Introduction: Navigating the Global Market for car upholstery fabric manufacturers

Navigating the global market for car upholstery fabric manufacturers presents a unique challenge for B2B buyers seeking quality materials that meet diverse regional demands. As buyers from Africa, South America, the Middle East, and Europe (including countries like Saudi Arabia and Nigeria) look to source durable and aesthetically pleasing upholstery fabrics, they must consider factors such as material types, applications, supplier reliability, and cost-effectiveness. This guide aims to streamline the decision-making process by providing an in-depth analysis of various upholstery materials, their benefits, and ideal applications.

In this comprehensive resource, we will explore the most common types of upholstery fabrics, including leather, vinyl, and synthetic options, along with their respective advantages and disadvantages. Additionally, we will cover essential aspects of supplier vetting, ensuring that buyers can confidently select reputable manufacturers capable of delivering high-quality products. Cost considerations will also be addressed, allowing buyers to strike the right balance between budget and durability.

By equipping international B2B buyers with valuable insights and actionable strategies, this guide empowers them to make informed purchasing decisions that enhance their vehicle offerings. Whether you are looking to upgrade existing inventory or explore new upholstery solutions, understanding the global landscape of car upholstery fabric manufacturers is vital for staying competitive in today’s market.

Table Of Contents

- Top 7 Car Upholstery Fabric Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car upholstery fabric manufacturers

- Understanding car upholstery fabric manufacturers Types and Variations

- Key Industrial Applications of car upholstery fabric manufacturers

- 3 Common User Pain Points for ‘car upholstery fabric manufacturers’ & Their Solutions

- Strategic Material Selection Guide for car upholstery fabric manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for car upholstery fabric manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car upholstery fabric manufacturers’

- Comprehensive Cost and Pricing Analysis for car upholstery fabric manufacturers Sourcing

- Alternatives Analysis: Comparing car upholstery fabric manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for car upholstery fabric manufacturers

- Navigating Market Dynamics and Sourcing Trends in the car upholstery fabric manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car upholstery fabric manufacturers

- Strategic Sourcing Conclusion and Outlook for car upholstery fabric manufacturers

- Important Disclaimer & Terms of Use

Understanding car upholstery fabric manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Upholstery | Luxurious feel, durable, ages well | High-end automotive, luxury vehicles | Pros: Long-lasting, easy to clean, elegant. Cons: Expensive, requires maintenance. |

| Vinyl Upholstery | Affordable, easy to clean, stain-resistant | Mass-market vehicles, fleet applications | Pros: Budget-friendly, versatile. Cons: Less breathable, can feel sticky in heat. |

| Fabric Upholstery | Soft, breathable, customizable in design | Family vehicles, comfort-focused models | Pros: Comfortable, wide variety. Cons: Can stain easily, requires more upkeep. |

| Synthetic Fabrics | Soft feel, durable, stain-resistant | Budget-conscious markets, rentals | Pros: Affordable, easy to maintain. Cons: Less luxurious, may show wear over time. |

| Eco-friendly Fabrics | Made from sustainable materials, environmentally friendly | Green automotive brands, eco-conscious markets | Pros: Sustainable, durable. Cons: Limited availability, potentially higher cost. |

What Are the Characteristics of Leather Upholstery in B2B Purchases?

Leather upholstery is synonymous with luxury and durability, making it a preferred choice for high-end automotive manufacturers and custom vehicle restorers. Its ability to withstand wear while providing an elegant aesthetic appeals to businesses targeting affluent customers. When considering leather, B2B buyers should evaluate the source of the leather, maintenance requirements, and overall cost implications, as high-quality leather often commands a premium price but can enhance vehicle resale value significantly.

How Does Vinyl Upholstery Meet Diverse B2B Needs?

Vinyl upholstery serves as a cost-effective alternative to leather, providing a similar appearance and ease of maintenance. It is particularly popular among manufacturers of mass-market vehicles and fleet services due to its affordability and stain-resistant properties. Businesses should consider the longevity of vinyl in high-traffic applications, as well as the potential for color and texture variations to meet branding needs.

What Advantages Does Fabric Upholstery Offer for Family Vehicles?

Fabric upholstery is characterized by its softness and breathability, making it an ideal choice for family-oriented vehicles. Its wide range of colors and patterns allows for customization, appealing to businesses that prioritize comfort and aesthetic appeal. B2B buyers should weigh the trade-offs of fabric, such as its susceptibility to stains and the need for regular cleaning, against the comfort and personalization options it provides.

Why Choose Synthetic Fabrics for Budget-Conscious Applications?

Synthetic fabrics like microfiber and polyester are gaining traction in the automotive industry due to their affordability and durable nature. These materials are ideal for rental services and budget-friendly vehicle lines. When purchasing synthetic fabrics, businesses should assess the balance between cost, comfort, and durability, as well as the potential for wear over time, which could affect long-term customer satisfaction.

What Are the Benefits of Eco-Friendly Fabrics in the Automotive Sector?

Eco-friendly fabrics are crafted from sustainable materials, appealing to automotive brands focused on environmental responsibility. These fabrics not only provide durability but also align with the growing consumer demand for green products. B2B buyers should consider the availability and pricing of eco-friendly options, as they may come at a premium but can enhance brand reputation and appeal to environmentally conscious consumers.

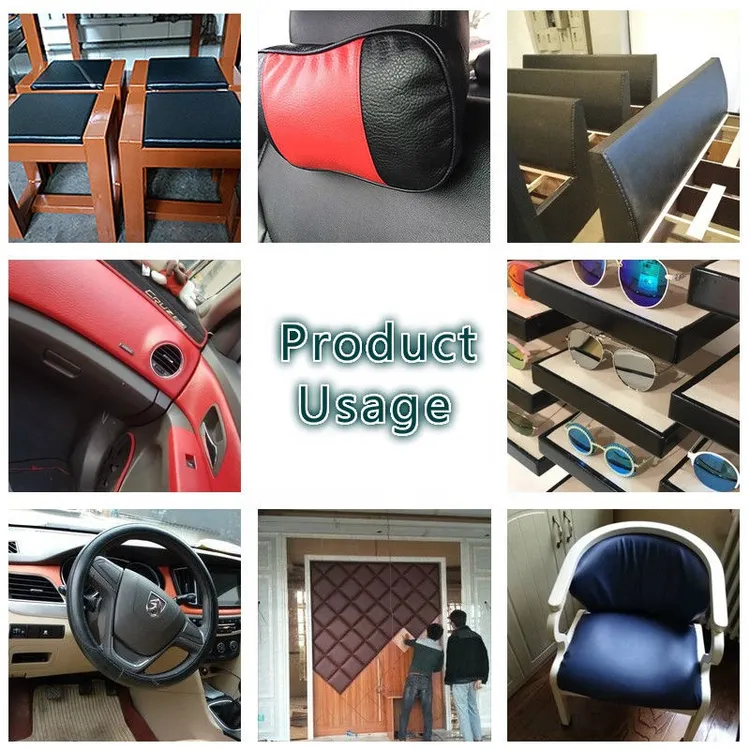

Illustrative image related to car upholstery fabric manufacturers

Key Industrial Applications of car upholstery fabric manufacturers

| Industry/Sector | Specific Application of car upholstery fabric manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicle interiors | Enhances vehicle aesthetics and comfort, improving marketability | Quality of materials, compliance with safety standards, bulk pricing |

| Fleet Management | Upholstery for commercial vehicle fleets | Reduces maintenance costs and improves driver satisfaction | Durability, ease of cleaning, availability of custom designs |

| Automotive Repair & Restoration | Reupholstering services for vehicles | Increases vehicle resale value and customer satisfaction | Variety of fabric options, expertise in installation, warranty offers |

| Luxury Vehicle Customization | Bespoke upholstery for high-end vehicles | Provides unique branding opportunities and enhances luxury appeal | Availability of premium materials, customization options, lead times |

| Public Transportation | Upholstery for buses and coaches | Improves passenger comfort and safety, enhances brand image | Compliance with fire safety regulations, durability, maintenance requirements |

How is Car Upholstery Fabric Used in Automotive Manufacturing?

In automotive manufacturing, car upholstery fabric manufacturers supply materials for vehicle interiors, including seats, door panels, and headliners. The use of high-quality fabrics enhances the vehicle’s aesthetic appeal and comfort, making it more attractive to consumers. Manufacturers must ensure that the materials comply with safety standards and are durable enough to withstand wear and tear. For international B2B buyers, understanding local regulations and consumer preferences is crucial when sourcing upholstery materials.

What Role Does Upholstery Fabric Play in Fleet Management?

In fleet management, car upholstery fabric manufacturers provide durable and easy-to-clean materials for commercial vehicles. This application is vital as it reduces maintenance costs and enhances driver satisfaction, leading to improved productivity. Buyers in this sector should focus on sourcing fabrics that are resistant to stains and wear, ensuring long-lasting performance. Additionally, the ability to customize designs can help fleet operators maintain a professional image.

How is Upholstery Fabric Utilized in Automotive Repair & Restoration?

Automotive repair and restoration businesses rely on car upholstery fabric manufacturers to provide materials for reupholstering vehicles. This process can significantly increase a vehicle’s resale value and improve customer satisfaction. Buyers in this industry must consider the variety of fabric options available, as well as the expertise of the manufacturers in installation techniques. Warranty offers can also provide added assurance regarding the quality of the materials used.

Why is Custom Upholstery Important for Luxury Vehicle Customization?

For luxury vehicle customization, car upholstery fabric manufacturers offer bespoke solutions that cater to high-end clientele. This application allows for unique branding opportunities and enhances the overall luxury appeal of the vehicle. Buyers need to ensure the availability of premium materials and customization options that align with their brand’s identity. Lead times for production should also be considered, as luxury clients often expect timely delivery.

How Does Upholstery Fabric Enhance Public Transportation?

In public transportation, upholstery fabric manufacturers supply materials for buses and coaches, focusing on passenger comfort and safety. The right upholstery can improve the overall travel experience and enhance the brand image of transport services. Buyers in this sector must prioritize compliance with fire safety regulations and durability, ensuring that the upholstery withstands heavy use. Maintenance requirements should also be evaluated to minimize operational costs over time.

3 Common User Pain Points for ‘car upholstery fabric manufacturers’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing Upholstery Fabrics

The Problem:

B2B buyers often encounter challenges when sourcing high-quality upholstery fabrics that meet specific durability and aesthetic requirements. This is especially critical in markets where vehicles are subjected to harsh conditions, such as extreme temperatures or heavy usage. Buyers may find themselves receiving samples that do not reflect the final product’s quality, leading to frustration and potential financial loss if they invest in inferior materials. This issue is compounded when working across international borders, where variations in manufacturing standards can further complicate the selection process.

The Solution:

To mitigate quality issues, buyers should establish a comprehensive vetting process for upholstery fabric manufacturers. This includes requesting detailed product specifications and certifications that confirm compliance with international standards. Engaging in direct communication with manufacturers can help clarify expectations and ensure alignment on quality standards. Additionally, consider visiting manufacturing facilities if possible or utilizing third-party inspection services to verify material quality before bulk orders. Building long-term relationships with trusted suppliers can also lead to more reliable quality assurance over time.

Illustrative image related to car upholstery fabric manufacturers

Scenario 2: Navigating Customization Challenges in Upholstery Design

The Problem:

Customization is a significant aspect of automotive upholstery, yet many B2B buyers struggle to communicate their design needs effectively to manufacturers. This challenge can stem from a lack of understanding of available materials, patterns, and finishes, leading to misalignment in expectations and outcomes. Buyers may receive upholstery that does not meet their design vision, resulting in wasted time and resources on revisions and remakes.

The Solution:

To overcome customization challenges, buyers should develop a clear and detailed specification document that outlines their design requirements, including material types, colors, patterns, and textures. Utilizing digital tools such as 3D design software can provide a visual representation of the final product, facilitating better communication with manufacturers. Additionally, organizing workshops or brainstorming sessions with design teams and manufacturers can foster collaborative creativity and ensure that the final product aligns with the buyer’s vision. Implementing a prototype phase before mass production can also help identify potential issues early in the process.

Scenario 3: Balancing Cost and Quality in Upholstery Fabric Procurement

The Problem:

B2B buyers often face the dilemma of balancing cost and quality when procuring upholstery fabrics. While budget constraints are a constant reality, opting for cheaper materials can compromise the durability and appearance of the finished product, ultimately affecting customer satisfaction and brand reputation. Buyers may feel pressured to make quick decisions, leading to regret when they realize that lower-cost fabrics do not meet performance expectations.

Illustrative image related to car upholstery fabric manufacturers

The Solution:

To effectively balance cost and quality, buyers should conduct a thorough market analysis to understand the price ranges for various upholstery materials. Establishing a budget that allows for flexibility in quality can help in sourcing better materials without overspending. Buyers should also explore options for bulk purchasing or long-term contracts with manufacturers, which can lead to cost savings while ensuring a consistent quality supply. Implementing a tiered pricing strategy, where different fabric grades are offered at varying price points, can also cater to diverse customer needs without sacrificing quality. Furthermore, fostering open discussions with suppliers about potential cost-saving measures, such as alternative materials or production efficiencies, can lead to mutually beneficial solutions.

Strategic Material Selection Guide for car upholstery fabric manufacturers

What Are the Key Properties of Leather Upholstery in Car Manufacturing?

Leather upholstery is a classic choice for car interiors, known for its luxurious appearance and durability. It typically offers excellent temperature resistance, maintaining comfort in both hot and cold conditions. Leather can withstand pressure well, making it suitable for high-use applications. However, it requires proper maintenance to prevent cracking and fading, particularly in harsh climates.

Pros and Cons of Leather Upholstery

Leather’s main advantages include its long lifespan, ease of cleaning, and sophisticated aesthetic appeal. However, it comes with a higher price point and requires regular conditioning to maintain its quality. Additionally, leather can become uncomfortably hot in summer and cold in winter, which may not be ideal for all regions.

Impact on Application

Leather is compatible with a range of automotive applications, from luxury vehicles to high-end sports cars. Its aesthetic appeal can significantly enhance the perceived value of a vehicle, making it a preferred choice among manufacturers targeting premium markets.

Considerations for International Buyers

International buyers, especially from regions like the Middle East and Africa, should consider local climate conditions when selecting leather upholstery. Compliance with international standards such as ASTM for material performance is essential, as well as understanding local preferences for luxury versus practicality.

Illustrative image related to car upholstery fabric manufacturers

How Does Vinyl Upholstery Compare for Car Interiors?

Vinyl upholstery is a cost-effective alternative to leather, offering a similar look without the associated expenses. It is highly resistant to stains and moisture, making it ideal for families and commercial vehicles. Vinyl performs well under pressure and is relatively easy to clean, which is crucial for high-traffic applications.

Pros and Cons of Vinyl Upholstery

The primary advantages of vinyl include its affordability, durability, and variety of colors and textures. However, it lacks the breathability of leather and can become sticky in hot weather, which may deter some buyers. Additionally, while vinyl is durable, it may not age as gracefully as leather, leading to a less appealing appearance over time.

Impact on Application

Vinyl is particularly suited for vehicles that experience high wear and tear, such as taxis or family cars. Its easy maintenance makes it a popular choice for upholstery in these applications.

Considerations for International Buyers

For buyers in regions like South America and Africa, vinyl’s affordability can be a significant advantage. Compliance with local regulations regarding materials and safety standards is crucial, as is ensuring that the vinyl meets international standards for durability and performance.

What Are the Benefits of Using Fabric Upholstery in Automotive Applications?

Fabric upholstery is favored for its comfort and variety. It offers excellent breathability and is available in numerous colors and patterns, allowing for customization. Fabric materials can withstand moderate pressure and provide a soft touch, enhancing passenger comfort during long drives.

Pros and Cons of Fabric Upholstery

The main benefits of fabric include its comfort, aesthetic flexibility, and cost-effectiveness. However, it can be less durable than leather or vinyl, requiring more frequent cleaning and maintenance. Fabric is also more susceptible to staining, which may be a concern for families or commercial applications.

Impact on Application

Fabric upholstery is commonly used in family cars and budget-friendly models, where comfort and customization are prioritized over luxury. Its adaptability makes it suitable for a wide range of vehicle types.

Considerations for International Buyers

Buyers from Europe and the Middle East should consider the availability of high-quality, stain-resistant fabrics that comply with local safety standards. Understanding regional preferences for colors and patterns can also inform better purchasing decisions.

Illustrative image related to car upholstery fabric manufacturers

How Do Synthetic Fabrics Perform in Car Upholstery?

Synthetic fabrics, such as microfiber and polyester, combine the benefits of comfort and durability. They are designed to be stain-resistant and easy to clean, making them an excellent choice for high-use vehicles. These materials can withstand moderate pressure and temperature variations, ensuring consistent performance.

Pros and Cons of Synthetic Fabrics

Synthetic fabrics are generally more affordable than leather and offer a soft, luxurious feel. However, they may lack the high-end appearance of leather and can show wear over time. Additionally, while they are durable, their longevity may not match that of premium materials.

Impact on Application

Synthetic fabrics are ideal for vehicles that require a balance of comfort and durability, such as family vehicles and commercial fleets. Their versatility allows for a range of applications, from seats to interior trim.

Considerations for International Buyers

For buyers in regions like Africa and South America, synthetic fabrics can provide a cost-effective solution without sacrificing quality. Compliance with international standards for materials and safety is essential, as is ensuring that the fabrics meet local preferences for aesthetics and functionality.

| Material | Typical Use Case for car upholstery fabric manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Luxury vehicles, high-end sports cars | Long-lasting, luxurious feel | Requires maintenance, high cost | Elevado |

| Vinyl | Family cars, commercial vehicles | Budget-friendly, easy to clean | Less breathable, can be sticky | Low |

| Fabric | Family cars, budget-friendly models | Comfortable, customizable | Can stain easily, less durable | Med |

| Synthetic Fabrics | Family vehicles, commercial fleets | Stain-resistant, affordable | May show wear over time | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for car upholstery fabric manufacturers

What Are the Main Stages of Manufacturing Car Upholstery Fabrics?

The manufacturing process for car upholstery fabrics involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for producing high-quality upholstery that meets the demands of both aesthetic appeal and durability.

Material Preparation: Sourcing and Treatment

The first step in the manufacturing process is sourcing raw materials, which can range from natural fibers like cotton and leather to synthetic options such as polyester and nylon. Quality assurance begins here, as manufacturers must ensure that materials meet specific standards for strength, durability, and aesthetic qualities.

Once sourced, materials undergo various treatments to enhance their properties. This can include dyeing processes, flame retardant treatments, or water-resistant coatings. These treatments are crucial, especially for fabrics intended for regions with extreme weather conditions, such as the Middle East or South America.

Forming: Cutting and Shaping

The forming stage involves cutting the treated materials into specific shapes and sizes according to design specifications. Advanced technologies like laser cutting may be employed for precision. This stage often includes creating patterns for upholstery, which requires meticulous attention to detail to minimize waste and ensure a perfect fit for the vehicle’s design.

Assembly: Stitching and Construction

In the assembly phase, the cut pieces of fabric are sewn together using industrial sewing machines. This step may involve adding features such as padding, zippers, or other components that enhance comfort and usability. Quality control checkpoints are critical during this phase to ensure that stitching is consistent and meets durability standards.

Finishing: Quality Checks and Final Touches

The final stage of manufacturing is finishing, where the assembled upholstery undergoes rigorous quality checks. This includes checking for defects, ensuring color consistency, and applying any final treatments. The finished product is then prepared for packaging and shipping, ready to meet the demands of international markets.

What International Standards Should B2B Buyers Know for Quality Assurance?

Quality assurance is paramount in the manufacturing of car upholstery fabrics, especially for B2B buyers who require consistency and reliability. International standards play a significant role in ensuring that products meet global expectations.

Understanding ISO 9001 and Other Relevant Certifications

ISO 9001 is a globally recognized quality management standard that provides a framework for consistent quality in manufacturing processes. Suppliers certified under ISO 9001 demonstrate a commitment to quality assurance and continuous improvement, which can be reassuring for B2B buyers.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for automotive applications are also essential. These certifications indicate compliance with safety and performance requirements, crucial for maintaining the integrity of the upholstery in vehicles.

Illustrative image related to car upholstery fabric manufacturers

What Are Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is integrated throughout the manufacturing process, with specific checkpoints to ensure that every aspect of production meets established standards.

Incoming Quality Control (IQC)

Incoming Quality Control (IQC) focuses on the raw materials before they enter the production line. This includes inspecting materials for defects and verifying that they meet specifications. A robust IQC process helps prevent issues later in manufacturing, which could affect product quality.

In-Process Quality Control (IPQC)

During the production phase, In-Process Quality Control (IPQC) ensures that the manufacturing process adheres to quality standards. This might involve monitoring stitching quality, checking dimensions, and conducting random sampling of finished products to ensure consistency.

Final Quality Control (FQC)

Final Quality Control (FQC) occurs after the product is completed. This stage involves a thorough inspection of the finished upholstery, checking for defects in stitching, color, and overall appearance. FQC is crucial for ensuring that the product meets customer expectations and regulatory standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing car upholstery fabrics, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies to consider:

Illustrative image related to car upholstery fabric manufacturers

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control processes is through on-site audits. These audits allow buyers to evaluate manufacturing practices, quality control checkpoints, and overall compliance with international standards. A thorough audit can uncover potential issues that may not be evident from documentation alone.

Requesting Quality Assurance Reports

B2B buyers should request detailed quality assurance reports from suppliers. These reports should outline the quality control measures in place, results from previous inspections, and any corrective actions taken in response to quality issues. Such documentation provides transparency and reassurance regarding product quality.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring that the products meet both the buyer’s specifications and international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control that can differ by region. Understanding these differences is crucial for ensuring successful transactions.

Regional Standards and Compliance

Different regions may have specific standards that must be met. For instance, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to meet local regulations. Buyers should familiarize themselves with these standards to avoid compliance issues.

Language and Cultural Barriers

Language and cultural differences can also impact communication regarding quality control. Buyers should ensure that they have clear and effective communication with suppliers to convey expectations and requirements. Utilizing bilingual professionals or translators may facilitate smoother interactions.

Conclusion: Ensuring Quality in Car Upholstery Fabric Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance practices in car upholstery fabric production is essential. By familiarizing themselves with key manufacturing stages, international standards, and quality control checkpoints, buyers can make informed decisions that align with their business needs. Conducting supplier audits, requesting quality assurance reports, and engaging third-party inspections are effective strategies for verifying supplier credibility and ensuring the highest quality upholstery products.

Illustrative image related to car upholstery fabric manufacturers

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car upholstery fabric manufacturers’

In the competitive landscape of automotive upholstery, sourcing high-quality materials from reliable manufacturers is essential for B2B buyers. This guide provides a practical checklist to streamline your procurement process and ensure you select the best car upholstery fabric manufacturers for your needs.

Step 1: Define Your Technical Specifications

Before you start your search, clearly outline your requirements. Consider the types of materials you need (e.g., leather, vinyl, synthetic fabrics), the intended use (luxury vehicles vs. commercial fleets), and any specific performance characteristics (stain resistance, durability). Having a detailed specification will help you communicate effectively with potential suppliers.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough market research to identify manufacturers that specialize in automotive upholstery fabrics. Look for companies with a solid reputation and experience in the industry. Use online resources, trade shows, and industry directories to compile a list of potential suppliers. Prioritize manufacturers with positive reviews and a history of servicing clients in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications and Compliance

It’s vital to verify that potential suppliers meet industry standards and regulations. Check for certifications such as ISO 9001, which indicates a commitment to quality management, and other relevant safety and environmental certifications. Ensuring compliance with international standards can protect your business from legal issues and enhance your brand’s reputation.

Step 4: Request Samples and Assess Quality

Once you have shortlisted suppliers, request fabric samples to evaluate their quality. Examine the materials for durability, texture, color fastness, and ease of maintenance. This step is critical to ensure that the fabrics will meet your performance expectations and resonate with your customer base. Additionally, consider how well the samples align with your defined specifications.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your shortlisted suppliers about pricing, payment terms, and minimum order quantities. Be transparent about your budget constraints while negotiating, but also weigh the value of quality over cost. Understanding the total cost of ownership—including shipping, duties, and potential tariffs—will help you make a more informed decision.

Step 6: Assess Lead Times and Production Capacity

Understanding the supplier’s lead times is crucial, especially if you have tight project deadlines. Inquire about their production capacity and delivery schedules to ensure they can meet your demands. A reliable supplier should provide clear timelines and be able to accommodate any fluctuations in order volume.

Illustrative image related to car upholstery fabric manufacturers

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that your chosen supplier has a dedicated point of contact for queries and updates. Establishing regular check-ins can help resolve any issues quickly and ensure that both parties are aligned throughout the procurement process.

By following this checklist, you will be well-equipped to source high-quality car upholstery fabrics that meet your business needs and enhance your product offerings.

Comprehensive Cost and Pricing Analysis for car upholstery fabric manufacturers Sourcing

What Are the Key Cost Components for Car Upholstery Fabric Manufacturers?

Understanding the cost structure of car upholstery fabric manufacturing is essential for B2B buyers seeking to make informed purchasing decisions. The primary components of the cost structure include:

-

Materials: The choice of materials significantly impacts pricing. High-end fabrics like leather or specialized synthetic materials typically incur higher costs due to their durability and aesthetic appeal. Conversely, budget-friendly options such as vinyl or standard fabrics can reduce upfront expenses.

-

Labor: Labor costs vary based on the complexity of the upholstery work. Skilled artisans command higher wages, particularly for custom or intricate designs. Additionally, labor costs may fluctuate based on geographic location, with regions experiencing labor shortages likely incurring higher wages.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these overheads, ultimately benefiting buyers through competitive pricing.

-

Tooling: Investment in specialized machinery or tools for cutting, sewing, and finishing upholstery can impact overall costs. Manufacturers that utilize advanced technology may offer better precision and quality, justifying higher prices.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that the final products meet industry standards and client specifications. While this adds to production costs, it can prevent costly returns and rework, thereby enhancing long-term value.

-

Logistics: Shipping and transportation costs can vary widely based on the location of the manufacturer and the buyer. International buyers should consider potential tariffs, customs duties, and freight costs when evaluating total expenses.

-

Margin: Manufacturers typically add a profit margin to their costs, influenced by market demand, competition, and brand reputation. Understanding these margins can aid buyers in negotiating more favorable pricing.

What Influences Pricing in Car Upholstery Fabric Sourcing?

Several factors affect the pricing structure that B2B buyers should consider:

-

Volume/MOQ: Larger orders often come with discounted pricing. Buyers should assess their needs and consider negotiating minimum order quantities (MOQs) that align with their purchasing capabilities.

-

Specifications and Customization: Custom designs or specialized materials typically incur additional costs. Buyers should weigh the importance of customization against budget constraints to find the right balance.

-

Materials: The quality and type of materials chosen will directly influence the price. Sustainable or high-performance fabrics may carry a premium but can offer long-term savings through durability.

-

Quality and Certifications: Fabrics that meet specific industry standards or certifications (e.g., fire resistance, eco-friendliness) may cost more upfront but can enhance safety and compliance, particularly important in international markets.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence pricing. Established suppliers with proven track records may charge more due to their reliability and product quality.

-

Incoterms: Understanding international shipping terms is crucial. Incoterms determine who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs.

What Are Essential Buyer Tips for Sourcing Car Upholstery Fabrics?

Navigating the complexities of sourcing requires strategic planning. Here are essential tips for international buyers:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders or long-term contracts. Leveraging relationships can lead to better terms and discounts.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also factors like maintenance, durability, and potential replacement costs. Investing in higher-quality materials may yield lower long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import regulations that may affect pricing. Building relationships with local suppliers can mitigate some of these challenges.

-

Disclaimer for Indicative Prices: Always request updated quotes and detailed breakdowns from suppliers, as prices can fluctuate based on market conditions, raw material costs, and geopolitical factors.

By understanding these cost components and pricing influencers, B2B buyers can make more informed decisions, optimizing their sourcing strategies for car upholstery fabrics.

Alternatives Analysis: Comparing car upholstery fabric manufacturers With Other Solutions

Understanding Alternatives to Car Upholstery Fabric Manufacturers

In the automotive industry, selecting the right upholstery solution is crucial for both aesthetic appeal and functional durability. While car upholstery fabric manufacturers offer a diverse range of materials designed specifically for automotive interiors, there are alternative solutions worth considering. These alternatives can provide unique benefits depending on the specific needs of B2B buyers, including cost efficiency, ease of maintenance, and customization options.

Comparison Table

| Comparison Aspect | Car Upholstery Fabric Manufacturers | Alternative 1: Pre-owned Upholstery | Alternative 2: DIY Upholstery Kits |

|---|---|---|---|

| Performance | High durability, custom options | Variable quality, depends on source | Moderate; depends on skill level |

| Cost | Mid to high, depending on material | Generally lower | Variable; can be cost-effective |

| Ease of Implementation | Professional installation recommended | Requires inspection and cleaning | Requires DIY skills and tools |

| Maintenance | Low; high-quality materials | Moderate; depends on condition | High; requires regular upkeep |

| Best Use Case | New builds and high-end restorations | Budget-conscious projects | Customization enthusiasts |

Exploring Alternative Solutions in Detail

Pre-owned Upholstery

Pre-owned upholstery refers to sourcing used materials from salvaged vehicles. This alternative can be a cost-effective solution, especially for budget-conscious projects. The primary advantage is the lower price point compared to new materials. However, the quality can vary significantly based on the source, and buyers must inspect the materials for wear and tear. Additionally, pre-owned options may not offer the same aesthetic choices or durability as new fabrics, making them suitable primarily for quick fixes or less visible areas of a vehicle.

Illustrative image related to car upholstery fabric manufacturers

DIY Upholstery Kits

DIY upholstery kits are designed for those who prefer a hands-on approach to car interior customization. These kits usually come with pre-cut materials and tools, allowing buyers to undertake the upholstery project themselves. The main benefit is the potential for significant cost savings, as labor costs are eliminated. However, the success of this method heavily depends on the buyer’s skill level and experience. Poor installation can lead to unsatisfactory results, including uneven seams or improper fitting. This option is best for automotive enthusiasts who enjoy customizing their vehicles and are willing to invest the time and effort to achieve a professional look.

Conclusion: Making the Right Choice for Your Upholstery Needs

When choosing between car upholstery fabric manufacturers and alternative solutions, B2B buyers should consider their specific needs, budget, and desired outcome. For businesses looking for high-quality, durable materials tailored to their brand’s aesthetic, partnering with reputable upholstery fabric manufacturers is often the best choice. However, for those on a tighter budget or seeking a unique, hands-on project, pre-owned upholstery or DIY kits may present viable alternatives. Assessing the factors of performance, cost, and maintenance will guide buyers in making informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for car upholstery fabric manufacturers

What Are the Key Technical Properties of Car Upholstery Fabrics?

When sourcing materials for car upholstery, several critical technical properties come into play. Understanding these properties can help B2B buyers make informed decisions that align with their needs and expectations.

1. Material Grade

Material grade refers to the quality and classification of the fabric used in upholstery. Higher-grade materials often indicate superior durability, aesthetic appeal, and performance. For manufacturers, selecting the right material grade is vital for meeting customer expectations regarding comfort and longevity. Buyers should look for industry standards, such as those set by ASTM or ISO, to ensure they choose the appropriate grade for their applications.

Illustrative image related to car upholstery fabric manufacturers

2. Abrasion Resistance

Abrasion resistance measures how well a fabric withstands wear and tear from friction. This property is crucial for automotive applications, where upholstery is subjected to regular use and potential damage from clothing, pets, and other factors. Fabrics with high abrasion resistance are essential for ensuring longevity and reducing the frequency of replacements, which can lead to cost savings for manufacturers and end-users alike.

3. UV Resistance

UV resistance indicates a fabric’s ability to withstand exposure to sunlight without degrading. This property is particularly important for vehicles that are often parked outdoors, as prolonged UV exposure can lead to fading and deterioration of the upholstery. Fabrics with high UV resistance help maintain the aesthetic quality of the vehicle’s interior, ensuring that it retains its appeal over time.

4. Flame Retardancy

Flame retardancy is a safety feature that reduces the risk of ignition and slows the spread of fire. For automotive upholstery, compliance with fire safety standards is often a legal requirement. Buyers must ensure that the fabrics they choose meet applicable regulations, as this not only protects passengers but also adds value to the vehicle by enhancing safety features.

5. Hydrophobic Properties

Hydrophobic properties refer to a fabric’s ability to repel water. This characteristic is particularly valuable for car upholstery, as it helps prevent stains and damage from spills. Fabrics with hydrophobic treatments are easier to clean and maintain, making them a preferred choice for manufacturers targeting family vehicles or those used in challenging environments.

Illustrative image related to car upholstery fabric manufacturers

What Are Common Trade Terms Used in Car Upholstery Manufacturing?

In the world of automotive upholstery, specific terminology is frequently used. Familiarity with these terms can facilitate smoother negotiations and improve understanding among B2B buyers and suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of upholstery, it denotes materials that meet the specifications set by vehicle manufacturers. Buyers seeking OEM upholstery materials ensure compatibility and quality that align with original vehicle standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it can impact inventory management and cash flow. Suppliers often set MOQs based on production costs and logistics, so negotiating favorable terms can lead to better pricing and lower upfront costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products or services. For car upholstery manufacturers, issuing an RFQ helps streamline the procurement process by clarifying needs and expectations, allowing for accurate comparisons between potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand the logistics and costs associated with importing upholstery materials, ensuring smoother transactions and fewer misunderstandings.

Illustrative image related to car upholstery fabric manufacturers

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This term is critical for manufacturers who need to plan their production schedules and manage customer expectations. Understanding lead times allows buyers to make informed decisions about ordering and inventory management, ultimately affecting their ability to meet market demand.

By familiarizing themselves with these key properties and trade terms, B2B buyers in the automotive upholstery sector can enhance their purchasing strategies, ensuring they select the best materials and negotiate favorable terms with suppliers.

Navigating Market Dynamics and Sourcing Trends in the car upholstery fabric manufacturers Sector

What Are the Key Market Dynamics and Trends in Car Upholstery Fabric Manufacturing?

The global market for car upholstery fabric is witnessing significant transformations driven by evolving consumer preferences, technological advancements, and economic factors. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly influenced by trends emphasizing durability, aesthetics, and functionality. A major driver is the rising demand for personalized vehicle interiors, as consumers seek materials that reflect their style while ensuring longevity. This has led to a surge in the adoption of synthetic fabrics, which provide an affordable yet durable alternative to traditional materials like leather.

Illustrative image related to car upholstery fabric manufacturers

Furthermore, emerging technologies such as 3D printing and digital fabric printing are revolutionizing the sourcing processes, enabling manufacturers to offer bespoke designs and rapid prototyping. These technologies not only reduce lead times but also allow for greater flexibility in production runs, catering to the specific needs of diverse markets. The integration of online platforms for sourcing and purchasing upholstery materials is also gaining traction, facilitating easier access to global suppliers and enhancing competition in pricing and quality.

Moreover, the automotive sector is increasingly focusing on the development of lightweight materials that enhance fuel efficiency. This trend is particularly relevant for international B2B buyers in regions like Saudi Arabia and Nigeria, where vehicle performance is a critical consideration. Understanding these dynamics is essential for manufacturers aiming to position themselves competitively in the market while meeting the unique demands of their clientele.

How Is Sustainability Shaping the Sourcing Landscape for Car Upholstery Fabrics?

Sustainability has emerged as a pivotal concern in the car upholstery fabric manufacturing sector, influencing sourcing decisions across the globe. As environmental awareness grows among consumers and regulatory bodies, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes utilizing eco-friendly materials such as organic cotton, recycled polyester, and other biodegradable options that minimize environmental impact.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing of raw materials, seeking assurances that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® are becoming essential benchmarks, providing buyers with the confidence that the products they source are not only high-quality but also environmentally responsible.

For manufacturers, adopting sustainable practices can offer a competitive edge in the marketplace. By investing in green technologies and sourcing certified materials, businesses can enhance their brand image and appeal to a growing segment of eco-conscious consumers. Furthermore, sustainability initiatives can lead to cost savings in the long run, as manufacturers often find efficiencies in resource use and waste reduction.

Illustrative image related to car upholstery fabric manufacturers

What Is the Historical Context of Car Upholstery Fabric Manufacturing?

The evolution of car upholstery fabric manufacturing is marked by significant advancements in materials and technologies. Initially, car interiors were predominantly made from natural materials like leather and cotton, which provided comfort but often lacked durability. As the automotive industry grew in the mid-20th century, the introduction of synthetic materials revolutionized the sector, offering enhanced durability, ease of maintenance, and a wider range of design options.

The late 20th century saw a shift towards more specialized upholstery fabrics, driven by consumer demand for aesthetics and comfort. Innovations in textile technology, including the development of stain-resistant and moisture-wicking fabrics, further expanded the possibilities for car interiors. Today, manufacturers are not only focused on enhancing the functional aspects of upholstery but also on aligning with sustainability goals, reflecting a broader shift in consumer values toward environmentally responsible products.

This historical context is vital for B2B buyers, as it highlights the ongoing trends and innovations that shape the current landscape of car upholstery fabrics. Understanding this evolution can inform sourcing strategies and help buyers anticipate future developments in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of car upholstery fabric manufacturers

-

How do I choose the right upholstery fabric for my vehicle?

Choosing the right upholstery fabric involves assessing various factors, including durability, aesthetics, and functionality. Start by considering your vehicle’s usage—if it endures heavy wear from children or pets, opt for robust, stain-resistant materials like synthetic fabrics. Evaluate the desired look; leather offers luxury, while fabrics provide a customizable touch. Additionally, think about comfort and maintenance requirements. Ultimately, the right choice aligns with your specific needs and enhances the overall driving experience. -

What is the best material for automotive upholstery in hot climates?

For hot climates, breathable and heat-resistant materials are essential. Synthetic fabrics like polyester or microfiber are excellent choices as they remain cooler and are often treated to resist fading. While leather can be luxurious, it may become uncomfortably hot. Opting for lighter colors can also help reflect heat. Additionally, ensure the chosen material has moisture-wicking properties to enhance comfort during long drives in high temperatures. -

What are the minimum order quantities (MOQs) for upholstery fabric?

Minimum order quantities (MOQs) for upholstery fabric can vary significantly among manufacturers. Typically, MOQs range from 50 to 500 yards, depending on the material type and the supplier’s production capabilities. It’s essential to communicate your specific requirements with potential manufacturers to understand their MOQ policies. Some suppliers may offer flexibility for new clients or bulk orders, so don’t hesitate to negotiate terms that suit your business needs. -

What payment terms should I expect when sourcing upholstery fabric?

Payment terms can vary based on the supplier’s policies and your business relationship. Common terms include a deposit of 30-50% upfront, with the remaining balance due upon shipment or delivery. Some suppliers may offer credit terms for established clients, allowing payment within 30 to 90 days. Always clarify the payment structure before finalizing any agreements to ensure smooth transactions and avoid potential misunderstandings. -

How do I vet upholstery fabric manufacturers for quality assurance?

Vetting upholstery fabric manufacturers involves several steps. Start by reviewing their certifications, such as ISO standards, which indicate adherence to quality management practices. Request samples to evaluate fabric quality firsthand, including durability, colorfastness, and texture. Additionally, read customer reviews and seek references from other businesses in your industry. Engaging in direct communication with the manufacturer about their quality control processes can also provide insights into their commitment to maintaining high standards. -

What are the shipping and logistics considerations for importing upholstery fabric?

When importing upholstery fabric, consider shipping costs, delivery timelines, and customs regulations. Verify the manufacturer’s shipping capabilities and whether they offer options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight). Understand the customs duties applicable to your region, as these can significantly affect total costs. It’s also wise to work with logistics providers experienced in international shipping to ensure timely and efficient delivery of your materials. -

Can I customize upholstery fabric designs with manufacturers?

Yes, many upholstery fabric manufacturers offer customization options. You can often specify colors, patterns, and even fabric composition to align with your branding or design needs. However, customization may come with higher MOQs or longer lead times. It’s advisable to discuss your design ideas upfront and request a prototype or sample to ensure the final product meets your expectations before placing a larger order. -

What are the common challenges faced when sourcing upholstery fabric internationally?

Sourcing upholstery fabric internationally can present challenges such as language barriers, cultural differences, and varying quality standards. Additionally, time zone differences can complicate communication. Delays in shipping and customs clearance can also impact timelines. To mitigate these issues, establish clear communication channels, verify supplier credentials, and consider working with local agents or representatives who understand the regional market dynamics. Proper planning and due diligence can help streamline the sourcing process.

Top 7 Car Upholstery Fabric Manufacturers Manufacturers & Suppliers List

1. Midwest Fabrics – Automotive Upholstery Solutions

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Automotive Upholstery Fabric, Original OEM Detroit Number Fabrics, GM, Ford, Chrysler, Honda, Toyota, Mazda, Nissan OEM Fabric, Heavy Duty Flock fabric, Culp Contract Fabrics, Marine Vinyl, Automotive Vinyl, Upholstery Supplies, Automotive Carpets, Headliner Fabric, Upholstery Foam, Upholstery Adhesives.

2. A·1 Foam & Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Car Interior Fabrics from A·1 Foam & Fabrics include a variety of options such as Velvets, Suedes, and Tweeds suitable for automotive, RV, and trucking applications. Key products include: 1. 555 Portfolio Tweed Collection – Abrasion resistance: 50,000+ DR #10 Cotton Duck, Flame Retardancy: California T.B. 117 Section E-Class 1 (Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pass), Lightf…

3. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies including: Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-Grain, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland, Perforated Palma, Plain Rosette, Morbern, Volkswagen Woven, Futura Xt…

4. MiamiCorp – Car Upholstery Fabrics

Domain: miamicorp.com

Registered: 2001 (24 years)

Introduction: This company, MiamiCorp – Car Upholstery Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Autofabric – Automotive Fabrics and Coatings

Domain: autofabric.com

Registered: 2000 (25 years)

Introduction: Autofabric offers a range of products including: Automobile Jacquard Woven Fabrics, Automobile Ceiling Fabrics, Embroidery, Fabric and Leather Car Seat and Coating, Leather Car Floor Coatings, and Alcantara-Velur-Flock-Colt. The production capabilities include Rachel Knitting, Flame Lamination, Woven Jacquard, Quality Control, Embroidery, Packaging, Suprem Knitting, and Glue Lamination. The compan…

6. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers the largest selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1956 Ford Fairlane Sunliner, 1968 Dodge Polara Convertible, and…

7. Nationwide Fabric – Dynamic Faux Leather Collection

Domain: nationwidefabric.com

Registered: 2015 (10 years)

Introduction: Car Upholstery Miami offers custom automotive fabrics in Miami-Dade, Broward, and Palm Beach Counties. The collection includes high-quality fabrics suitable for class and exotic automobiles, catering to custom automotive shops and retailers. Key offerings include the Dynamic Faux Leather Collection and various Cloud Velvet and Antique Velvet options in multiple colors such as Storm, Ivory, Gold, a…

Strategic Sourcing Conclusion and Outlook for car upholstery fabric manufacturers

In conclusion, strategic sourcing in the car upholstery fabric industry is pivotal for international B2B buyers seeking quality, durability, and aesthetic appeal. By understanding the diverse range of materials available—from luxurious leather to practical synthetics—buyers can make informed decisions that align with their specific needs and market demands. The emphasis on durability, functionality, and eco-friendliness reflects a growing trend that prioritizes long-term value over short-term savings.

As buyers from regions such as Africa, South America, the Middle East, and Europe navigate this dynamic landscape, they are encouraged to establish strong relationships with reputable manufacturers. This collaboration not only ensures access to high-quality materials but also fosters innovation in design and sustainability practices.

Illustrative image related to car upholstery fabric manufacturers

Looking ahead, the automotive upholstery market is poised for growth, driven by increasing consumer expectations and technological advancements. International B2B buyers are invited to leverage this opportunity by engaging with suppliers who can provide tailored solutions that enhance both vehicle aesthetics and performance. Embrace strategic sourcing today to secure a competitive edge in this evolving industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.