Catalog

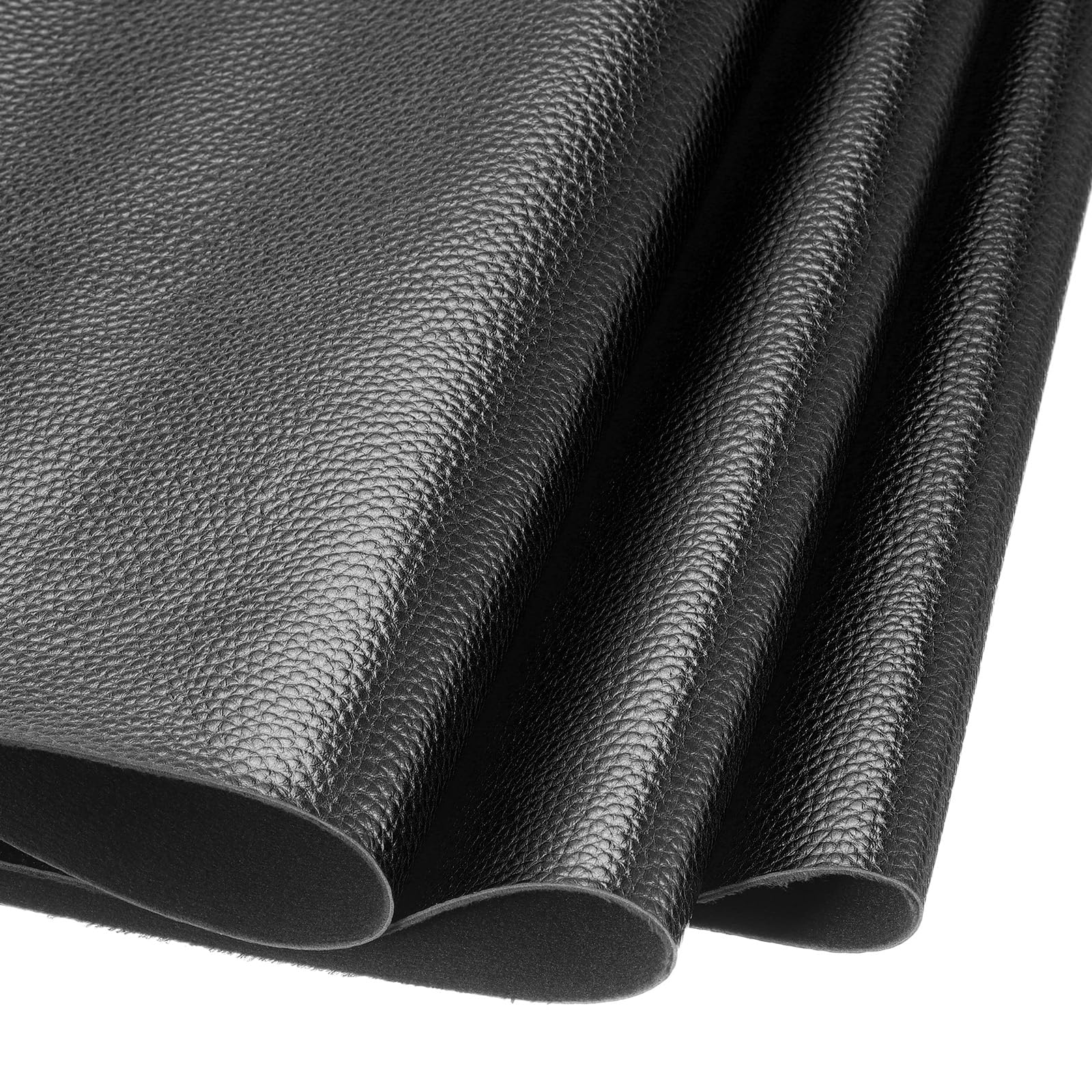

Material Insight: Pu Faux Leather

B2B Product Guide: PU Faux Leather Solutions

Introduction to PU Faux Leather

Polyurethane (PU) faux leather is a high-performance synthetic material engineered to replicate the aesthetic and functional qualities of genuine leather, without its inherent limitations. Constructed by coating a durable textile base (typically polyester or rayon) with a polyurethane layer, it delivers exceptional consistency, design flexibility, and sustainability. Unlike natural leather, PU faux leather eliminates variability from animal hide defects, ensuring uniform texture, color, and thickness across every batch—critical for precision-driven manufacturing in upholstery, automotive interiors, fashion, and technical applications.

Why PU Faux Leather Is the Optimal Choice for Modern Applications

For B2B partners prioritizing performance, ethics, and scalability, PU faux leather outperforms traditional materials:

– Consistent Quality & Yield: Eliminates waste from natural hide imperfections, ensuring 95%+ material utilization versus 60–70% for genuine leather.

– Enhanced Sustainability: Requires 80% less water and generates 50% lower CO₂ emissions during production compared to bovine leather tanning.

– Design Versatility: Offers unlimited color, texture, and finish customization (e.g., matte, glossy, embossed) without supply chain constraints.

– Ethical Compliance: Fully animal-free and free from hazardous chromium salts, aligning with EU REACH, OEKO-TEX®, and global ESG mandates.

– Performance Durability: Resists fading, abrasion, and microbial growth while maintaining flexibility across extreme temperatures (-30°C to 80°C).

WINIW: Your Trusted Partner in Advanced Synthetic Leather

With over 20 years of specialized expertise, WINIW has pioneered innovations in eco-conscious PU faux leather for global B2B markets. We combine rigorous R&D with closed-loop manufacturing to deliver materials that meet the highest standards of performance and planetary responsibility. Our vertically integrated process—from raw material sourcing to finished roll—ensures traceability, batch-to-batch reliability, and rapid scalability for OEMs and designers. By choosing WINIW, you gain a partner committed to advancing sustainable material science without compromising on luxury, durability, or compliance.

Engineered for excellence. Built for tomorrow.

Technical Performance & Standards

WINIW PU Faux Leather – Technical Product Guide

WINIW’s polyurethane (PU) faux leather is engineered for B2B partners seeking a sustainable, high-performance alternative to genuine leather. Designed for industries including automotive interiors, furniture, apparel, and accessories, our PU leather delivers exceptional value across cost, durability, and compliance. By integrating advanced manufacturing with eco-conscious practices, WINIW ensures reliable performance and environmental responsibility.

Key Technical Advantages

-

Cost-Effective:

WINIW’s PU faux leather reduces material and production costs without sacrificing quality. Unlike genuine leather, it offers consistent thickness and yield, minimizing waste during cutting and fabrication. This uniformity enhances production efficiency, especially in high-volume manufacturing. -

Durable Performance:

Our PU leather is formulated for high abrasion resistance, excellent tensile strength, and long-term flexibility. It maintains integrity under repeated stress and exposure to light, heat, and humidity, making it ideal for demanding applications such as seating and upholstery. -

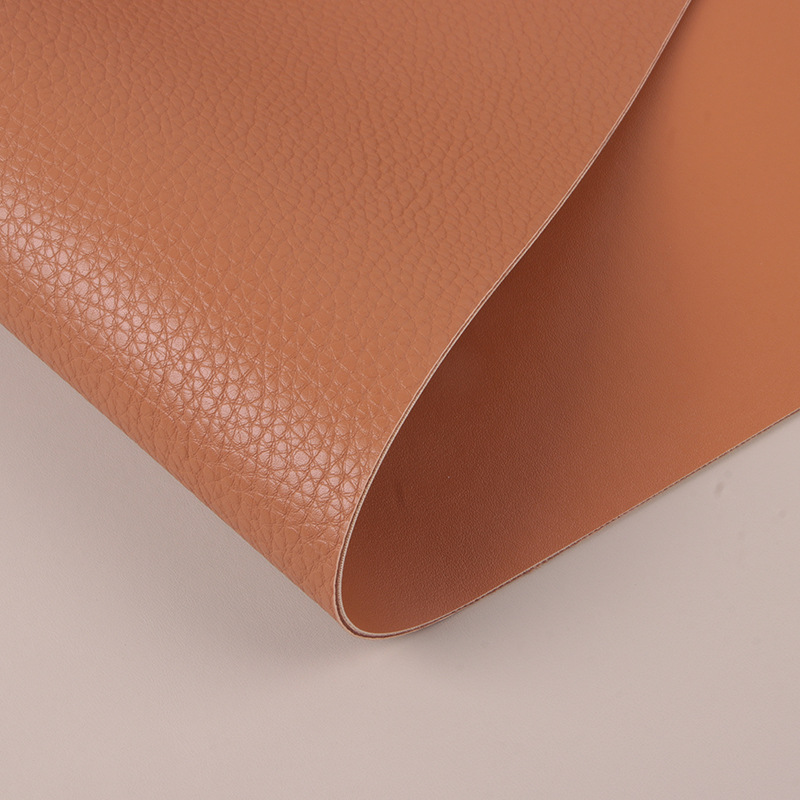

Customizable Colors & Finishes:

WINIW offers full color customization with precise Pantone matching and consistent batch-to-batch color reproduction. Finishes can be tailored to matte, glossy, soft-touch, or textured surfaces, enabling brand-specific design flexibility. -

REACH Compliance:

WINIW’s PU faux leather meets REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) standards, ensuring the absence of harmful substances such as phthalates, heavy metals, and carcinogenic dyes. This compliance supports safer working environments and end-user safety. -

ISO9001 Certified Production:

Manufactured under a certified ISO9001 quality management system, WINIW maintains rigorous process control, traceability, and continuous improvement. This ensures consistent product quality, on-time delivery, and reliable performance across global supply chains.

Technical Specifications

| Property | Especificação |

|---|---|

| Base Material | High-density polyester fabric + PU coating |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Weight Range | 180 g/m² – 450 g/m² |

| Tensile Strength | ≥ 50 N/5cm (warp & weft) |

| Elongation at Break | ≥ 80% |

| Color Fastness to Rubbing | Dry: ≥ 4, Wet: ≥ 3 (on Blue Wool Scale) |

| Light Fastness | ≥ 30 hours (Xenon test, ISO 105-B02) |

| Martindale Abrasion | ≥ 30,000 cycles (no break) |

| Cold Crack Resistance | ≤ -20°C |

| Environmental Compliance | REACH, RoHS compliant; free from AZO dyes |

| Quality Management | ISO9001:2015 certified production facility |

WINIW’s PU faux leather is a strategic material solution for forward-thinking manufacturers aiming to balance performance, sustainability, and cost-efficiency. With scalable production and technical support, we enable partners to innovate responsibly and competitively in global markets.

Why Choose Synthetic over Real Leather

B2B Product Guide: PU Faux Leather vs. Real Leather for Sustainable Manufacturing

As a leader in innovative synthetic materials, WINIW provides performance-driven, eco-conscious alternatives to traditional leather. Understanding the core differences between PU faux leather and real leather is critical for manufacturers prioritizing cost efficiency, product longevity, and environmental responsibility. Below is an objective comparison focused on key operational metrics.

Key Comparison: PU Faux Leather vs. Real Leather

| Metric | PU Faux Leather (WINIW Grade) | Real Leather (Full-Grain) |

|---|---|---|

| Cost (USD/sq.m) | $8–$25 (Material + Low Processing) | $25–$100+ (Material + High Tanning/Labor) |

| Durabilidade | 50,000–100,000+ double rubs (Martindale Test); Consistent surface; Resists fading/staining | 20,000–50,000 double rubs; Natural variations; Prone to scratches/fading over time |

| Eco-Friendliness | – 90% less water used in production – Zero animal sourcing – WINIW Bio-PU options: 30–50% plant-based content – Recyclable at end-of-life (mechanical/chemical) |

– 15,000–20,000L water per kg hide – High CO2 from livestock & chemical tanning – Chromium pollution risk – Biodegradable but slow (decades) |

Critical Considerations for B2B Decision-Making

- Supply Chain Stability: PU faux leather offers consistent color/texture batches and avoids hide scarcity or price volatility tied to livestock markets.

- Processing Efficiency: Requires no pre-treatment (e.g., dehairing, liming); compatible with standard cutting/sewing lines; reduces production lead times by 30–50%.

- End-of-Life Impact: WINIW’s bio-based PU grades are engineered for circularity—compatible with industrial recycling streams, unlike chrome-tanned leather which contaminates soil/water.

- Performance Customization: PU formulations can be tailored for specific needs (e.g., enhanced UV resistance for automotive, antimicrobial for healthcare) without compromising ethics.

Why WINIW Delivers Sustainable Value

WINIW’s R&D focuses on closing the performance gap while advancing circularity. Our latest EcoSphere™ Bio-PU line uses corn-derived polyols, cuts carbon emissions by 40% vs. conventional PU, and meets Global Recycled Standard (GRS) certification. For brands targeting ESG goals without sacrificing durability or aesthetics, synthetic leather is no longer a compromise—it’s a strategic advantage.

Partner with WINIW to access traceable, high-performance materials that align with tomorrow’s regulatory and consumer expectations. Request technical datasheets or samples to validate performance for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B markets. With a strong commitment to quality, sustainability, and technological advancement, WINIW serves industries ranging from automotive and furniture to fashion and sports.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry. This expansive campus integrates advanced production lines, research laboratories, and logistics centers to ensure seamless operations from raw material processing to final product delivery.

Key strengths of WINIW’s manufacturing capabilities include:

- A dedicated R&D team of over 100 professionals focused on material innovation, durability enhancement, and sustainable development. The team regularly introduces new textures, finishes, and eco-conscious formulations, including water-based and recycled raw materials.

- Strict quality control protocols implemented throughout the production process. Each batch undergoes rigorous testing for color fastness, abrasion resistance, tensile strength, and environmental compliance to meet international standards.

- Certification to ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OEKO-TEX® STANDARD 100, ensuring safe and sustainable production practices.

- Advanced automation and digital monitoring systems that enhance consistency, reduce waste, and improve production efficiency.

WINIW exports to key global markets, with a strong presence in Europe and the USA. Our products are trusted by leading brands and manufacturers who value reliability, performance, and environmental responsibility.

The following table highlights key aspects of WINIW’s factory and capabilities:

| Feature | Especificação |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ engineers and technicians |

| Annual Production | Over 150 million meters |

| Key Certifications | ISO 9001, ISO 14001, OEKO-TEX® STANDARD 100 |

| Primary Export Markets | Europe, USA, Japan, South Korea |

| Sustainability Focus | Water-based PU, recycled content, low VOC |

With robust infrastructure, continuous innovation, and a global quality mindset, WINIW stands as a trusted partner for businesses seeking high-performance synthetic leather solutions.

Contact Us for Samples

WINIW Premium PU Faux Leather: Engineered for Sustainable Performance

WINIW delivers next-generation synthetic leather solutions designed for discerning B2B partners seeking uncompromising quality, ethical production, and circular innovation. Our PU faux leather replaces traditional materials without sacrificing durability or aesthetics, aligning with global sustainability mandates while optimizing your supply chain.

Why Partner with WINIW?

- Eco-Conscious Innovation: Achieve 30% lower carbon footprint vs. conventional synthetics through water-based PU systems and recycled content (up to 40% post-industrial waste).

- Performance Engineered: Engineered for high-abrasion applications with 100,000+ double-rub durability (Martindale test), UV resistance (5,000+ hrs), and temperature stability (-30°C to 80°C).

- Regulatory Ready: Fully compliant with REACH, OEKO-TEX® STANDARD 100, and Prop 65; free of DMF, phthalates, and heavy metals.

- Customization Agility: Rapid prototyping for color (Pantone® matched), texture (suede, grain, embossed), thickness (0.6mm–2.0mm), and roll width (1.38m standard).

Technical Comparison: WINIW PU Faux Leather vs. Alternatives

| Especificação | WINIW PU Faux Leather | Couro PVC | Conventional PU | Genuine Leather |

|---|---|---|---|---|

| CO₂ Emissions (kg/m²) | 2.1 | 4.8 | 3.5 | 11.0 |

| Water Usage (L/m²) | 8.5 | 22.0 | 15.0 | 17,000* |

| Recycled Content | Up to 40% | 0% | 0–10% | 0% |

| Abrasion Resistance | 100,000+ cycles | 15,000 cycles | 50,000 cycles | Varies |

| Biodegradability | 45% in 5 years (ASTM D5511) | Non-biodegradable | Non-biodegradable | 100% (slow) |

*Includes tanning and livestock processing

Target Applications for Maximum ROI

- Automotive: Seat covers, door panels, and dash trims meeting FMVSS 302 flammability standards.

- Furniture: Commercial seating, hospitality upholstery, and contract furniture with anti-stain topcoats.

- Apparel & Accessories: Durable linings, bags, and footwear uppers with breathability (MVTR: 800g/m²/24h).

- Electronics: Scratch-resistant covers for tablets, laptops, and wearables.

Elevate Your Product Line Sustainably

WINIW PU faux leather reduces environmental impact while exceeding performance benchmarks for global brands. Our closed-loop manufacturing and traceable supply chain ensure your products meet ESG goals without compromising on quality or cost-efficiency.

Request Complimentary Samples Today

Experience WINIW’s premium feel and technical superiority firsthand. Contact our B2B solutions team for:

– Free 30cm x 30cm samples (custom colors/textures available)

– Technical datasheets and compliance documentation

– Volume pricing for orders ≥5,000 meters

MKT88@MicrofiberLeather.com

WINIW: Where Innovation Meets Responsibility

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.