. Its high strength and resistance to corrosion make it suitable for heavy-duty applications.

Illustrative image related to hot leather stamp

Pros: Stainless steel offers excellent durability and can withstand high pressures and temperatures, making it ideal for industrial applications. Its longevity means fewer replacements are needed over time.

Cons: The manufacturing process for steel stamps can be more complex and costly, which may deter small businesses from investing in them.

Impact on Application: Steel stamps can be used effectively on various leather types, including thicker materials, due to their robust nature.

Considerations for International Buyers: Compliance with international standards for metal products is crucial, especially in markets like Germany, where stringent regulations exist.

What Role Does Copper Play in Hot Leather Stamping?

Copper is less commonly used than brass or aluminum but can still be an effective material for hot leather stamps. It has good thermal conductivity and can produce clear impressions.

Pros: Copper is relatively easy to work with and can be shaped into intricate designs, making it suitable for custom stamps.

Cons: Copper is softer than brass and steel, which may lead to faster wear and a shorter lifespan for the stamps.

Impact on Application: While copper can work well with various leather types, it is best suited for lighter applications where intricate designs are required.

Considerations for International Buyers: Buyers should consider the cost-effectiveness of copper, especially in regions where import tariffs may affect pricing.

Illustrative image related to hot leather stamp

Summary Table of Material Selection for Hot Leather Stamps

| Material | Typical Use Case for hot leather stamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Custom branding on various leather types | High durability and excellent impression quality | Higher initial cost and complex manufacturing | Elevado |

| Aluminum | Budget-friendly options for small operations | Lightweight and cost-effective | Less durable, prone to wear over time | Low |

| Steel | Heavy-duty industrial applications | Exceptional strength and longevity | More complex and costly manufacturing | Elevado |

| Copper | Intricate designs on lighter leather | Easy to shape for custom designs | Softer material, shorter lifespan | Medium |

This analysis provides a comprehensive overview of the materials used in hot leather stamps, allowing B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hot leather stamp

What are the Key Stages in the Manufacturing Process of Hot Leather Stamps?

The manufacturing process of hot leather stamps involves several key stages that ensure high-quality output tailored to the specific needs of B2B buyers. Understanding these stages can help buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials are Typically Used?

The primary materials used in the production of hot leather stamps include solid brass and high-grade steel. Brass is favored for its durability and resistance to wear, making it ideal for creating long-lasting stamps. Steel, often used for hot stamping machines, provides strength and precision.

Before manufacturing begins, these materials are sourced from reputable suppliers who adhere to international quality standards. Buyers should ensure that the materials meet industry specifications for hardness and heat resistance, as these factors significantly impact the performance of the final product.

Illustrative image related to hot leather stamp

Forming: How are Hot Leather Stamps Shaped?

The forming stage typically involves CNC machining or other precision techniques to shape the stamps. CNC (Computer Numerical Control) machining allows for high precision and repeatability, ensuring that each stamp meets the exact specifications provided by the buyer.

During this stage, the design is transferred to the material, where it is engraved or cut using advanced machinery. This process can include several operations, such as milling, drilling, and grinding, to achieve the desired depth and clarity of the stamp design.

Assembly: What Components are Assembled?

In the assembly phase, various components of the hot stamping machine are brought together. This includes the heating element, which is critical for the stamping process, as well as any additional features such as adjustable temperature controls.

The assembly process must be conducted with precision to ensure that all parts fit together correctly and function as intended. Proper alignment is crucial, as misalignment can lead to inconsistent stamping results, affecting the overall quality of the stamped leather products.

Finishing: How is Quality Enhanced Post-Production?

Finishing is the final stage in the manufacturing process, where the stamps undergo surface treatment to enhance their durability and appearance. This may include polishing, coating, or applying protective finishes to prevent corrosion and wear over time.

Quality checks during this phase ensure that the stamps not only meet aesthetic standards but also function effectively in practical applications. Buyers should inquire about the specific finishing processes used, as these can significantly influence the longevity and performance of the stamps.

How is Quality Assurance Implemented in Hot Leather Stamp Production?

Quality assurance is a critical aspect of the manufacturing process for hot leather stamps, ensuring that products meet both international and industry-specific standards.

What International Standards Should Buyers Look For?

When selecting suppliers, B2B buyers should look for compliance with international quality management standards such as ISO 9001. This standard ensures that companies have a consistent quality management system in place, which is vital for maintaining product quality over time.

Additionally, industry-specific certifications such as CE marking, which indicates compliance with European safety standards, and API (American Petroleum Institute) standards for materials used in specific applications, should also be considered. These certifications provide assurance that the stamps are manufactured according to rigorous safety and quality protocols.

What are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential throughout the manufacturing process to catch any defects early. Common checkpoints include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and detect any deviations from quality standards.

-

Final Quality Control (FQC): After production, finished products are thoroughly inspected for any defects in design, material, or workmanship before they are packaged and shipped.

These QC checkpoints help mitigate risks and ensure that the final products meet the required specifications.

What Testing Methods are Commonly Used?

Common testing methods for hot leather stamps include:

-

Dimensional Inspection: Measuring the dimensions of the stamps to ensure they meet design specifications.

-

Hardness Testing: Assessing the hardness of the material to ensure it can withstand repeated use without degrading.

-

Thermal Testing: Evaluating the performance of the heating elements to ensure they reach and maintain the necessary temperatures for effective stamping.

B2B buyers should request documentation of these tests to verify that the products meet their quality requirements.

Illustrative image related to hot leather stamp

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should take proactive steps to verify their quality control processes.

What Audits Should Buyers Conduct?

Buyers can conduct on-site audits of suppliers to assess their manufacturing processes and quality control measures. During these audits, it is essential to evaluate the machinery used, the qualifications of the workforce, and the implementation of quality standards.

Buyers should also review the supplier’s quality management documentation, including quality control plans, inspection reports, and certifications. This documentation provides insight into the supplier’s commitment to maintaining quality throughout the production process.

Illustrative image related to hot leather stamp

How Important are 3rd-Party Inspections?

Engaging third-party inspection services can further enhance confidence in the quality of the products. These independent inspectors can conduct comprehensive evaluations at various stages of the manufacturing process, providing unbiased reports on compliance with quality standards.

What Are the QC Nuances for International B2B Buyers?

International B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

How Do Regional Standards Differ?

Different regions may have varying regulatory requirements and standards for manufacturing processes. Buyers should familiarize themselves with these regional standards to ensure compliance. For instance, products sold in Europe may require CE marking, while those in the Middle East may need to adhere to specific local regulations.

What Role Does Communication Play?

Clear communication with suppliers regarding quality expectations, certifications, and compliance requirements is crucial. Buyers should establish a solid line of communication to address any issues promptly and ensure that all parties are aligned on quality standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for hot leather stamps is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can ensure they select suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot leather stamp’

When sourcing a hot leather stamp, it is essential to follow a structured approach to ensure you acquire a product that meets your specific requirements. This guide provides a practical checklist to help B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for the hot leather stamp, including size, material, and design intricacies. This step is crucial as it will guide your supplier selection and ensure that the final product aligns with your branding needs. Consider factors such as the type of leather you will be stamping, as different materials may require varying temperatures and stamp designs.

Step 2: Research Suppliers with Industry Experience

Identify suppliers who specialize in hot leather stamps and have a proven track record in the industry. Look for companies that have been in the market for several years and can provide testimonials or case studies from reputable clients. This helps ensure that you are partnering with a supplier who understands the nuances of leather stamping and can deliver high-quality products.

Step 3: Evaluate Supplier Certifications and Quality Standards

Before making a purchase, verify that potential suppliers adhere to industry certifications and quality standards. This may include ISO certifications or compliance with local manufacturing regulations. Ensuring that your supplier meets these standards will help mitigate risks associated with product defects and ensure consistent quality in your orders.

Step 4: Request Samples for Assessment

Always request samples of the hot leather stamps you are considering. Testing samples allows you to evaluate the quality of the stamp, including the depth of the imprint and the ease of use. Pay attention to how well the stamp performs on different types of leather, as this will directly impact the quality of your finished products.

Step 5: Inquire About Customization Options

Discuss customization capabilities with your potential suppliers. A good supplier should offer options for creating custom designs that reflect your brand identity. Ensure they can accommodate your specific design needs, including size and complexity, and ask about the lead time for custom orders.

Step 6: Assess Pricing and Payment Terms

Compare pricing structures from different suppliers, taking into account the overall value rather than just the cost. Be sure to clarify payment terms and conditions, including any upfront deposits or bulk order discounts. This step is vital to ensure that you remain within budget while securing high-quality products.

Step 7: Review Shipping and Delivery Policies

Finally, confirm the shipping and delivery options provided by your supplier. Ensure that they can meet your timelines and discuss any associated costs. Understanding the logistics involved will help you plan your inventory and manage customer expectations effectively.

By following these steps, you can confidently navigate the sourcing process for hot leather stamps, ensuring you select a supplier that aligns with your business goals and quality standards.

Comprehensive Cost and Pricing Analysis for hot leather stamp Sourcing

What Are the Key Cost Components in Sourcing Hot Leather Stamps?

When sourcing hot leather stamps, several cost components come into play. Understanding these components can help buyers make informed decisions and negotiate better deals.

-

Materials: The primary material for hot leather stamps is typically brass, known for its durability and ability to retain fine details. Other materials, like aluminum, may be used but generally offer lower longevity. The choice of material significantly impacts the overall cost, with brass being more expensive due to its robustness.

-

Labor: Labor costs encompass the wages paid to skilled artisans for crafting custom stamps. This can vary widely based on the region of production. For instance, labor costs in regions with a high skill level, such as Germany, may be higher than in some African or South American countries.

-

Manufacturing Overhead: This includes costs related to the operation of machinery and facilities where the stamps are produced. Overhead costs can vary depending on the supplier’s location and efficiency.

-

Tooling: Custom tooling for the creation of specific designs adds to the initial cost. This includes CNC machining setup and maintenance. The more intricate the design, the higher the tooling cost.

-

Quality Control (QC): Ensuring that each stamp meets quality standards incurs additional costs. Rigorous QC processes are essential, especially for B2B transactions where consistency is crucial.

-

Logistics: Shipping and handling costs can fluctuate based on the distance between the supplier and the buyer, as well as the chosen Incoterms. International buyers should be particularly aware of potential customs duties and taxes.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. This margin can vary significantly based on market demand and competition.

How Do Price Influencers Affect Hot Leather Stamp Costs?

Several factors influence the pricing of hot leather stamps, and understanding these can aid buyers in negotiating better terms.

-

Volume/MOQ: The minimum order quantity (MOQ) significantly affects price. Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should consider their projected needs to optimize order sizes.

-

Specifications and Customization: The complexity and specificity of a design can increase costs. Customization requests, such as specific dimensions or unique engravings, may incur additional fees.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (e.g., eco-friendly sourcing) can raise prices. Buyers seeking to ensure product integrity should factor in these potential costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with strong track records may charge higher prices but offer better quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate who is responsible for shipping costs, insurance, and tariffs, which can significantly affect the total landed cost.

What Are Effective Buyer Tips for Sourcing Hot Leather Stamps?

To navigate the complexities of sourcing hot leather stamps effectively, buyers can employ several strategies:

-

Negotiation: Engage suppliers in discussions about pricing, particularly if placing large orders. Be prepared to discuss potential discounts based on volume or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential replacement costs over time. Selecting durable materials can minimize long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, understanding local market conditions can provide leverage in negotiations.

-

Request Samples: Before finalizing orders, request samples to evaluate quality. This can also help establish trust and ensure the supplier meets your specifications.

Disclaimer on Indicative Prices

Pricing for hot leather stamps can vary widely based on the factors discussed above. The prices mentioned in references (e.g., around $103 to $148 for custom stamps) are indicative and subject to change based on market dynamics, supplier pricing strategies, and specific buyer requirements. Always confirm current pricing directly with suppliers before making purchasing decisions.

Illustrative image related to hot leather stamp

Alternatives Analysis: Comparing hot leather stamp With Other Solutions

In the competitive landscape of leather branding, businesses often seek the best methods to personalize their products effectively. While hot leather stamping is a popular choice, several alternative solutions exist that can also achieve high-quality branding. Understanding the advantages and limitations of each method can help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Hot Leather Stamp | Custom Handheld Steel Stamp | Electric Branding Iron |

|---|---|---|---|

| Performance | Produces deep, lasting impressions on various leather types. | Effective for smaller, detailed designs but may lack consistency for larger brands. | Consistent and clean results, ideal for larger logos and high-volume production. |

| Cost | Generally priced around $148 for a basic setup. | Lower initial cost starting at $103, but may require additional tools. | Higher initial investment, typically over $200, depending on features. |

| Ease of Implementation | Requires minimal setup; user-friendly. | Simple to use, but requires manual force which can lead to uneven results. | Easy to operate with adjustable temperature controls for various leather types. |

| Maintenance | Low maintenance; durable brass material. | Moderate; needs careful handling to avoid damage. | Requires regular cleaning and occasional servicing to maintain temperature accuracy. |

| Best Use Case | Best for small to medium production runs with intricate designs. | Suitable for hobbyists or small businesses focusing on detailed work. | Ideal for large-scale operations needing consistent branding across multiple products. |

What Are the Advantages and Disadvantages of Using a Custom Handheld Steel Stamp?

Custom handheld steel stamps are a popular alternative for businesses that prioritize craftsmanship. They are generally more affordable than hot leather stamps, making them accessible for small businesses or startups. However, the need for manual force can lead to inconsistencies in the branding, particularly when stamping larger designs. This method is better suited for detailed, smaller impressions and may not perform as well in high-volume production settings where uniformity is key.

How Does an Electric Branding Iron Compare to Hot Leather Stamping?

Electric branding irons offer a modern alternative to hot leather stamping, particularly for businesses that require a high degree of consistency. These tools allow users to adjust the temperature according to the type of leather being used, which is essential for achieving optimal results across various materials. While the initial cost can be higher, the efficiency and quality of branding can lead to cost savings over time, especially in large-scale operations. However, maintenance can be more demanding, as these devices require regular cleaning and calibration.

Conclusion: Which Solution Should B2B Buyers Choose for Leather Branding?

When selecting the right branding solution, B2B buyers should consider several factors, including production volume, design complexity, and budget constraints. Hot leather stamping is ideal for businesses that value high-quality, intricate designs and can manage smaller production runs. In contrast, custom handheld steel stamps may appeal to artisans focusing on detailed work, while electric branding irons are perfect for companies seeking efficiency and consistency in larger production environments. Ultimately, the best choice will align with the specific needs and operational capabilities of the business, ensuring that the branding method enhances both product quality and brand identity.

Essential Technical Properties and Trade Terminology for hot leather stamp

What Are the Key Technical Properties of Hot Leather Stamps?

When considering hot leather stamps for branding or embossing leather products, understanding their technical specifications is crucial for ensuring quality and effectiveness. Here are some of the essential properties to consider:

-

Material Composition

Hot leather stamps are typically made from high-grade materials such as brass or steel. Brass is known for its durability and resistance to corrosion, making it ideal for high-volume applications. Steel, while slightly less resistant to wear, can provide a sharper imprint. The choice of material impacts not only the quality of the stamp but also its longevity, which is critical for businesses that rely on consistent branding. -

Temperature Control

An adjustable temperature range (usually between 200°C to 450°C) is vital for achieving optimal results across different types of leather. Different leathers, such as vegetable-tanned and chrome-tanned, require specific heat levels to ensure the best imprint quality. This feature is particularly important for B2B buyers who work with diverse leather types and need to maintain a high standard of branding across their product lines. -

Stamp Size and Design Capability

The size of the stamp can vary significantly, often accommodating designs up to 10 cm². Understanding the maximum dimensions is essential for businesses that intend to use intricate logos or larger branding elements. A larger stamp can facilitate more elaborate designs, allowing for greater customization and brand representation. -

Interchangeability and Compatibility

Many hot leather stamping machines offer interchangeable stamps, which provide flexibility for businesses to switch between designs quickly. This feature is particularly beneficial for companies that handle multiple brands or product lines, as it reduces downtime and increases operational efficiency. -

Power Rating

The power rating of the hot stamping machine (e.g., 60W or 500W) affects its efficiency and the speed at which it can operate. Higher wattage machines can heat up more quickly and maintain consistent temperatures, which is crucial for high-volume production environments where time efficiency is a priority. -

Durability and Warranty

A warranty period (often 12 months) signals the manufacturer’s confidence in their product’s durability. For B2B buyers, this is an assurance of quality and a safeguard against potential manufacturing defects, making it an important consideration when selecting equipment for leather branding.

What Are Common Trade Terms Related to Hot Leather Stamps?

Familiarity with industry jargon can streamline communication and negotiations in the B2B landscape. Here are several essential terms that buyers should know:

Illustrative image related to hot leather stamp

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hot leather stamps, an OEM may provide custom stamping solutions tailored to a specific brand’s requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for businesses to ensure they can meet their production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for a specific product or service. It’s a crucial step in procurement, allowing buyers to compare options and make informed decisions. -

Incoterms (International Commercial Terms)

These are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping, insurance, and liability arrangements, which are essential for global trade. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving it. This metric is particularly important for B2B buyers who need to plan their inventory and production schedules effectively. -

Customization

This term refers to the ability to tailor products to meet specific requirements, such as unique logo designs or dimensions for hot leather stamps. Customization is vital for brands that want to differentiate their products in a competitive market.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding their hot leather stamping needs, ensuring they select the right tools for their branding efforts.

Navigating Market Dynamics and Sourcing Trends in the hot leather stamp Sector

What Are the Current Market Dynamics and Key Trends in the Hot Leather Stamp Sector?

The global market for hot leather stamps is experiencing significant growth, driven by the increasing demand for personalized leather goods and branding solutions. B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany, are increasingly seeking high-quality stamping tools that allow for customization and branding on various leather products. The rise of e-commerce platforms has also facilitated access to specialized equipment and materials, enabling businesses to source hot leather stamps more conveniently.

Emerging technologies are shaping the hot leather stamp sector, with advancements in CNC machining and electric branding irons allowing for precision and efficiency. These innovations not only enhance the quality of the stamped designs but also reduce production times, catering to the growing need for quick turnaround times in the fashion and accessory industries. Additionally, the introduction of variable-temperature systems in branding irons ensures that businesses can work with different types of leather, optimizing results and minimizing waste.

The market is also witnessing a trend towards customization, with B2B buyers looking for suppliers that offer bespoke solutions tailored to their branding needs. As the leather goods market becomes increasingly competitive, companies are focusing on unique branding techniques to differentiate their products. This trend is amplified by the growing popularity of leather crafting workshops and DIY projects, as individuals and small businesses seek tools that enable them to create personalized leather items.

How Is Sustainability and Ethical Sourcing Impacting the Hot Leather Stamp Industry?

Sustainability is becoming a crucial consideration for B2B buyers in the hot leather stamp sector, as companies increasingly recognize the environmental impact of leather production. The leather industry has faced criticism for its resource-intensive practices, including high water usage and pollution from tanning processes. As a result, buyers are seeking suppliers who prioritize ethical sourcing and sustainable practices, such as using vegetable-tanned leather or sourcing materials from certified suppliers.

Ethical supply chains are essential for fostering trust and transparency between buyers and suppliers. Businesses are now more inclined to partner with manufacturers who can provide information on the sourcing of their materials, including certifications that verify sustainable practices. Green certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, are becoming increasingly important for buyers who wish to demonstrate their commitment to sustainability.

The demand for ‘green’ materials is also shaping product offerings in the hot leather stamp sector. Suppliers are now innovating to provide eco-friendly stamping solutions, including biodegradable foils and non-toxic adhesives, aligning with the broader trend towards sustainable production. By prioritizing sustainability and ethical sourcing, businesses can not only meet regulatory demands but also appeal to environmentally conscious consumers.

How Has the Hot Leather Stamp Sector Evolved Over Time?

The evolution of the hot leather stamp sector is closely tied to advancements in technology and changes in consumer preferences. Historically, leather branding was a manual process, relying on handheld tools and mallets. This traditional method, while effective, was labor-intensive and limited in terms of design complexity.

With the advent of electric branding irons and CNC machining, the industry has transformed dramatically. These technological advancements have allowed for greater precision, speed, and the ability to produce intricate designs that were previously unattainable. As the demand for customization has surged, manufacturers have adapted by offering more versatile and user-friendly tools. The combination of traditional craftsmanship with modern technology continues to shape the landscape of the hot leather stamp sector, making it an exciting field for international B2B buyers seeking quality and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of hot leather stamp

-

1. How do I choose the right hot leather stamp for my products?

Selecting the appropriate hot leather stamp involves considering the type of leather you will be using, such as vegetable tanned or chrome tanned leather. Evaluate the design complexity and size; larger designs may require a more powerful branding iron. Ensure the stamp material is durable; brass is often preferred for its longevity. Additionally, assess the heat settings of the branding tool to accommodate different leather types, allowing for a crisp, professional finish. -

2. What is the best method for hot stamping leather?

The best method for hot stamping leather depends on your specific needs. For intricate designs and logos, an electric branding iron with adjustable temperature settings is ideal, as it can accommodate various leather types. Ensure your leather is free of sealants, which can melt during stamping. For bulk production, hot stamping provides consistency and efficiency, making it preferable for branding larger quantities of items. -

3. How can I customize my hot leather stamp design?

Customization of your hot leather stamp can be achieved by providing your design in a vector format (like AI or PDF) to the supplier. Many manufacturers can also convert JPGs or other formats. Discuss the dimensions and depth of the design, as these factors influence the stamp’s effectiveness. A reputable supplier will collaborate with you to ensure your design meets the necessary specifications for high-quality stamping results. -

4. What are the minimum order quantities (MOQs) for hot leather stamps?

Minimum order quantities for hot leather stamps can vary significantly based on the supplier and the complexity of the design. Some manufacturers may have a low MOQ for basic designs, while customized or more intricate stamps may require higher quantities. It’s advisable to communicate your needs directly with the supplier to negotiate MOQs that align with your business requirements, especially for international orders. -

5. What payment terms should I expect when sourcing hot leather stamps internationally?

Payment terms for international orders typically vary by supplier and may include options such as upfront payment, partial payments, or net terms based on creditworthiness. Common methods include bank transfers, credit cards, and platforms like PayPal. It’s crucial to clarify payment terms before placing an order to avoid misunderstandings, and ensure that the supplier provides a secure payment method to protect your transaction. -

6. How do I ensure quality assurance (QA) for my hot leather stamps?

To ensure quality assurance for your hot leather stamps, request samples before committing to larger orders. Evaluate the stamp’s durability, heat retention, and the clarity of the imprint on leather. Establish clear quality standards with your supplier, including specifications for materials, dimensions, and functionality. Regular communication and feedback during the production process can also help maintain quality and address any issues promptly. -

7. What are the logistics considerations for shipping hot leather stamps internationally?

When shipping hot leather stamps internationally, consider the shipping method, estimated delivery times, and costs. Choose a reliable logistics partner experienced in handling international shipments to mitigate delays and ensure safe delivery. Understand any customs duties or taxes applicable in your country to avoid unexpected costs. Additionally, confirm packaging standards with your supplier to protect the stamps during transit. -

8. How can I vet suppliers for hot leather stamps to ensure reliability?

Vetting suppliers for hot leather stamps involves researching their reputation, customer reviews, and industry experience. Request references and check their manufacturing capabilities to ensure they can meet your quality standards. Verify certifications and compliance with international trade regulations, particularly if sourcing from regions with different standards. Engaging in direct communication and requesting samples can further confirm their reliability before making a significant investment.

Top 5 Hot Leather Stamp Manufacturers & Suppliers List

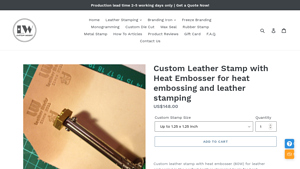

1. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Custom Leather Stamp with Heat Embosser for leather embossing and leather stamping. Regular price: US$148.00. Custom Stamp Size options: Up to 1.25 x 1.25 inch and Up to 1.5 x 1.5 inch. Power: 60W (110V / 220V). Adjustable temperature: 200-450 °C. Works with vegetable tanned leather, suede, and PU leather. Gold foiling possible for small stamps (within 1x1cm). Custom stamp specifications: Material…

2. Infinity Stamps – Hot Stamps for Leather

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Hot Stamps for Leather – Infinity Stamps Inc. offers a variety of stamping products specifically designed for leather. The product range includes: Leather Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, and Hot Stamps. All products are made in the USA and the company has been family-owned for over 25 years. Customers can contact a stamping specialist at 818-576-1188 or…

3. RM Leather Supply – Hot Stamp Metallic Foil

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Hot Stamp Metallic Foil”, “price”: “$8.99”, “shipping”: “Free shipping within the continental US”, “dimensions”: {“roll_length”: “~ 120 meters”, “width_options”: [“30mm”, “60mm”]}, “colors_available”: “18 color options”, “application”: “Designed for hot stamping applications using a metal stamp on leather or paper substrates”, “finish_options”: [“shiny”, “matte”], “compatibility”…

4. Artisan Leather Supply – Hot Foil Stamping & Creasing Machines

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: Maxita Hot Foil Stamping Machine – $950, Maxita Hot Foil Stamping Machine – Compact – From $70, Multi-function Stamping Machine – From $650, ARTISAN Electric Creaser – $135, Electric Creaser Machine – From $285, Small Creaser Tips – $14.50, Electric Creaser Tip – From $17, Mini Creaser Tips – $14, Multi-function Steel Press – From $325, Starter Series Creaser Tips – $14, Brass Letter Set – $75, Sp…

5. Profoil – ProPress 310

Domain: profoil.com

Registered: 2000 (25 years)

Introduction: Hot Stamping Leather involves using metallic or colored foils to embellish leather products, creating a luxurious and customized feel. To start, you need a machine capable of stamping leather, such as Profoil’s ProPress 310 for beginners, which produces up to 1 ton of pressure, or the ProPress 450 for larger images, producing up to 3 tons of pressure. You also need a metal stamp (die or cliché), s…

Strategic Sourcing Conclusion and Outlook for hot leather stamp

In the evolving landscape of leather goods manufacturing, strategic sourcing of hot leather stamps is crucial for businesses aiming to differentiate their products in competitive markets. Customization options, such as adjustable temperature controls and material specifications, enable brands to enhance their product appeal while ensuring quality and consistency. By opting for high-quality brass stamps and electric branding irons, companies can achieve durable and aesthetically pleasing results, meeting the demands of diverse leather types, from vegetable-tanned to chrome-tanned.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing will not only streamline production processes but also foster brand loyalty through distinctive branding solutions. As the market continues to grow, adopting innovative stamping techniques can set your business apart, providing a unique value proposition to your clientele.

Now is the time to engage with suppliers who understand your specific needs and can offer tailored solutions. Embrace the future of leather branding by investing in quality hot leather stamps, and position your brand for success in an increasingly global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.