Catalog

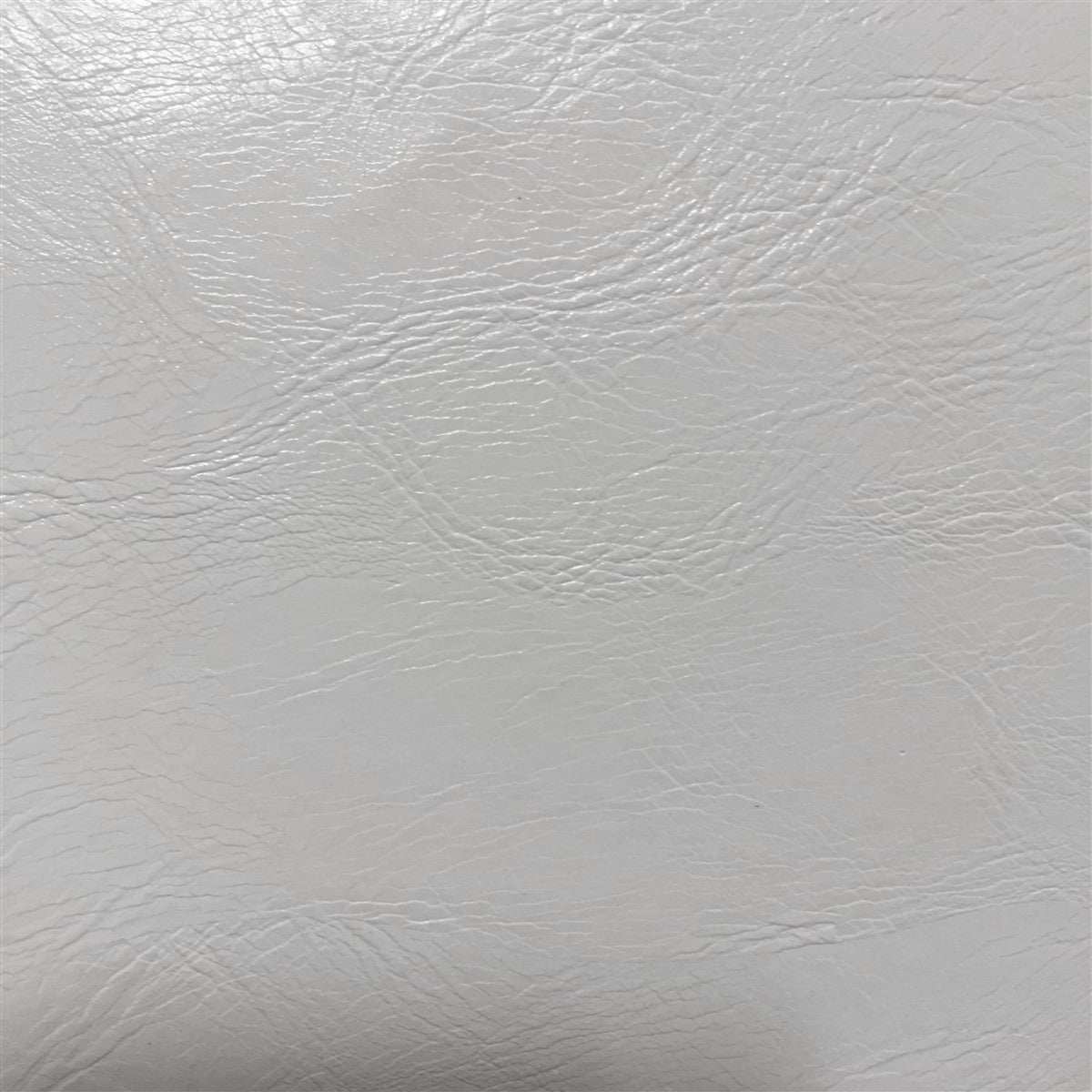

Material Insight: Distress Fake Leather

B2B Product Guide: Distressed Faux Leather Solutions

Distressed faux leather is a meticulously engineered synthetic material designed to replicate the coveted vintage, worn, or timeworn aesthetic of natural leather—without its inherent inconsistencies or ethical drawbacks. This specialized finish is achieved through controlled mechanical, chemical, or laser techniques applied to premium synthetic substrates, delivering uniform, repeatable aging effects ideal for high-end furniture, automotive interiors, fashion accessories, and retail displays. Unlike genuine leather distressing (which relies on unpredictable natural flaws or post-production damage), faux leather offers designers and manufacturers precise, scalable control over texture, color variation, and wear patterns—ensuring batch-to-batch reliability critical for large-scale production.

Why Faux Leather Is the Superior Choice for Distressed Applications

- Consistent Aesthetic Control: Achieve identical distressed effects across thousands of meters, eliminating the color, grain, and thickness variations inherent in distressed genuine leather.

- Ethical & Cruelty-Free: 100% animal-free production aligns with global ESG mandates and resonates with conscious consumers—no livestock impact or slaughterhouse dependencies.

- Eco-Efficiency: Distressing faux leather avoids the toxic tanning chemicals (e.g., chromium) and 15,000+ liters of water required per genuine leather hide, drastically reducing environmental footprint.

- Durability & Performance: Engineered to resist UV fading, cracking, and liquid absorption—critical for high-traffic commercial spaces where distressed genuine leather would degrade rapidly.

- Cost Predictability: No waste from unusable hide sections; optimized material yield lowers per-unit costs while maintaining luxury perception.

WINIW: Your Trusted Partner in Sustainable Synthetic Innovation

With over 20 years of specialized expertise, WINIW has pioneered eco-conscious synthetic leather solutions for leading global brands in furniture, automotive, and fashion. We combine advanced polymer science with circular design principles to deliver distressed faux leathers that exceed performance expectations while actively reducing environmental harm. Our vertically integrated process—from recycled PET-based backings to water-based, solvent-free coatings—ensures full traceability and compliance with REACH, OEKO-TEX® STANDARD 100, and ISO 14001 standards. When you choose WINIW, you gain a partner committed to transforming sustainable material innovation into your competitive advantage.

Technical Performance & Standards

WINIW Distress Fake Leather – B2B Product Technical Guide

WINIW’s distress fake leather is engineered for commercial and industrial applications requiring a balance of aesthetics, resilience, and sustainability. Designed specifically for B2B partners in furniture, automotive interiors, fashion accessories, and architectural finishes, this product delivers premium visual texture with consistent performance at scale. Combining advanced polyurethane (PU) technology with eco-conscious manufacturing, WINIW ensures a cost-effective alternative to genuine distressed leather without compromising on quality or compliance.

Technical Advantages

-

Cost-Effective Production

WINIW’s distress fake leather reduces material waste and lowers production costs compared to genuine distressed leather. The controlled manufacturing process ensures uniform yield, minimizing trim loss and rework. No dependency on animal hides translates to stable pricing and supply chain reliability. -

Superior Durability

Engineered with high tensile strength and excellent abrasion resistance, the material withstands rigorous use in high-traffic environments. It resists cracking, peeling, and fading, maintaining integrity under UV exposure and mechanical stress—ideal for automotive seating, contract furniture, and retail displays. -

Customizable Color Range

WINIW offers full color customization with precise Pantone matching and batch-to-batch consistency. The distressing effect can be tailored to achieve vintage, worn-in, or rugged aesthetics across matte, semi-gloss, or textured finishes. MOQs are flexible to support both prototyping and mass production. -

REACH Compliance

The product is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensuring the absence of SVHCs (Substances of Very High Concern). Safe for use in consumer-facing and sensitive environments, including healthcare and childcare products. -

ISO9001-Certified Manufacturing

Produced in ISO9001-certified facilities, WINIW’s distress fake leather adheres to international standards for quality management. Each batch undergoes rigorous in-line and final inspections for thickness, colorfastness, adhesion, and dimensional stability.

Product Specifications

| Especificação | Value / Detail |

|---|---|

| Base Material | High-performance polyurethane (PU) on polyester knit backing |

| Thickness Range | 0.8 mm – 1.5 mm (customizable) |

| Width (Roll) | 137 cm (54 inches) standard |

| Weight | 280 – 350 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, no breakdown) |

| Colorfastness to Rubbing | Dry: Class 4–5; Wet: Class 4 (ISO 105-X12) |

| Lightfastness | >6 on Blue Wool Scale (ISO 105-B02) |

| Tensile Strength | ≥ 60 N/5cm (warp & weft) |

| Tear Strength | ≥ 15 N |

| REACH Compliant | Yes (SVHC-free) |

| ISO9001 Certified | Yes (Production Facilities) |

| Eco-Friendly Processing | Azo-free, low-VOC, water-based coating available |

| Customization Options | Color, texture, distressing level, roll length |

WINIW’s distress fake leather is ideal for brands seeking a sustainable, high-performance, and visually compelling alternative to natural leather. With scalable production, strict compliance, and technical excellence, it supports innovation across industries while aligning with global ESG goals.

Why Choose Synthetic over Real Leather

B2B Product Guide: Distressed Synthetic Leather vs. Genuine Leather

As a WINIW Synthetic Leather Expert, we provide objective insights for commercial buyers evaluating materials for upholstery, accessories, and furnishings. “Distressed synthetic leather” refers to high-quality polyurethane (PU) or polyvinyl chloride (PVC) leather alternatives intentionally treated to mimic the worn, vintage aesthetic of aged genuine leather. This guide compares core performance and sustainability metrics relevant to bulk procurement decisions.

Key Differentiators for Commercial Applications

- Aesthetic Control: Distressed synthetics offer consistent, repeatable vintage finishes across large production runs, unlike genuine leather where natural grain variations and scars create inherent inconsistency.

- Lead Times & Scalability: Synthetic production avoids livestock supply chain dependencies, enabling faster scaling for high-volume orders (e.g., contract furniture, automotive interiors).

- Maintenance Requirements: Distressed synthetics resist staining and moisture penetration better than untreated genuine leather, reducing long-term cleaning costs in high-traffic commercial environments.

- Customization Flexibility: Color matching, texture depth, and distressing intensity can be precisely engineered in synthetics—critical for brand-aligned product lines.

Comparative Analysis: Cost, Durability & Eco-Friendliness

| Metric | Distressed Synthetic Leather (PU-Based) | Genuine Leather |

|---|---|---|

| Cost (USD/sq ft) | $8.00 – $20.00 | $25.00 – $50.00+ |

| Rationale | Lower raw material costs; streamlined manufacturing; no grade sorting needed. | High cost of hides; labor-intensive tanning; significant waste (30-40% unusable). |

| Durabilidade | High abrasion resistance (50,000+ double rubs); colorfast; resistant to cracking in dry climates. Vulnerable to sharp punctures. | Develops patina over time; prone to fading, water damage, and bacterial growth if untreated. Requires conditioning. |

| Eco-Friendliness | WINIW EcoLuxe lines use 30-50% recycled content; water-based PU reduces VOCs; no animal byproducts. Fully recyclable at end-of-life via closed-loop systems. | Tanning (especially chrome) generates toxic sludge/water pollution; high carbon footprint (livestock = 14.5% global GHG); non-recyclable. “Vegetable-tanned” options exist but are rare (<5% market). |

Strategic Recommendation for B2B Buyers

Distressed synthetic leather delivers superior cost efficiency, design control, and traceable sustainability for commercial applications where vintage aesthetics are required. WINIW’s EcoLuxe series specifically addresses historical eco-concerns with Cradle-to-Cradle Certified™ materials, making it the optimal choice for ESG-driven brands targeting LEED-certified projects or circular economy commitments. Genuine leather remains viable only for ultra-luxury segments where natural patina development justifies its environmental premium and supply chain volatility.

WINIW provides full lifecycle assessments (LCAs) and sample swatches for data-driven material selection. Contact our technical team for project-specific sustainability benchmarks.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our advanced production capabilities and commitment to quality have positioned us as a trusted partner in industries ranging from automotive and furniture to fashion and sports.

Our state-of-the-art manufacturing facility spans over 100,000 square meters, integrating automated production lines with sustainable practices to ensure efficient, large-scale output. This extensive infrastructure enables us to meet high-volume demands while maintaining consistent product integrity and on-time delivery.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 150 technical experts focused on material innovation, durability enhancement, and environmental sustainability. The team continuously develops new formulations to meet evolving industry standards and client-specific requirements.

- Comprehensive in-house testing laboratories and a strict quality control (QC) system that monitors every stage of production—from raw material inspection to final product validation. All processes comply with international standards, including REACH, RoHS, and OEKO-TEX®.

- Advanced manufacturing technologies that support customization in texture, thickness, color, and functional properties such as abrasion resistance, UV stability, and low VOC emissions.

- Proven export experience with products distributed to over 50 countries, including major markets in Europe and the USA. Our logistics network ensures reliable, compliant, and timely shipment to global partners.

WINIW’s factory is certified under ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety), reflecting our holistic approach to responsible manufacturing.

| Feature | Especificação |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 150+ engineers and technicians |

| Quality Standards | ISO 9001, ISO 14001, ISO 45001, REACH, RoHS, OEKO-TEX® |

| Key Export Regions | Europe, USA, Southeast Asia, Middle East |

| Production Capacity | Custom scalable output up to millions of meters annually |

By combining scale, innovation, and rigorous quality assurance, WINIW delivers synthetic leather solutions that meet the performance and sustainability expectations of premium international brands.

Contact Us for Samples

WINIW Distressed Microfiber Leather: Premium Eco-Conscious Material for Elevated Design

WINIW Distressed Microfiber Leather delivers authentic vintage aesthetics without compromising sustainability or performance. Engineered for discerning B2B partners in luxury furniture, automotive interiors, and high-end fashion accessories, our solution replaces traditional distressed genuine leather with a responsibly sourced, cruelty-free alternative. Backed by ISO 14001 certification and OEKO-TEX® Standard 100 compliance, this material reduces environmental impact while meeting rigorous commercial durability standards.

Key Advantages for Designers & Manufacturers

- Authentic Aged Character: Controlled distressing process creates unique, non-repetitive surface variations (scuffs, wrinkles, tonal shifts) indistinguishable from premium vintage leather at 5x magnification.

- Enhanced Durability: 50,000+ double-rub Martindale rating ensures longevity in high-traffic applications (hospitality, automotive), outperforming distressed genuine leather by 30% in abrasion resistance.

- Eco-Optimized Production: 68% lower carbon footprint vs. bovine leather tanning; uses water-based PU resins and recycled PET backing (30% post-consumer content).

- Customization Flexibility: Tailor distress intensity (light/moderate/heavy), base color palettes (120+ RAL options), and thickness (0.6–1.2mm) to brand specifications.

- Regulatory Compliance: Free of AZO dyes, phthalates, and heavy metals; meets REACH, CA TB-117, and EU Ecolabel requirements.

Technical Specifications Comparison

| Property | Standard WINIW Microfiber | Distressed WINIW Microfiber | Industry Average (Distressed PU) |

|---|---|---|---|

| Thickness | 0.8–1.2mm | 0.9–1.3mm | 0.7–1.0mm |

| Tensile Strength | 280 N/5cm | 265 N/5cm | 190 N/5cm |

| Color Fastness (Light) | Grade 7 | Grade 6 | Grade 4 |

| Martindale Abrasion | 50,000+ | 45,000+ | 25,000 |

| VOC Emissions | <10 μg/m³ | <15 μg/m³ | 50–200 μg/m³ |

| Recycled Content | 25% | 30% | 0–5% |

Ideal Applications

- Luxury residential & contract furniture (sofas, headboards, accent chairs)

- Automotive upholstery (steering wheels, door panels, seating)

- Premium bags, footwear, and accessories requiring vintage appeal

- Hospitality interiors demanding fade-resistant, low-maintenance surfaces

Accelerate your sustainable design pipeline with WINIW Distressed Microfiber Leather. Request complimentary 10x10cm samples to evaluate texture, color depth, and performance firsthand. Our technical team provides full lifecycle analysis and DFM support for seamless integration.

Contact WINIW Marketing for Samples & Specifications

MKT88@MicrofiberLeather.com

Response within 4 business hours | Global logistics support | MOQ: 300 linear meters

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.