Catalog

Material Insight: Imitation Leather Fabric

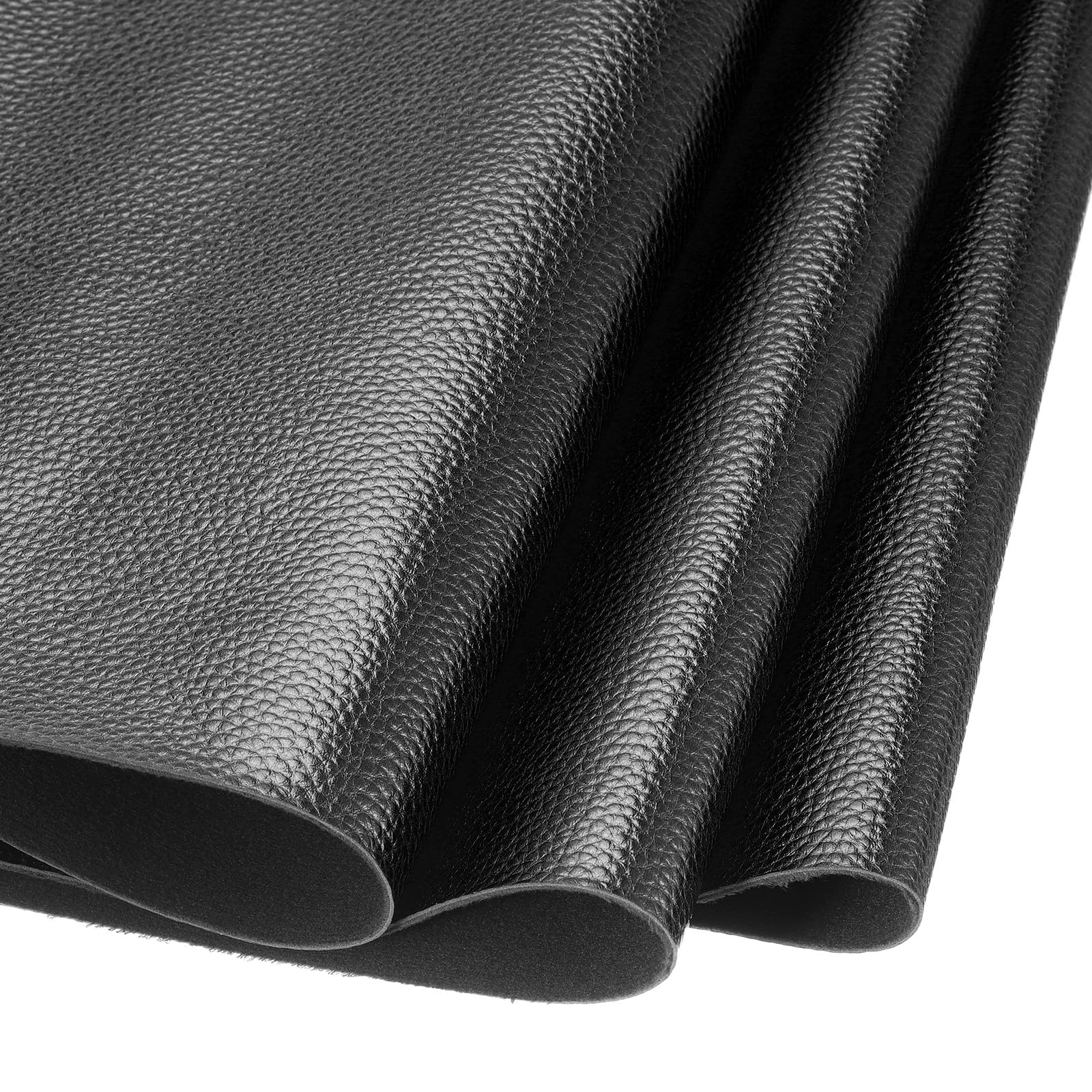

Imitation Leather Fabric: The Strategic Material Choice for Modern Manufacturing

In today’s competitive manufacturing landscape, selecting the right material is critical for balancing performance, sustainability, and cost-efficiency. Imitation leather fabric—engineered to replicate the aesthetic and functional properties of genuine leather without its limitations—has become the material of choice for forward-thinking brands across furniture, automotive, fashion, and consumer goods. Unlike traditional leather, which carries ethical concerns, supply volatility, and significant environmental burdens, modern synthetic alternatives deliver consistent quality, design flexibility, and verifiable eco-credentials without compromising durability or luxury appeal.

Why Faux Leather Outperforms for Industrial Applications

- Supply Chain Resilience: Eliminates dependency on volatile rawhide markets and seasonal fluctuations, ensuring uninterrupted production schedules.

- Precision Consistency: Engineered for uniform color, texture, and thickness across every meter—critical for large-scale manufacturing and brand integrity.

- Sustainability by Design: Reduces water consumption by up to 95% and land use by 100% compared to bovine leather, with traceable eco-certifications (e.g., OEKO-TEX®, GRS).

- Performance Tailoring: Custom formulations meet exact requirements for abrasion resistance, UV stability, flame retardancy, or softness—unachievable with natural hides.

- Ethical Assurance: Fully animal-free and free from hazardous tanning chemicals (e.g., chromium VI), aligning with global ESG mandates.

WINIW: Your Trusted Partner in Advanced Synthetic Leather

For over 20 years, WINIW has pioneered innovation in high-performance imitation leather fabrics, serving Tier-1 manufacturers across 50+ countries. Since 2003, we’ve combined relentless R&D with uncompromising environmental stewardship to deliver materials that drive commercial success and sustainability goals. Our vertically integrated production—spanning proprietary polymer science, ISO 14001-certified manufacturing, and circular-economy initiatives—ensures every meter of WINIW® fabric meets the rigorous demands of premium B2B applications. Partner with us to transform material challenges into competitive advantages, backed by technical expertise and a commitment to a cleaner industrial future.

Technical Performance & Standards

WINIW Imitation Leather Fabric – B2B Product Technical Guide

WINIW’s premium imitation leather fabric is engineered for industrial and commercial applications requiring high performance, sustainability, and cost efficiency. Designed specifically for B2B clients in furniture, automotive interiors, fashion accessories, and upholstery, our synthetic leather delivers consistent quality and compliance with international standards. The material combines advanced polymer technology with eco-conscious manufacturing to offer a durable, customizable, and responsible alternative to genuine leather.

Technical Advantages

-

Cost-Effective Production

WINIW’s imitation leather reduces material and processing costs compared to natural leather. With minimal waste during cutting and no variability in hide quality, manufacturers benefit from predictable pricing and lower total production costs. -

Superior Durability

Engineered for high abrasion resistance, tensile strength, and dimensional stability, WINIW’s fabric maintains integrity under prolonged mechanical stress. It resists cracking, peeling, and color fading, ensuring long service life in demanding environments. -

Customizable Color Options

Our production process supports full color customization with precise color matching (Pantone, RAL, or customer-provided samples). Batch consistency ensures uniformity across large orders, ideal for brand-aligned product lines. -

REACH Compliance

WINIW’s imitation leather is fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. Safe for consumer and industrial use. -

ISO 9001-Certified Quality Management

All production processes are governed by ISO 9001 standards, guaranteeing consistent product quality, traceability, and continuous improvement in manufacturing performance.

Technical Specifications

| Property | Especificação |

|---|---|

| Base Material | High-density polyurethane (PU) / Polyester fabric backing |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Width | 137 cm ± 2 cm (standard roll width) |

| Weight | 200 – 450 g/m² |

| Tensile Strength (MD/CMD) | ≥ 60 N/5cm / ≥ 55 N/5cm |

| Elongation at Break | ≥ 80% (MD), ≥ 75% (CMD) |

| Martindale Abrasion | ≥ 30,000 cycles (color change) |

| Color Fastness to Rubbing | Dry: 4–5, Wet: 3–4 (ISO 105-X12) |

| Color Fastness to Light | ≥ 6 (Blue Scale, ISO 105-B02) |

| Cold Crack Resistance | ≤ -20°C |

| REACH SVHC Status | Compliant (no listed substances) |

| Fire Resistance | Optional: meets CAL 117, BS 5852, or DIN 4102 upon request |

| Environmental Standards | Phthalate-free, AZO-free, low VOC emissions |

| Certifications | ISO 9001, REACH, OEKO-TEX® Standard 100 (on request) |

WINIW’s imitation leather fabric is a strategic material solution for forward-thinking manufacturers seeking to balance performance, compliance, and sustainability. With scalable production capacity and dedicated R&D support, we enable B2B partners to innovate with confidence.

Why Choose Synthetic over Real Leather

B2B Product Guide: Imitation Leather Fabric vs. Real Leather for Commercial Applications

As a leading innovator in sustainable materials, WINIW provides this objective comparison to support informed sourcing decisions for manufacturers, designers, and brands. Understanding the core differences between imitation leather fabric (synthetic leather) and real leather is critical for balancing performance, cost, ethics, and environmental impact in commercial product development.

Key Differences at a Glance

The table below compares fundamental attributes relevant to B2B procurement:

| Attribute | Imitation Leather Fabric (Synthetic Leather) | Real Leather |

|---|---|---|

| Cost | – Lower upfront cost (30-60% less than premium hides) – Consistent pricing, unaffected by hide quality fluctuations – Reduced waste in cutting (repeat patterns, larger widths) |

– Higher initial cost (driven by hide grade, origin, scarcity) – Price volatility due to livestock market/seasonal factors – Significant waste (15-30%) due to natural hide defects |

| Durabilidade | – High resistance to stains, moisture, and UV fading – Uniform strength across the roll – Less prone to cracking in fluctuating humidity – Typical lifespan: 5-12 years (varies by formulation) |

– Develops rich patina over time but requires conditioning – Vulnerable to water damage, stains, and drying/cracking without maintenance – Lifespan: 10-25+ years with meticulous care (premium full-grain) |

| Eco-Friendliness | – WINIW Advantage: Modern synthetics use recycled PET (rPET), plant-based PU, and water-based coatings – Zero animal sourcing; avoids tannery chromium pollution – Lower carbon footprint in production (per ISO 14040) – Challenge: Microplastic shedding; end-of-life recycling complexity |

– Uses a byproduct of meat industry (reducing waste) – Naturally biodegradable (if vegetable-tanned) – Significant Impact: High water/energy use in tanning; toxic chemical runoff (chrome tanning); methane emissions from livestock |

Critical Considerations for Commercial Buyers

- Supply Chain Stability: Imitation leather offers reliable volume and color consistency for global production, avoiding hide scarcity issues. Real leather supply is constrained by livestock cycles and geographic hide availability.

- Design Flexibility: Synthetic leather enables unlimited color, texture, and performance customization (e.g., antimicrobial, flame-retardant) without compromising aesthetics. Real leather options are limited by natural hide characteristics.

- Ethical Compliance: Imitation leather eliminates animal welfare concerns and simplifies certifications (e.g., PETA-Approved Vegan). Real leather requires rigorous traceability to verify ethical slaughter and tanning practices.

- End-of-Life Impact: WINIW’s advanced recycled-content synthetics (e.g., WINIW® R-TEX) support circularity through take-back programs. Real leather’s biodegradability is offset by persistent tanning chemicals in landfills.

WINIW’s Sustainable Solution

For brands prioritizing eco-performance without compromising quality, WINIW’s synthetic leather fabrics deliver:

– Up to 60% recycled content (ocean-bound rPET + bio-based PU)

– Zero-COBALT, heavy-metal-free tanning equivalent to LWG Gold standards

– Carbon-neutral production via ISO 14067-certified processes

– Commercial-grade durability validated for 50,000+ double rubs (ASTM D4157)

Choose WINIW to meet evolving ESG targets while ensuring supply chain resilience and design innovation. Request our full technical dossier for material specifications aligned with your industry requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, eco-friendly materials. Our vertically integrated production capabilities and commitment to quality have positioned us as a trusted partner in the global supply chain.

Our manufacturing strength is anchored in a state-of-the-art facility spanning 100,000 square meters. This large-scale production base enables us to maintain efficient operations, high output capacity, and flexible customization to meet diverse industry demands—from automotive and furniture to fashion and accessories.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated systems for consistent material quality and enhanced efficiency.

- A dedicated R&D team of over 50 engineers and material scientists focused on innovation, sustainability, and performance optimization.

- Continuous investment in eco-friendly technologies, including water-based and solvent-free PU processes, aligning with global environmental standards.

- Strict quality control (QC) protocols implemented at every stage—from raw material inspection to final product testing. Each batch undergoes rigorous checks for abrasion resistance, color fastness, tensile strength, and environmental compliance.

- Compliance with international certifications such as REACH, RoHS, OEKO-TEX®, and ISO 9001, ensuring safety and reliability for European and U.S. markets.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our logistics network ensures timely delivery, while our technical support team provides seamless collaboration for OEM and ODM projects.

| Feature | Especificação |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 50+ specialists |

| Annual Production Capacity | 180 million meters |

| Key Export Regions | Europe, USA, Japan, Southeast Asia |

| Certifications | REACH, RoHS, OEKO-TEX®, ISO 9001 |

With integrated innovation, scalable manufacturing, and a commitment to sustainable development, WINIW delivers synthetic leather solutions that meet the highest global standards.

Contact Us for Samples

WINIW MicroSuede™: Premium Synthetic Leather for Sustainable B2B Applications

WINIW delivers high-performance, eco-conscious synthetic leather solutions engineered for discerning commercial and industrial partners. Our MicroSuede™ fabric redefines imitation leather with uncompromising durability, ethical production, and versatility for furniture, automotive, fashion, and technical textiles. Backed by decades of material science expertise, we empower brands to meet sustainability targets without sacrificing quality or aesthetics.

Why Partner with WINIW for Synthetic Leather?

- Eco-Engineered Production: 100% solvent-free manufacturing process, eliminating toxic emissions and hazardous waste.

- Certified Sustainable: OEKO-TEX® STANDARD 100 Class I (skin-safe), ISO 14001 certified, and 30%+ recycled content in core product lines.

- Superior Performance: Engineered for 50,000+ double rubs (Martindale), UV resistance (5,000+ hrs), and 100% waterproof backing.

- Customization Agility: Tailored thickness (0.6mm–1.8mm), weight (200–500g/m²), textures, and color matching (Pantone®/RAL).

- Circular Economy Ready: Fully recyclable substrate and backing materials; end-of-life take-back program available.

Performance Comparison: WINIW MicroSuede™ vs. Conventional Alternatives

| Feature | WINIW MicroSuede™ | Traditional PU Leather | Couro PVC |

|---|---|---|---|

| Eco-Impact | Zero solvent emissions; 30%+ recycled content | Solvent-based; low recyclability | Phthalates; non-recyclable |

| Durabilidade | 50,000+ double rubs | 20,000–30,000 double rubs | 15,000–25,000 double rubs |

| Water Resistance | 100% waterproof | Moderate (peeling risk) | High (but stiffens) |

| Respirabilidade | 800 g/m²/24hrs | <300 g/m²/24hrs | Non-breathable |

| Certifications | OEKO-TEX® 100, ISO 14001 | Limited safety certs | REACH-compliant only |

Key Applications Driving Client Success

- Contract Furniture: Hospitality seating, office upholstery, and healthcare surfaces requiring antimicrobial properties.

- Automotive Interiors: Door panels, seats, and dash trims meeting FMVSS 302 flammability standards.

- Fashion & Accessories: Handbags, footwear, and luxury apparel with supple drape and color consistency.

- Technical Textiles: Marine upholstery, aviation interiors, and protective gear needing extreme weather resistance.

Commit to Sustainable Innovation with Zero Risk

Experience WINIW MicroSuede™ firsthand with complimentary material samples. Our technical team collaborates with you to optimize performance for your specific application, ensuring seamless integration into your supply chain while advancing ESG goals.

Request Samples & Technical Specifications

Contact WINIW’s Material Innovation Team:

MKT88@MicrofiberLeather.com

Free samples available for qualified B2B partners. Specify your application and volume requirements.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.