Introduction: Navigating the Global Market for pu coated

In the ever-evolving landscape of global commerce, sourcing high-quality PU coated materials can pose significant challenges for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The demand for durable, waterproof, and breathable fabrics is on the rise, driven by industries such as outdoor apparel, automotive, and construction. This guide aims to demystify the complexities surrounding PU coated products by providing a comprehensive overview of their types, applications, supplier vetting processes, and associated costs.

International buyers will find valuable insights into the various forms of PU coatings available, including single-coated and multi-coated options, and how each is suited for specific applications. The guide also addresses the environmental considerations associated with PU coatings, an increasingly critical factor for businesses looking to align with sustainable practices. By highlighting key supplier evaluation criteria, it empowers buyers to make informed decisions that meet both their operational needs and ethical standards.

Ultimately, this guide serves as an essential resource for international B2B buyers, enabling them to navigate the global market for PU coated materials with confidence and precision, ensuring that they secure the best products for their unique requirements.

Table Of Contents

- Top 5 Pu Coated Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu coated

- Understanding pu coated Types and Variations

- Key Industrial Applications of pu coated

- 3 Common User Pain Points for ‘pu coated’ & Their Solutions

- Strategic Material Selection Guide for pu coated

- In-depth Look: Manufacturing Processes and Quality Assurance for pu coated

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu coated’

- Comprehensive Cost and Pricing Analysis for pu coated Sourcing

- Alternatives Analysis: Comparing pu coated With Other Solutions

- Essential Technical Properties and Trade Terminology for pu coated

- Navigating Market Dynamics and Sourcing Trends in the pu coated Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu coated

- Strategic Sourcing Conclusion and Outlook for pu coated

- Important Disclaimer & Terms of Use

Understanding pu coated Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Coated PU | One layer of PU applied, lightweight | Outdoor apparel, lightweight gear | Pros: Cost-effective, lighter weight. Cons: Less durable, limited waterproofing. |

| Multi-Coated PU | Multiple layers of PU for enhanced protection | Heavy-duty outdoor gear, industrial use | Pros: Superior waterproofing, increased durability. Cons: Heavier, bulkier garments. |

| Microporous PU | Contains tiny holes for breathability | Sportswear, hiking gear | Pros: Breathable while waterproof, versatile. Cons: May be less durable than thicker coatings. |

| PU Coated Cordura | Strong polyamide fabric with PU coating | Tactical gear, workwear | Pros: Excellent abrasion resistance, durable. Cons: Heavier than regular fabrics, costlier. |

| PU Coated Fabrics | General category of fabrics coated with PU | Tent floors, tarps, protective gear | Pros: Versatile applications, good waterproofing. Cons: Environmental concerns in production. |

What are the Characteristics of Single-Coated PU Fabrics?

Single-coated PU fabrics feature a single layer of polyurethane, making them lightweight and cost-effective. These fabrics are primarily used in outdoor apparel and lightweight gear, ideal for conditions where moderate water resistance is required. When considering B2B purchasing, buyers should evaluate the trade-off between weight and durability, as this option may not withstand heavy rain or intense wear as effectively as multi-coated alternatives.

How Do Multi-Coated PU Fabrics Differ in Application?

Multi-coated PU fabrics offer enhanced waterproofing and durability due to the application of multiple layers of polyurethane. This makes them suitable for heavy-duty outdoor gear and industrial applications where protection from the elements is crucial. Buyers should consider the increased weight and bulkiness of these fabrics, which may affect the comfort and mobility of the end user, especially in high-intensity activities.

What Advantages Does Microporous PU Offer for Breathability?

Microporous PU fabrics are designed with tiny holes that allow moisture vapor to escape while preventing water ingress. This makes them ideal for sportswear and hiking gear, where breathability is as important as waterproofing. B2B buyers should prioritize these fabrics for applications where users engage in aerobic activities in wet conditions, but they should also be aware that durability may be compromised compared to thicker coatings.

Why Choose PU Coated Cordura for Tactical Gear?

PU coated Cordura is a specialized fabric known for its exceptional strength and abrasion resistance, making it a preferred choice for tactical gear and workwear. The durability of this material ensures it can withstand harsh conditions and rough handling. When purchasing, B2B buyers should weigh the benefits of longevity and protection against potential higher costs and weight considerations.

What are the General Applications of PU Coated Fabrics?

PU coated fabrics encompass a broad category of textiles treated with polyurethane for waterproofing and durability. Common applications include tent floors, tarps, and protective gear. Buyers should consider the versatility of these fabrics but also be mindful of the environmental impact associated with PU production. Selecting suppliers that prioritize sustainable practices can help mitigate these concerns while ensuring quality.

Key Industrial Applications of pu coated

| Industry/Sector | Specific Application of pu coated | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Apparel | Waterproof jackets and gear | Enhanced durability and weather resistance for outdoor activities | Ensure breathability and weight specifications meet user needs |

| Construction | Protective coatings for building materials | Long-lasting protection against moisture and abrasion | Evaluate environmental impact and compliance with local regulations |

| Automotive | Interior and exterior coatings | Improved aesthetics and protection from environmental factors | Consider compatibility with existing materials and finishes |

| Sports Equipment | Coatings for tents and sleeping bags | Increased durability and waterproofing for outdoor use | Assess weight and bulkiness to ensure user comfort |

| Industrial Packaging | Coated fabrics for tarps and covers | Superior resistance to wear and tear in harsh environments | Check for UV stability and chemical resistance |

How is PU Coated Used in Outdoor Apparel?

In the outdoor apparel industry, PU coatings are commonly applied to jackets, pants, and other gear to provide waterproof and breathable properties. This application addresses the need for reliable protection against rain and moisture, essential for outdoor enthusiasts. Buyers in regions with diverse weather conditions, such as Europe and South America, should prioritize sourcing PU-coated fabrics that balance durability with lightweight characteristics to enhance comfort during extended wear.

What Role Does PU Coated Play in Construction?

In construction, PU coatings are utilized on various building materials, such as insulation panels and membranes, to enhance their resistance to moisture and abrasion. This application is crucial for maintaining structural integrity and longevity, especially in regions prone to harsh weather conditions. B2B buyers should consider the environmental sustainability of PU coatings and ensure compliance with local building regulations to avoid future liabilities.

How is PU Coated Beneficial in Automotive Applications?

The automotive sector employs PU coatings on both interior and exterior components to improve durability and aesthetic appeal. These coatings protect vehicles from environmental factors such as UV rays, rain, and dirt, thereby extending their lifespan. When sourcing PU-coated materials, buyers must ensure compatibility with existing automotive finishes and consider the overall weight impact on vehicle performance.

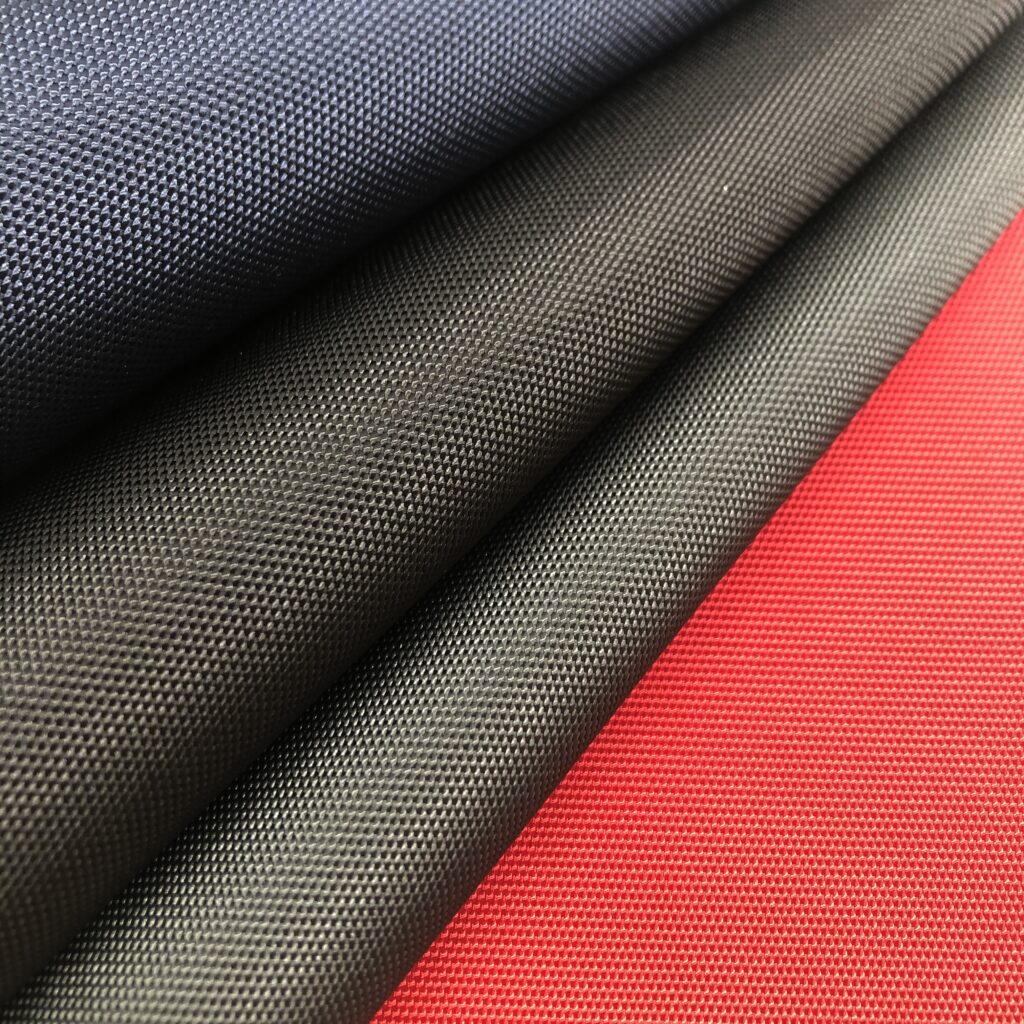

Illustrative image related to pu coated

Why is PU Coated Important for Sports Equipment?

PU coatings are extensively used in sports equipment, particularly for tents and sleeping bags, where waterproofing and durability are paramount. This application helps ensure that outdoor gear can withstand the rigors of nature while keeping users dry and comfortable. Buyers from regions with fluctuating climates, such as Africa and the Middle East, should prioritize sourcing PU-coated products that offer a balance of weight and insulation to meet diverse outdoor needs.

How Does PU Coated Enhance Industrial Packaging?

In the industrial packaging sector, PU coatings are applied to fabrics used for tarps and covers to provide superior resistance to wear and tear. This application is vital for protecting goods in transit or storage, particularly in harsh environments. Buyers should focus on sourcing PU-coated materials that offer UV stability and chemical resistance, ensuring that the packaging remains functional and protective over time.

3 Common User Pain Points for ‘pu coated’ & Their Solutions

Scenario 1: Weight and Bulkiness of PU Coated Fabrics

The Problem:

B2B buyers in the apparel and outdoor gear sectors often face challenges with the weight and bulkiness of PU coated materials. For instance, manufacturers aiming to produce lightweight and highly portable outdoor gear may find that PU coatings add considerable weight to the final product. This can lead to a negative perception among consumers who prioritize ultralight options, especially in markets like Europe and South America, where outdoor activities are prevalent. The bulkiness can also affect the aesthetic appeal and marketability of the product, making it less competitive against alternatives with lighter treatments.

The Solution:

To mitigate this issue, B2B buyers should focus on sourcing PU coated fabrics that are specifically designed for lightweight applications. Look for suppliers that offer advanced microporous coatings, which provide durability and waterproofing without excessive weight. Additionally, consider using a single layer of PU coating rather than multiple layers, as this can significantly reduce bulk while still maintaining essential protective features. It’s also beneficial to collaborate with manufacturers who are experienced in creating lightweight designs, ensuring that the end product meets both performance and aesthetic criteria. Investing in R&D to innovate and test new lightweight PU formulations can further enhance product offerings, making them more appealing to target markets.

Scenario 2: Durability Concerns with PU Coatings

The Problem:

Durability is a significant concern for B2B buyers looking to produce long-lasting outdoor equipment. PU coatings, while providing waterproof and protective qualities, can wear down over time, leading to issues such as peeling, cracking, or decreased performance. This is particularly critical in harsh environments like those found in Africa or the Middle East, where extreme temperatures and abrasive conditions can expedite the deterioration of coated fabrics. Buyers must navigate the fine line between cost and quality, as cheaper options often compromise on durability.

Illustrative image related to pu coated

The Solution:

To address these durability concerns, B2B buyers should prioritize sourcing PU coated materials from reputable manufacturers known for their rigorous quality control processes. Request samples and conduct thorough testing under various environmental conditions to assess the longevity of the coatings. Consider investing in PU coatings that have been enhanced with additional protective agents, such as anti-abrasion or UV-resistant additives, which can significantly extend the lifespan of the fabric. Establishing strong partnerships with suppliers who offer warranties or guarantees on their coatings can also provide peace of mind and minimize risks associated with product failure.

Scenario 3: Breathability Limitations of PU Coated Fabrics

The Problem:

Another common pain point for B2B buyers is the breathability of PU coated fabrics. While these coatings are excellent for waterproofing, they can often inhibit moisture vapor transfer, leading to discomfort for end-users during high-intensity activities. This is particularly relevant for markets in hot and humid regions, where breathability is a crucial factor for consumer satisfaction. Buyers must ensure that the products they source not only protect against external moisture but also allow for internal moisture to escape, preventing overheating and discomfort.

The Solution:

To enhance breathability, B2B buyers should look for PU coated fabrics that incorporate innovative microporous technologies. These coatings feature tiny pores that allow moisture vapor to escape while still blocking water ingress. When selecting suppliers, prioritize those who invest in research and development to create breathable PU coatings that do not compromise on waterproofing. Additionally, consider integrating design features such as ventilation systems or mesh linings in the final product to further improve airflow. Providing education to end-users about the proper care and maintenance of PU coated products can also help maximize breathability and overall performance, leading to higher customer satisfaction and retention.

Strategic Material Selection Guide for pu coated

What Are the Key Materials Used in PU Coated Products?

When selecting materials for PU coatings, understanding the properties, advantages, and limitations of each option is essential for B2B buyers. Here, we analyze four common materials used in PU coatings, focusing on their performance characteristics and applications.

1. Polyester

Key Properties:

Polyester is known for its excellent tensile strength, resistance to stretching and shrinking, and quick-drying capabilities. It can withstand temperatures up to 150°C, making it suitable for various applications.

Illustrative image related to pu coated

Pros & Cons:

Polyester is durable and cost-effective, making it a popular choice for outdoor gear and apparel. However, it can be less breathable compared to other materials, which may limit its use in high-intensity activities.

Impact on Application:

Polyester is compatible with a range of PU coatings, enhancing waterproofing and durability. It is often used in jackets, tents, and other outdoor equipment.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider the local climate when selecting polyester-coated products. Compliance with standards such as ASTM for fabric performance is crucial, especially for outdoor applications.

2. Nylon

Key Properties:

Nylon is known for its exceptional strength, abrasion resistance, and elasticity. It can handle temperatures up to 200°C and is inherently resistant to mildew and mold.

Pros & Cons:

The primary advantage of nylon is its lightweight nature combined with high durability, making it ideal for outdoor gear. However, it can be more expensive than polyester and may require more complex manufacturing processes.

Impact on Application:

Nylon’s compatibility with PU coatings allows for the creation of lightweight, waterproof fabrics suitable for high-performance applications like hiking and cycling gear.

Considerations for International Buyers:

In regions with high humidity, such as parts of the Middle East, nylon’s resistance to mildew can be a significant advantage. Buyers should also ensure that products meet local standards for performance and safety.

Illustrative image related to pu coated

3. Cordura

Key Properties:

Cordura is a brand of fabric known for its durability and resistance to abrasions, tears, and scuffs. It is typically made from nylon or polyester and can withstand high temperatures.

Pros & Cons:

Cordura’s primary advantage is its exceptional durability, making it suitable for heavy-duty applications. However, it can be heavier and bulkier than other options, which may not appeal to all consumers.

Impact on Application:

The robust nature of Cordura makes it ideal for applications requiring high abrasion resistance, such as military gear, workwear, and outdoor equipment.

Considerations for International Buyers:

Buyers should be aware of the specific Cordura grade required for their application, as different grades offer varying levels of durability and weight. Compliance with industry standards is also essential for safety and performance.

4. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a synthetic plastic polymer known for its chemical resistance and waterproof properties. It can withstand temperatures up to 60°C and is often used in industrial applications.

Pros & Cons:

PVC is highly durable and cost-effective, making it suitable for a wide range of applications. However, it is less flexible than PU and may not offer the same level of breathability.

Impact on Application:

PVC-coated fabrics are often used in applications requiring high waterproofing and chemical resistance, such as tarps, tents, and industrial covers.

Considerations for International Buyers:

Buyers should consider the environmental impact of PVC, as it can be less sustainable than other materials. Compliance with local environmental regulations is crucial, particularly in Europe, where standards are stringent.

Summary Table

| Material | Typical Use Case for pu coated | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor apparel, tents | Cost-effective and durable | Less breathable | Low |

| Nylon | High-performance gear | Lightweight and abrasion-resistant | Higher cost and manufacturing complexity | Medium |

| Cordura | Military gear, workwear | Exceptional durability | Heavier and bulkier | Elevado |

| PVC | Industrial covers, tarps | Highly durable and waterproof | Less flexible and breathable | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing PU-coated products tailored to their specific needs and regional standards.

Illustrative image related to pu coated

In-depth Look: Manufacturing Processes and Quality Assurance for pu coated

What Are the Main Stages of the Manufacturing Process for PU Coated Products?

The manufacturing process for PU coated materials involves several key stages, each crucial for ensuring the quality and performance of the final product.

-

Material Preparation: The process begins with the selection and preparation of the base fabric, which is often a synthetic material such as polyester or nylon. This fabric is chosen for its inherent properties such as strength and durability. The material is then treated to ensure it is clean and free of contaminants, which can affect the adhesion of the polyurethane coating.

-

Forming the PU Coating: In this stage, the polyurethane resin is prepared. This involves mixing the resin components, which typically include polyols and isocyanates. The mixture is then applied to the base fabric using methods such as spraying, roll coating, or dip coating. The thickness of the coating can be adjusted based on the intended use of the fabric, with options for single or multiple coats to enhance waterproofing and durability.

-

Curing Process: After application, the coated fabric undergoes a curing process, where it is subjected to heat or UV light. This step is critical as it enables the polyurethane to form a strong bond with the fabric, enhancing its waterproof and abrasion-resistant properties. The curing time and temperature are meticulously controlled to achieve optimal results.

-

Finishing Touches: Once cured, the PU coated fabric may go through additional finishing processes. This can include treatments to improve breathability, color application, or the addition of special finishes for enhanced tactile properties.

-

Quality Control: Throughout the manufacturing process, quality checks are integrated to ensure that the products meet the required specifications and standards.

How Is Quality Assurance Implemented in PU Coating Manufacturing?

Quality assurance (QA) is a critical component in the production of PU coated products. B2B buyers should be aware of the international standards and checkpoints that manufacturers adhere to in order to ensure product reliability and safety.

-

International Standards Compliance: Manufacturers typically seek certifications such as ISO 9001, which outlines the requirements for a quality management system. Compliance with these standards ensures that the manufacturing processes are consistent and that products meet customer and regulatory requirements.

-

Industry-Specific Certifications: Depending on the application of the PU coated products, additional certifications may be necessary. For example, CE marking is essential for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet the required specifications before entering production.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the coating application and curing processes. This helps in identifying any deviations from quality standards early on.

– Final Quality Control (FQC): Once production is complete, final inspections are carried out to assess the overall quality of the finished PU coated products. Tests may include waterproofness, breathability, and durability assessments.

What Testing Methods Are Commonly Used for PU Coated Products?

To ensure that PU coated products meet performance standards, various testing methods are employed during the manufacturing process:

-

Waterproof Testing: Commonly conducted using the hydrostatic head test, this method measures the fabric’s ability to withstand water pressure. A higher hydrostatic head value indicates better waterproof performance.

-

Abrasion Resistance Testing: The Martindale test or Taber abrasion test is often used to evaluate the durability of the PU coating against wear and tear. This is crucial for products intended for heavy-duty applications.

-

Breathability Testing: The Moisture Vapor Transmission Rate (MVTR) test assesses how well moisture vapor can escape from the fabric, ensuring comfort for the end-user.

-

Tensile Strength Testing: This test determines the maximum amount of tensile (pulling) stress that the fabric can withstand before breaking, which is vital for ensuring the structural integrity of the product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing PU coated products, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some effective strategies:

Illustrative image related to pu coated

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and industry-specific certifications firsthand.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of various tests conducted on the products. This documentation should include information on the testing methods used, the results, and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct quality checks at different stages of the manufacturing process, providing unbiased evaluations of product quality.

-

Understanding Certification Nuances: It is essential for buyers to familiarize themselves with the specific certifications relevant to their market. For instance, understanding the differences between CE marking and ISO certifications can help in assessing a supplier’s credibility and compliance with local regulations.

What Challenges Do International Buyers Face in Quality Assurance for PU Coated Products?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges in ensuring quality assurance for PU coated products:

-

Regulatory Variances: Different regions may have varying regulations regarding product safety and environmental standards. Buyers must navigate these complexities to ensure compliance with local laws.

-

Communication Barriers: Language differences and cultural nuances can lead to misunderstandings in specifications and quality expectations. Clear communication channels and detailed documentation are crucial to mitigate these risks.

-

Supply Chain Reliability: Disruptions in the supply chain can impact the availability and quality of raw materials. Buyers should evaluate the supplier’s sourcing strategies and resilience to ensure consistent product quality.

-

Logistical Challenges: Transporting PU coated products across international borders can present logistical issues, such as delays and damages. Buyers should consider suppliers with robust logistics capabilities to minimize risks.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing PU coated products, ensuring they meet the necessary standards for performance and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu coated’

Introdução

This guide serves as a comprehensive checklist for B2B buyers looking to procure PU-coated materials. Understanding the nuances of PU coatings can significantly enhance your sourcing strategy, ensuring you select the right products that meet your specific needs. This checklist will help streamline your procurement process and align your requirements with supplier capabilities.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s vital to outline your technical specifications for the PU-coated materials you require. Consider factors such as the intended application (e.g., outdoor clothing, industrial uses), desired waterproofing levels, and breathability. Clearly defined specifications will not only help you communicate effectively with suppliers but also ensure you receive products that meet your performance criteria.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in PU-coated products. Utilize online platforms, industry directories, and trade shows to compile a list. Pay attention to suppliers with a proven track record in your region, particularly those familiar with the specific requirements of buyers from Africa, South America, the Middle East, and Europe.

Illustrative image related to pu coated

Step 3: Evaluate Supplier Certifications

It is crucial to verify supplier certifications to ensure compliance with international quality and environmental standards. Look for certifications such as ISO 9001 for quality management and OEKO-TEX for ecological safety. These certifications indicate that the supplier adheres to best practices, reducing the risk of receiving subpar or harmful products.

Step 4: Request Product Samples

Before finalizing any contracts, request samples of the PU-coated materials. This step allows you to assess the quality, durability, and performance of the products first-hand. Evaluate factors such as weight, flexibility, and waterproof capabilities, as these attributes will significantly impact the end-user experience.

Step 5: Inquire About Manufacturing Processes

Understanding the manufacturing processes used by your potential suppliers is vital. Inquire about the techniques they employ to apply PU coatings, as well as their quality control measures. Suppliers that utilize advanced coating technologies, like microporous coatings for breathability, may offer superior products that align better with your needs.

Step 6: Discuss Lead Times and Minimum Order Quantities

Engage in discussions regarding lead times and minimum order quantities (MOQs). This information is critical for planning your inventory and ensuring timely delivery to your customers. Suppliers with flexible MOQs and reliable lead times can help you better manage your supply chain and meet market demands.

Step 7: Negotiate Terms and Conditions

Once you’ve narrowed down your options, negotiate terms and conditions, including pricing, payment terms, and warranties. Ensure that you understand the implications of each term, particularly regarding returns and product guarantees. A well-negotiated agreement can safeguard your investment and foster a positive long-term relationship with your supplier.

By following these steps, you can effectively navigate the procurement of PU-coated materials, ensuring you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for pu coated Sourcing

When sourcing PU coated materials, understanding the cost structure and pricing dynamics is crucial for B2B buyers. The complexity of the cost components and the various price influencers can significantly impact your sourcing decisions. This analysis aims to provide actionable insights for international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in PU Coated Sourcing?

The cost structure for PU coated materials consists of several components:

-

Materials: The primary expense is the polyurethane itself, which varies in price based on quality and specifications. Different grades of PU can significantly impact the overall cost. Additionally, the base fabric on which the PU is applied also contributes to the cost.

-

Labor: Labor costs can vary by region and are influenced by the complexity of the application process. Skilled labor is often required for applying coatings, especially if multiple layers are needed for enhanced waterproofing or durability.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and other indirect costs. Overhead can differ significantly depending on the geographical location of the manufacturer.

-

Tooling: For custom applications, tooling costs can be substantial. Specific molds or machinery may be required for unique shapes or designs, adding to the upfront investment.

-

Quality Control (QC): Ensuring that the PU coatings meet specified standards necessitates investment in quality control measures. This can include testing for waterproofing, breathability, and durability, which adds to the overall cost.

-

Logistics: Shipping and handling costs also play a critical role in pricing. International buyers must consider freight, customs duties, and potential tariffs, which can add to the total cost.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. This margin can vary based on the supplier’s pricing strategy and market competition.

What Factors Influence PU Coated Pricing?

Several elements can affect the pricing of PU coated materials:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Understanding a supplier’s MOQ can help you negotiate better pricing.

-

Specifications and Customization: Customized solutions typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., environmental compliance) will generally command higher prices. Buyers should assess the value of these certifications against their needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge premium prices.

-

Incoterms: Understanding the terms of delivery is crucial for calculating the total cost. Different Incoterms can shift the responsibility for shipping, insurance, and customs duties between the buyer and seller.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Volume Discounts: If possible, consolidate orders to reach higher volumes and negotiate better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs, including durability, maintenance, and replacement rates of the PU coated materials.

-

Be Prepared for Negotiation: Understanding your supplier’s cost structure can provide leverage during negotiations. Be clear about your budget and requirements.

-

Consider Regional Dynamics: Prices may vary significantly across regions due to local market conditions, labor costs, and material availability. Buyers should be aware of these nuances when sourcing internationally.

-

Request Samples: Before committing to a large order, request samples to assess quality and suitability. This can help avoid costly mistakes later.

Conclusion

Sourcing PU coated materials involves a multifaceted cost structure and pricing dynamics that require careful consideration. By understanding the key cost components, price influencers, and effective negotiation strategies, international buyers can make informed decisions that align with their operational needs and budget constraints. While indicative prices can vary, thorough research and strategic sourcing practices will ultimately lead to successful procurement outcomes.

Alternatives Analysis: Comparing pu coated With Other Solutions

Understanding Alternatives in PU Coating Solutions

In the quest for high-performance textiles, polyurethane (PU) coatings have become a staple in various industries due to their waterproof and durable characteristics. However, there are several alternative technologies and methods that can achieve similar goals. This section explores these alternatives, providing B2B buyers with a comprehensive comparison to help in decision-making.

Comparison Table of PU Coated and Alternative Solutions

| Comparison Aspect | PU Coated | DWR (Durable Water Repellent) | PVC Coated |

|---|---|---|---|

| Performance | Excellent waterproofing, good durability | Moderate waterproofing, less durable | Strong waterproofing, heavy and less flexible |

| Cost | Moderate to high | Low to moderate | Low to moderate |

| Ease of Implementation | Requires specialized coating process | Simple application methods | Straightforward application |

| Maintenance | Requires periodic reproofing | Easily re-treated | Difficult to maintain |

| Best Use Case | Outdoor apparel, heavy-duty applications | Light outdoor clothing, casual wear | Industrial applications, tarps, flooring |

In-Depth Analysis of Alternatives

What is DWR (Durable Water Repellent) and How Does It Compare?

DWR is a surface treatment applied to fabrics that repels water without completely sealing the material. While it offers a lightweight and flexible solution, its effectiveness diminishes over time, especially after washing. DWR-treated fabrics are typically less expensive and easier to maintain, making them suitable for casual outdoor wear. However, for applications requiring long-term waterproofing, DWR may not provide the necessary protection against heavy rain or abrasion, making PU coatings a better choice for rugged environments.

Exploring PVC Coating: Advantages and Disadvantages

PVC (Polyvinyl Chloride) coatings are another alternative known for their strong waterproofing abilities. They are commonly used in industrial applications due to their durability and affordability. However, PVC coatings tend to be heavier and less flexible than PU coatings, which can limit their comfort and versatility in clothing applications. Furthermore, the environmental impact of PVC production and disposal is significant, making it a less sustainable option compared to PU. While PVC can be an excellent choice for heavy-duty applications, it may not be suitable for high-performance outdoor apparel where breathability and weight are crucial.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a coating technology for textiles, B2B buyers must consider various factors, including performance requirements, cost constraints, and the intended use of the fabric. PU coatings offer a robust solution for demanding applications requiring long-lasting waterproofing and durability. In contrast, alternatives like DWR and PVC coatings may be more suitable for less intensive uses or budget-conscious projects. Ultimately, understanding the specific needs of your application will guide you in choosing the right coating solution that balances performance, cost, and sustainability.

Essential Technical Properties and Trade Terminology for pu coated

What Are the Essential Technical Properties of PU Coated Materials?

PU (polyurethane) coatings are essential in various industries, particularly in outdoor clothing and equipment. Understanding their key technical properties can help B2B buyers make informed purchasing decisions.

Illustrative image related to pu coated

1. Waterproof Rating (Hydrostatic Head)

The waterproof rating is measured by the hydrostatic head, usually expressed in millimeters (mm). This rating indicates the amount of water pressure a fabric can withstand before leaking. For example, a fabric with a hydrostatic head of 5000 mm is capable of withstanding 5000 mm of water column pressure. This property is crucial for outdoor applications, ensuring the longevity and usability of products in wet conditions.

2. Breathability (MVTR)

Breathability is quantified by the Moisture Vapor Transmission Rate (MVTR), measured in grams per square meter per 24 hours (g/m²/24h). This metric indicates how effectively moisture vapor can escape from the inside of the fabric to the outside. High MVTR values are essential for active wear, as they allow sweat to evaporate while keeping external moisture out. This property is vital for maintaining comfort during physical activities in variable weather conditions.

3. Durability and Abrasion Resistance

Durability refers to the material’s ability to withstand wear, pressure, and damage, while abrasion resistance specifically measures how well the material can resist surface wear caused by rubbing against other materials. Fabrics treated with PU coatings tend to be more robust and can last longer in rugged environments, making them ideal for outdoor gear that experiences heavy use, such as tents and backpacks.

Illustrative image related to pu coated

4. Weight and Bulkiness

While PU coatings enhance protective properties, they can also add weight and bulk to the material. This aspect is important for buyers focused on lightweight gear, as heavier materials can hinder mobility and comfort. Understanding the trade-off between protection and weight can help buyers choose the right products for their needs, especially in sectors like outdoor apparel and equipment.

5. Chemical Resistance

PU coatings provide a degree of resistance to various chemicals, which can be crucial for industrial applications. This property ensures that products can withstand exposure to oils, solvents, and other harsh substances without degrading. For B2B buyers in industries such as manufacturing or construction, this characteristic can significantly impact the longevity and safety of their equipment.

6. Environmental Impact

The production and disposal of PU materials can have environmental implications. As such, understanding the sustainability of PU coatings compared to alternatives (like fluorocarbon treatments) is critical for companies aiming to enhance their green credentials. This property has become increasingly relevant for buyers looking to align with eco-friendly practices.

What Are Common Trade Terms Related to PU Coated Products?

Navigating the language of the industry can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some essential trade terms:

Illustrative image related to pu coated

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are used in another company’s end product. Understanding OEM relationships is crucial for buyers who require specific PU-coated materials that meet certain standards for integration into their own products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting a price quote for specific products. This term is vital for B2B transactions as it initiates the negotiation process and ensures that buyers receive competitive pricing for PU-coated materials.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers, particularly those in regions like Africa or South America, to avoid misunderstandings in cross-border transactions.

Illustrative image related to pu coated

5. Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the goods. Understanding lead times is critical for B2B buyers to manage their supply chains effectively and ensure timely project completion.

6. Certification Standards

These are industry-specific benchmarks that products must meet to ensure quality and safety. Certifications can include ISO standards, environmental certifications, or safety ratings. Buyers must be aware of these standards to ensure compliance and maintain product integrity.

By grasping these technical properties and trade terminologies, B2B buyers can make better-informed decisions when sourcing PU-coated products for their businesses.

Illustrative image related to pu coated

Navigating Market Dynamics and Sourcing Trends in the pu coated Sector

What Are the Key Market Trends Influencing PU Coated Products?

The global market for PU coated materials is witnessing robust growth, driven by increasing demand for high-performance textiles across various sectors, including outdoor apparel, automotive, and construction. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on durable, waterproof, and breathable solutions that PU coatings provide. A significant trend is the shift towards multifunctional fabrics that not only offer waterproofing but also enhanced durability and breathability, making them suitable for diverse applications.

Emerging technologies in coating processes, such as microporous coatings, are transforming how manufacturers approach fabric performance. These advancements enable the creation of lighter, more flexible materials without compromising on strength or waterproof capabilities. Furthermore, the integration of digital sourcing platforms is streamlining procurement, allowing international buyers to easily compare suppliers, materials, and costs. As B2B buyers increasingly prioritize quick turnaround times and reliable delivery, digital tools are becoming essential in navigating the complexities of global sourcing.

How Is Sustainability Shaping the PU Coated Sector?

Sustainability is a critical consideration for B2B buyers in the PU coated sector. The environmental impact of traditional coatings, particularly those using harmful chemicals, is prompting companies to seek more sustainable alternatives. Ethical sourcing and supply chain transparency are no longer just compliance issues; they are essential components of brand reputation and consumer trust. Buyers are increasingly looking for suppliers that can demonstrate adherence to sustainability standards and provide certifications for eco-friendly materials.

Illustrative image related to pu coated

The use of water-based PU coatings and the reduction of volatile organic compounds (VOCs) in production processes are gaining traction. These innovations not only minimize environmental impact but also enhance the safety of the end products. Moreover, certifications such as Global Organic Textile Standard (GOTS) and Oeko-Tex Standard 100 are becoming important benchmarks for B2B buyers aiming to align with sustainable practices. As consumer awareness of environmental issues continues to grow, suppliers that prioritize ethical practices and sustainability in their offerings will have a competitive edge in the market.

What Is the Historical Context of PU Coated Materials in B2B Markets?

The history of PU coated materials dates back to the early 20th century, with significant advancements made post-World War II. Initially utilized for insulation and construction applications, polyurethane found its way into various industries, including textiles, thanks to its versatility and durability. The introduction of PU coatings in the outdoor apparel sector transformed the functionality of fabrics, providing waterproofing and abrasion resistance that was previously unattainable.

Over the decades, the technology behind PU coatings has evolved, leading to the development of breathable fabrics and lighter coatings. This evolution has enabled manufacturers to cater to a growing market that demands high-performance textiles without sacrificing comfort or mobility. As B2B buyers continue to seek innovative solutions, the PU coated sector remains at the forefront of material science, adapting to meet the ever-changing needs of industries worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of pu coated

-

How do I choose the right PU-coated fabric for my application?

Selecting the appropriate PU-coated fabric involves understanding your specific needs, such as durability, water resistance, and breathability. Evaluate the intended use, whether for outdoor apparel, industrial applications, or protective gear. Consider the fabric’s weight and bulkiness, as PU coatings can add significant mass. Request samples from suppliers to assess the texture and performance under real-world conditions. Also, inquire about the manufacturing process, as modern techniques can enhance breathability and environmental sustainability, which are crucial for many buyers today. -

What are the advantages of using PU coatings in my products?

PU coatings offer numerous benefits, including permanent waterproofing, durability, and resistance to abrasion. They are particularly advantageous in outdoor clothing, tents, and gear that require protection from harsh weather. Unlike traditional DWR treatments, PU coatings provide long-lasting impermeability and enhanced tear resistance. Additionally, advancements in technology have led to the creation of breathable PU fabrics, allowing moisture vapor to escape while keeping water out, making them suitable for various applications across different climates. -

What should I consider when vetting suppliers for PU-coated materials?

When vetting suppliers, assess their manufacturing capabilities, quality control processes, and compliance with international standards. Request information on their certifications, such as ISO or OEKO-TEX, to ensure they meet safety and environmental regulations. It’s also beneficial to review their production timelines and past client testimonials. Consider engaging in a trial order to evaluate the product quality and responsiveness of the supplier. Building a strong relationship with a reliable supplier can significantly impact your sourcing strategy. -

What are typical minimum order quantities (MOQs) for PU-coated fabrics?

Minimum order quantities for PU-coated fabrics can vary significantly based on the supplier and the specific type of fabric. Generally, MOQs can range from 500 to 1,000 meters for standard fabrics. However, for specialized or custom coatings, MOQs may be higher due to production constraints. It’s advisable to discuss your specific needs with suppliers to negotiate terms that fit your business model. Some suppliers may offer flexibility for first-time buyers or for those interested in long-term partnerships. -

What payment terms are common in international trade for PU-coated products?

Payment terms in international trade can vary widely, but common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit of 30% to 50% upfront, with the remainder due before shipping. It’s crucial to clarify payment terms and conditions upfront to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when making international payments, as these can impact overall costs. -

How do I ensure quality assurance (QA) for PU-coated materials?

To ensure quality assurance for PU-coated materials, establish clear specifications and standards during the procurement process. Request samples for testing before placing bulk orders and consider conducting third-party inspections at the supplier’s facility. Implement a system for ongoing quality checks upon receipt of goods to catch any defects early. Collaborating with suppliers on QA processes, such as regular audits or adherence to specific testing methods, can further enhance product consistency and reliability. -

What logistics considerations should I keep in mind when importing PU-coated fabrics?

Logistics considerations for importing PU-coated fabrics include understanding shipping regulations, customs duties, and potential tariffs that may apply to your products. Work with freight forwarders who specialize in textile imports to streamline the shipping process. Be mindful of lead times, as PU-coated materials may require longer production periods. Additionally, ensure that your supplier can provide necessary documentation for customs clearance, such as certificates of origin and compliance. -

Can PU coatings be customized for specific applications?

Yes, PU coatings can often be customized to meet specific performance requirements, including varying levels of water resistance, breathability, and durability. Collaborating with suppliers early in the design process allows for adjustments in coating thickness, application methods, and additives that enhance performance. Discuss your unique needs and potential formulations with your supplier to create a tailored solution that aligns with your product’s intended use, ensuring optimal functionality and customer satisfaction.

Top 5 Pu Coated Manufacturers & Suppliers List

1. Ripstop by the Roll – PU Coated Fabrics

Domain: ripstopbytheroll.com

Registered: 2013 (12 years)

Introduction: PU coating is a type of polyurethane coating applied to fabrics to enhance water resistance, durability, and overall performance. It is commonly used in outdoor gear and applications where waterproofing is essential.

2. Reddit – Waxed Cotton vs PU Coated Materials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Waxed Cotton:

– Slightly breathable

– Medium water resistance

– Fails faster in heavy downpours

– Water-retentive, increases weight when wet

– Requires frequent rewaxing

– Not suitable for outdoor gear compared to synthetic materials

2. PU Coated:

– Low breathability

– Superior waterproofing

– Typically a silicon-coated nylon material

– Can trap moistur…

3. Canvas Etc. – Denier Fabric Coatings

Domain: canvasetc.com

Registered: 2005 (20 years)

Introduction: Denier fabric coatings are treatments applied to synthetic fabrics, primarily nylon or polyester, characterized by their denier value indicating fiber thickness. The main coating types include: 1. Polyurethane (PU): Offers balanced performance with water resistance, potential breathability, and good flexibility. 2. Polyvinyl Chloride (PVC): Provides maximum waterproofing and high durability but is…

4. Seattle Fabrics – Coated Ripstop Nylon & Polyester

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: Coated Ripstop – Nylon & Polyester By The Yard

Sub-Categories:

1. 1.3 Ounce Silicone Impregnated Ripstop – 60″ @ $15.50/linear yard, 1.3 oz/sq yd, 30 denier, high tenacity, bright nylon, zero porosity, ripstop with heat and light inhibitors.

2. 1.9 Ounce Polyurethane Coated Ripstop – 60″ @ $15.75/linear yard, 1.9 oz/sq yd before coating, 70 Denier, tear resistant squares.

3. 1.9 Ounce Polyurethan…

5. American Plastics – 600D Polyester Fabric with PU Coating

Domain: americanplastics.com

Registered: 1996 (29 years)

Introduction: {“name”:”600 x 600 100% Polyester Fabric with PU Coating”,”sku”:”FABP6*6″,”barcode”:”Available Now!”,”price”:”$44.80″,”colors”:[“Black”,”Burgundy”],”size”:”600D x 600D”,”width”:”60 inches”,”material”:”100% Polyester”,”length”:”100 yards/roll”,”sold_in”:”yards of 5″,”shipping_info”:”Add $150.00 more for FREE shipping!”}

Strategic Sourcing Conclusion and Outlook for pu coated

As the global demand for durable, weather-resistant materials continues to rise, PU coatings emerge as a compelling choice for various applications, particularly in outdoor apparel and equipment. Their unique combination of waterproofing, durability, and flexibility makes them invaluable for B2B buyers looking to enhance product offerings in competitive markets.

What Are the Key Advantages of PU Coatings for B2B Buyers?

Strategic sourcing of PU-coated materials can yield substantial benefits, including improved product longevity and customer satisfaction. The advanced breathability of modern PU coatings further addresses the needs of diverse climates, making them suitable for markets across Africa, South America, the Middle East, and Europe. Additionally, as environmental sustainability becomes increasingly important, PU coatings present a more eco-friendly alternative compared to traditional treatments.

How Can B2B Buyers Leverage PU Coatings for Future Growth?

Moving forward, international buyers should focus on building partnerships with suppliers who prioritize innovative coating technologies and sustainable practices. By doing so, they can not only meet growing consumer demands but also position themselves as leaders in their respective markets. Investing in PU-coated products will not only enhance your brand’s reputation but also ensure you remain competitive in a rapidly evolving landscape.

Embrace the advantages of PU coatings today and explore new sourcing opportunities that can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.