Introduction: Navigating the Global Market for custom leather coasters

In an increasingly competitive global market, sourcing custom leather coasters can present unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for high-quality, customizable products is on the rise, making it essential for businesses to navigate the complexities of supplier selection, pricing structures, and product specifications effectively. This guide aims to provide a comprehensive overview of the various types of leather coasters available, their practical applications across different industries, and strategies for vetting suppliers to ensure quality and reliability.

From understanding the nuances of leather types to exploring bulk purchasing options, this resource is designed to empower international B2B buyers with the knowledge necessary to make informed decisions. Whether you are looking to enhance your brand presence with personalized coasters for corporate events or seeking elegant solutions for hospitality settings, this guide will equip you with actionable insights. By addressing key considerations such as cost analysis, customization options, and supplier relationships, we aim to streamline your procurement process and enhance your business’s overall operational efficiency. With this information at your fingertips, you can confidently navigate the global market for custom leather coasters and secure the best products for your business needs.

Table Of Contents

- Top 5 Custom Leather Coasters Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather coasters

- Understanding custom leather coasters Types and Variations

- Key Industrial Applications of custom leather coasters

- 3 Common User Pain Points for ‘custom leather coasters’ & Their Solutions

- Strategic Material Selection Guide for custom leather coasters

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather coasters

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather coasters’

- Comprehensive Cost and Pricing Analysis for custom leather coasters Sourcing

- Alternatives Analysis: Comparing custom leather coasters With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather coasters

- Navigating Market Dynamics and Sourcing Trends in the custom leather coasters Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather coasters

- Strategic Sourcing Conclusion and Outlook for custom leather coasters

- Important Disclaimer & Terms of Use

Understanding custom leather coasters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather Coasters | Made from premium full-grain leather, durable, develops a unique patina | Corporate gifts, promotional items, events | Pros: High durability, luxury appeal. Cons: Higher cost compared to other types. |

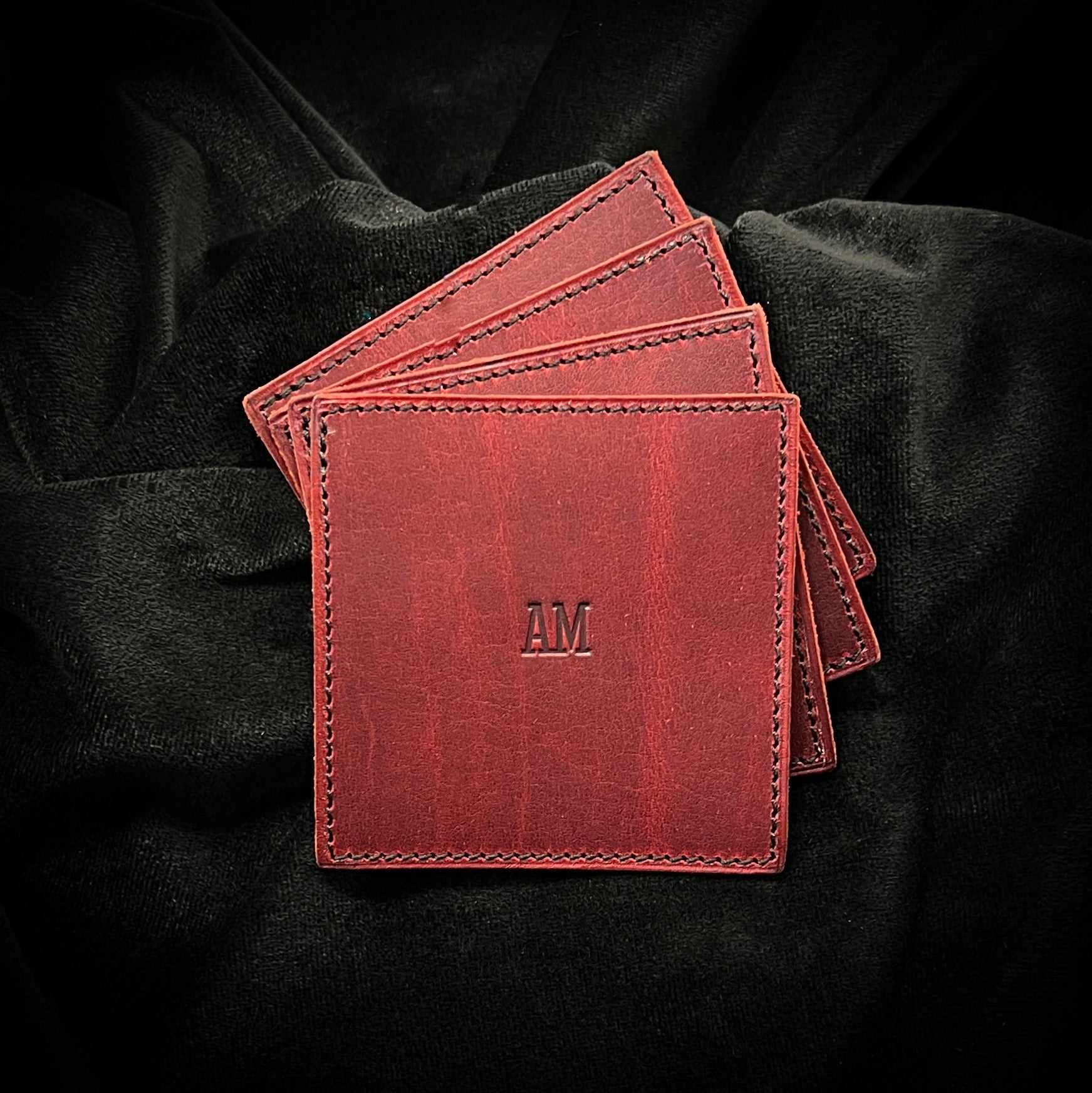

| Custom Engraved Coasters | Personalized with logos or designs, ideal for branding | Brand marketing, weddings, corporate events | Pros: Unique branding opportunity. Cons: Setup fees and longer lead times. |

| Leatherette Coasters | Synthetic leather alternative, cost-effective, easy to clean | Budget-conscious businesses, mass events | Pros: Affordable, versatile. Cons: Less durable than genuine leather. |

| Square vs. Round Coasters | Shape variations to suit different aesthetics and uses | Office decor, hospitality settings | Pros: Versatile design options. Cons: Limited functional differences. |

| Coaster Sets with Holders | Includes storage options, enhances presentation | Conference rooms, reception areas | Pros: Organized storage, professional look. Cons: Higher upfront cost. |

What are the Characteristics of Full-Grain Leather Coasters?

Full-grain leather coasters are crafted from the highest quality leather, retaining the natural grain and texture of the hide. This type of coaster is known for its durability and ability to develop a rich patina over time, making each piece unique. B2B buyers often choose full-grain leather coasters for corporate gifts or promotional items due to their luxurious appearance and tactile feel. Key purchasing considerations include the sourcing of the leather, as well as the potential for customization through branding or engraving.

How Do Custom Engraved Coasters Enhance Branding?

Custom engraved coasters provide businesses with a unique opportunity to showcase their brand identity. By adding logos or specific designs, these coasters become more than just functional items; they serve as memorable marketing tools during events or corporate gatherings. The setup fees for engraving and the lead time for production are essential factors to consider for B2B buyers. Businesses looking to create a lasting impression should weigh the investment against the potential return in brand recognition.

Why Choose Leatherette Coasters for Budget-Conscious Purchases?

Leatherette coasters are an excellent alternative for businesses seeking a cost-effective solution without sacrificing style. Made from synthetic materials, they offer ease of maintenance and a variety of colors and styles. These coasters are particularly popular for large events or promotions where budget constraints are a priority. Buyers should consider the trade-offs between durability and cost, as leatherette may not provide the same longevity as genuine leather options.

Illustrative image related to custom leather coasters

What are the Benefits of Square vs. Round Coasters?

The choice between square and round coasters often comes down to aesthetic preference and functionality. Square coasters may align better with modern decor, while round coasters can evoke a more traditional feel. B2B applications include office decor and hospitality settings, where the visual appeal of the coasters can complement the overall design. Buyers should evaluate the intended use and setting to determine the most suitable shape for their needs.

How Do Coaster Sets with Holders Enhance Professional Presentation?

Coaster sets that include holders not only provide practical storage solutions but also enhance the presentation of the coasters. Ideal for conference rooms or reception areas, these sets convey professionalism and attention to detail. B2B buyers should consider the added value of organization and aesthetic appeal when investing in these products. While the upfront cost may be higher, the potential for improved brand image and client impression can justify the expense.

Key Industrial Applications of custom leather coasters

| Industry/Sector | Specific Application of custom leather coasters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Branded coasters for restaurants and cafes | Enhances brand visibility and customer experience | Bulk ordering options, custom branding capabilities |

| Corporate Events | Gifts for conferences and trade shows | Creates lasting impressions and brand loyalty | Customization options, lead times for large orders |

| Retail | Promotional items for product launches | Increases customer engagement and brand recognition | Quality of leather, design options, and pricing tiers |

| Real Estate | Coasters for property showings and open houses | Adds a touch of luxury and professionalism | Custom designs that reflect brand identity, durability |

| Event Planning | Favors for weddings and special occasions | Personalized keepsakes that enhance guest experience | Minimum order quantities, design flexibility, and delivery times |

How Are Custom Leather Coasters Used in the Hospitality Industry?

In the hospitality sector, custom leather coasters are utilized in restaurants, bars, and cafes to enhance the dining experience. These coasters not only serve a practical purpose by protecting surfaces from drink rings but also act as branding tools. By featuring the establishment’s logo or theme, they elevate the overall ambiance and create a memorable impression on patrons. For international buyers, sourcing coasters that are durable yet stylish is crucial, especially in high-traffic environments.

What Role Do Custom Leather Coasters Play in Corporate Events?

For corporate events, custom leather coasters are often used as promotional gifts during conferences and trade shows. They provide a unique way to showcase a brand while serving a functional purpose. These coasters can be personalized with logos or messages, making them effective conversation starters that foster brand loyalty. Buyers in this sector should consider the lead times for bulk orders, as well as the quality of the leather to ensure a premium feel that reflects their brand’s image.

How Are Custom Leather Coasters Beneficial in Retail Settings?

In retail, custom leather coasters are increasingly used as promotional items during product launches or as part of gift-with-purchase strategies. They serve to engage customers while reinforcing brand identity. By offering high-quality, branded coasters, retailers can enhance customer experience and promote their products in a subtle yet effective manner. Buyers should prioritize the quality of the leather and the design capabilities available to ensure the coasters align with their brand’s aesthetics.

Illustrative image related to custom leather coasters

Why Are Custom Leather Coasters Important for Real Estate Professionals?

Real estate agents often use custom leather coasters during property showings or open houses to create a sophisticated environment. These coasters help to convey a sense of luxury and attention to detail, appealing to prospective buyers. For international buyers in this sector, it’s essential to consider coasters that can be customized to reflect the agent’s branding and the property’s unique style, ensuring a cohesive presentation.

How Do Custom Leather Coasters Enhance Event Planning?

In the realm of event planning, custom leather coasters are popular as personalized favors for weddings and special occasions. They serve as memorable keepsakes for guests, adding a personal touch to the event. Event planners should focus on sourcing coasters that can be tailored to the theme of the event, considering minimum order quantities and design flexibility to accommodate various client needs. This customization not only enhances the guest experience but also reinforces the event’s branding.

3 Common User Pain Points for ‘custom leather coasters’ & Their Solutions

Scenario 1: Quality Assurance for Custom Leather Coasters

The Problem: One significant challenge B2B buyers face when sourcing custom leather coasters is ensuring the quality of the materials and craftsmanship. Many suppliers may provide coasters that look good in photos but fail to meet expectations upon delivery. Issues such as inconsistent leather quality, inadequate stitching, or poor finishing can lead to customer dissatisfaction and damage to the brand’s reputation. This is particularly critical for businesses in the hospitality or corporate gifting sectors, where the perception of quality can directly impact customer loyalty.

The Solution: To mitigate this risk, buyers should prioritize suppliers who offer samples before committing to a bulk order. Requesting a sample allows you to assess the leather’s texture, durability, and overall craftsmanship firsthand. Additionally, consider suppliers who provide detailed information about the leather sourcing process and quality certifications. Establishing a clear communication channel with the supplier can also help address any concerns and set expectations regarding the final product. Ensure to read reviews and ratings from other businesses that have sourced similar products to gauge reliability.

Scenario 2: Customization Complexity and Lead Times

The Problem: Customization is a key selling point for leather coasters, but it can also introduce complexity. Buyers often struggle with lengthy lead times for design approval, production, and shipping, which can disrupt their promotional timelines or event planning. For instance, a company planning a corporate event may find that their coasters arrive late, compromising the quality of their branding efforts. Additionally, unclear customization options can lead to confusion and mismatched expectations.

The Solution: To streamline the customization process, establish a clear timeline with the supplier from the outset. Communicate your deadlines and confirm the lead times for design approvals, production, and shipping. Choosing suppliers that offer a user-friendly online design tool can also simplify the customization process, allowing for real-time adjustments and quicker approvals. Additionally, consider ordering coasters in advance of peak seasons to avoid last-minute rush fees or delays. Building a strong relationship with your supplier can also facilitate smoother communication and quicker resolution of any issues that arise.

Scenario 3: Cost Management and Bulk Ordering

The Problem: Cost management is a critical concern for B2B buyers, especially when ordering custom leather coasters in bulk. Many businesses may find that the quoted prices vary significantly based on order quantity, customization level, and additional features like packaging. This variability can lead to budget overruns or miscalculations in expected costs, which is particularly challenging for small to medium enterprises (SMEs) looking to maximize their marketing ROI.

Illustrative image related to custom leather coasters

The Solution: To effectively manage costs, it is advisable to conduct thorough market research before placing an order. Compare quotes from multiple suppliers while considering the total cost of ownership, which includes shipping, handling, and any design fees. Inquire about bulk discounts and tiered pricing structures that could lower the unit cost as you increase your order volume. Additionally, consider consolidating orders with other promotional items to take advantage of shipping efficiencies and volume discounts. Establishing a long-term relationship with a supplier can also lead to better pricing and negotiation opportunities in future orders.

Strategic Material Selection Guide for custom leather coasters

What are the Key Properties and Considerations for Different Leather Materials Used in Custom Coasters?

When selecting materials for custom leather coasters, various leather types offer distinct properties that can significantly influence product performance and suitability for specific applications. Below, we analyze four common leather materials: full-grain leather, top-grain leather, bonded leather, and synthetic leather, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Full-Grain Leather: The Premium Choice for Durability

Full-grain leather is the highest quality leather available, made from the top layer of the hide, retaining the natural grain. This material is known for its exceptional durability and ability to develop a rich patina over time.

- Key Properties: Full-grain leather is highly resistant to wear and tear, making it suitable for high-traffic environments. Its natural fibers provide good insulation against temperature changes.

- Pros & Cons: While full-grain leather offers superior durability and aesthetic appeal, it comes at a higher cost and can be more challenging to clean. Its premium nature makes it ideal for luxury markets but may not fit all budgets.

- Impact on Application: This material is compatible with various beverages, including hot drinks, due to its thermal resistance.

- Considerations for International Buyers: Buyers in regions like Europe and the Middle East may prefer full-grain leather for its prestige, while compliance with sustainability standards is crucial, especially in environmentally conscious markets.

Top-Grain Leather: A Balanced Alternative

Top-grain leather is the second-highest quality leather, made by sanding down the surface of full-grain leather. This process results in a more uniform appearance and a slightly softer feel.

- Key Properties: Top-grain leather is less porous than full-grain, making it more resistant to stains and easier to clean.

- Pros & Cons: It strikes a balance between cost and quality, making it a popular choice for businesses. However, it may not be as durable as full-grain leather and can show wear more quickly.

- Impact on Application: Suitable for a wide range of beverages, top-grain leather coasters can withstand moderate heat and moisture.

- Considerations for International Buyers: Buyers in South America and Africa may find top-grain leather a cost-effective option, but they should ensure that the leather meets local quality standards.

Bonded Leather: The Economical Option

Bonded leather is made from leftover leather scraps that are bonded together with adhesives and then coated with a polyurethane layer.

Illustrative image related to custom leather coasters

- Key Properties: This material is less durable than genuine leather but offers a leather-like appearance at a fraction of the cost.

- Pros & Cons: Bonded leather is lightweight and easy to produce, making it economical. However, it is less resistant to heat and moisture, which can limit its use.

- Impact on Application: Best suited for promotional items or low-cost giveaways, bonded leather coasters may not withstand heavy use.

- Considerations for International Buyers: In regions like Nigeria, where budget constraints are common, bonded leather can be an attractive option, but buyers should be aware of its lower durability and potential environmental impact.

Synthetic Leather: The Versatile Alternative

Synthetic leather, often made from polyurethane or PVC, mimics the look and feel of real leather without using animal products.

- Key Properties: This material is water-resistant and easy to clean, making it suitable for various environments.

- Pros & Cons: Synthetic leather is often more affordable and can be produced in a variety of colors and textures. However, it lacks the natural feel and aesthetic of genuine leather and may not appeal to luxury markets.

- Impact on Application: It is compatible with all types of beverages and is particularly useful in settings where spills are common.

- Considerations for International Buyers: In the Middle East, where cultural preferences may lean towards animal welfare, synthetic leather can serve as an ethical alternative, but buyers should ensure compliance with local regulations regarding synthetic materials.

Summary Table of Material Properties

| Material | Typical Use Case for custom leather coasters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end corporate gifts, luxury settings | Exceptional durability and patina | Higher cost and harder to clean | Elevado |

| Top-Grain Leather | General corporate gifts, events | Good balance of quality and cost | Less durable than full-grain | Medium |

| Bonded Leather | Promotional items, budget-friendly gifts | Economical and lightweight | Less durable and heat-resistant | Low |

| Couro sintético | Casual settings, outdoor events | Water-resistant and easy to clean | Lacks the luxury feel of real leather | Low to Medium |

This guide provides a comprehensive overview of the materials available for custom leather coasters, helping B2B buyers make informed decisions based on their specific needs and market considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather coasters

What Are the Main Stages in the Manufacturing Process of Custom Leather Coasters?

The manufacturing process for custom leather coasters involves several key stages that ensure the final product meets quality and design specifications. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to custom leather coasters

How Is Material Prepared for Custom Leather Coasters?

The first step in producing leather coasters is selecting high-quality leather, typically full-grain or top-grain, which is known for its durability and aesthetic appeal. The leather is then cut into specific shapes and sizes using precision cutting tools or dies. This process is critical as it determines the overall appearance and functionality of the coasters. Additionally, any custom branding, such as logos or designs, can be stamped or embossed onto the leather at this stage.

What Techniques Are Used in Forming and Assembly?

Once the leather is prepared, the next stage is forming. This involves shaping the coasters, which may include adding any necessary features such as rounded edges or specific thicknesses. Techniques such as die-cutting or laser cutting are commonly employed to ensure uniformity.

During the assembly stage, the individual pieces are combined. If the coasters are designed to include additional elements, such as cork backing or decorative stitching, these components are affixed. Adhesive bonding, stitching, or other joining methods are used to ensure durability and longevity, particularly for coasters intended for high-use environments like restaurants or corporate offices.

Illustrative image related to custom leather coasters

What Finishing Processes Enhance the Quality of Leather Coasters?

Finishing is the final stage of the manufacturing process and plays a vital role in the product’s appeal and functionality. This step may involve treatments such as dyeing, sealing, and polishing the leather to enhance its color and protect it from moisture and stains. A well-finished leather coaster will not only look attractive but also resist wear over time. The application of protective coatings can also be an essential part of this process, particularly for coasters that will see frequent use.

What Quality Assurance Measures Are Essential for Custom Leather Coasters?

Quality assurance (QA) is critical in ensuring that custom leather coasters meet international standards and customer expectations. The QA process typically includes several checkpoints throughout the manufacturing stages, ensuring that any defects are identified and addressed promptly.

Which International Standards Apply to Leather Coaster Manufacturing?

For B2B buyers, it’s essential to understand the relevant international standards that govern quality assurance. ISO 9001 is a widely recognized standard for quality management systems, ensuring that manufacturers adhere to consistent quality practices. Additional certifications, such as CE marking for products sold within the European Union, may also apply, depending on the market.

Illustrative image related to custom leather coasters

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to the production process. These typically include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials as they arrive at the manufacturing facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random inspections are conducted to monitor adherence to quality specifications. This includes checking the accuracy of cuts, the consistency of stitching, and the quality of any adhesives used.

- Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive review is performed. This includes checking the finished coasters for defects, ensuring branding accuracy, and verifying that all specifications have been met.

What Common Testing Methods Are Used in Quality Assurance?

Common testing methods for leather coasters include visual inspections, tensile strength tests, and water resistance tests. Visual inspections help identify any visible defects, while tensile strength tests assess the durability of the materials used. Water resistance tests determine how well the coasters can withstand spills and moisture, which is essential for maintaining their functionality over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Buyers can take several steps to ensure that their suppliers maintain high-quality standards:

- Conduct Audits: Schedule regular audits of the manufacturing facility to observe the production process firsthand and assess compliance with quality standards.

- Request Quality Reports: Suppliers should provide documentation regarding their quality assurance processes, including any certifications they hold and results from recent quality inspections.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of product quality. These inspectors can evaluate the manufacturing process, conduct random sampling of products, and verify that QC standards are being met.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from different regions, particularly in Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances in quality control practices. Cultural differences may impact communication and expectations, making it vital to establish clear guidelines and quality standards upfront.

Additionally, understanding local regulations and market requirements can help mitigate risks associated with product compliance. For instance, products sold in the EU must meet specific environmental and safety regulations, which may differ from those in other regions.

By carefully considering these factors and maintaining open communication with suppliers, B2B buyers can ensure they receive high-quality custom leather coasters that meet their specific needs and expectations.

Illustrative image related to custom leather coasters

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather coasters’

When sourcing custom leather coasters for your business, a structured approach can enhance your procurement process and ensure you achieve the best value. This guide provides a detailed checklist to help international B2B buyers navigate the complexities of sourcing these elegant and functional items.

Step 1: Identify Your Requirements

Begin by clearly defining what you need in terms of design, size, and material. Consider the purpose of the coasters—are they for corporate gifts, events, or retail? This will influence your choices regarding style and branding.

- Material Type: Opt for full-grain leather for durability and a premium look.

- Design Elements: Decide if you want embossed logos, colors, or specific shapes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather goods. Utilize online directories, trade shows, and industry forums to create a shortlist.

- Supplier Reputation: Look for reviews and testimonials to gauge reliability.

- Portfolio Review: Examine previous work to ensure their craftsmanship meets your standards.

Step 3: Request Samples

Before placing a bulk order, always request samples. This step allows you to assess the quality of materials and craftsmanship firsthand.

Illustrative image related to custom leather coasters

- Quality Check: Evaluate the feel, finish, and overall appearance of the samples.

- Functionality Test: Ensure the coasters serve their intended purpose, such as absorbing moisture and preventing scratches.

Step 4: Verify Production Capabilities

Understanding a supplier’s production capacity is crucial, especially if you have tight deadlines or large order quantities.

- Lead Times: Inquire about typical production timelines to align with your needs.

- Customization Options: Confirm the extent of customization available, including design variations and bulk order discounts.

Step 5: Assess Pricing and Payment Terms

Gather detailed quotes from your shortlisted suppliers. Compare pricing not just on the unit cost but also on potential hidden fees.

- Bulk Discounts: Ask about pricing tiers for larger orders.

- Payment Flexibility: Ensure payment terms are favorable; consider options like deposits or installment payments.

Step 6: Check Compliance and Certifications

Verify that the suppliers adhere to industry standards and regulations, particularly if you are sourcing from international suppliers.

- Sustainability Practices: Inquire about their sourcing methods and environmental policies.

- Quality Certifications: Look for certifications that validate the quality of their products, such as ISO standards.

Step 7: Establish Clear Communication

Effective communication is key to a successful procurement process. Ensure that your supplier is responsive and open to discussions throughout the sourcing process.

Illustrative image related to custom leather coasters

- Point of Contact: Designate a primary contact for streamlined communication.

- Feedback Mechanism: Set up a system for providing feedback during the production phase to address any concerns early.

By following this checklist, B2B buyers can enhance their procurement process for custom leather coasters, ensuring they find reliable suppliers who meet their quality and design expectations while also providing excellent customer service.

Comprehensive Cost and Pricing Analysis for custom leather coasters Sourcing

When sourcing custom leather coasters, understanding the cost structure and pricing nuances is essential for B2B buyers. This analysis highlights key cost components, price influencers, and practical tips for negotiating favorable terms, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Custom Leather Coaster Production?

The cost structure for custom leather coasters typically consists of several components:

-

Materials: The choice of leather significantly influences the cost. Full-grain leather, known for its durability and aesthetic appeal, often commands higher prices than lower-grade alternatives. Additionally, dyes and finishes can add to material costs.

-

Labor: Handcrafted products like leather coasters require skilled labor. The cost of labor varies by region and can affect overall pricing, especially if the production facility is in a country with higher wage standards.

-

Manufacturing Overhead: This includes expenses related to the production facility, equipment maintenance, and utilities. Overhead costs can fluctuate based on the scale of production and operational efficiency.

-

Tooling: Custom designs may require specific tooling or molds, which can incur initial setup fees. This one-time cost is crucial for custom orders, as it impacts the overall price per unit.

-

Quality Control (QC): Ensuring that each batch meets quality standards requires investment in QC processes. This may involve testing for durability and finish quality, adding to the overall cost.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier, volume of the order, and chosen shipping methods. For international buyers, understanding Incoterms is vital to determining who bears these costs.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on competition, market demand, and the perceived value of the product.

What Factors Influence Pricing for Custom Leather Coasters?

Several factors can affect the pricing of custom leather coasters:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Bulk orders often attract discounts, making it more cost-effective per unit.

-

Specifications/Customization: More complex designs or personalized branding increase production complexity and costs. Buyers should evaluate whether the added expense aligns with their marketing goals.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., eco-friendly leather) can elevate costs. Buyers should assess the value of these attributes against their target market’s expectations.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers with a track record may charge more but offer greater assurance in quality and service.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is essential for calculating total landed costs, as they dictate who is responsible for shipping, insurance, and tariffs.

What Negotiation Tips Can Help Buyers Secure Better Prices?

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms. Consider long-term partnerships that might encourage suppliers to offer more competitive pricing.

-

Leverage Volume Discounts: If feasible, consolidate orders with other buyers to exceed MOQs and negotiate bulk pricing.

-

Consider Total Cost of Ownership (TCO): Assess the long-term benefits of higher-quality coasters versus cheaper alternatives. Investing in durable products can reduce replacement costs over time.

-

Be Mindful of Currency Fluctuations: For international buyers, fluctuations in currency can impact pricing. Locking in prices in your local currency may mitigate risks.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow constraints. Discuss options like deferred payments or installment plans to enhance purchasing power.

Conclusion

Sourcing custom leather coasters involves navigating a complex cost structure influenced by various factors. By understanding these components and employing strategic negotiation techniques, B2B buyers can secure favorable pricing while ensuring quality that aligns with their brand standards. As always, potential buyers should consider these prices as indicative, as market conditions and supplier dynamics can lead to variations.

Alternatives Analysis: Comparing custom leather coasters With Other Solutions

Introduction: Exploring Alternatives to Custom Leather Coasters

In the realm of promotional products and corporate gifts, custom leather coasters have emerged as a sophisticated choice. However, businesses may seek alternatives that can offer similar functionalities with varying benefits. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs, budget constraints, and branding strategies.

Comparison Table

| Comparison Aspect | Custom Leather Coasters | Cork Coasters | Silicone Coasters |

|---|---|---|---|

| Performance | Durable, develops a patina | Absorbent, eco-friendly | Flexible, non-slip |

| Cost | $9.00 – $14.00 per unit | $0.50 – $3.00 per unit | $1.00 – $5.00 per unit |

| Ease of Implementation | Customization requires setup | Easy to print and customize | Simple production process |

| Maintenance | Wipe clean, not waterproof | Washable, can stain | Easy to clean, waterproof |

| Best Use Case | High-end events, corporate gifts | Casual settings, eco-conscious brands | Outdoor events, casual use |

Detailed Breakdown of Alternatives

Cork Coasters

Cork coasters are a popular alternative due to their eco-friendliness and affordability. They are naturally absorbent, making them ideal for beverages, and they typically cost much less than leather options. Their lightweight nature and ease of customization make them suitable for promotional giveaways. However, cork can stain and may not offer the same level of durability as leather, especially in high-end settings. Businesses focused on sustainability may find cork coasters align well with their brand image.

Illustrative image related to custom leather coasters

Silicone Coasters

Silicone coasters are another viable option, particularly for outdoor or casual settings. They are flexible, non-slip, and waterproof, which makes them practical for various environments. Silicone coasters can be easily cleaned, making them low maintenance compared to leather or cork options. The downside is that they often lack the aesthetic appeal and perceived luxury of leather coasters, which may not align with branding for more formal occasions. Their price point is generally more accessible, making them a cost-effective choice for large-scale events.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating promotional coasters, B2B buyers should consider their target audience, branding objectives, and the intended use case of the product. Custom leather coasters offer a premium feel and long-lasting durability, ideal for upscale corporate gifts or events. However, alternatives like cork and silicone coasters provide budget-friendly, practical options that can still effectively promote brand visibility. Ultimately, the choice should reflect the company’s values, aesthetic preferences, and budget considerations, ensuring that the selected solution resonates with the intended market.

Essential Technical Properties and Trade Terminology for custom leather coasters

What Are the Key Technical Properties of Custom Leather Coasters?

When sourcing custom leather coasters, understanding their technical properties is essential for making informed purchasing decisions. Here are the critical specifications to consider:

1. Material Grade

Leather coasters are typically made from various grades of leather, including full-grain, top-grain, and genuine leather. Full-grain leather is the highest quality, retaining the natural grain and texture, making it durable and aesthetically pleasing. B2B buyers should prioritize full-grain leather for long-lasting products that develop a rich patina over time, enhancing their appearance and value.

2. Thickness

The thickness of the leather, often measured in ounces (oz), affects the coaster’s durability and weight. Common thicknesses range from 8oz to 12oz. Thicker coasters provide better insulation against heat and moisture, making them ideal for high-end settings such as hotels and corporate offices. Selecting the right thickness ensures that the product meets the specific needs of the intended use.

Illustrative image related to custom leather coasters

3. Water Resistance

While most leather coasters are not fully waterproof, some may have water-resistant treatments. This property is crucial for coasters intended for use in environments where spills are common. B2B buyers should inquire about the water resistance of the coasters to ensure they can withstand daily use without deteriorating.

4. Finish and Color Options

The finish of the leather can significantly affect its appearance and functionality. Options may include matte, glossy, or embossed finishes, each offering a different aesthetic and tactile experience. Additionally, a variety of color options allows businesses to align the coasters with their branding. Customization in finish and color is vital for creating a cohesive brand image.

5. Customization Capabilities

Customization options, such as embossing or printing logos, are essential for businesses looking to enhance brand visibility. Understanding the available customization techniques and their limitations can help B2B buyers choose the right manufacturer that aligns with their marketing strategies.

6. Durability and Care Instructions

Durability is a key consideration, as coasters are subject to frequent use and exposure to liquids. Understanding the care instructions can help ensure that the coasters maintain their appearance over time. Buyers should look for coasters that are easy to clean and maintain, thus prolonging their lifespan.

Illustrative image related to custom leather coasters

What Are Common Trade Terms Related to Custom Leather Coasters?

Navigating the procurement process for custom leather coasters involves familiarizing oneself with industry jargon. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products or components that are marketed by another company under its brand name. In the context of custom leather coasters, an OEM may create coasters based on specific designs or specifications provided by a buyer.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to produce or sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet their budget and inventory requirements. It also affects pricing; larger orders often lead to discounts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a detailed quote for specific products or services. For custom leather coasters, an RFQ can include details such as quantities, specifications, and customization options, helping buyers receive tailored proposals.

Illustrative image related to custom leather coasters

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to understand shipping responsibilities and costs associated with their orders.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead time is vital for B2B buyers to plan their inventory and marketing strategies effectively. Custom orders often have longer lead times, so clear communication with suppliers is necessary.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather coasters, ensuring they receive products that meet their needs and align with their brand values.

Illustrative image related to custom leather coasters

Navigating Market Dynamics and Sourcing Trends in the custom leather coasters Sector

What Are the Key Market Dynamics and Trends Affecting Custom Leather Coasters?

The custom leather coasters market is experiencing dynamic growth driven by several global factors. Increasing demand for personalized and branded products is a significant trend, particularly among businesses looking to enhance their brand visibility. Coasters serve as effective promotional items for corporate events and hospitality industries, where aesthetics and functionality are paramount. Moreover, the rise of e-commerce platforms has made sourcing custom leather coasters more accessible for international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

B2B technology is also reshaping sourcing strategies. Businesses are increasingly leveraging digital solutions for bulk orders, customization options, and supply chain management. This transition is particularly beneficial for buyers in emerging markets like Nigeria and Saudi Arabia, where efficient logistics and communication can significantly impact procurement processes. Additionally, the trend toward minimalism and sophistication in design has led to a preference for high-quality, artisan-crafted leather products, further boosting the market for custom leather coasters.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Coasters Market?

Sustainability and ethical sourcing are becoming critical components in the procurement of custom leather coasters. As global awareness of environmental issues rises, buyers are increasingly seeking products that minimize environmental impact. This includes sourcing leather from tanneries that employ eco-friendly processes and adhere to strict waste management practices.

Ethical supply chains are not just a trend but a necessity for B2B buyers looking to align with consumers’ values. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) signal a commitment to sustainability, making these products more attractive. Additionally, businesses are considering alternative materials, such as vegetable-tanned leather, which offers a lower environmental footprint. By prioritizing sustainability, companies can enhance their brand reputation and appeal to a conscientious customer base.

What Is the Historical Context of Custom Leather Coasters in B2B Markets?

The custom leather coasters market has evolved significantly over the past few decades. Initially, leather coasters were primarily seen as luxury items used in high-end establishments or as gifts. However, the democratization of design and production has opened the market to a wider audience. With advancements in manufacturing technology and the rise of online platforms, businesses of all sizes can now access customized options, making leather coasters a staple in both corporate and casual settings.

Illustrative image related to custom leather coasters

This evolution reflects broader shifts in consumer preferences, where personalization and quality craftsmanship are increasingly valued. Today, custom leather coasters not only serve a functional purpose but also function as branding tools that convey a sense of sophistication and attention to detail, appealing to diverse international markets.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather coasters

-

How can I ensure the quality of custom leather coasters from a supplier?

To ensure quality, request samples before placing a bulk order. Evaluate the leather type, thickness, and craftsmanship. Check for certifications that verify the supplier’s adherence to quality standards. Also, consider reviews and testimonials from other B2B buyers. A reliable supplier should provide detailed product specifications and be transparent about their manufacturing processes. -

What is the ideal material for custom leather coasters?

Full-grain leather is often the best choice for durability and aesthetic appeal. It develops a rich patina over time, enhancing its character. Ensure the leather is sourced responsibly, with options like vegetable-tanned leather for environmentally conscious businesses. Assess the weight and thickness to ensure they can withstand regular use without warping or degrading. -

What customization options are available for leather coasters?

Customization typically includes options for size, shape, color, and branding. Many suppliers offer embossing or debossing for logos, as well as various finishes to enhance aesthetics. Discuss your specific requirements with the supplier to explore all available options. Some may also offer unique designs or packaging solutions for promotional purposes. -

What are the minimum order quantities (MOQ) for custom leather coasters?

MOQs can vary widely among suppliers, often starting from as low as 50 units to several hundred. It’s important to clarify this upfront, as it impacts your budget and planning. If you require a smaller quantity, inquire if the supplier offers a lower MOQ for specific designs or if they can accommodate your needs through a custom order arrangement. -

How do I handle international shipping for bulk orders of leather coasters?

Coordinate with your supplier to understand their shipping policies and options. Determine whether they provide freight services or if you need to arrange your own logistics. Be aware of customs regulations in your country, as well as potential tariffs or import taxes. It’s wise to track shipping times and ensure all necessary documentation is provided for smooth delivery. -

What payment terms should I expect when ordering custom leather coasters?

Payment terms can vary by supplier, but common practices include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net terms for established businesses. Always clarify payment methods accepted, such as wire transfers, credit cards, or payment platforms, and ensure secure transactions to protect your investment. -

How can I vet a supplier for custom leather coasters?

Start by researching the supplier’s reputation through online reviews and industry referrals. Request references from previous clients to gauge their experience. Evaluate their production capabilities and quality assurance processes. A reliable supplier should be open to communication, provide detailed information about their operations, and be willing to accommodate your specific needs. -

What are the lead times for custom orders of leather coasters?

Lead times typically range from 2 to 6 weeks, depending on order complexity, quantity, and the supplier’s production schedule. Always confirm these timelines during the ordering process. If you have a specific deadline, communicate this clearly to the supplier to avoid delays. Consider potential holidays or shipping disruptions that may affect delivery.

Top 5 Custom Leather Coasters Manufacturers & Suppliers List

1. Popov Leather – Leather Coasters

Domain: popovleather.com

Registered: 2013 (12 years)

Introduction: Leather Coasters: Made from 9oz full-grain, heavy-weight leather. Diameter: 4 inches round. Not water-resistant but durable and easy to clean. Available in multiple colors: Heritage Brown, English Tan, Natural, Black. Price: $9.00 USD (regular price $14.00 USD) with code HARVEST. Customization options available for bulk orders. Hand-crafted with illustrations by artist Liam Ashurst. Designed to de…

2. The Elegant Office – Leather Coaster Set Collection

Domain: theelegantoffice.com

Registered: 2004 (21 years)

Introduction: Leather Coaster Set Collection includes various styles and colors such as Classic Black, Chocolate Brown, and Navy Blue. Coasters are available in round and square designs, with options for 4, 8, and 10 piece sets. Materials include top-grain leather, bonded leather, and leatherette. Features include firm core construction, wrapped edge design, and options for holders with compartments for station…

3. The Local Branch – Custom Leather Coasters

Domain: thelocalbranch.co

Registered: 2013 (12 years)

Introduction: {“product_name”: “Custom Leather Coasters – USA Made”, “description”: “Our custom branded, handcrafted Leather Coasters are the perfect gift for your corporate event, brand marketing, wedding favors or for any occasion that deserves to be celebrated with this custom branded keepsake. Made in the USA by small makers. 100% genuine leather drink coaster, handcrafted in Upstate NY by The Local Branch….

4. Buckleguy – Customizable Leather Coaster Sets

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Leather Coasters, Customizable Coaster Set

– Variety of colors and shapes available

– Customizable options: blank, monograms, logos, icons, foil inlay

– Suitable for gifts or resale

– Bulk quantities available upon request

– Price: $10.70 per 4pc set

– Tannery options: Horween, Wickett & Craig

– Cut options: Square, Circle

– Weight/Thickness: 8/9oz (3.2-3.6mm), 8/10oz (3.2-4.0mm), 9/11oz (3.6-4.4m…

5. Lazer Designs – Custom Engraved Coasters

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: This company, Lazer Designs – Custom Engraved Coasters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather coasters

What Are the Key Takeaways for Sourcing Custom Leather Coasters?

In today’s competitive market, custom leather coasters offer a unique blend of functionality and elegance, making them an excellent choice for corporate branding, gifts, and event favors. International buyers should prioritize sourcing high-quality, durable materials, such as full-grain leather, to ensure longevity and aesthetic appeal. Bulk purchasing options can significantly reduce costs while enhancing brand visibility through personalized designs.

Why Is Strategic Sourcing Essential for Your Business?

Strategic sourcing is vital not only for cost management but also for building strong supplier relationships that can lead to better quality products and services. By evaluating suppliers based on craftsmanship, sustainability practices, and customization capabilities, businesses can ensure they are investing in products that reflect their brand values and resonate with their target audience.

How Can You Position Your Business for Future Success?

As global markets continue to evolve, the demand for custom leather coasters is expected to grow. Buyers from regions like Africa, South America, the Middle East, and Europe should leverage this trend by exploring diverse suppliers to find the best fit for their needs. Engaging with manufacturers who offer flexible designs and quick turnaround times will enable businesses to stay ahead of market trends and customer preferences.

Take action now by reaching out to potential suppliers, conducting thorough research, and positioning your brand to capitalize on the opportunities that custom leather coasters present.

Illustrative image related to custom leather coasters

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.