Catalog

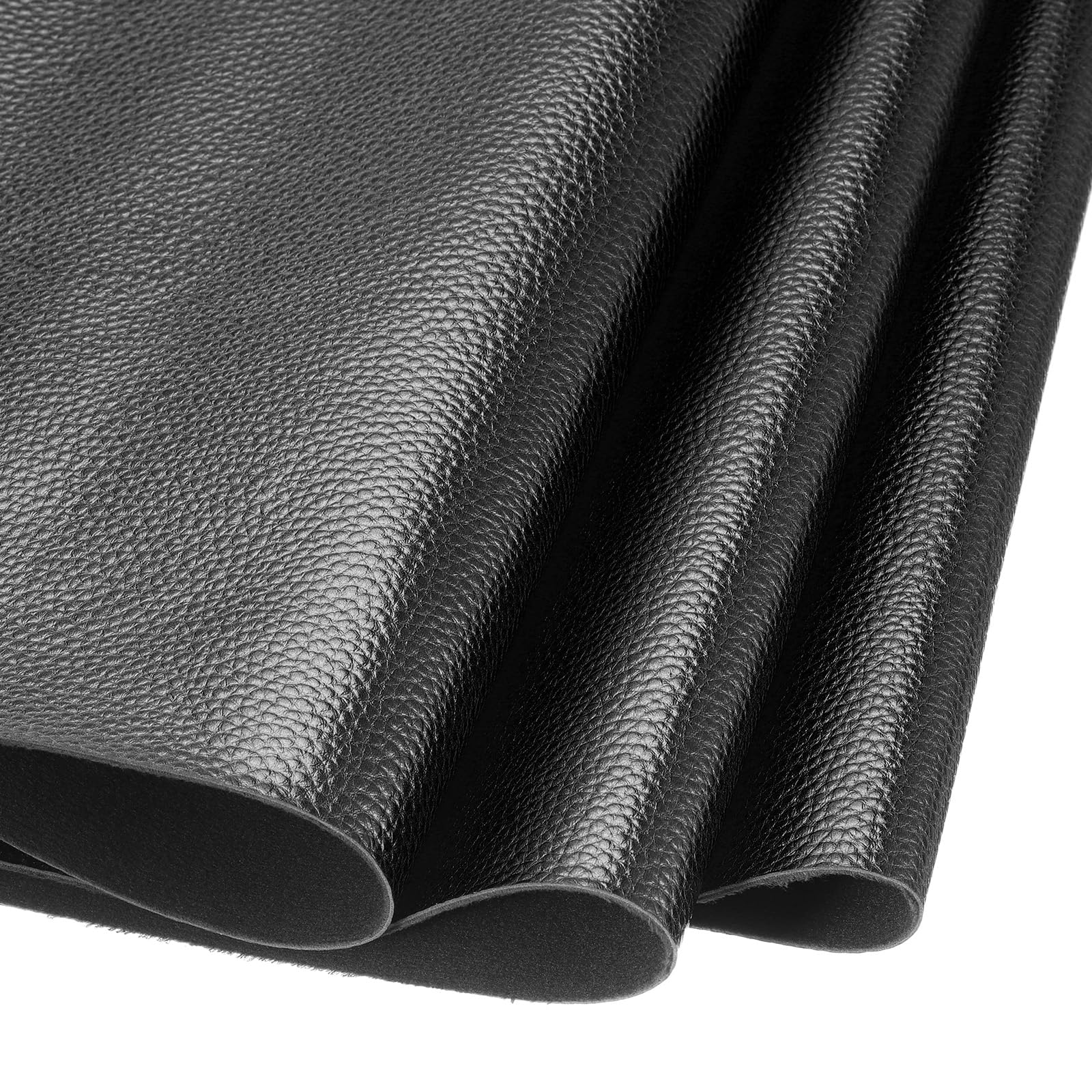

Material Insight: Fake Leather Texture

B2B Product Guide: Faux Leather Textures

Faux leather, also known as synthetic or artificial leather, has become a preferred material across industries due to its versatility, durability, and sustainable advantages over traditional animal leather. In applications ranging from automotive interiors and furniture upholstery to fashion accessories and architectural design, faux leather offers a consistent texture, customizable finishes, and ethical sourcing—all without compromising on performance or aesthetics.

Faux leather is the best choice for modern manufacturing and design applications because it delivers:

- Consistent Quality: Unlike natural leather, which can vary in grain and texture, synthetic leather provides uniform appearance and performance across large production runs.

- Design Flexibility: Available in a wide range of textures, colors, and finishes—from smooth and glossy to embossed and matte—faux leather can be engineered to meet specific aesthetic and functional requirements.

- Sustainability: As a cruelty-free and often recyclable material, synthetic leather supports eco-conscious production and aligns with global ESG (Environmental, Social, and Governance) goals.

- Durability & Performance: Resistant to abrasion, UV exposure, and moisture, faux leather maintains its integrity in demanding environments, making it ideal for high-use products.

- Cost Efficiency: With lower production lead times and reduced dependency on raw animal materials, faux leather offers a more predictable and scalable supply chain.

With over 20 years of industry expertise, WINIW is a trusted leader in high-performance synthetic leather solutions. We specialize in developing customized faux leather textures that meet the exact needs of global manufacturers and designers. Our advanced production technologies, combined with a commitment to sustainability and innovation, enable us to deliver premium materials that perform across diverse applications. From R&D to large-scale manufacturing, WINIW partners with businesses to create smarter, greener, and more efficient material solutions.

Technical Performance & Standards

WINIW Synthetic Leather Texture: Technical Product Guide for B2B Applications

WINIW’s advanced synthetic leather textures deliver engineered performance for demanding commercial and industrial applications. Our solutions eliminate the cost volatility and ethical concerns of genuine leather while exceeding functional requirements through precision manufacturing. Below are the core technical advantages validated for long-term operational value.

Key Technical Advantages

- Cost-Effectiveness: Reduced total cost of ownership via 30% lower material waste during cutting/conversion compared to natural leather, combined with 50% faster production cycles due to consistent roll goods and elimination of grading/sorting. No hidden costs from shrinkage or irregularities.

- Enhanced Durability: Engineered with high-density polyurethane (PU) backing and reinforced fiber substrates to achieve 100,000+ double rubs (Martindale ASTM D4966), 50N+ tear strength (ASTM D2261), and resistance to UV degradation (5,000+ hours QUV testing). Maintains integrity under repeated flexing and abrasion.

- Precision Color Customization: Full Pantone® matching capability across 1,200+ standard colors with <1.0 ΔE color deviation (measured via spectrophotometer). Batch-to-batch consistency guaranteed through ISO 9001-controlled dyeing processes, supporting brand-specific requirements without minimum order penalties.

- REACH Compliance: Fully compliant with EU REACH Annex XVII, including zero detection of restricted phthalates (DEHP, BBP, DBP), CMR substances, and heavy metals (Cd, Pb, Hg, Cr⁶⁺). Certificates of Conformity available per shipment.

- ISO 9001 Quality Assurance: Every production batch undergoes 12-point quality validation – from raw material traceability to final surface inspection – ensuring dimensional stability (±0.5mm thickness tolerance) and performance consistency.

Technical Specifications

All values represent minimum guaranteed performance under standard testing conditions (23°C, 50% RH).

| Parâmetro | Especificação | Test Standard |

|---|---|---|

| Thickness Range | 0.6mm – 1.8mm (customizable) | ISO 2417 |

| Weight | 280g/m² – 650g/m² | ISO 9073-3 |

| Abrasion Resistance | ≥100,000 double rubs | ASTM D4966 |

| Tear Strength | ≥50N (machine direction) | ASTM D2261 |

| Color Fastness (Light) | Grade 7-8 (ISO Blue Scale) | ISO 105-B02 |

| Martindale Pilling | Class 4-5 (no pilling after 12,000 rubs) | ISO 12945-1 |

| Width | 137cm, 142cm, 150cm rolls | Internal QC |

| Custom Color Lead Time | 15 business days (from approval) | – |

| Certifications | REACH, ISO 9001, OEKO-TEX® STANDARD 100 | EC Declaration |

WINIW’s synthetic leather textures provide predictable performance for upholstery, automotive interiors, luggage, and technical goods manufacturing. Our closed-loop production system uses water-based PU and 30% recycled content (GRS-certified), aligning durability with environmental responsibility. All materials undergo quarterly third-party verification for regulatory adherence. Contact WINIW Technical Services for application-specific validation data or sample kits.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather – A Comparative Overview

For manufacturers, designers, and procurement professionals in industries ranging from automotive and furniture to fashion and accessories, selecting the right leather alternative is critical. This guide compares real leather with synthetic (commonly referred to as “fake”) leather, focusing on texture, performance, and sustainability metrics. WINIW specializes in high-performance synthetic leather solutions that offer consistency, durability, and reduced environmental impact—ideal for forward-thinking B2B applications.

Texture and Aesthetic Comparison

Real leather is valued for its natural grain, depth, and soft hand feel, which develops a unique patina over time. However, its texture varies significantly between hides due to natural imperfections and animal origin, presenting challenges for large-scale, uniform production.

Synthetic leather, particularly premium microfiber and PU-based materials like those developed by WINIW, replicates the tactile and visual qualities of real leather with enhanced consistency. Advanced embossing and coating technologies allow for precise control over texture, color, and grain patterns, enabling brands to achieve a high-end aesthetic across entire product lines.

- Real Leather: Natural grain variation, prone to surface irregularities, develops patina over time.

- Synthetic Leather: Uniform texture, customizable grain patterns, consistent color fastness, no animal-origin variation.

Performance and Application Suitability

In commercial and industrial applications, consistency, scalability, and maintenance are key. Synthetic leather offers predictable performance and is engineered for specific use cases—such as high-abrasion environments in automotive interiors or moisture-prone settings in marine upholstery.

Below is a comparative analysis based on critical decision-making factors:

| Criteria | Real Leather | Synthetic Leather (WINIW Grade) |

|---|---|---|

| Cost | High (raw material + processing) | Moderate to low (scalable production) |

| Durabilidade | Good, but sensitive to UV/moisture | High (abrasion, UV, and stain resistant) |

| Eco-friendliness | Low (high water/land use, tanning chemicals) | High (low VOC, recyclable options, PFC-free processes) |

Key Advantages of Synthetic Leather for B2B Buyers

- Cost Efficiency: Lower raw material and processing costs enable competitive pricing and higher margins.

- Durability Control: Engineered for resistance to cracking, fading, and microbial growth—ideal for transportation, healthcare, and contract furniture.

- Sustainability Profile: WINIW’s synthetic leathers are produced with reduced water usage, no animal farming, and compliance with REACH and OEKO-TEX® standards.

- Design Flexibility: Available in custom textures, colors, and performance grades (e.g., flame retardant, anti-microbial).

- Ethical Alignment: Supports cruelty-free and vegan product lines, meeting growing consumer and regulatory demands.

Conclusion

While real leather maintains a legacy of prestige, synthetic leather—especially advanced formulations from leaders like WINIW—offers B2B clients a smarter, scalable, and sustainable alternative. With comparable aesthetics, superior consistency, and a significantly lower environmental footprint, synthetic leather is the strategic choice for modern manufacturing and responsible branding.

WINIW Factory Capabilities

WINIW Factory Capabilities: Engineered for Global B2B Excellence

WINIW operates from a state-of-the-art manufacturing hub designed to meet the exacting demands of international partners. Our vertically integrated facility spans 100,000 square meters, enabling end-to-end control over production while ensuring scalability for large-volume contracts. This strategic infrastructure, combined with deep technical expertise, positions WINIW as a trusted supplier for premium synthetic leather across regulated markets.

Core Manufacturing Strengths:

– Integrated 100,000 sqm Facility: Comprehensive in-house capabilities from resin synthesis and coating to finishing and testing, minimizing supply chain dependencies and ensuring consistent lead times.

– Dedicated R&D Team: 50+ engineers and material scientists focused on eco-innovation, including water-based PU development, recycled content integration (up to 40% PCR), and biodegradable substrate solutions compliant with EU/USA regulations.

– Strict Quality Control Protocols: Multi-stage QC checkpoints aligned with ISO 9001 standards, including AATCC/ASTM-compliant testing for colorfastness, abrasion resistance, and chemical safety (REACH, CPSIA, OEKO-TEX® STANDARD 100). Real-time IoT monitoring ensures batch uniformity.

– Global Export Compliance: Direct shipments to 30+ countries, with specialized documentation for EU (REACH SVHC screening) and USA (CPC, Prop 65) markets. Dedicated logistics partners ensure customs efficiency and carbon-neutral shipping options.

Our facility’s scale and certification framework (ISO 14001, GRS) enable WINIW to deliver not only superior product performance but also verifiable sustainability credentials demanded by global brands. This operational rigor ensures every meter of WINIW synthetic leather meets the dual imperatives of environmental responsibility and uncompromising quality for B2B partners.

Contact Us for Samples

B2B Product Guide: Premium Synthetic Leather Textures by WINIW

WINIW specializes in high-performance, eco-conscious synthetic leather solutions tailored for industries ranging from automotive and furniture to fashion and interior design. Our advanced microfiber technology delivers durability, aesthetic versatility, and sustainability—without compromising on quality.

Our synthetic leathers are engineered to replicate the look and feel of genuine leather while offering superior resistance to abrasion, UV exposure, and environmental wear. With a strong commitment to sustainability, WINIW utilizes low-impact production processes and eco-friendly materials, making our products ideal for environmentally responsible brands.

Key Benefits of WINIW Synthetic Leather:

- Exceptional softness and realistic leather texture

- High tensile and tear strength for long-term durability

- Breathable, lightweight construction for comfort and performance

- Resistance to cracking, fading, and staining

- Eco-friendly manufacturing with reduced carbon footprint

- Customizable thickness, color, and surface finish

- Compliant with global environmental standards (REACH, RoHS, OEKO-TEX®)

Available Textures in Our Synthetic Leather Line:

- Smooth Grain – Ideal for upholstery and fashion applications requiring a refined finish

- Embossed Patterns – Custom embossing options including crocodile, snakeskin, and geometric designs

- Suede Touch – Soft, matte surface perfect for automotive interiors and premium apparel

- Nubuck Effect – Slightly brushed finish for a sophisticated, natural leather appearance

- 3D Textured Surfaces – Deep embossing for decorative and high-design applications

Technical Specifications Overview:

| Property | Value Range |

|---|---|

| Thickness | 0.6 mm – 2.0 mm |

| Weight | 180 g/m² – 450 g/m² |

| Color Fastness (ISO 105) | ≥ Grade 4 |

| Martindale Abrasion | 30,000 – 100,000 cycles |

| Light Fastness | ≥ 6 (Blue Scale) |

| Eco-Certifications | REACH, RoHS, OEKO-TEX® Standard 100 |

All products are produced in ISO-certified facilities and can be customized to meet specific industrial requirements.

Request Free Samples Today

Experience the quality and versatility of WINIW’s synthetic leather textures firsthand. We offer free samples to qualified B2B partners to support your material selection and design development.

For inquiries about ‘fake leather texture’ options, customization, or technical details, contact our marketing team:

- Correio eletrónico: MKT88@MicrofiberLeather.com

- Service: Free sample program available for business clients

Elevate your product line with sustainable, high-end synthetic leather from WINIW—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.