Introduction: Navigating the Global Market for how to make a leather belt

In today’s competitive landscape, sourcing high-quality leather belts presents a unique challenge for B2B buyers, particularly those operating across diverse international markets such as Africa, South America, the Middle East, and Europe. This comprehensive guide on how to make a leather belt is designed to equip businesses with the knowledge necessary to navigate the complexities of this essential accessory. From understanding the various types of leather and their applications to vetting suppliers and evaluating costs, this resource addresses every facet of the leather belt-making process.

As you delve into this guide, you will discover actionable insights that empower informed purchasing decisions. We will explore the intricacies of selecting the right leather, tools, and techniques, ensuring you can produce high-quality belts that meet market demands. Additionally, this guide will provide strategies for identifying reliable suppliers, enabling you to establish partnerships that enhance your product offerings.

Whether you are a seasoned buyer or new to the leather goods market, understanding how to make a leather belt not only enhances your product range but also positions your business for growth in a global marketplace. Join us on this journey to unlock the potential of leather craftsmanship and elevate your brand’s presence.

Table Of Contents

- Top 5 How To Make A Leather Belt Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather belt

- Understanding how to make a leather belt Types and Variations

- Key Industrial Applications of how to make a leather belt

- 3 Common User Pain Points for ‘how to make a leather belt’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather belt

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather belt

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather belt’

- Comprehensive Cost and Pricing Analysis for how to make a leather belt Sourcing

- Alternatives Analysis: Comparing how to make a leather belt With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather belt

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather belt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather belt

- Strategic Sourcing Conclusion and Outlook for how to make a leather belt

- Important Disclaimer & Terms of Use

Understanding how to make a leather belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Belt | Made from full-grain or top-grain leather, simple design, often with a single prong buckle | Fashion retailers, uniform suppliers | Pros: Durable, timeless appeal. Cons: Higher cost for quality leather. |

| Tool Belt | Reinforced leather with multiple pockets, often wider and thicker | Construction, trades, and DIY retailers | Pros: Functional, durable for heavy use. Cons: Bulkier, less stylish. |

| Designer Leather Belt | High-end finishes, unique designs, and branding elements | Luxury fashion brands, boutiques | Pros: High profit margins, brand prestige. Cons: Limited market appeal, higher production costs. |

| Custom Leather Belt | Tailored sizes, colors, and styles, often made to order | Specialty shops, promotional products | Pros: Personalized offerings, higher customer satisfaction. Cons: Longer lead times, potential for overstock. |

| Eco-Friendly Leather Belt | Made from sustainable leather alternatives or recycled materials | Sustainable brands, eco-conscious retailers | Pros: Appeals to environmentally aware consumers. Cons: Potentially higher costs, limited durability. |

What Are the Characteristics of a Classic Leather Belt?

Classic leather belts are typically crafted from full-grain or top-grain leather, ensuring durability and a timeless aesthetic. They often feature a simple design, usually with a single prong buckle, making them versatile for both casual and formal wear. For B2B buyers, investing in classic belts can enhance product lines in fashion retail or uniform supply, as they appeal to a broad audience. However, the initial investment may be higher due to the quality of leather used.

Illustrative image related to how to make a leather belt

How Do Tool Belts Differ in Functionality?

Tool belts are designed for practicality, featuring reinforced leather and multiple pockets to hold tools and equipment. They are generally wider and thicker than standard belts, making them suitable for tradespeople and construction workers. B2B buyers in construction or DIY sectors benefit from offering tool belts that enhance productivity and safety. While they are robust and functional, their bulkiness may not appeal to all customers, particularly in fashion-oriented markets.

What Sets Designer Leather Belts Apart?

Designer leather belts are characterized by high-end finishes, unique designs, and branding elements that cater to luxury consumers. These belts are often produced in limited quantities, making them desirable for high-end boutiques and fashion brands. B2B buyers can enjoy high profit margins and brand prestige by incorporating designer belts into their offerings. However, the production costs are typically higher, and the market appeal may be limited to affluent consumers.

Why Choose Custom Leather Belts?

Custom leather belts are tailored to specific sizes, colors, and styles, often made to order for individual customers. This personalization enhances customer satisfaction and can be a unique selling proposition for specialty shops and promotional product suppliers. B2B buyers must consider the longer lead times associated with custom orders and the potential for overstock if demand fluctuates. However, the ability to offer personalized products can lead to increased sales and customer loyalty.

What Are the Benefits of Eco-Friendly Leather Belts?

Eco-friendly leather belts are made from sustainable materials, including leather alternatives or recycled leather. They cater to a growing market of environmentally conscious consumers, making them an appealing option for sustainable brands and retailers. B2B buyers can leverage the increasing demand for eco-friendly products to differentiate their offerings. However, these belts may come with higher production costs and potentially lower durability, which should be factored into purchasing decisions.

Key Industrial Applications of how to make a leather belt

| Industry/Sector | Specific Application of how to make a leather belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather belts for high-end fashion brands | Enhances brand image with unique, quality products | Sourcing premium leather, skilled artisans, and design flexibility |

| Retail & E-commerce | Manufacturing leather belts for online sales | Expands product offerings, attracts diverse customers | Reliable suppliers for consistent quality and timely delivery |

| Automotive & Industrial | Leather belts for automotive accessories | Adds value to products, improves customer satisfaction | Durable materials and compliance with industry standards |

| Craft & Hobby | DIY leather belt kits for enthusiasts | Engages customers and fosters brand loyalty | Quality tools and leather, clear instructions for users |

| Corporate Gifting | Customized leather belts for corporate gifts | Strengthens client relationships and brand recognition | Personalization options and bulk sourcing capabilities |

How is ‘how to make a leather belt’ utilized in the Fashion & Apparel industry?

In the fashion and apparel sector, the ability to make leather belts allows brands to offer bespoke products that cater to discerning customers. High-end fashion labels often seek unique designs and quality craftsmanship to enhance their brand image. By sourcing premium leather and employing skilled artisans, businesses can create distinctive belts that not only serve a functional purpose but also act as fashion statements. International buyers, particularly from regions like Europe and the Middle East, demand high-quality materials and craftsmanship, making it essential to establish reliable supply chains.

What role do leather belts play in Retail & E-commerce?

Retailers and e-commerce platforms benefit from manufacturing leather belts as part of their product offerings. Customizable options can attract a broader customer base, especially in markets such as South America and Africa, where fashion trends are rapidly evolving. Businesses must focus on sourcing reliable suppliers that can deliver consistent quality and maintain timely production schedules. This ensures that retailers can meet customer expectations and capitalize on seasonal trends, thereby maximizing sales.

How do leather belts enhance products in the Automotive & Industrial sector?

In the automotive and industrial sectors, leather belts are utilized in various accessories, adding a touch of luxury and durability. These belts are often used in vehicle interiors, enhancing overall aesthetics and user experience. Businesses in this sector must prioritize sourcing durable materials that comply with industry standards, ensuring that products can withstand wear and tear. This focus on quality not only improves customer satisfaction but also positions the brand as a leader in innovation and design.

Why are DIY leather belt kits valuable in Craft & Hobby markets?

DIY leather belt kits cater to the growing market of craft and hobby enthusiasts, offering a hands-on experience that fosters creativity. These kits typically include quality leather, tools, and step-by-step instructions, enabling users to craft their own belts. For businesses, this represents an opportunity to engage customers and build brand loyalty. It is crucial to source high-quality materials and provide clear, accessible instructions, particularly for international buyers who may have varying levels of expertise in leatherworking.

Illustrative image related to how to make a leather belt

How can customized leather belts be effective for Corporate Gifting?

Customized leather belts serve as excellent corporate gifts, strengthening relationships with clients and enhancing brand recognition. Companies can use these belts as promotional items or rewards, showcasing their brand through personalized designs. To effectively implement this strategy, businesses must consider personalization options and the ability to source in bulk. Ensuring high-quality production and timely delivery is essential for maintaining a positive brand image, particularly in competitive markets across Africa and Europe.

3 Common User Pain Points for ‘how to make a leather belt’ & Their Solutions

Scenario 1: Inconsistent Quality in Leather Materials

The Problem: B2B buyers often encounter challenges related to the quality of leather when sourcing materials for belt manufacturing. Inconsistencies in the thickness, texture, and durability can lead to subpar finished products that do not meet customer expectations. This variability can stem from differences in suppliers, regions, or even batches from the same supplier. Buyers are not only concerned about the immediate impact on production but also about long-term brand reputation and customer satisfaction.

The Solution: To ensure consistent quality, it is critical for buyers to establish strong relationships with reputable leather suppliers. Conduct thorough research to identify suppliers with a track record of reliability and quality. Request samples before committing to larger orders, and conduct quality checks on each batch received. Additionally, consider implementing strict quality control measures within your production process, such as testing the leather for durability and finish. By prioritizing quality sourcing and establishing clear specifications for leather materials, businesses can mitigate the risks associated with inconsistent product quality.

Illustrative image related to how to make a leather belt

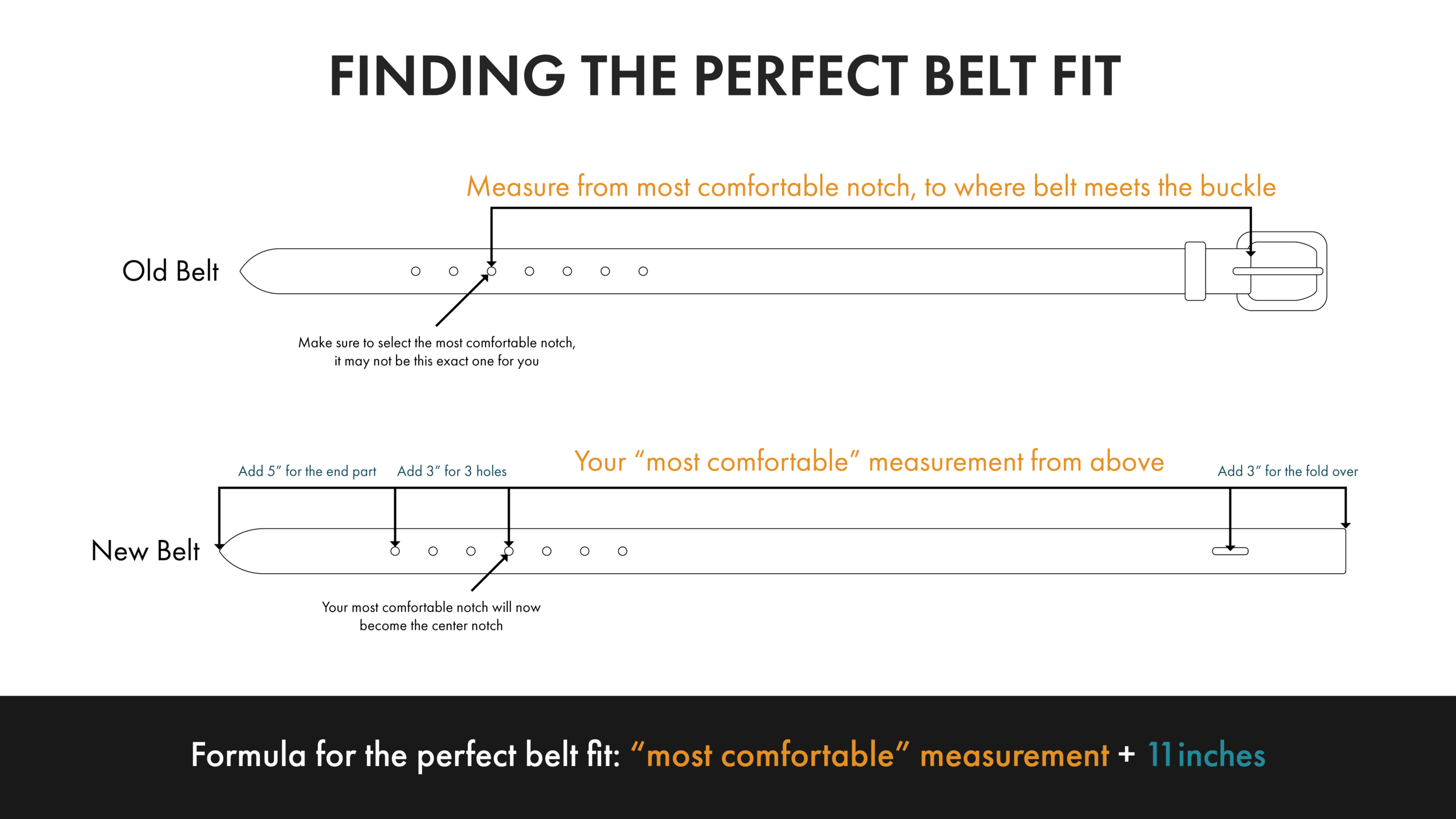

Scenario 2: Difficulty in Achieving Precise Measurements

The Problem: Another common pain point for B2B buyers involved in leather belt production is the challenge of achieving accurate measurements. Inaccuracies in cutting leather can result in belts that do not fit properly, leading to increased returns and customer dissatisfaction. This issue is particularly pertinent when creating custom belts, where precise lengths and widths are essential. Buyers may struggle with various measuring techniques, leading to wasted materials and inefficiencies in production.

The Solution: To address measurement challenges, buyers should adopt a systematic approach to measuring and cutting leather. Utilize a standardized measuring tool, such as a long ruler or measuring tape, and create a detailed template for common belt sizes. When cutting leather, always ensure that the leather is flat and secure to prevent slipping. For custom orders, consider using existing belts as templates to gauge proper lengths. Training staff on measurement techniques and investing in reliable cutting tools, such as strap cutters, can further enhance accuracy. By emphasizing precision in measurement and cutting, businesses can reduce waste and improve product fit, ultimately enhancing customer satisfaction.

Scenario 3: Complexity in the Belt Assembly Process

The Problem: The assembly process of leather belts can be complex, especially for manufacturers who are new to the craft. Challenges such as uneven stitching, poorly aligned components, and inadequate finishing can compromise the overall aesthetic and functionality of the belt. For B2B buyers, these issues can lead to increased production costs and time delays, impacting their ability to meet client demands and deadlines.

The Solution: To streamline the belt assembly process, buyers should focus on creating a detailed workflow that includes step-by-step instructions for each assembly stage. Standardizing processes for tasks such as stitching, hole punching, and edge finishing will help maintain consistency. Investing in quality tools, such as diamond chisels for stitching and reliable hole punches, can improve the precision of assembly. Additionally, consider implementing a training program for employees to enhance their skills in leatherworking techniques. By refining the assembly process and prioritizing training and quality tools, businesses can enhance productivity and deliver high-quality leather belts that meet client expectations.

Strategic Material Selection Guide for how to make a leather belt

What Are the Key Materials for Making a Leather Belt?

When selecting materials for leather belt production, it’s essential to consider various types of leather and their properties. The choice of material directly impacts the durability, aesthetic appeal, and overall performance of the final product. Below are analyses of four common materials used in leather belt manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to how to make a leather belt

How Does Full-Grain Leather Perform in Belt Manufacturing?

Key Properties: Full-grain leather is derived from the top layer of the hide, retaining the natural grain and imperfections. This type of leather is known for its strength, breathability, and ability to develop a rich patina over time.

Pros & Cons: The primary advantage of full-grain leather is its unparalleled durability and resistance to wear and tear. It can withstand high levels of stress and is less prone to cracking. However, it is also the most expensive option, which may not be suitable for all budget ranges. Manufacturing complexity is higher due to the need for skilled craftsmanship to work with its natural characteristics.

Impact on Application: Full-grain leather belts are ideal for high-end markets where quality and longevity are paramount. They are compatible with various climates, making them suitable for international markets.

Considerations for International Buyers: Buyers in regions like Africa and South America may need to consider local sourcing of full-grain leather to reduce costs. Compliance with international leather standards, such as ISO 17075, is crucial for ensuring quality.

What Are the Advantages of Top-Grain Leather for Belt Production?

Key Properties: Top-grain leather is the second-highest quality leather, made from the outer layer of the hide but sanded and treated to remove imperfections. It is more flexible than full-grain leather.

Illustrative image related to how to make a leather belt

Pros & Cons: The key advantage of top-grain leather is its balance between quality and cost. It offers good durability and a refined appearance at a lower price point than full-grain leather. However, it is less resistant to scratches and may not develop the same depth of character over time.

Impact on Application: Top-grain leather is suitable for mid-range products, appealing to consumers seeking quality without the premium price. It performs well in various environments but may not be as resilient as full-grain leather.

Considerations for International Buyers: Buyers should look for suppliers who adhere to quality standards such as ASTM D7255 for leather testing, ensuring that the top-grain leather meets durability expectations.

Illustrative image related to how to make a leather belt

How Does Genuine Leather Compare in Belt Manufacturing?

Key Properties: Genuine leather is made from lower-quality hides and is often processed to enhance its appearance. It is less durable than full-grain or top-grain leather.

Pros & Cons: The main advantage of genuine leather is its affordability, making it accessible for budget-conscious consumers. However, its lower durability and tendency to wear out faster are significant drawbacks, limiting its use to less demanding applications.

Impact on Application: Genuine leather belts are often used in fast fashion or lower-end markets where cost is a primary concern. They are suitable for casual wear but may not hold up under heavy use.

Considerations for International Buyers: Buyers should be cautious of misleading labeling and ensure compliance with local regulations regarding leather quality. Understanding the differences between genuine leather and higher-quality options is essential for maintaining brand integrity.

What Role Does Synthetic Leather Play in Belt Production?

Key Properties: Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), mimics the look and feel of real leather. It is water-resistant and easy to clean.

Illustrative image related to how to make a leather belt

Pros & Cons: The primary advantage of synthetic leather is its cost-effectiveness and ethical appeal, as it does not involve animal products. However, it lacks the durability and breathability of natural leather, which can lead to quicker wear and a less premium feel.

Impact on Application: Synthetic leather belts are popular in budget markets and among consumers seeking cruelty-free options. They perform well in humid environments but may not offer the same longevity as natural leather.

Considerations for International Buyers: Buyers should ensure that synthetic materials comply with environmental regulations, such as REACH in Europe, and verify the quality through relevant standards like ASTM D2000 for rubber and plastic materials.

Summary Table of Material Selection for Leather Belts

| Material | Typical Use Case for how to make a leather belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end, luxury belts | Unmatched durability and patina | High cost and manufacturing complexity | Elevado |

| Top-Grain Leather | Mid-range, quality belts | Good balance of quality and cost | Less scratch-resistant than full-grain | Medium |

| Genuine Leather | Budget-friendly, casual belts | Affordable and accessible | Lower durability and faster wear | Low |

| Couro sintético | Budget and ethical markets | Cost-effective and easy to maintain | Lacks durability and premium feel | Low |

This guide provides a comprehensive overview of material options for leather belt production, emphasizing the importance of informed decision-making for international B2B buyers.

Illustrative image related to how to make a leather belt

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather belt

What Are the Key Stages in the Manufacturing Process of Leather Belts?

The manufacturing process of leather belts can be broken down into several critical stages: material preparation, forming, assembly, and finishing. Each stage requires specialized techniques and attention to detail to ensure a high-quality final product.

How Is Material Prepared for Leather Belt Manufacturing?

The first step in the manufacturing process involves selecting the right leather. Typically, vegetable-tanned leather is preferred for its durability and ability to develop a rich patina over time. The leather is then cut to size, typically 8-12 ounces in thickness, depending on the desired strength and flexibility of the belt.

Once the leather is selected, it undergoes a thorough inspection for imperfections such as scars or excessive grain. This is crucial, as these flaws can affect the belt’s aesthetics and longevity. The leather is then conditioned, dyed, and treated to enhance its durability. This preparation stage is critical, as the quality of the raw material directly impacts the final product.

What Techniques Are Used in the Forming Stage of Leather Belt Production?

Forming involves cutting the prepared leather into strips using tools like strap cutters or rotary cutters. Precision is vital during this stage, as uneven cuts can lead to wasted material and inconsistent product quality. A straight edge is established along the leather, often from the spine area of the hide, to ensure minimal waste and optimal strength.

After cutting, the leather is shaped into the desired belt profile. This may include creating the English Point at the end of the belt and punching holes for the buckle. Techniques such as skiving may be used to reduce thickness at edges, ensuring a sleek finish that enhances comfort and appearance.

How Is the Assembly Process Conducted for Leather Belts?

The assembly stage involves stitching components together to form the final belt. This includes attaching the belt buckle and any additional features, such as loops or decorative elements. The stitching must be strong and consistent, often utilizing techniques like saddle stitching, which provides durability.

Quality assurance checkpoints during assembly include verifying the alignment of buckle attachments and ensuring that all holes are punched correctly. Any misalignment at this stage can compromise the belt’s functionality and aesthetic appeal.

What Finishing Techniques Are Employed in Leather Belt Production?

Finishing is where the belt receives its final touches, including edge burnishing and application of protective finishes. Burnishing edges not only enhances the visual appeal but also prevents fraying and wear. This is typically done using water or dye along with a canvas cloth to create a smooth, polished edge.

After burnishing, the belt may be treated with beeswax or other protective coatings to enhance water resistance and overall longevity. Final inspections are carried out to ensure that the belt meets all specifications and quality standards before packaging.

What Are the Quality Control Measures Relevant to Leather Belt Manufacturing?

Quality control (QC) is paramount in leather belt manufacturing to ensure that products meet international and industry-specific standards. The implementation of robust QC measures can significantly enhance product reliability and consumer satisfaction.

Which International Standards Should Leather Belt Manufacturers Adhere To?

Manufacturers should align their processes with international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards not only ensures consistency in production but also builds trust with B2B buyers.

For specific markets, certifications like CE (Conformité Européenne) may be necessary, particularly for products entering the European market. These certifications ensure that products meet health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in Leather Belt Production?

Quality control in leather belt manufacturing typically involves several checkpoints throughout the production process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify that they meet specified quality standards.

- In-Process Quality Control (IPQC): Conducting checks during manufacturing, such as measuring cut lengths and inspecting stitching quality.

- Final Quality Control (FQC): Performing a thorough inspection of the finished product to ensure it meets design specifications and quality standards.

Common testing methods include tensile strength tests, colorfastness tests, and abrasion resistance tests. These assessments help identify any potential weaknesses in the product before it reaches the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should be proactive in verifying the quality control measures of their suppliers to ensure product reliability. Here are several strategies to consider:

- Audits: Conducting on-site audits of the manufacturing facility allows buyers to assess the QC practices firsthand. Auditors can evaluate processes, equipment, and employee training programs.

- Reports: Requesting detailed QC reports can provide insights into the supplier’s inspection processes and any corrective actions taken in response to quality issues.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and final products. This is particularly important for international buyers who may not have the resources for on-site inspections.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing leather belts from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of regional nuances in quality control and certification requirements. Each market may have distinct regulations governing product safety and environmental impact.

For instance, buyers in the European market must ensure compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations, which govern the use of hazardous substances in products. In contrast, suppliers in Africa may face different regulatory environments, and buyers must be diligent in understanding these differences to mitigate risks.

Additionally, cultural factors can influence quality perceptions and expectations. Building strong relationships with suppliers and maintaining open communication can help bridge any gaps in understanding and ensure that quality standards are consistently met.

In conclusion, a meticulous approach to the manufacturing processes and quality assurance of leather belts not only enhances product quality but also fosters trust and reliability among international B2B buyers. By understanding these processes and implementing effective QC measures, businesses can ensure they deliver high-quality products that meet diverse market demands.

Illustrative image related to how to make a leather belt

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather belt’

Introdução

This practical sourcing guide is designed for B2B buyers interested in procuring the necessary materials and tools for manufacturing leather belts. By following this checklist, you can streamline your sourcing process, ensuring that you select high-quality suppliers, materials, and equipment that meet your production needs.

Step 1: Identify Your Leather Specifications

Understanding the type of leather you require is crucial for quality output. Look for leather thickness (typically 8-12 oz for belts) and finish (vegetable-tanned or chrome-tanned) that suits your brand and target market.

– Sub-bullet: Ensure the leather is sourced from reputable tanneries to guarantee durability and ethical practices.

Step 2: Source Essential Tools

Procure the necessary tools for the belt-making process, including strap cutters, leather knives, hole punches, and rivet setters. These tools are integral to achieving precision and quality in your production.

– Sub-bullet: Consider bulk purchasing to reduce costs, especially if you plan on scaling your production.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to validate their reliability and quality.

– Sub-bullet: Check for certifications that demonstrate compliance with international standards, ensuring that your suppliers adhere to best practices.

Step 4: Request Samples

Always request samples of both leather and tools before finalizing your order. This step allows you to assess the quality and suitability of materials for your specific belt designs.

– Sub-bullet: Evaluate the samples against your specifications, checking for consistency in color, texture, and durability.

Step 5: Confirm Lead Times and Shipping Costs

Understanding lead times and shipping costs is essential for planning your production schedule. Ensure suppliers can meet your timelines without compromising quality.

– Sub-bullet: Negotiate terms that allow for flexibility in case of unforeseen delays, which can be critical for maintaining your supply chain.

Step 6: Establish Payment Terms

Set clear payment terms with your suppliers to avoid misunderstandings. Consider options such as letters of credit, which can provide security for both parties.

– Sub-bullet: Discuss bulk order discounts and payment schedules that align with your cash flow and production cycles.

Step 7: Monitor Quality Control

Once production begins, implement a quality control process to ensure that all materials and finished products meet your standards. Regular checks can prevent costly errors and maintain your brand reputation.

– Sub-bullet: Set up feedback loops with suppliers to address any quality issues promptly, fostering a collaborative relationship.

By following this step-by-step checklist, B2B buyers can effectively source the materials and tools necessary for producing high-quality leather belts, ensuring a successful manufacturing process.

Comprehensive Cost and Pricing Analysis for how to make a leather belt Sourcing

What Are the Key Cost Components for Making a Leather Belt?

When sourcing leather belts, understanding the cost structure is vital for accurate budgeting and pricing. The primary cost components include:

Illustrative image related to how to make a leather belt

-

Materials: The choice of leather significantly impacts costs. Quality leather (8-12 oz) ranges from $4 to $10 per square foot, depending on type and finish. Additional materials like buckles, rivets, and dye can add another $2 to $5 per belt, depending on quality and supplier.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. In regions with lower labor costs, such as parts of Africa and South America, labor can range from $1 to $5 per belt. In contrast, European labor costs may start at $5 and can exceed $15 for skilled artisans.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Overhead can contribute an additional 10-20% to the total production cost.

-

Tooling: Initial tooling costs for equipment like strap cutters and hole punches can be significant, particularly for custom designs. Expect to invest anywhere from $500 to $2,000, depending on the scale and specifications of production.

-

Quality Control (QC): Implementing QC processes ensures product consistency and quality, often adding 5-10% to overall costs. This is crucial for maintaining standards, particularly for international buyers who may require certifications.

-

Logistics: Shipping and handling costs vary by destination and can be influenced by Incoterms. For instance, shipping costs from Europe to Africa can range from $100 to $500 per shipment, depending on weight and mode of transport.

-

Margin: Manufacturers typically aim for a profit margin of 20-40%, which should be factored into the final price to buyers.

How Do Price Influencers Affect Leather Belt Sourcing?

Several factors can influence the final pricing of leather belts:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for higher volumes, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Be prepared for potential surcharges for bespoke features or non-standard sizes.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly leather) can lead to increased prices. Buyers should evaluate the trade-off between cost and quality based on their target market.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a history of quality may charge more, but can also reduce risks associated with poor product quality.

-

Incoterms: Understanding the terms of shipping can greatly affect the total cost. For instance, FOB (Free on Board) may shift more costs to the buyer, while CIF (Cost, Insurance, and Freight) may provide a more predictable total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Leather Belt Sourcing?

International buyers can optimize their sourcing strategies by following these tips:

-

Negotiate Effectively: Always engage in negotiation to secure the best prices. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs. Consider maintenance, durability, and potential returns when assessing the overall value of the product.

-

Understand Pricing Nuances: Be aware that pricing can fluctuate due to market demand, currency exchange rates, and geopolitical factors. Regular market analysis can help in making informed purchasing decisions.

-

Build Relationships with Suppliers: Long-term relationships can lead to better pricing, improved communication, and more favorable terms in future transactions.

-

Leverage Local Knowledge: Engaging local agents or representatives can provide insights into market conditions and supplier capabilities, particularly in regions like Africa and South America.

Disclaimer

Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how to make a leather belt With Other Solutions

Introduction to Alternatives for Crafting Leather Belts

When considering how to make a leather belt, it’s essential to evaluate various alternatives that can achieve similar results. The choice of method can significantly impact the quality, cost, and usability of the final product. This analysis will compare traditional leather crafting against alternative solutions, helping B2B buyers make informed decisions based on their specific needs and market demands.

Comparison Table

| Comparison Aspect | How To Make A Leather Belt | Alternative 1: Pre-made Leather Belts | Alternative 2: Synthetic Belt Manufacturing |

|---|---|---|---|

| Performance | High durability and aesthetic quality | Variable quality; depends on the manufacturer | Good durability but may lack premium feel |

| Cost | Moderate to high (materials and tools) | Low to moderate (bulk pricing available) | Generally low, especially for mass production |

| Ease of Implementation | Requires skill and tools; time-intensive | Very easy; no skills or tools needed | Moderate; requires machinery but little manual skill |

| Maintenance | Long-lasting with proper care | Minimal maintenance required | Varies; synthetic materials may wear faster |

| Best Use Case | Custom, high-quality products for niche markets | Retail or wholesale for quick sales | High-volume production for budget-conscious consumers |

Detailed Breakdown of Alternatives

Alternative 1: Pre-made Leather Belts

Pre-made leather belts offer a convenient option for businesses looking to stock products without the complexities of manufacturing. These belts can vary in quality, depending on the manufacturer, and can often be sourced in bulk at competitive prices. The primary advantage is the ease of implementation; businesses can quickly fill inventory without needing leatherworking skills or specialized tools. However, the downside is that customization options are limited, potentially affecting brand differentiation in markets where unique products are valued.

Alternative 2: Synthetic Belt Manufacturing

Synthetic belt manufacturing utilizes materials like polyester or nylon, which can be produced at a lower cost than leather. This method allows for high-volume production, making it ideal for businesses targeting budget-conscious consumers. The manufacturing process is generally more straightforward, requiring less skill than leather crafting. However, the performance may not match that of genuine leather belts, as synthetic materials can lack the premium aesthetic and tactile qualities that consumers often prefer. Additionally, synthetic belts may not offer the same durability over time, leading to higher replacement rates and potential customer dissatisfaction.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the right method for creating leather belts depends on various factors, including target market, budget, and desired product quality. For businesses aiming to offer high-end, customized products, traditional leather crafting remains the best choice despite its higher costs and complexity. Conversely, those looking for quick inventory solutions may find pre-made belts more suitable, while synthetic manufacturing could serve high-volume, cost-sensitive markets effectively. Ultimately, understanding your business goals and customer preferences will guide you in making the most informed choice for your belt manufacturing needs.

Essential Technical Properties and Trade Terminology for how to make a leather belt

What Are the Essential Technical Properties for Making a Leather Belt?

When producing leather belts, understanding key technical properties is crucial for ensuring product quality and meeting customer expectations. Here are some critical specifications to consider:

1. Leather Thickness (Oz)

Leather thickness is typically measured in ounces (oz), with common belt leather ranging from 8 to 12 oz. This measurement indicates the leather’s durability and rigidity; thicker leather is more robust and better suited for belts that endure daily wear. In a B2B context, specifying the thickness helps suppliers understand the intended use and longevity of the product, ensuring that the final product meets durability requirements.

2. Material Grade

The grade of leather—such as full-grain, top-grain, or corrected grain—affects both appearance and performance. Full-grain leather, for instance, is the highest quality and retains the natural grain, making it more durable and aesthetically appealing. Understanding material grades is vital for B2B buyers to make informed purchasing decisions, ensuring they select products that align with their brand’s quality standards.

3. Colorfastness

Colorfastness refers to a leather’s ability to retain its color when exposed to various elements, including sunlight and moisture. This property is essential for maintaining the aesthetic integrity of the belt over time. For B2B buyers, inquiring about colorfastness can help ensure that the leather will maintain its appearance, reducing the likelihood of returns and increasing customer satisfaction.

Illustrative image related to how to make a leather belt

4. Edge Finish

The edge finish of a leather belt impacts both its visual appeal and comfort. Well-finished edges prevent fraying and provide a polished look. Techniques such as burnishing or sealing can be employed to achieve a smooth edge. In the B2B sector, understanding edge finishing processes can help buyers ensure that the products they procure meet their design specifications and quality expectations.

5. Stitching Type and Density

The type of stitching and its density (stitches per inch) are critical for the durability and aesthetics of the belt. Common stitching methods include straight, zigzag, or decorative stitching, each offering different strengths and visual styles. For B2B buyers, specifying stitching requirements ensures that the belts will withstand stress and wear, aligning with the intended market positioning.

What Are Common Trade Terms in the Leather Belt Industry?

Familiarizing oneself with industry jargon is essential for effective communication in the leather belt supply chain. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods that are then marketed by another company under its brand name. In the leather belt industry, understanding OEM arrangements can help businesses source belts that meet their specifications while leveraging the manufacturer’s expertise.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases in alignment with demand forecasts.

Illustrative image related to how to make a leather belt

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers. This is particularly useful when dealing with custom orders or bulk purchases. For businesses in the leather belt market, issuing RFQs can streamline procurement and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and risk management effectively, ensuring smoother logistics and clearer contracts.

5. Tolerance Levels

Tolerance levels define the permissible limits of variation in dimensions and properties of the leather belts. Specifying tolerance levels is crucial in B2B transactions to ensure that all products meet the required specifications, thereby reducing the likelihood of defects and enhancing customer satisfaction.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions that enhance their leather belt offerings and strengthen their market position.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather belt Sector

What Are the Key Market Trends Influencing the Leather Belt Manufacturing Sector?

The leather belt sector is currently experiencing a dynamic shift influenced by various global drivers. One of the most significant trends is the increasing demand for customized and high-quality leather products. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are seeking unique designs and durable materials that reflect cultural nuances and personal style. This trend is supported by advancements in technology, such as 3D printing and AI-driven design tools, which enable manufacturers to produce bespoke leather belts efficiently and at scale.

Moreover, e-commerce platforms are transforming how buyers source leather products. Businesses are increasingly leveraging digital marketplaces to connect with suppliers globally, facilitating easier access to diverse materials and craftsmanship. This trend is particularly pronounced in regions like Nigeria and Brazil, where local artisans are gaining visibility on international platforms, enabling cross-border trade.

Additionally, there is a growing emphasis on traceability within the supply chain. Buyers are looking for manufacturers who can provide insights into the sourcing and production processes of leather goods, ensuring quality and authenticity. This demand for transparency is shaping market dynamics, encouraging suppliers to adopt more sophisticated tracking systems and certifications that appeal to environmentally-conscious consumers.

How Are Sustainability and Ethical Sourcing Shaping the Leather Belt Industry?

Sustainability and ethical sourcing are at the forefront of the leather belt sector, driven by increasing consumer awareness and regulatory pressures. The environmental impact of traditional leather production, including water usage and chemical waste, has led buyers to seek suppliers who prioritize eco-friendly practices. B2B companies are now focusing on sourcing leather from tanneries that utilize vegetable tanning methods, which are less harmful to the environment compared to conventional chemical tanning processes.

Moreover, certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction among B2B buyers. These certifications not only assure quality but also demonstrate a commitment to sustainable practices throughout the supply chain. Buyers are encouraged to collaborate with suppliers who can provide certified materials, thereby enhancing their marketability and aligning with the growing demand for sustainable products.

Illustrative image related to how to make a leather belt

In addition to material sourcing, ethical labor practices are crucial. Buyers are increasingly demanding transparency regarding labor conditions in manufacturing facilities, which has led to the rise of fair-trade certified leather. By prioritizing ethical sourcing, businesses can not only mitigate risks associated with reputational damage but also cater to a market segment that values social responsibility.

What Is the Historical Context of Leather Belt Manufacturing for B2B Buyers?

The history of leather belt manufacturing dates back centuries, evolving from simple utility items to fashion statements and status symbols. Originally crafted by artisans using traditional techniques, leather belts were primarily functional, designed to hold garments in place and secure tools. Over time, the industrial revolution introduced mechanization, allowing for mass production and wider availability of leather goods.

In the 20th century, leather belts began to embody personal style, with designers experimenting with various materials, colors, and embellishments. This evolution reflects broader shifts in consumer behavior, where belts transitioned from purely functional items to essential fashion accessories. For B2B buyers today, understanding this historical context is vital, as it informs current trends in customization, quality expectations, and the importance of craftsmanship in the leather industry.

Overall, the leather belt sector is poised for continued growth, influenced by technological advancements, sustainability initiatives, and evolving consumer preferences. B2B buyers can capitalize on these trends by aligning their sourcing strategies with market demands, ensuring they remain competitive in this dynamic landscape.

Illustrative image related to how to make a leather belt

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather belt

-

How do I choose the right leather for making belts?

Selecting the appropriate leather is crucial for the durability and aesthetic of your belts. Look for full-grain or top-grain leather, as they offer superior strength and aging qualities. For belts, a thickness of 8-12 oz is recommended, ensuring it can withstand wear while maintaining a stylish appearance. It’s also essential to consider the leather’s finish; vegetable-tanned leather is popular for its natural look and ability to develop a patina over time. Always request samples from suppliers to assess quality before making bulk purchases. -

What is the best method for cutting leather for belts?

Using a strap cutter is the most efficient way to achieve clean, straight cuts when making belts. Ensure your cutter is set to the desired width before starting, typically around 1.25 inches for standard belts. If you are cutting leather manually, a long ruler and a sharp leather knife can also yield good results. Always make sure the leather is secured to prevent slipping, which can lead to uneven cuts and wasted material. -

How can I customize leather belts for my brand?

Customization options for leather belts include embossing your logo, selecting unique colors, and varying buckle styles. When sourcing from manufacturers, inquire about their capabilities for custom designs and minimum order quantities (MOQs). Many suppliers also offer a range of finishes and stitching options to match your brand’s aesthetic. Request prototypes to ensure the final product aligns with your vision before committing to larger orders. -

What are the typical minimum order quantities (MOQs) for leather belts?

MOQs for leather belts vary by supplier and can range from as low as 50 units to several hundred. Factors influencing MOQs include the complexity of the design, customization requirements, and the supplier’s production capacity. When negotiating, clarify whether the MOQ includes only one style or multiple styles, as this can impact your inventory management and costs. -

What payment terms should I expect when sourcing leather belts internationally?

Payment terms can vary significantly among suppliers and regions. Common terms include a 30% deposit upfront with the remaining 70% due upon shipment or delivery. Some suppliers may offer favorable terms like net 30 or net 60 days, especially for established relationships. Always negotiate terms that align with your cash flow needs and ensure they are documented in a purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) in leather belt production?

To maintain high standards in leather belt production, implement a robust quality assurance process. This includes conducting initial inspections of raw materials, establishing clear specifications for production, and performing final inspections before shipment. Collaborate closely with your supplier to understand their QA processes and request certifications or third-party inspections if necessary. Regular communication and feedback loops can also help in addressing any quality issues promptly. -

What logistics considerations should I be aware of when importing leather belts?

Logistics plays a critical role in the timely delivery of your leather belts. Factor in shipping costs, customs duties, and potential delays in transit when planning your inventory. It’s advisable to work with a freight forwarder familiar with international trade regulations, especially if you’re importing from regions with stringent customs processes. Additionally, consider the impact of local regulations in your country regarding the importation of leather goods to avoid legal complications. -

How can I find reliable suppliers for leather belts?

Finding trustworthy suppliers requires thorough research and vetting. Utilize trade platforms, industry trade shows, and B2B directories to identify potential manufacturers. Assess their credibility by checking reviews, requesting references, and examining their production capabilities. Conducting factory visits, if feasible, or requesting video tours can also provide insights into their operations. Establishing a trial order is a practical way to evaluate their quality and reliability before committing to larger contracts.

Top 5 How To Make A Leather Belt Manufacturers & Suppliers List

1. Gold Bark Leather – DIY Leather Belt Guide

Domain: goldbarkleather.com

Registered: 2015 (10 years)

Introduction: DIY Leather Belt Guide

Materials Needed:

– 8-12oz Leather (a side)

– Strap Cutter

– Leather Knife (or Rotary Cutter)

– Leather Glue

– Leather Dye

– Beeswax

– Thread & Needles

– Long Ruler (4ft+)

– Hammer

– Hole Punch

– Divider

– Skiving Knife (Optional)

– Diamond Chisels

– Scratch Awl

– Craft Sponge

– Canvas Cloth

– Rivets

– Rivet Setter

– Belt Buckle (available on Amazon or Buckleguy.com)

Steps…

2. Reddit – Handcrafted Italian Leather Belt

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Made with 10-11 Oz Italian vegetable-tanned leather from a local tannery. Cut the whole belt by hand. Features nickel rivets and a roller buckle.

3. MrLentz – Leather Belt Making Guide

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: How to make a leather belt, step by step tutorial with photos by MrLentz, includes detailed instructions and specific products used in the process.

4. Weaver Leather Supply – Leather Belt Making Kits

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather Belt Making Kits & Supplies – Weaver Leather Supply. Products include: 1. Belt Leathercrafting Kit, Veg Tanned Crazy Horse – $37.75 2. Belt Leathercrafting Kit, Veg Tanned Hermann Oak® – $53.00 3. Natural Strap Belt Blank, 8/9 oz. – From $7.80 4. #50 Buckle – Sale price from $1.88 (Regular price $3.00) 5. #999 Buckle – Sale price from $0.45 (Regular price $0.70) 6. #400 Belt Buckle – From …

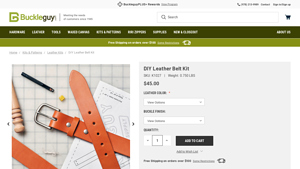

5. Buckleguy – DIY Leather Belt Kit

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “DIY Leather Belt Kit”, “sku”: “K1027”, “price”: “$45.00”, “weight”: “0.750 LBS”, “leather_colors”: [“Black – (English Bridle, Wickett)”, “Dark Brown – (English Bridle, Wickett)”, “Tan – (English Bridle, Wickett)”, “Natural – (Carving, Wickett)”], “buckle_finishes”: [“Natural Brass”, “Antique Brass”, “Nickel”, “Matte Nickel Plate”, “Shiny PVD”, “Matte Black”], “kit_contents”: [“1 …

Strategic Sourcing Conclusion and Outlook for how to make a leather belt

As you consider entering the leather belt manufacturing market, strategic sourcing remains a pivotal element for success. By selecting high-quality leather and tools, you not only enhance the durability and appeal of your products but also streamline production processes. This commitment to quality ensures that your offerings resonate with discerning customers across diverse markets, including Africa, South America, the Middle East, and Europe.

Collaborating with reliable suppliers and investing in skilled artisans can significantly reduce operational costs while maximizing craftsmanship. Additionally, staying attuned to evolving fashion trends and consumer preferences allows you to innovate and differentiate your product line.

Looking ahead, the global demand for bespoke leather goods is on the rise. By leveraging strategic sourcing practices, you can position your business to capitalize on this growing market. Engage with local artisans, explore sustainable sourcing options, and continuously refine your production techniques. As you embark on this journey, remember that the quality of your leather belt is a direct reflection of your brand. Seize the opportunity to make a lasting impact in the leather industry by prioritizing excellence at every step.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make a leather belt

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.