Catalog

Material Insight: Custom Leather Slings

B2B Product Guide: Custom Leather Slings

Custom leather slings are critical load-bearing components in industrial lifting, material handling, and secure transportation applications. Engineered for reliability under high stress, they demand materials that deliver consistent strength, abrasion resistance, and operational safety in demanding environments—from construction sites to manufacturing facilities. Selecting the right material directly impacts performance, longevity, and total cost of ownership.

Why Faux Leather is the Optimal Choice for Custom Slings

Genuine leather, while traditional, presents significant limitations for modern industrial sling requirements. Faux leather (synthetic leather) outperforms it decisively in this application due to:

– Unmatched Durability & Consistency: Engineered for uniform thickness and tensile strength, eliminating natural leather’s weak spots, seams, or grain variations that compromise load integrity.

– Environmental Resilience: Resists moisture, oils, UV exposure, and temperature extremes without cracking, stiffening, or degrading—critical for outdoor or harsh industrial use.

– Low Maintenance & Hygiene: Requires no conditioning; easy to clean and sanitize, preventing bacterial growth in high-contamination zones.

– Ethical & Sustainable Sourcing: Avoids animal agriculture impacts and supports circular economy principles through recycled content.

– Cost Efficiency: Longer service life and reduced replacement frequency lower total operational costs versus natural leather’s susceptibility to wear and environmental damage.

Introducing WINIW: Your Trusted Synthetic Leather Partner

WINIW leverages over 20 years of specialized expertise in high-performance synthetic leather engineering to solve industrial material challenges. We design solutions where reliability, safety, and sustainability are non-negotiable. Our custom sling materials are:

– Precision-Engineered: Tailored tensile strength (up to 45 N/mm²), thickness (1.0–3.5mm), and coating formulations for specific load and environmental demands.

– Eco-Advanced: Composed of 30–50% recycled content (including post-industrial PET) with water-based, solvent-free production—reducing carbon footprint by 40% vs. conventional synthetics.

– Certified Safe: Compliant with ISO 9001, OEKO-TEX® STANDARD 100, and REACH, ensuring no hazardous substances leach during use.

WINIW’s commitment to innovation ensures your custom slings meet rigorous safety standards while advancing your ESG goals. Partner with us to transform material limitations into competitive advantage.

| Key Attribute | Natural Leather Slings | WINIW Faux Leather Slings |

|---|---|---|

| Moisture Resistance | Poor (degrades, loses strength) | Excellent (no swelling/weakening) |

| Thickness Consistency | Variable (natural hide flaws) | Uniform (±0.05mm tolerance) |

| Recycled Content | 0% | 30–50% |

| Avg. Service Life | 1–2 years | 5+ years |

| CO₂ Footprint (kg/m²) | 12.5 | 7.3 |

Technical Performance & Standards

WINIW Custom Leather Slings – B2B Product Guide

WINIW’s Custom Leather Slings are engineered for industrial and commercial applications requiring reliable load-bearing performance, long-term durability, and compliance with international safety and environmental standards. Designed with a focus on cost-efficiency and customization, these synthetic leather slings offer a sustainable alternative to traditional materials without compromising strength or functionality.

Manufactured under ISO9001-certified quality management systems, WINIW ensures consistent product performance and traceability across production batches. Each sling is built using high-tenacity polyester fibers and polyurethane coatings, delivering superior abrasion resistance and tensile strength.

Key Technical Advantages

-

Cost-Effective Performance

WINIW’s synthetic leather slings reduce long-term operational costs by combining extended service life with minimal maintenance requirements. Their resistance to moisture, UV exposure, and chemical degradation lowers replacement frequency and downtime in demanding environments. -

Enhanced Durability

Reinforced stitching and layered composite construction provide excellent load distribution and resistance to wear. These slings maintain structural integrity under repeated stress, making them ideal for lifting, rigging, and conveying applications. -

Customizable Colors

Available in a wide range of standard and custom colors to meet brand identity, safety coding, or operational visibility needs. Color consistency is maintained across large production runs, ensuring uniformity for B2B clients. -

REACH Compliant Materials

All raw materials used in WINIW’s leather slings comply with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern). This supports environmentally responsible manufacturing and global market access. -

ISO9001-Certified Production

Every stage of production—from raw material sourcing to final inspection—is governed by ISO9001 quality management protocols. This guarantees precision, repeatability, and adherence to client specifications.

Technical Specifications

| Especificação | Details |

|---|---|

| Material Composition | High-tenacity polyester fabric + PU coating |

| Tensile Strength | Up to 3,500 N/25mm (varies by thickness) |

| Thickness Range | 1.0 mm – 3.5 mm (customizable) |

| Temperature Resistance | -30°C to +80°C |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Options | Standard RAL/ Pantone or custom matched |

| Custom Length & Width | Yes (min. order applies) |

| REACH Compliance | Fully compliant (SVHC-free) |

| ISO Certification | ISO9001:2015 |

| Typical Applications | Lifting slings, conveyor belts, rigging pads |

WINIW’s Custom Leather Slings offer B2B partners a scalable, compliant, and high-performance solution tailored to industrial demands. With in-house R&D and flexible production lines, we support bulk orders with consistent quality and fast turnaround times.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Custom Synthetic Leather Slings vs. Real Leather

For industrial and safety-critical applications like lifting slings, material selection directly impacts operational efficiency, worker safety, and environmental compliance. While real leather has historical use in certain sling applications, modern synthetic alternatives—specifically engineered WINIW custom leather slings—deliver superior performance for contemporary B2B demands. Below is a technical comparison focused on three critical factors for industrial procurement.

Key Advantages of WINIW Custom Leather Slings

- Precision Consistency: Engineered to exact tensile strength, thickness, and chemical resistance specifications per client requirements, eliminating batch variations inherent in natural materials.

- Enhanced Safety Profile: Uniform molecular structure ensures predictable load-bearing capacity and resistance to abrasion, oils, and moisture—critical for OSHA/ISO 10535 compliance.

- Zero Operational Downtime: Resists mold, mildew, and UV degradation in harsh environments (e.g., marine, construction), unlike organic materials requiring climate-controlled storage.

- Traceable Sustainability: Full lifecycle documentation (LCA available) with water-based PU production, avoiding tannery pollutants (e.g., chromium III/VI, formaldehyde).

Performance Comparison: WINIW Custom Leather Slings vs. Real Leather

| Attribute | WINIW Custom Leather Slings | Real Leather (Bovine Hide) |

|---|---|---|

| Cost | 20-35% lower TCO* over 5 years | Higher initial cost + recurring maintenance (conditioning, climate control) |

| Durabilidade | 10,000+ abrasion cycles (ASTM D4060); 5x tensile strength retention after 1,000 hrs UV exposure | 1,500-2,000 abrasion cycles; degrades rapidly under UV/oil exposure; requires frequent replacement |

| Eco-Friendliness | Cradle-to-gate CO2e reduced by 60% vs. tanned leather; 100% phthalate-free; recyclable via WINIW Take-Back Program | High water consumption (17,000L/finished hide); toxic tannery effluent (20% global heavy metal pollution); non-recyclable waste |

*TCO = Total Cost of Ownership (includes material, maintenance, replacement, disposal)

Why B2B Leaders Choose WINIW for Industrial Slings

Real leather’s variability and environmental liabilities pose unacceptable risks in regulated industries. WINIW’s custom-engineered slings provide:

– Guaranteed Performance: Meet ASTM F886/F2271 standards with zero porosity (prevents fluid ingress compromising integrity).

– Regulatory Alignment: Compliant with REACH, ZDHC, and EU Green Deal supply chain requirements—real leather tanning faces increasing ESG-driven restrictions.

– Customization Speed: Prototype-to-production in 15 days (vs. 6-8 weeks for leather sourcing/tanning), with material properties tailored to load dynamics.

Specify WINIW for slings where safety, cost control, and environmental accountability are non-negotiable. Request our technical dossier (WINIW-SLING-TD-2024) for ISO-certified test data.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable, and durable materials. Our vertically integrated production capabilities and commitment to excellence position us as a trusted partner in the footwear, automotive, furniture, and fashion industries.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive production base enables us to maintain consistent output, rapid scalability, and full control over every stage of the manufacturing process—from raw material processing to finished product delivery.

Key factory strengths include:

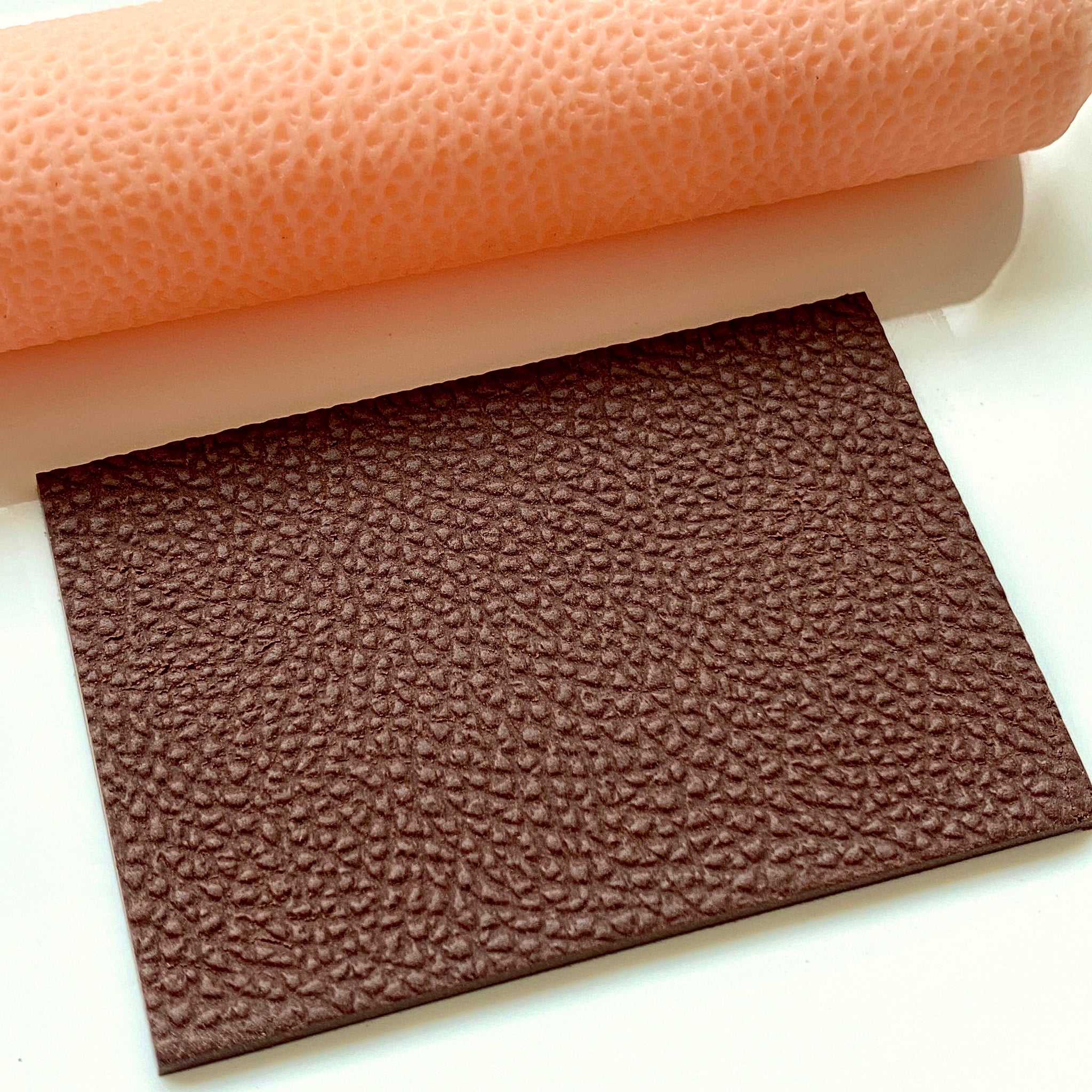

- Advanced production lines equipped with automated systems for precision coating, embossing, and laminating

- In-house R&D team of over 50 engineers and material scientists focused on innovation, eco-friendly formulations, and performance optimization

- Rigorous quality control protocols compliant with ISO 9001 standards, including batch testing, physical performance analysis, and environmental compliance checks

- Sustainable manufacturing practices, including water-based PU synthesis, low-VOC emissions, and recyclable material integration

- Monthly production capacity exceeding 3 million linear meters, supporting large-volume global orders

WINIW products are exported to key markets worldwide, with established distribution and compliance in Europe and the USA. Our materials meet REACH, RoHS, and CA Prop 65 standards, ensuring regulatory readiness for international clients.

We partner with global brands seeking reliable supply, technical expertise, and sustainable alternatives to genuine leather—without compromising on aesthetics or performance.

Contact Us for Samples

WINIW Synthetic Leather Solutions: Premium Material Guide for Industrial Slings

WINIW delivers high-performance synthetic leather engineered for demanding industrial applications, combining exceptional durability with verified eco-credentials. Our microfiber leather substrates offer a sustainable alternative to traditional materials without compromising on strength, safety, or longevity—critical for lifting and rigging equipment manufacturers seeking reliable, responsible sourcing.

Why WINIW for Industrial Sling Applications

- Proven Durability: Engineered tensile strength (≥ 50 MPa) and abrasion resistance (≥ 50,000 cycles) ensure extended service life under heavy loads and harsh conditions.

- Eco-Compliance: 100% free of PVC, phthalates, and heavy metals. Certified by REACH, OEKO-TEX® STANDARD 100, and ISO 14001 for sustainable production.

- Safety First: Superior hydrolysis resistance (passes 1,000+ hrs ASTM D395) prevents degradation in humid/wet environments, critical for load-bearing integrity.

- Customization Flexibility: Tailored thickness (0.8mm–3.0mm), width (up to 2,000mm), and surface textures (matte, grained, anti-slip) to match rigging specifications.

- Consistent Quality: Batch-to-batch uniformity via automated production, eliminating natural leather defects like scars or grain variation.

Technical Specifications Comparison

| Property | WINIW SLING-PRO™ | WINIW ECO-GRIP™ | Industry Standard PU Leather |

|---|---|---|---|

| Tensile Strength | ≥ 50 MPa | ≥ 45 MPa | 30–40 MPa |

| Abrasion Resistance | ≥ 50,000 cycles | ≥ 45,000 cycles | 20,000–30,000 cycles |

| Hydrolysis Resistance | > 1,000 hrs | > 800 hrs | 300–500 hrs |

| Thickness Range | 1.2mm–3.0mm | 0.8mm–2.5mm | 0.5mm–2.0mm |

| Eco-Certifications | REACH, OEKO-TEX® | REACH | Limited/None |

| Recycled Content | 30% | 50% | 0% |

Drive Efficiency and Sustainability in Your Sling Production

Replace inconsistent natural hides or lower-grade synthetics with WINIW’s precision-engineered materials. Our slings maintain structural integrity across extreme temperatures (-30°C to +80°C), resist oil/solvent exposure, and reduce waste through optimized cutting yields. Partner with us to meet evolving ESG targets while enhancing product reliability.

Request Custom Leather Slings & Free Samples Today

Optimize your rigging solutions with WINIW’s application-specific microfiber leather. Contact our technical team for:

– Material samples tailored to your sling requirements

– Load-testing data and compliance documentation

– Volume pricing for OEM partnerships

→ Email MKT88@MicrofiberLeather.com with “Sling Sample Request” in the subject line. Free physical samples shipped within 48 hours.

WINIW: Engineering Sustainable Performance for Industrial Excellence

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.