Introduction: Navigating the Global Market for leather making supplies

Navigating the complexities of sourcing leather making supplies can be a daunting challenge for international B2B buyers. With varying quality standards, diverse supplier capabilities, and fluctuating costs, making informed purchasing decisions is crucial. This guide aims to streamline the process by providing a comprehensive overview of the leather making supply market, including essential types of materials, their applications across various industries, and best practices for supplier vetting.

From understanding the nuances of vegetable-tanned versus chrome-tanned leather to exploring the latest machinery and hand tools, this resource equips buyers with the insights needed to navigate the global market effectively. Special attention is given to regional considerations, ensuring that buyers from Africa, South America, the Middle East, and Europe—such as Germany and Saudi Arabia—can adapt their sourcing strategies to local demands and conditions.

By delving into cost analysis and offering tips for negotiating with suppliers, this guide empowers businesses to make strategic purchasing decisions that align with their operational goals. Whether you are a startup looking to make your first bulk purchase or an established company seeking to optimize your supply chain, this comprehensive resource will serve as your roadmap to success in the leather making industry.

Table Of Contents

- Top 8 Leather Making Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather making supplies

- Understanding leather making supplies Types and Variations

- Key Industrial Applications of leather making supplies

- 3 Common User Pain Points for ‘leather making supplies’ & Their Solutions

- Strategic Material Selection Guide for leather making supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather making supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather making supplies’

- Comprehensive Cost and Pricing Analysis for leather making supplies Sourcing

- Alternatives Analysis: Comparing leather making supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather making supplies

- Navigating Market Dynamics and Sourcing Trends in the leather making supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather making supplies

- Strategic Sourcing Conclusion and Outlook for leather making supplies

- Important Disclaimer & Terms of Use

Understanding leather making supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned Leather | Natural tanning process; eco-friendly; develops a patina over time | Handcrafted goods, high-end products | Pros: Sustainable, strong, customizable. Cons: Prone to water damage, may require more care. |

| Chrome-Tanned Leather | Quick tanning process; soft and supple; water-resistant | Mass production, apparel, upholstery | Pros: Durable, affordable, consistent quality. Cons: Less environmentally friendly, limited customization. |

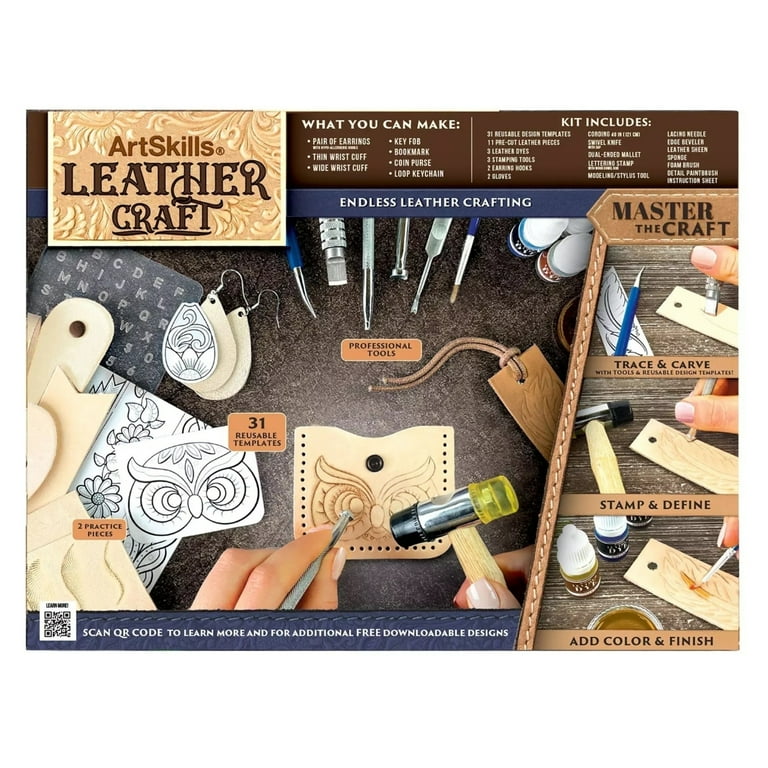

| Leather Tools | Includes cutting, stitching, and finishing tools | Leather crafting, repair services | Pros: Essential for quality craftsmanship. Cons: Initial investment can be high, requires skill to use effectively. |

| Leather Dyes & Finishes | Wide range of colors and finishes; enhances appearance and durability | Custom leather goods, fashion items | Pros: Versatile, can change leather aesthetics. Cons: Requires expertise to apply correctly, potential for color fading. |

| Hardware & Accessories | Buckles, rivets, and clasps; essential for finished products | Bags, belts, and fashion accessories | Pros: Complements leather products, enhances functionality. Cons: Quality varies widely, can increase overall product cost. |

What Are the Characteristics of Vegetable-Tanned Leather and Its B2B Suitability?

Vegetable-tanned leather is known for its environmentally friendly tanning process, utilizing natural tannins from plant sources. This type of leather is favored for its durability and ability to develop a unique patina over time, making it ideal for high-end handcrafted goods, such as wallets, belts, and saddles. B2B buyers should consider sourcing this type for products aimed at eco-conscious consumers, as it aligns well with sustainable practices. However, it is essential to note that vegetable-tanned leather is more susceptible to water damage and may require additional care.

Illustrative image related to leather making supplies

How Does Chrome-Tanned Leather Differ and What Are Its B2B Applications?

Chrome-tanned leather is produced through a faster, chemical-based tanning process, resulting in a softer and more supple material that is also water-resistant. This type is widely used in mass production settings, especially for apparel and upholstery, where durability and cost-effectiveness are critical. B2B buyers looking for consistent quality at lower prices will find chrome-tanned leather appealing. However, it is important to acknowledge that its production process is less environmentally friendly, which may be a concern for brands focusing on sustainability.

Why Are Leather Tools Critical for Quality Craftsmanship?

Leather tools encompass a variety of essential instruments, including cutting, stitching, and finishing tools that are crucial for the leather crafting process. For B2B buyers, investing in high-quality tools is vital for ensuring the precision and craftsmanship of their products. These tools can significantly impact the overall quality of leather goods, making them a necessary consideration for manufacturers and artisans alike. However, the initial investment can be substantial, and proper training is required to maximize their effectiveness.

What Role Do Leather Dyes and Finishes Play in Customization?

Leather dyes and finishes are pivotal in enhancing the aesthetic appeal and durability of leather products. They come in a wide array of colors and finishes, allowing for customization that can differentiate products in a competitive market. B2B buyers should consider the application techniques and the expertise required to achieve the desired results, as improper application can lead to issues like color fading. While dyes and finishes can elevate product value, they also necessitate a knowledge of best practices to ensure quality.

How Do Hardware and Accessories Enhance Leather Products?

Hardware and accessories, such as buckles, rivets, and clasps, are essential components that enhance the functionality and appeal of leather goods. For B2B buyers, sourcing high-quality hardware is crucial for producing durable and attractive products, such as bags and belts. While these components can significantly improve the overall design, buyers must be cautious, as quality can vary widely between suppliers, potentially impacting the final product’s integrity and cost-effectiveness.

Key Industrial Applications of leather making supplies

| Industry/Sector | Specific Application of leather making supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Production of high-quality leather garments | Enhances brand prestige and consumer appeal | Quality of leather, sourcing certifications, and ethical practices |

| Automotive | Interior upholstery for vehicles | Improves luxury feel and durability of vehicle interiors | Compliance with automotive standards, material longevity |

| Footwear | Crafting durable and stylish shoes | Offers comfort and unique design opportunities | Leather weight and flexibility, availability of various textures |

| Furniture | Upholstery and leather accents for furniture | Adds aesthetic value and durability to products | Sourcing from sustainable suppliers, color and texture matching |

| Sporting Goods | Manufacturing leather sports equipment | Provides superior performance and durability | Material strength, resistance to wear, and sourcing logistics |

How Are Leather Making Supplies Utilized in the Fashion and Apparel Industry?

In the fashion and apparel industry, leather making supplies are integral for creating high-quality garments, including jackets, bags, and accessories. The use of premium leather not only enhances the aesthetic appeal of products but also elevates brand prestige among consumers. Buyers in this sector must prioritize sourcing leather that meets strict quality standards and ethical practices, ensuring that the materials align with their brand values and consumer expectations.

What Role Does Leather Making Supplies Play in the Automotive Sector?

Leather making supplies are essential for the automotive industry, particularly for crafting luxurious interiors that include seats, dashboards, and trims. The use of leather enhances the overall feel of vehicles, contributing to a sense of luxury and comfort. Automotive buyers must consider compliance with industry-specific standards, ensuring the leather’s durability and resistance to wear. Additionally, sourcing from reliable suppliers who can guarantee consistent quality is crucial to maintaining brand integrity.

How Is Leather Used in Footwear Production?

In the footwear industry, leather making supplies are pivotal for producing durable and stylish shoes. High-quality leather offers flexibility and comfort, making it a preferred choice for various footwear styles, from formal shoes to sports sneakers. B2B buyers should focus on the specific weight and flexibility of leather to ensure it meets the performance requirements of their designs. Sourcing partners should also provide a range of textures and finishes to meet diverse consumer preferences.

What Are the Applications of Leather in Furniture Design?

Leather making supplies are widely used in the furniture sector for upholstery and decorative accents. High-quality leather not only enhances the visual appeal of furniture but also contributes to its longevity and durability. Buyers in this industry must consider sourcing from sustainable suppliers, ensuring that the leather matches the desired color and texture for their designs. Additionally, understanding the maintenance requirements of leather can help manufacturers provide added value to their customers.

Illustrative image related to leather making supplies

Why Is Leather Important in the Sporting Goods Industry?

The sporting goods industry utilizes leather making supplies for crafting high-performance equipment, such as balls, gloves, and protective gear. Leather’s natural properties provide superior durability and performance, making it ideal for rigorous sports applications. Buyers should focus on the strength and wear resistance of the leather, as well as the logistics of sourcing to ensure timely delivery for production schedules. Selecting suppliers with a strong reputation for quality can significantly impact the end product’s success.

3 Common User Pain Points for ‘leather making supplies’ & Their Solutions

Scenario 1: Sourcing Quality Leather at Competitive Prices

The Problem: B2B buyers often struggle to find high-quality leather that meets their specifications without breaking the bank. This challenge is compounded when dealing with international suppliers who may have varying standards of quality, inconsistent pricing, and opaque sourcing practices. Buyers from regions such as Africa and South America may face additional hurdles, including limited access to premium leather types or inflated shipping costs, making it hard to maintain profitability while ensuring product quality.

The Solution: To overcome these sourcing challenges, B2B buyers should establish strong relationships with reputable suppliers known for their quality assurance processes. It’s advisable to conduct thorough research into potential suppliers, focusing on their production methods, ethical sourcing practices, and customer reviews. Buyers can benefit from visiting trade shows or industry exhibitions where they can meet suppliers directly, inspect products firsthand, and negotiate better deals. Additionally, leveraging online platforms that specialize in leather supplies can facilitate bulk purchasing at discounted rates. It’s also beneficial to request samples before committing to large orders, allowing buyers to assess quality and suitability for their needs.

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem: Fluctuations in demand and unexpected supply chain disruptions can severely impact B2B buyers’ ability to maintain adequate inventory levels of leather making supplies. Factors such as political instability, transportation issues, or sudden changes in market trends can lead to shortages or overstock situations. This unpredictability can hinder production timelines, affect customer satisfaction, and ultimately harm the bottom line.

The Solution: To effectively manage inventory amidst these challenges, B2B buyers should implement a robust inventory management system that provides real-time data on stock levels and demand forecasting. Utilizing software that integrates with suppliers can streamline ordering processes and automate reordering when inventory falls below a certain threshold. Moreover, establishing partnerships with multiple suppliers can create a buffer against disruptions, ensuring that alternative sources are available when needed. Additionally, maintaining a flexible supply chain that can adapt to changing circumstances, such as seasonal demand spikes, will enhance resilience and minimize risks.

Scenario 3: Understanding Leather Types and Their Applications

The Problem: Many B2B buyers encounter difficulties in selecting the right type of leather for specific applications, especially when dealing with various grades, finishes, and tanning processes. Misunderstanding the properties of different leather types can lead to unsuitable purchases, resulting in wasted resources and unsatisfied clients. This is particularly relevant for buyers looking to enter new markets or develop new product lines.

The Solution: To address this knowledge gap, buyers should invest time in educational resources and training on leather types and their applications. Engaging with suppliers who offer product knowledge workshops or detailed catalogs can provide valuable insights. Additionally, creating a comparison chart of different leather types, their characteristics, and ideal uses can serve as a quick reference tool for decision-making. Buyers should also seek out industry experts or consultants who can offer tailored advice based on their specific needs. Networking within industry associations can further enhance knowledge-sharing, allowing buyers to learn from the experiences of others in similar markets.

Strategic Material Selection Guide for leather making supplies

What Are the Key Properties of Common Leather Making Materials?

When selecting materials for leather making supplies, understanding the properties of each option is crucial for ensuring product performance. Here, we analyze four common materials: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and suede. Each material has unique characteristics that cater to different applications and preferences.

How Does Vegetable-Tanned Leather Perform in Leather Making?

Vegetable-tanned leather is known for its natural tanning process using plant-based substances. This type of leather is highly durable and ages beautifully, developing a rich patina over time. It is ideal for products that require tooling and dyeing, making it suitable for belts, wallets, and bags.

Illustrative image related to leather making supplies

Pros: Its durability and ability to be molded and dyed make it a favorite among artisans. Additionally, it is biodegradable, which appeals to environmentally conscious buyers.

Cons: The tanning process can be time-consuming and may result in higher costs. It is also less resistant to water and stains compared to chrome-tanned leather.

Impact on Application: Vegetable-tanned leather is compatible with various media, including dyes and finishes. However, it requires proper care to maintain its appearance.

Considerations for International Buyers: Compliance with environmental regulations is critical, especially in Europe, where stricter standards are enforced. Buyers should look for certifications that confirm adherence to guidelines such as REACH.

What Advantages Does Chrome-Tanned Leather Offer?

Chrome-tanned leather is processed using chromium salts, resulting in a softer and more pliable material that is resistant to water and stains. This type of leather is commonly used in automotive upholstery, footwear, and fashion accessories.

Pros: Its resistance to environmental factors makes it suitable for a range of products. It is also faster to produce, often resulting in lower costs.

Illustrative image related to leather making supplies

Cons: The tanning process can involve harmful chemicals, raising environmental concerns. Additionally, it may not have the same aesthetic appeal as vegetable-tanned leather.

Impact on Application: Chrome-tanned leather is compatible with various finishes but may not accept dye as well as vegetable-tanned leather.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations, such as Germany, should ensure that the leather complies with local standards for chemical safety.

How Does Synthetic Leather Compare in Terms of Performance?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to natural leather. It is widely used in fashion, upholstery, and accessories.

Pros: Synthetic leather is generally more affordable and easier to clean. It is also available in a wide range of colors and textures, allowing for creative flexibility.

Cons: While durable, synthetic leather may not have the same lifespan as natural leather. It is also less breathable, which can affect comfort in certain applications.

Impact on Application: Synthetic leather is compatible with various media but may not provide the same aesthetic or tactile experience as natural leather.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for synthetic materials across regions. Compliance with regulations such as ASTM and DIN is essential, especially in Europe.

Illustrative image related to leather making supplies

What Role Does Suede Play in Leather Making?

Suede, made from the underside of animal hides, is characterized by its soft texture and luxurious feel. It is commonly used in fashion accessories, upholstery, and footwear.

Pros: Suede offers a unique aesthetic and is highly desirable for high-end products. It is also relatively lightweight and flexible.

Cons: Suede is less durable than other types of leather and can be more challenging to clean. It is also more susceptible to water damage.

Illustrative image related to leather making supplies

Impact on Application: Suede is compatible with various finishes but requires special care to maintain its appearance.

Considerations for International Buyers: Buyers should consider the sourcing of suede, as ethical concerns regarding animal welfare are increasingly important in markets like Europe and North America.

Summary Table of Leather Making Materials

| Material | Typical Use Case for leather making supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, wallets, bags | Biodegradable and durable | Higher cost and less water-resistant | Medium |

| Chrome-Tanned Leather | Automotive upholstery, footwear | Water-resistant and cost-effective | Environmental concerns | Medium |

| Couro sintético | Fashion, upholstery, accessories | Affordable and easy to clean | Shorter lifespan and less breathable | Low |

| Camurça | Fashion accessories, upholstery | Luxurious feel and aesthetic appeal | Less durable and challenging to clean | Medium |

This analysis provides a comprehensive overview of material selection for leather making supplies, enabling international B2B buyers to make informed decisions based on their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather making supplies

What Are the Main Stages of Manufacturing Leather Making Supplies?

The manufacturing process for leather making supplies involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers looking to source high-quality products.

-

Material Preparation: The first step involves selecting the right type of leather, which can vary based on the intended application. Common materials include vegetable-tanned leather, chrome-tanned leather, and exotic leathers. Each type has distinct characteristics affecting its usability, durability, and appearance. Preparation also includes cutting hides to size and grading them based on quality standards.

-

Forming: This stage involves shaping the leather into specific forms, which can include cutting, stamping, or molding. Advanced techniques such as laser cutting or die-cutting are often employed to ensure precision. This is particularly important for creating intricate designs or components such as straps, belts, and bags. The forming process must be handled with care to avoid damaging the leather, which can compromise its quality.

-

Assembly: Once the leather pieces are formed, they are assembled using various methods. Hand stitching, machine sewing, and riveting are common techniques. The choice of assembly method can affect the product’s strength and aesthetic appeal. For instance, hand-stitched products often command higher prices due to the craftsmanship involved.

-

Finishing: The final stage involves applying dyes, finishes, and protective coatings to enhance the leather’s appearance and durability. This may include oiling, waxing, or applying special treatments to achieve desired textures and colors. Quality assurance during this stage is critical, as the finishing touches can significantly impact the product’s overall quality and marketability.

How is Quality Assurance Integrated into Leather Manufacturing?

Quality assurance (QA) is a vital aspect of the leather manufacturing process, ensuring that products meet both industry standards and customer expectations. For B2B buyers, understanding the QA process can help mitigate risks associated with sourcing leather products.

-

International Standards: Many manufacturers adhere to international quality management standards, such as ISO 9001. This standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Other industry-specific certifications, such as CE marking for products sold in the European market or API standards for specific applications, may also apply.

-

Quality Control Checkpoints: Implementing a robust QA system involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial phase checks raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, regular inspections are conducted to verify that manufacturing processes are being followed correctly and that the products are being made to specification.

– Final Quality Control (FQC): Once the products are completed, a final inspection is performed to assess their overall quality, including appearance, functionality, and adherence to specifications. -

Common Testing Methods: Various tests can be conducted to ensure the quality and performance of leather products. These may include:

– Physical Tests: Assessing tensile strength, tear resistance, and flexibility.

– Chemical Tests: Evaluating the presence of harmful substances, such as heavy metals or allergens.

– Durability Tests: Simulating wear and tear to assess longevity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers to ensure they are receiving high-quality leather products.

-

Supplier Audits: Conducting regular audits of suppliers can help buyers gain insights into their manufacturing processes and quality control measures. This can be done through on-site visits or third-party audits, which provide an impartial assessment of a supplier’s compliance with industry standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide transparency regarding their QA processes. These reports should outline the results of any inspections or tests conducted, along with any corrective actions taken to address issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer additional assurance regarding product quality. These services can perform independent assessments of products before shipment, ensuring they meet agreed-upon specifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control.

-

Regulatory Compliance: Different countries have varying regulations regarding the import and sale of leather products. Buyers must be aware of these regulations to avoid potential legal issues. For instance, European markets may impose stricter requirements regarding chemical safety and environmental impact than other regions.

-

Cultural and Market Expectations: Buyers should also consider cultural preferences and market expectations when sourcing leather products. For example, European buyers may prioritize sustainable practices and eco-friendly materials, while Middle Eastern buyers may have specific aesthetic preferences that influence their purchasing decisions.

-

Supply Chain Transparency: Ensuring transparency within the supply chain is critical for international buyers. This includes understanding the sourcing of raw materials, the manufacturing process, and the ethical practices employed by suppliers. Buyers should prioritize suppliers who provide clear information about their supply chain practices, as this can significantly impact brand reputation and customer trust.

Conclusion

Understanding the manufacturing processes and quality assurance measures in the leather supply industry is essential for B2B buyers. By familiarizing themselves with the stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions that enhance their supply chain reliability. Additionally, being aware of international regulations and market expectations can help mitigate risks and foster successful partnerships across borders.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather making supplies’

Introdução

In the competitive world of leather crafting, sourcing high-quality supplies is paramount for ensuring the success of your products. This guide provides a step-by-step checklist for B2B buyers looking to procure leather making supplies effectively. By following these steps, you can streamline your purchasing process, ensure quality, and build lasting relationships with suppliers.

Illustrative image related to leather making supplies

Step 1: Define Your Technical Specifications

Clearly outline the types of leather and tools you require based on your production needs. This includes specifying grades of leather (e.g., vegetable-tanned, chrome-tanned) and the necessary tools (e.g., cutting dies, stitching machines). Precise specifications help suppliers understand your requirements and prevent miscommunication.

- Considerations:

- Leather thickness and type.

- Essential tools for your production processes.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the leather industry. Look for companies that have been in business for several years and have positive reviews from other B2B clients. A reliable supplier can significantly impact your production quality and timelines.

- Where to Look:

- Industry trade shows.

- Online marketplaces and supplier directories.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage in direct communication to assess their customer service and responsiveness.

- What to Ask:

- Request samples of materials.

- Inquire about their production capabilities.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with international quality standards and regulations, especially if sourcing materials from different countries. Certifications can indicate adherence to ethical practices, environmental standards, and quality assurance.

- Key Certifications:

- ISO certifications.

- Environmental compliance certifications.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers, but don’t make decisions based solely on cost. Consider the overall value, including the quality of materials, customer service, and delivery timelines. Additionally, clarify payment terms to avoid unexpected costs later.

- Negotiation Tips:

- Inquire about bulk order discounts.

- Understand shipping costs and delivery schedules.

Step 6: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Set up regular check-ins and updates with your suppliers to ensure alignment on orders and any potential issues. Clear communication can prevent misunderstandings and foster a strong working relationship.

- Recommended Practices:

- Use project management tools for tracking orders.

- Schedule regular meetings to discuss any concerns.

Step 7: Monitor and Evaluate Supplier Performance

After establishing a partnership, continuously monitor supplier performance based on delivery times, product quality, and customer service. Regular evaluations help maintain high standards and can lead to renegotiation opportunities or the need to seek alternative suppliers.

- Performance Metrics:

- On-time delivery rates.

- Quality consistency of supplies.

By following this checklist, you can enhance your sourcing process for leather making supplies, ensuring that you receive high-quality materials and tools that meet your business needs.

Comprehensive Cost and Pricing Analysis for leather making supplies Sourcing

What Are the Key Cost Components in Leather Making Supplies Sourcing?

When sourcing leather making supplies, it’s crucial to understand the various cost components that contribute to the overall expenditure. These include:

Illustrative image related to leather making supplies

-

Materials: The quality and type of leather—such as vegetable-tanned or chrome-tanned—significantly affect the price. Specialty leathers, like exotic skins, command higher costs due to their rarity and the complexity involved in sourcing them.

-

Labor: Labor costs can vary based on the region and the skill level required. In countries with a strong tradition of leather crafting, skilled artisans may demand higher wages, impacting the overall cost structure.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, but they must be factored into the pricing strategy.

-

Tooling: The investment in machinery and tools necessary for production also plays a role in the cost. Advanced equipment may require higher initial investment but can lead to cost savings in the long run through increased efficiency.

-

Quality Control (QC): Implementing strict quality control measures ensures the final product meets industry standards and buyer expectations. However, these processes incur additional costs that should be reflected in the pricing.

-

Logistics: Transportation and warehousing costs can fluctuate based on distance, mode of transport, and local regulations. International shipping can be particularly costly and may involve additional duties and tariffs.

-

Margin: Suppliers typically add a markup to cover their operational costs and ensure profitability. Understanding this margin is essential for B2B buyers when negotiating prices.

What Factors Influence Pricing for Leather Making Supplies?

Several factors can influence the pricing of leather making supplies, particularly in international trade:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing and optimize their supply chain.

-

Specifications and Customization: Custom orders—such as specific colors or finishes—often come at a premium. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly tanning processes) typically incur higher costs. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their credibility and track record, but they often provide better quality assurance.

-

Incoterms: The agreed Incoterms (e.g., FOB, CIF) can significantly impact total costs, including shipping and insurance. Understanding these terms is crucial for accurate cost estimations.

What Are Effective Buyer Tips for Leather Making Supplies Sourcing?

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can enhance cost-efficiency:

-

Negotiation Skills: Develop strong negotiation skills to secure favorable terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider the TCO, which includes shipping, handling, and potential waste. This holistic view can help in making informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and how they impact costs. When sourcing internationally, consider potential tariffs and trade agreements that may affect pricing.

-

Build Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing, more favorable terms, and enhanced service levels over time.

Disclaimer on Indicative Prices

Prices for leather making supplies can fluctuate based on market conditions, supplier negotiations, and global economic factors. It is advisable for buyers to conduct thorough market research and engage with multiple suppliers to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing leather making supplies With Other Solutions

Introduction to Alternatives in Leather Making Supplies

In the world of leather crafting, the choice of supplies can significantly impact the quality and efficiency of the final product. While traditional leather making supplies have long been the go-to for artisans and manufacturers, there are emerging alternatives that can offer different advantages. This analysis will compare conventional leather making supplies with synthetic alternatives and fabric-based solutions to help B2B buyers make informed decisions based on their specific needs.

Illustrative image related to leather making supplies

Comparison Table

| Comparison Aspect | Leather Making Supplies | Synthetic Leather Alternatives | Fabric-Based Solutions |

|---|---|---|---|

| Performance | High durability, aesthetic appeal | Good durability, less authentic feel | Moderate durability, diverse designs |

| Cost | Varies by quality, generally higher | Typically lower, budget-friendly | Often lower, depending on fabric type |

| Ease of Implementation | Requires specific tools and skills | Easy to cut and sew, no special tools needed | Generally easy to work with, versatile |

| Maintenance | Requires regular conditioning and care | Low maintenance, easy to clean | Varies; some fabrics may require special care |

| Best Use Case | High-end products, custom designs | Cost-effective mass production | Fashion items, light-duty applications |

Detailed Breakdown of Alternatives

Synthetic Leather Alternatives

Synthetic leather, often made from polyvinyl chloride (PVC) or polyurethane (PU), has gained popularity due to its lower cost and ease of production. These materials mimic the look of real leather but often lack the same level of durability and breathability. For manufacturers aiming for mass production, synthetic options can be a cost-effective solution. However, they may not appeal to luxury markets that value authentic materials and craftsmanship. B2B buyers should weigh the importance of brand perception against the cost savings when considering synthetic leathers.

Fabric-Based Solutions

Fabric-based alternatives, such as canvas or denim, provide a lightweight and often more colorful option for leather substitutes. These materials are typically easier to manipulate and require less specialized equipment, making them accessible for smaller operations or start-ups. While they offer versatility in design, fabric-based solutions may not provide the same durability as leather, especially in heavy-use applications. This makes them ideal for fashion items or accessories but less suitable for items that demand longevity, such as belts or heavy-duty bags.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate leather making supplies or alternatives, B2B buyers should consider factors such as the intended use, target market, and budget constraints. Leather remains a premium choice for high-quality and durable products, while synthetic and fabric-based alternatives can serve well in more cost-sensitive applications. By assessing performance, cost, and ease of implementation, buyers can make informed decisions that align with their business goals and customer expectations. Ultimately, the right choice will depend on balancing quality with practicality in their specific market context.

Essential Technical Properties and Trade Terminology for leather making supplies

What Are the Critical Technical Properties of Leather Making Supplies?

When sourcing leather making supplies, understanding the technical specifications is essential for ensuring product quality and compatibility with manufacturing processes. Here are several critical specifications to consider:

Illustrative image related to leather making supplies

-

Material Grade: This refers to the quality classification of leather, typically categorized into grades such as full grain, top grain, genuine leather, and bonded leather. Full grain leather, for example, is the highest quality, retaining the natural grain and durability, making it suitable for premium products. B2B buyers should choose the material grade that aligns with their target market and product positioning.

-

Thickness: Leather thickness is measured in ounces (oz) or millimeters (mm), indicating the heft and durability of the leather. For instance, a leather thickness of 2-3 oz is often used for lightweight applications like wallets, while 8-10 oz is preferred for belts and bags. Understanding the appropriate thickness for specific applications helps in selecting the right material for durability and aesthetics.

-

Tannery Specifications: This includes details on the tanning process (e.g., chrome vs. vegetable tanning) and the resultant properties of the leather, such as colorfastness, flexibility, and resistance to wear and tear. Buyers should assess these specifications to ensure the leather meets their product requirements and environmental standards.

-

Finish Type: The finish applied to leather affects its appearance, feel, and durability. Common finishes include aniline, semi-aniline, and pigmented. Each finish offers different benefits, such as breathability or resistance to stains. Understanding the finish type is vital for ensuring that the final product meets customer expectations for quality and performance.

-

Weight: The weight of leather is an important factor that influences both the feel and the intended use of the material. Heavier leathers are generally more durable and suited for products that require robust construction, while lighter options are better for items requiring flexibility. This specification helps in determining the right leather for specific applications.

Which Trade Terms Should B2B Buyers of Leather Making Supplies Know?

Navigating the leather supply chain involves familiarity with industry jargon. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In leather supply, understanding OEM relationships can help buyers identify potential suppliers who can provide customized solutions tailored to their needs.

-

MOQ (Minimum Order Quantity): This is the smallest amount of product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to understand the financial commitment required when ordering leather supplies and to manage inventory effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should utilize RFQs to compare prices and terms from multiple suppliers, ensuring they secure the best deal for their leather making supplies.

-

Incoterms (International Commercial Terms): These are pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs involved in cross-border transactions.

-

Lead Time: This term refers to the amount of time it takes from placing an order until the goods are delivered. Understanding lead times is essential for planning production schedules and managing customer expectations regarding delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline their procurement processes, and foster stronger relationships with suppliers in the leather industry.

Navigating Market Dynamics and Sourcing Trends in the leather making supplies Sector

What Are the Current Market Dynamics and Key Trends in the Leather Making Supplies Sector?

The leather making supplies sector is experiencing dynamic shifts driven by globalization and technological advancements. Key market drivers include an increasing demand for high-quality leather products across diverse industries such as fashion, automotive, and furniture. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly seeking innovative solutions to enhance their production processes. This has led to the emergence of advanced leatherworking tools and machinery, as well as digital platforms that facilitate seamless sourcing and procurement.

Emerging trends highlight a growing reliance on e-commerce platforms, enabling buyers to access a broader range of suppliers and products from around the world. Technologies such as artificial intelligence and machine learning are being integrated into inventory management and supply chain optimization, allowing businesses to forecast demand more accurately and reduce waste. Additionally, the rise of customization options is encouraging suppliers to offer more tailored solutions, meeting the specific needs of various markets.

Furthermore, with consumers becoming more conscious of their purchasing decisions, there is a notable shift towards sustainable practices. Buyers are increasingly looking for suppliers who can demonstrate a commitment to ethical sourcing and environmental stewardship, reflecting a broader trend towards responsible consumption.

Illustrative image related to leather making supplies

How Is Sustainability Shaping Sourcing Practices in the Leather Making Supplies Sector?

Sustainability has become a cornerstone in the leather making supplies sector, influencing sourcing practices and supplier selection criteria. The environmental impact of leather production has prompted international buyers to prioritize suppliers who adopt sustainable practices. This includes the use of eco-friendly tanning methods, such as vegetable tanning, which minimizes harmful chemical usage and reduces pollution.

Ethical sourcing is not just a trend; it is essential for maintaining a competitive edge in the marketplace. B2B buyers are increasingly demanding transparency in supply chains, looking for certifications such as the Leather Working Group (LWG) and ISO 14001, which indicate a commitment to sustainable and ethical practices. Additionally, there is a rising interest in alternative materials, such as synthetic leathers made from recycled plastics or plant-based sources, which appeal to environmentally conscious consumers.

For businesses in Africa, South America, the Middle East, and Europe, aligning with sustainable suppliers not only enhances brand reputation but also opens doors to new markets where consumers are willing to pay a premium for eco-friendly products. This shift towards sustainability is reshaping the landscape of leather supplies, making it imperative for B2B buyers to stay informed about their suppliers’ environmental practices.

Illustrative image related to leather making supplies

What Is the Historical Context of the Leather Making Supplies Sector?

The leather making supplies sector has evolved significantly over the centuries, transitioning from traditional methods to modern industrial practices. Historically, leather production was a local craft, deeply rooted in regional cultures and practices. The introduction of mechanization during the Industrial Revolution marked a pivotal change, allowing for mass production and greater accessibility to leather goods.

In recent decades, globalization has further transformed the industry, facilitating international trade and the establishment of supply chains that span the globe. This evolution has led to the diversification of leather types and finishes available in the market, catering to an array of consumer preferences and applications.

As the sector continues to adapt to technological advancements and changing consumer demands, understanding this historical context provides valuable insights for B2B buyers looking to navigate the complexities of the modern leather making supplies landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of leather making supplies

-

How do I select the right leather making supplies for my business needs?

When selecting leather making supplies, consider the specific products you need based on your projects, such as tools, dyes, or different types of leather. Research the grades and types of leather that align with your end products, whether it’s for fashion, accessories, or upholstery. Additionally, evaluate supplier catalogs for quality, availability, and pricing. It’s beneficial to request samples to assess the texture and durability before committing to larger orders, ensuring that your materials meet your quality standards. -

What is the best type of leather for crafting high-quality goods?

The best type of leather for crafting high-quality goods often depends on the intended use. Vegetable-tanned leather is ideal for items that require tooling and dyeing, as it absorbs finishes well. For durable goods like bags or belts, chrome-tanned leather offers flexibility and resistance to wear. For luxury items, full-grain leather is preferred due to its natural look and durability. Always consider the weight and thickness that suits your specific application to ensure optimal results. -

What should I look for when vetting a supplier for leather making supplies?

When vetting a supplier for leather making supplies, assess their reputation in the industry through reviews and testimonials. Ensure they have a reliable quality assurance process to maintain consistent product standards. Check their certifications, such as compliance with international trade regulations and sustainability practices. Request references from other B2B buyers and inquire about their customer service, responsiveness, and ability to meet deadlines, which are crucial for maintaining your production schedule. -

What are the typical minimum order quantities (MOQs) for leather supplies?

Minimum order quantities (MOQs) for leather supplies can vary significantly depending on the supplier and type of product. Commonly, MOQs range from 50 to 500 units for bulk leather hides, while tools and accessories might have lower MOQs. It’s essential to discuss your specific needs with potential suppliers, as many may offer flexibility for established relationships or larger orders. Understanding MOQs helps you manage inventory costs and align purchasing with your production capabilities. -

What are standard payment terms for international B2B transactions in leather supplies?

Standard payment terms for international B2B transactions often include options such as letters of credit, wire transfers, or PayPal. Many suppliers require a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Terms can vary based on the relationship with the supplier and the order size. It’s advisable to negotiate favorable terms that protect your cash flow while ensuring the supplier feels secure in the transaction, especially in new business relationships. -

How can I ensure the quality of leather supplies I receive?

To ensure the quality of leather supplies, establish clear quality standards and specifications in your purchase agreements. Request samples before placing large orders to evaluate the leather’s texture, color, and durability. Implement a quality assurance process upon receipt, checking for defects, consistency, and compliance with your specifications. Building a strong relationship with your supplier can also facilitate better quality control, as they will be more inclined to meet your standards consistently. -

What logistics considerations should I be aware of when importing leather supplies?

Logistics considerations for importing leather supplies include understanding shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with the leather industry to navigate international shipping complexities efficiently. Additionally, factor in lead times for production and shipping, as well as storage capabilities upon arrival. Having a comprehensive logistics plan will help minimize delays and ensure your supplies arrive in good condition and on schedule. -

How can I customize leather products for my brand?

Customizing leather products for your brand can be achieved through various methods, including selecting specific leather types, colors, and finishes that align with your brand identity. Work with suppliers who offer customization options, such as embossing or debossing your logo on products. Additionally, consider developing unique patterns or designs that differentiate your offerings. Collaborating with skilled artisans or manufacturers can also enhance the uniqueness of your products, making them more appealing in the competitive marketplace.

Top 8 Leather Making Supplies Manufacturers & Suppliers List

1. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies, including various types of leather such as ChahinLeather®, Hermann Oak® Veg Tan, and Chrome Tanned options. The product categories include leather cuts (double shoulders, backs, bends, panels, half sides, whole hides, bellies, belt blanks, laces, and remnants), textures (top grain, pebbled, smooth, pull-up, w…

2. Tandy Leather – Quality Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Makers Leather Supply – Hermann Oak Tooling Side

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: 1. Hermann Oak – Branded Natural Tooling & Carving Side: £172.00, 11 reviews

2. Maker’s Breezy Clutch Purse/Wallet Acrylic Template Set: £27.00, 4 reviews

3. Maker’s Contact Cement: £26.00, 25 reviews

4. Maker’s Indelible Leather Marker – Precision Dye & Edge Finishing Pen: £6.00, 13 reviews

5. MLS Double Sided Tape, 1/4″ (Small): £12.00, 16 reviews

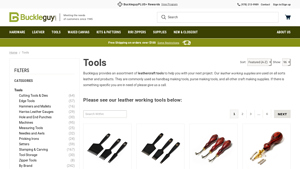

4. Buckleguy – BG Awl Needles

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Buckleguy offers a wide range of leather working tools and supplies, including cutting tools, edge tools, hammers, mallets, gauges, punches, machines, measuring tools, needles, awls, pricking irons, setters, and stamping & carving tools. Notable products include:

– BG Awl Needles (Multiple Shapes) – $10.62 – $14.13

– BG Leather Bone Folder/Edge Slicker (Multi-Function) – $28.94

– BG Stitching Punc…

5. Stecks Store – Custom Leather Craft Supplies

Domain: stecksstore.com

Registered: 2006 (19 years)

Introduction: Custom Leather Craft Stamps & Lace Accessories Supplier. Categories include: Conchos (various sizes), Medallions, Stamps (Alphabet & Number, Easy-To-Do Sets, Craftool Sets), Tools (Handtools, Lacing Tools, Knives, Punches), Chicago Screw Posts, Buckles (various sizes), Lace & Stitching (Finished Lace, Suede & Deerskin Lace, Leather Lace), Threads & Sinews, Dye (Eco-Flo, Edge Paint, Fiebing’s), Har…

6. Artisan Leather Supply – Leather Craft Tools & Supplies

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: Leather Craft Tools & Supplies, including machines, edge tools, cutting & skiving tools, hammers, marking & measuring tools, sewing & stitching tools, watch strap tools, threads, reinforcement webbing, and YKK EXCELLA® products. Free shipping on orders over $35 (US only).

7. Leathercraft Tools – Premium Dyed Leather

Domain: leathercrafttools.com

Registered: 2000 (25 years)

Introduction: Products: LC Premium Dyed Leather, Okayama Denim, Edge Top Wax, LC Super PRO Edge Tool, YKK Zipper EXCELLA, TOKO PRO Burnishing Gum, LC SP Edge Kote. New Items: Round Flat US Spots (Nickel and Brass), Express Spots (Nickel and Brass), Talon Zipper 42, Oblong Spot (Nickel and Brass), Square Head Spot (Brass), Dinosaur Charm Spinosaurus, Diamond Spot (Nickel and Brass), Flat Head Screw Rivet, Square…

8. Identity Leathercraft – Premium Leather & Craft Tools

Domain: identityleathercraft.com

Registered: 2016 (9 years)

Introduction: Leather, Craft Tools, Products and Materials including: Vegetable Tanned Leather, Pre-cut Strips & Belt Blanks, Heritage UK Leathers, Modern & Speciality Leathers, Falconry Leather, Hair-on & Wool-on Sheepskin (Nappa), Soft Suede, Metallic Leathers, Pearlised Leathers, Small & Craft Cuts, Remnant Pieces & Bags, Embossing & Carving tools, Individual Stamps, 3D Stamps, Mini 3D Stamps, Stamping Sets,…

Strategic Sourcing Conclusion and Outlook for leather making supplies

In the evolving landscape of leather making supplies, strategic sourcing has emerged as a pivotal factor for international B2B buyers. By prioritizing quality, sustainability, and supplier relationships, businesses can enhance their product offerings while ensuring compliance with global standards. As highlighted throughout this guide, the diverse range of leather types, tools, and finishing supplies available today empowers manufacturers to create innovative products that resonate with consumer demands across different markets.

The value of strategic sourcing extends beyond mere cost savings; it fosters long-term partnerships that can lead to shared knowledge and advancements in leather technology. For buyers in Africa, South America, the Middle East, and Europe, leveraging local suppliers alongside global networks can result in a more resilient supply chain, capable of adapting to market fluctuations and consumer preferences.

As we look to the future, the leather industry is poised for growth, driven by trends in sustainability and customization. Now is the time for international buyers to explore new sourcing opportunities, invest in robust supplier relationships, and align with market trends. Embrace this journey towards excellence in leather crafting, and let your business thrive in this dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.