Introduction: Navigating the Global Market for custom leather gun holster

In the competitive landscape of the global market, sourcing custom leather gun holsters presents unique challenges for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With diverse regulations, varying consumer preferences, and a multitude of suppliers, navigating this sector requires a strategic approach. This comprehensive guide aims to equip international buyers with the insights necessary to make informed purchasing decisions.

We will explore the various types of custom leather gun holsters available, their specific applications across different markets, and best practices for supplier vetting. Additionally, we will address cost considerations and highlight quality indicators that ensure durability and functionality. By understanding these key elements, buyers can confidently assess potential suppliers, ensuring that they select products that not only meet their operational needs but also align with their brand values.

This guide empowers B2B buyers to streamline their procurement processes, minimize risks, and foster long-term partnerships with reputable manufacturers. Whether you are a retailer looking to expand your product line or a distributor seeking reliable sources, this resource will serve as your roadmap to successfully navigating the global market for custom leather gun holsters.

Table Of Contents

- Top 2 Custom Leather Gun Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather gun holster

- Understanding custom leather gun holster Types and Variations

- Key Industrial Applications of custom leather gun holster

- 3 Common User Pain Points for ‘custom leather gun holster’ & Their Solutions

- Strategic Material Selection Guide for custom leather gun holster

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gun holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gun holster’

- Comprehensive Cost and Pricing Analysis for custom leather gun holster Sourcing

- Alternatives Analysis: Comparing custom leather gun holster With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather gun holster

- Navigating Market Dynamics and Sourcing Trends in the custom leather gun holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gun holster

- Strategic Sourcing Conclusion and Outlook for custom leather gun holster

- Important Disclaimer & Terms of Use

Understanding custom leather gun holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inside the Waistband (IWB) | Concealed carry, snug fit, minimal bulk | Law enforcement, civilian concealed carry | Pros: Discreet, comfortable; Cons: Limited access, may require specific clothing. |

| Outside the Waistband (OWB) | More accessible, larger profile, typically more comfortable | Open carry, tactical applications | Pros: Quick access, variety of styles; Cons: Less discreet, may print under clothing. |

| Shoulder Holster | Cross-body carry, distributes weight, often adjustable | Law enforcement, security personnel | Pros: Comfort during long wear, good for larger firearms; Cons: Bulky, requires cover garment. |

| Ankle Holster | Concealed carry option for smaller firearms, worn on ankle | Off-duty law enforcement, civilian carry | Pros: Highly discreet, good for backup weapons; Cons: Limited firearm options, slower access. |

| Crossdraw Holster | Draws from the opposite side of the body, often angled | Hunting, cowboy action shooting | Pros: Comfortable for seated positions, quick draw; Cons: May not be suitable for all firearms. |

What Are the Key Characteristics of Inside the Waistband (IWB) Holsters?

Inside the Waistband (IWB) holsters are designed for concealed carry, providing a snug fit that minimizes bulk. They are typically made from leather or synthetic materials that allow for a comfortable experience while securely holding the firearm. B2B buyers in law enforcement and civilian markets favor IWB holsters for their discreet nature. When purchasing, consider the fit for specific firearms and the wearer’s clothing style, as these factors influence comfort and accessibility.

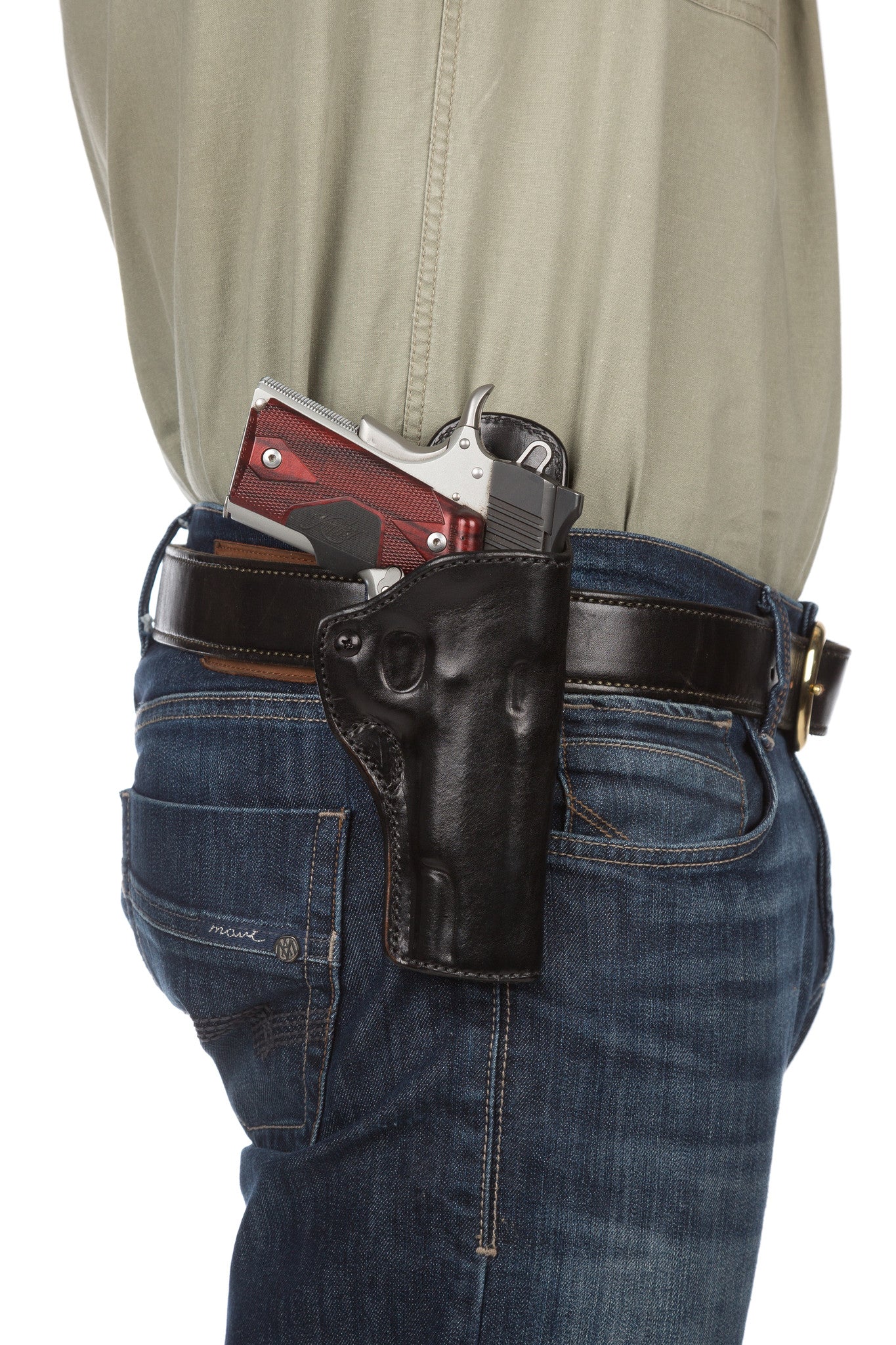

Why Choose Outside the Waistband (OWB) Holsters?

OWB holsters are known for their accessibility and larger profile, making them suitable for open carry and tactical applications. These holsters are often more comfortable for extended wear due to their design, which distributes weight evenly. B2B buyers involved in open carry or tactical operations appreciate the quick access OWB holsters provide. When selecting an OWB holster, buyers should assess the balance between concealment and ease of access, as well as the holster’s compatibility with various firearm models.

Illustrative image related to custom leather gun holster

What Are the Advantages of Shoulder Holsters?

Shoulder holsters offer a unique cross-body carry option that distributes the weight of the firearm across the shoulders, enhancing comfort during prolonged use. These holsters are adjustable and can accommodate larger firearms, making them popular among law enforcement and security personnel. When purchasing shoulder holsters, B2B buyers should consider the need for a cover garment to ensure discretion and evaluate the holster’s adjustability for a proper fit.

When Should You Consider Ankle Holsters?

Ankle holsters are ideal for concealed carry of smaller firearms, making them a popular choice for off-duty law enforcement officers and civilians seeking discreet options. They are worn on the ankle and provide a highly concealed carry method, especially for backup weapons. However, the limited firearm options and slower access can be drawbacks. B2B buyers should assess the intended use and the size of the firearm to ensure compatibility and comfort.

What Makes Crossdraw Holsters Unique?

Crossdraw holsters allow the user to draw the firearm from the opposite side of the body, often at an angle that facilitates easy access while seated. These holsters are particularly favored in hunting and cowboy action shooting scenarios. When considering crossdraw holsters, B2B buyers should evaluate the intended use and the firearm’s compatibility, as this can significantly influence the effectiveness of the draw and overall comfort during use.

Key Industrial Applications of custom leather gun holster

| Industry/Sector | Specific Application of custom leather gun holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Officers use custom leather holsters for duty weapons. | Enhanced safety and accessibility of firearms during operations. | Durability, comfort, and security features are paramount. |

| Military | Custom holsters for tactical operations and training. | Increased operational efficiency and firearm retention in dynamic environments. | Must meet military specifications for resilience and functionality. |

| Security Services | Security personnel utilize holsters for concealed carry. | Provides secure and discreet carry options for personal protection. | Customization options for different firearm types and user comfort. |

| Outdoor Recreation | Hunters and sports shooters require holsters for their firearms. | Ensures safe and accessible carry during outdoor activities. | Weather resistance and ergonomic design are critical for outdoor use. |

| Firearms Retailers | Retailers offer custom holsters as part of their product range. | Attracts customers by providing tailored solutions for firearm storage and carry. | Quality assurance and variety in designs to cater to diverse customer preferences. |

How Are Custom Leather Gun Holsters Used in Law Enforcement?

In the law enforcement sector, custom leather gun holsters are essential for officers who carry firearms as part of their daily duties. These holsters provide enhanced safety and accessibility, ensuring that officers can quickly access their weapons when necessary. Buyers in this sector must prioritize durability and comfort, as holsters are often worn for extended periods. Additionally, security features that prevent accidental discharges are critical, making sourcing from reputable manufacturers imperative.

Illustrative image related to custom leather gun holster

What Role Do Custom Holsters Play in Military Operations?

Military personnel utilize custom leather holsters during tactical operations and training exercises. These holsters are designed to withstand harsh conditions while ensuring that firearms remain secure during movement. The increased operational efficiency and firearm retention offered by these holsters are vital in high-stakes environments. Buyers in the military sector should consider holsters that meet specific military specifications for resilience, functionality, and ease of access.

How Do Security Services Benefit from Custom Leather Holsters?

In the security services industry, personnel often require custom leather holsters for concealed carry. These holsters provide a secure and discreet means of carrying firearms, enhancing personal protection without drawing attention. Customization options are particularly important, as security personnel may use various firearm types. Buyers should focus on sourcing holsters that offer comfort, accessibility, and quality craftsmanship to ensure reliable performance.

Why Are Custom Holsters Important for Outdoor Recreation?

For hunters and sports shooters, custom leather gun holsters are critical for safely carrying firearms during outdoor activities. These holsters ensure that weapons are easily accessible while maintaining safety standards. Buyers in this sector must look for features such as weather resistance and ergonomic designs, as outdoor conditions can vary significantly. Sourcing holsters that combine functionality with aesthetics can also enhance the overall experience for outdoor enthusiasts.

Illustrative image related to custom leather gun holster

How Do Firearms Retailers Leverage Custom Holsters?

Firearms retailers often include custom leather holsters in their product offerings, providing customers with tailored solutions for firearm storage and carry. This not only attracts customers but also enhances their shopping experience by offering a complete package. Key considerations for retailers include quality assurance and a variety of designs to cater to diverse customer preferences. Establishing relationships with reputable manufacturers can help ensure consistent quality and availability of stock.

3 Common User Pain Points for ‘custom leather gun holster’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality and Durability in Leather Holsters

The Problem: B2B buyers often face challenges in sourcing high-quality custom leather gun holsters that can withstand rigorous use. This is particularly critical for businesses such as law enforcement agencies or security firms, where the reliability of equipment can directly impact safety and performance. Many buyers find themselves overwhelmed by the varying standards of craftsmanship, materials, and durability claims made by different manufacturers, leading to uncertainty about whether the products will meet their long-term needs. This concern can hinder purchasing decisions and affect operational efficiency.

The Solution: To ensure quality and durability when sourcing custom leather gun holsters, buyers should prioritize manufacturers with a proven track record and transparent sourcing practices. Conducting thorough research on potential suppliers, including examining customer testimonials and reviews, is essential. Buyers can request samples or prototypes to evaluate the craftsmanship, leather quality, and stitching. Additionally, engaging with manufacturers who provide detailed information about their production processes and material sourcing can help buyers make informed decisions. Establishing long-term relationships with reputable suppliers who offer warranties or guarantees can further mitigate risks associated with quality.

Illustrative image related to custom leather gun holster

Scenario 2: Limited Customization Options Leading to Poor Fit

The Problem: One of the significant pain points for B2B buyers is the challenge of finding custom leather gun holsters that fit specific firearms and user preferences. Many manufacturers offer a one-size-fits-all approach, which often results in poor fit and functionality, impacting both comfort and accessibility. This issue is particularly pronounced for specialized firearms or unique user requirements, leading to dissatisfaction and potential safety risks during usage.

The Solution: To address customization challenges, buyers should communicate their specific needs clearly when engaging with manufacturers. This includes providing detailed specifications of the firearms, preferred carry styles (e.g., inside-the-waistband, outside-the-waistband), and any additional features such as retention systems or accessibility options. Working with manufacturers that specialize in bespoke solutions and have the capability to create prototypes can ensure that the final product meets exact requirements. Additionally, buyers should consider establishing a feedback loop with end-users to gather insights on fit and functionality, allowing for iterative improvements in the customization process.

Scenario 3: Navigating Import Regulations and Compliance Issues

The Problem: For international B2B buyers, particularly from regions like Africa and the Middle East, navigating import regulations and compliance issues related to custom leather gun holsters can be daunting. Different countries have varying laws regarding firearms and holster imports, and failure to comply can result in delays, additional costs, or even legal repercussions. This complexity can discourage buyers from sourcing high-quality products that meet their operational needs.

The Solution: To effectively navigate import regulations, buyers should conduct comprehensive research on the legal requirements for importing custom leather gun holsters in their respective countries. Engaging with legal experts or consultants who specialize in firearms and import laws can provide valuable insights and help avoid pitfalls. Additionally, buyers should work closely with manufacturers who are experienced in international shipping and compliance. Establishing clear communication regarding documentation, labeling, and any necessary certifications can streamline the import process. Furthermore, leveraging local partnerships or distributors familiar with the regional laws can simplify logistics and ensure that products meet all legal standards.

Strategic Material Selection Guide for custom leather gun holster

What Are the Key Materials for Custom Leather Gun Holsters?

When selecting materials for custom leather gun holsters, various options are available, each with distinct properties and implications for performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, where specific standards and preferences may influence purchasing decisions.

Illustrative image related to custom leather gun holster

How Does Full-Grain Leather Perform in Custom Holster Applications?

Full-grain leather is renowned for its durability and natural aesthetics. It retains the hide’s original surface, showcasing unique grain patterns while providing excellent resistance to wear and tear. This material can withstand significant pressure and temperature variations, making it suitable for various climates.

Pros: Full-grain leather offers superior durability, a luxurious appearance, and natural breathability, enhancing comfort during extended wear. It ages beautifully, developing a rich patina over time.

Cons: The cost of full-grain leather is relatively high, which may impact budget-conscious buyers. Additionally, its manufacturing process can be complex, requiring skilled artisans to ensure quality.

Impact on Application: Full-grain leather is ideal for holsters designed for everyday carry, as it provides a secure fit and easy access to firearms. Its moisture resistance is also beneficial in humid environments.

Illustrative image related to custom leather gun holster

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding leather sourcing and treatment. Familiarity with standards like ASTM for leather quality can aid in making informed choices.

What Advantages Does Top-Grain Leather Offer for Gun Holsters?

Top-grain leather is a popular choice for custom holsters due to its balance of quality and cost. This material is sanded and refinished to remove imperfections, resulting in a smoother surface.

Pros: Top-grain leather is generally more affordable than full-grain leather while still offering good durability and a refined appearance. It is easier to work with, allowing for more intricate designs and faster production times.

Cons: While durable, top-grain leather is less robust than full-grain leather and may not age as gracefully. It is also more susceptible to scratches and wear.

Illustrative image related to custom leather gun holster

Impact on Application: This leather type is suitable for holsters that require a polished look, such as those used in formal settings or law enforcement. It provides adequate protection and accessibility for firearms.

Considerations for International Buyers: Buyers should consider the environmental impact of leather processing in their region, as well as adherence to any local leather quality standards.

How Does Synthetic Leather Compare in Custom Holster Production?

Synthetic leather, often made from polyurethane or PVC, has gained popularity due to its affordability and ease of maintenance. It can mimic the appearance of genuine leather while offering unique benefits.

Pros: Synthetic leather is lightweight, water-resistant, and often more affordable than natural leather. It is easier to clean and maintain, making it a practical choice for active users.

Cons: The durability of synthetic leather can be inferior to that of high-quality natural leathers. It may also lack the aesthetic appeal and breathability that many users prefer.

Illustrative image related to custom leather gun holster

Impact on Application: Synthetic leather is suitable for holsters intended for casual use or outdoor activities, where exposure to the elements is a concern. Its lightweight nature can enhance comfort during extended wear.

Considerations for International Buyers: Buyers should verify the quality and safety certifications of synthetic materials, as standards can vary significantly across regions.

What Role Does Suede Play in Custom Leather Holster Design?

Suede, a type of leather made from the underside of animal hides, offers a unique texture and aesthetic. While not as common as full-grain or top-grain leather, it has specific applications in holster design.

Pros: Suede is soft and pliable, providing a comfortable fit against the body. It can also be treated for water resistance, making it suitable for various environments.

Cons: Suede is less durable than other leather types and can be more challenging to clean. It may absorb moisture and dirt, which can affect its longevity.

Impact on Application: Suede is often used in holsters designed for casual or fashion-forward applications, where comfort and style are prioritized over ruggedness.

Considerations for International Buyers: Buyers should be aware of the sourcing and treatment processes for suede, ensuring compliance with local regulations on animal products.

Summary Table of Material Properties

| Material | Typical Use Case for custom leather gun holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Everyday carry holsters | Superior durability and aesthetics | High cost and complex manufacturing | Elevado |

| Top-Grain Leather | Formal or law enforcement holsters | Good balance of quality and cost | Less durable than full-grain | Medium |

| Couro sintético | Casual or outdoor activity holsters | Lightweight and easy to maintain | Inferior durability and aesthetics | Low |

| Camurça | Fashion-forward or casual use holsters | Soft and comfortable | Less durable and harder to clean | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gun holster

What Are the Key Stages in the Manufacturing Process of Custom Leather Gun Holsters?

The manufacturing of custom leather gun holsters involves several critical stages, each contributing to the overall quality and functionality of the final product. Here’s an in-depth look at these stages:

Illustrative image related to custom leather gun holster

Material Preparation: What Materials Are Used and How Are They Prepared?

The foundation of any high-quality leather holster lies in the selection of materials. Typically, full-grain leather is preferred due to its durability, breathability, and natural aesthetic appeal. Before production begins, the leather must undergo careful inspection to ensure it meets quality standards. This includes checking for defects such as scars, blemishes, or inconsistencies in thickness.

Once selected, the leather is cut into specific patterns using precision tools. The choice of cutting technique—whether manual or laser—can significantly impact the accuracy of the parts. Additionally, tanning processes may be applied to enhance the leather’s resistance to wear and environmental factors.

How Are Custom Holsters Formed and Shaped?

The forming process is crucial for achieving the desired fit and functionality. This typically involves molding the leather around a specific firearm to ensure a secure fit. Techniques such as wet molding are commonly used, where the leather is dampened and then shaped around the gun, allowing it to take on the firearm’s unique contours.

This stage may also include stitching and reinforcement. Holsters often require double stitching in critical areas to enhance durability. The type of thread used—often bonded nylon or polyester—also plays a vital role in the strength of the seams.

What Assembly Techniques Are Used in Crafting Holsters?

Once the leather components are formed, they are assembled. This step may involve attaching additional elements such as belt loops, retention straps, or clips. The assembly process must be performed with precision to ensure that all components fit together seamlessly.

Illustrative image related to custom leather gun holster

Quality control checks should be integrated throughout the assembly process to catch any defects early. For instance, verifying that all stitching is consistent and that attachments are secure can prevent costly rework later on.

What Finishing Touches Enhance the Quality of Leather Holsters?

The finishing stage involves several key processes, including dyeing, polishing, and applying protective coatings. Hand dyeing is often preferred for its ability to produce rich colors that enhance the leather’s natural grain.

After dyeing, the edges of the holster are sanded and burnished to prevent fraying and moisture absorption. A final polish is typically applied to achieve a glossy finish, enhancing both aesthetics and durability.

How Is Quality Assurance Implemented in Leather Holster Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that each holster meets both international standards and customer expectations.

What International Standards Are Relevant for Leather Holster Manufacturing?

Many manufacturers adhere to ISO 9001 standards, which focus on maintaining effective quality management systems. This certification is recognized globally and assures B2B buyers of the manufacturer’s commitment to quality.

Illustrative image related to custom leather gun holster

In addition to ISO, industry-specific certifications such as CE marking for safety or API standards for firearms-related products may also apply. These certifications ensure that the products not only meet quality expectations but also comply with regulatory requirements in various markets.

What Are the Key Quality Control Checkpoints?

Quality control in leather holster manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage assesses raw materials upon arrival, ensuring that they meet predefined specifications before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to ensure that each stage meets quality standards. This includes verifying stitching, fit, and other critical attributes.

-

Final Quality Control (FQC): Once production is complete, each holster undergoes a final inspection to confirm that it meets quality and safety standards. This includes functional tests, such as retention and draw speed.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

What Are Effective Methods for Supplier Audits?

-

On-Site Audits: Conducting on-site visits allows buyers to observe the manufacturing processes firsthand. This can help assess the supplier’s adherence to quality standards and their overall operational capabilities.

-

Requesting Quality Reports: Suppliers should provide comprehensive quality assurance reports detailing their processes, inspection results, and any certifications they hold. This transparency builds trust and confidence in their capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These inspections can be especially valuable when dealing with overseas suppliers.

What Are the Nuances of Quality Control for International Buyers?

When sourcing custom leather holsters internationally, buyers should be aware of regional differences in quality standards and regulations. For instance, certain countries may have stricter safety and environmental regulations that could affect production methods.

Illustrative image related to custom leather gun holster

Additionally, communication barriers may lead to misunderstandings regarding quality expectations. Therefore, establishing clear specifications and maintaining open lines of communication throughout the manufacturing process is essential for ensuring product quality.

Conclusion: Ensuring Quality in Custom Leather Gun Holster Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance measures in custom leather gun holsters is vital for making informed purchasing decisions. By focusing on material selection, production techniques, and rigorous quality control, manufacturers can deliver holsters that not only meet but exceed customer expectations. Buyers should leverage audits, reports, and third-party inspections to ensure they partner with reliable suppliers who prioritize quality at every stage of production.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gun holster’

When procuring custom leather gun holsters, a structured approach can significantly enhance your sourcing process. This guide provides a practical checklist to ensure that you select the best suppliers and products that meet your specific requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the custom leather gun holsters you need. This includes the type of holster (IWB, OWB, shoulder, etc.), materials (genuine leather, stitching type), and any specific features (retention systems, custom designs). Defining these details upfront helps to communicate your needs effectively to potential suppliers.

Illustrative image related to custom leather gun holster

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in custom leather gun holsters. Utilize online directories, trade shows, and industry forums to compile a list of potential suppliers. Pay attention to their experience, reputation, and range of products offered, as this will help you narrow down your options.

Step 3: Evaluate Supplier Capabilities and Experience

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record in producing high-quality leather products and those who understand the specific requirements of your market.

Step 4: Request Samples for Quality Assessment

Always request samples to evaluate the craftsmanship and quality of the holsters. Examine the leather quality, stitching, and overall finish to ensure they align with your specifications. Quality samples can also help you gauge the supplier’s attention to detail and commitment to excellence.

Step 5: Verify Compliance with Industry Standards

Ensure that the suppliers comply with relevant industry standards and regulations, especially if you are sourcing from international markets. Check for certifications that confirm the quality and safety of the materials used. This step is vital to avoid legal issues and ensure product reliability.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms. Understand the cost per unit, potential discounts for bulk orders, and shipping costs. Transparent pricing helps you budget effectively and prevents unexpected expenses down the line.

Illustrative image related to custom leather gun holster

Step 7: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier. Establish points of contact for both technical discussions and order tracking. Clear communication is essential for addressing any concerns promptly and ensuring that your orders are fulfilled as expected.

By following this checklist, B2B buyers can navigate the procurement process for custom leather gun holsters more effectively, ensuring that they select the right suppliers and products for their needs.

Comprehensive Cost and Pricing Analysis for custom leather gun holster Sourcing

What Are the Key Cost Components in Custom Leather Gun Holster Production?

When sourcing custom leather gun holsters, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly affects the cost. High-quality, full-grain leather sourced from reputable suppliers typically commands a premium. Additionally, hardware such as buckles and stitching materials can add to the overall expense.

-

Labor: Skilled craftsmanship is essential for producing durable and aesthetically pleasing holsters. Labor costs vary based on the region, expertise of the craftsmen, and the complexity of the design. In regions with a high cost of living, labor can be a substantial part of the cost structure.

-

Manufacturing Overhead: This encompasses utilities, rent, and maintenance costs of manufacturing facilities. Overhead can be minimized in regions with lower operational costs, thus impacting the final pricing of the holsters.

-

Tooling: Custom designs often require specialized tools and molds, which can be a significant upfront investment. Tooling costs are amortized over the production volume, influencing pricing for smaller orders.

-

Quality Control (QC): Implementing stringent QC measures ensures that the final products meet specifications and quality standards. This adds to labor and overhead costs but is essential for maintaining a good reputation and minimizing returns.

-

Logistics: Transporting materials to the manufacturing site and delivering finished products to buyers involves logistics costs. These can vary greatly depending on the distance, mode of transport, and any tariffs or duties applicable to international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Custom Leather Gun Holster Costs?

Several factors can influence the pricing of custom leather gun holsters, particularly in international B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower unit prices due to economies of scale. Suppliers may offer discounts for bulk orders, making it more cost-effective for buyers.

-

Specifications and Customization: Custom features such as embossing, specific cuts, or additional compartments can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Premium materials that comply with safety and environmental standards tend to be more expensive. Certifications can also add to the cost but may be necessary for compliance in certain markets.

-

Supplier Factors: The supplier’s location, reputation, and manufacturing capabilities can all impact pricing. Established suppliers with a track record of quality may charge more but offer better reliability.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) define who bears the shipping costs and risks, impacting the total purchase price.

What Negotiation and Cost-Efficiency Tips Should B2B Buyers Consider?

To maximize value when sourcing custom leather gun holsters, buyers should consider the following strategies:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing, volume discounts, and payment terms. Building a relationship can often lead to better terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as durability, maintenance, and potential replacement. High-quality holsters may have a higher upfront cost but can save money over time.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying standards for quality and pricing. Conduct market research to understand local pricing benchmarks and be prepared for negotiations based on regional dynamics.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times, enhancing overall efficiency.

Disclaimer on Indicative Prices

Prices for custom leather gun holsters can vary widely based on the factors discussed. Buyers are advised to seek detailed quotes from multiple suppliers to gain a comprehensive understanding of the market.

Alternatives Analysis: Comparing custom leather gun holster With Other Solutions

Understanding Alternatives for Custom Leather Gun Holsters

When it comes to selecting a holster for firearms, B2B buyers have various options available, each with unique attributes and suitability for different use cases. This analysis will compare custom leather gun holsters against two viable alternatives: synthetic holsters and kydex holsters. Understanding the strengths and weaknesses of each option is essential for making an informed purchasing decision.

| Comparison Aspect | Custom Leather Gun Holster | Synthetic Holster | Kydex Holster |

|---|---|---|---|

| Performance | High durability and comfort; molds to the body over time | Moderate durability; can wear out faster with heavy use | High retention and quick draw; not as comfortable for extended wear |

| Cost | Generally higher ($130 – $700) due to craftsmanship | Lower cost ($20 – $100) | Mid-range ($40 – $150) |

| Ease of Implementation | Requires customization and longer lead time | Readily available; off-the-shelf options | Easy to acquire; fits many models |

| Maintenance | Requires regular conditioning and care to maintain appearance | Minimal maintenance; easy to clean | Low maintenance; wipe clean |

| Best Use Case | Ideal for collectors or everyday carry with a focus on aesthetics and comfort | Suitable for casual users or budget-conscious buyers | Best for tactical applications and competitive shooting |

Pros and Cons of Alternatives

Synthetic Holsters

Synthetic holsters, often made from materials such as nylon or other polymers, provide a lightweight and cost-effective option for firearm carry. Their primary advantage is affordability; they are generally less expensive than custom leather holsters. Additionally, these holsters are readily available in various styles and sizes, making them an attractive choice for those who need a quick solution. However, they may lack the durability and comfort that leather offers, especially for prolonged use. Over time, synthetic materials can wear out or lose shape, potentially compromising firearm security.

Kydex Holsters

Kydex holsters are crafted from a thermoplastic material known for its rigidity and retention capabilities. This type of holster is ideal for tactical or competitive environments where quick access and secure retention are critical. Kydex holsters typically provide a faster draw compared to leather options, making them popular among law enforcement and military personnel. However, they may not offer the same level of comfort for everyday wear, as the rigid nature of the material can lead to discomfort when seated or during extended periods of use. Additionally, while Kydex holsters are often designed to fit specific firearm models, they may not provide the aesthetic appeal that custom leather holsters offer.

Choosing the Right Solution for Your Needs

When selecting the ideal holster for your business needs, consider the specific application and user requirements. Custom leather gun holsters excel in providing comfort, aesthetics, and durability, making them suitable for collectors and everyday carry enthusiasts. On the other hand, synthetic and Kydex options may be more appropriate for budget-conscious consumers or tactical applications requiring rapid access. Ultimately, assessing factors such as performance, cost, ease of implementation, and maintenance will guide B2B buyers in making a decision that aligns with their operational needs and budget constraints.

Illustrative image related to custom leather gun holster

Essential Technical Properties and Trade Terminology for custom leather gun holster

What Are the Key Technical Properties of Custom Leather Gun Holsters?

When sourcing custom leather gun holsters, understanding the technical specifications is crucial for ensuring quality and suitability for your needs. Here are several critical specifications to consider:

-

Material Grade

The quality of leather used in holster manufacturing is paramount. Full-grain leather is often preferred due to its durability and natural appearance. This grade of leather retains the original texture and strength, providing long-lasting use. For B2B buyers, selecting high-grade materials ensures that the holsters can withstand wear and tear, making them a worthy investment. -

Stitching Quality

The stitching should be robust, typically using bonded nylon thread, which resists fraying and breaking. Double-stitching in critical areas enhances durability, ensuring that the holster maintains its shape and integrity over time. For businesses, this translates to fewer returns and higher customer satisfaction, as clients appreciate well-constructed products. -

Retention Level

This specification refers to how securely the firearm is held within the holster. A well-designed holster should balance retention with ease of draw. High retention levels prevent accidental discharges while still allowing for quick access. For B2B buyers, understanding retention levels helps in selecting holsters that meet specific usage scenarios, such as law enforcement or civilian concealed carry. -

Holster Design (IWB vs. OWB)

The design type—Inside the Waistband (IWB) or Outside the Waistband (OWB)—affects comfort, concealment, and accessibility. IWB holsters are generally more discreet, while OWB holsters provide quicker access. For businesses, aligning the design with the target market’s preferences is essential for maximizing sales potential. -

Finish and Treatment

The surface finish can impact both aesthetics and functionality. Treatments such as waterproofing or chemical resistance can extend the life of the holster and make it suitable for various environments. For B2B buyers, considering the finish is vital for ensuring the product meets specific use cases, especially in diverse climates or operational conditions.

Which Trade Terms Should B2B Buyers Understand When Purchasing Custom Leather Gun Holsters?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some essential trade terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. For buyers, partnering with an OEM can ensure high-quality products that meet specific design and performance standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, as it can affect pricing and the feasibility of a purchase. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process helps buyers compare costs and negotiate better terms, ensuring they receive competitive pricing. -

Incoterms (International Commercial Terms)

These are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for managing shipping costs and responsibilities. -

Lead Time

This refers to the time taken from placing an order to receiving the product. Knowing lead times helps businesses plan their inventory and sales strategies effectively, ensuring they meet customer demands without delays. -

Customization Options

This term encompasses the various ways a holster can be tailored to meet specific buyer requirements, such as size, color, or additional features. Understanding customization options allows businesses to cater to their customers’ needs more effectively, enhancing satisfaction and loyalty.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing custom leather gun holsters, ultimately contributing to successful procurement strategies and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the custom leather gun holster Sector

What Are the Key Market Dynamics and Trends Influencing Custom Leather Gun Holsters?

The global custom leather gun holster market is experiencing significant growth driven by several key factors. The increasing awareness of personal safety and self-defense, particularly in regions such as Africa and South America, has led to a surge in firearm ownership. This, in turn, has amplified the demand for high-quality, durable holsters that offer both functionality and style. Additionally, technological advancements in manufacturing processes are allowing for more customizable options, catering to specific needs and preferences of consumers.

Emerging B2B trends include the rise of e-commerce platforms, enabling international buyers to source products directly from manufacturers. This trend is particularly relevant in markets like Nigeria and Vietnam, where online purchasing is becoming increasingly popular. Furthermore, the integration of augmented reality (AR) in the shopping experience is allowing buyers to visualize how holsters will fit their firearms, enhancing customer satisfaction and reducing return rates.

Importantly, international buyers are also becoming more conscious of product quality and craftsmanship. The demand for premium materials, such as American leather, is on the rise as buyers seek products that not only meet functional requirements but also reflect a commitment to quality and style.

Illustrative image related to custom leather gun holster

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Gun Holster Market?

The growing emphasis on sustainability is reshaping the custom leather gun holster sector. Buyers are increasingly aware of the environmental impact associated with leather production, pushing manufacturers to adopt more sustainable practices. Ethical sourcing of materials is becoming a crucial consideration, with many companies now prioritizing the use of leather derived from environmentally responsible tanneries that follow strict regulations.

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining importance as B2B buyers seek assurance that their products are sourced responsibly. Manufacturers that can demonstrate compliance with these standards will likely gain a competitive edge in the market.

Moreover, the use of eco-friendly dyes and tanning processes is becoming more prevalent, appealing to a market that values sustainability without compromising on quality or aesthetics. Buyers are encouraged to inquire about the sourcing and production processes when selecting suppliers, ensuring they align with their own ethical standards.

What Is the Evolution of Custom Leather Gun Holsters and Its Relevance to Today’s Market?

The history of custom leather gun holsters dates back to the early days of firearms when practicality and accessibility were paramount. Initially crafted for utility, these holsters have evolved into a blend of functionality and artistry. As firearm technology advanced, so did the designs of holsters, transitioning from simple leather pouches to intricate, custom-made solutions that cater to specific firearm models and user preferences.

Illustrative image related to custom leather gun holster

Today, this evolution is significant for B2B buyers as it highlights the importance of selecting suppliers who not only understand the technical aspects of holster design but also the cultural and aesthetic preferences of diverse markets. This historical perspective informs current trends, emphasizing the need for innovation while respecting traditional craftsmanship. As buyers navigate the market, understanding this evolution can help them identify suppliers that blend modern technology with time-honored techniques, ensuring they acquire products that are both functional and culturally relevant.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gun holster

-

How do I ensure the quality of custom leather gun holsters from suppliers?

To ensure the quality of custom leather gun holsters, start by requesting samples from potential suppliers. Evaluate their craftsmanship, materials, and design features. Look for suppliers with a proven track record in the leather industry, ideally those with decades of experience. Additionally, consider visiting their production facilities, if feasible, to assess their manufacturing processes and quality control measures. Customer testimonials and reviews can also provide insight into the reliability and quality of the products. -

What is the best type of leather for custom gun holsters?

The best type of leather for custom gun holsters is typically full-grain leather, known for its durability and ability to age beautifully. It offers excellent resistance to wear and tear while maintaining a luxurious appearance. For added comfort and flexibility, some manufacturers may use premium cowhide or saddle leather. When sourcing, inquire about the specific leather grades and treatments used, as this can significantly impact the holster’s longevity and performance. -

How can I customize leather gun holsters for my brand?

Customization options for leather gun holsters can include size, color, stitching patterns, and branding elements like embossed logos. When discussing with suppliers, provide detailed specifications and examples of designs you envision. Many manufacturers offer design consultations to help you align your branding with functional aspects. It’s also essential to discuss the minimum order quantities for customized items, as these can vary significantly between suppliers. -

What are the minimum order quantities (MOQ) for custom leather gun holsters?

Minimum order quantities for custom leather gun holsters can vary widely depending on the supplier and the level of customization required. Typically, MOQs can range from as low as 50 units to several hundred. When negotiating, clarify whether MOQs apply to specific designs or color variations. Some suppliers may offer flexibility for first-time buyers or larger businesses looking to establish long-term partnerships. -

What payment terms should I expect when ordering from international suppliers?

Payment terms for international orders can vary based on the supplier’s policies and your negotiation. Common arrangements include deposits (usually 30-50%) upfront with the balance due upon completion or prior to shipping. Some suppliers may offer payment via letters of credit, especially for larger orders. Always ensure to clarify these terms before finalizing the contract to avoid any misunderstandings during the transaction. -

How can I vet suppliers for custom leather gun holsters?

Vetting suppliers involves several steps: research their business history, request references, and read customer reviews. Consider their certifications, such as ISO standards, which can indicate quality assurance practices. Ask for samples to evaluate the craftsmanship and materials firsthand. Additionally, engage in direct communication to assess their responsiveness and willingness to accommodate your requirements, which can be indicative of a reliable partnership. -

What logistics considerations should I be aware of when importing holsters?

When importing custom leather gun holsters, consider shipping methods, customs regulations, and potential tariffs. Ensure that your supplier provides clear shipping timelines and handles the necessary documentation for customs clearance. It’s advisable to work with a logistics partner experienced in international trade to navigate these complexities effectively. Additionally, factor in lead times for production and shipping to ensure timely delivery to your market. -

What quality assurance processes should I expect from a reputable supplier?

A reputable supplier of custom leather gun holsters should have established quality assurance processes, including regular inspections throughout the production cycle. Inquire about their testing methods for material durability and craftsmanship. Look for suppliers who provide guarantees or warranties on their products, indicating their confidence in quality. Additionally, consider discussing potential returns or exchanges for defective items to ensure you’re protected in case of quality issues.

Top 2 Custom Leather Gun Holster Manufacturers & Suppliers List

1. Mernickle Holsters – Custom Leather Holsters for Everyday Carry

Domain: mernickleholsters.com

Registered: 1999 (26 years)

Introduction: Custom Handmade in the USA Leather Holsters for Everyday Carry, including: Outside the Waist Band, Inside the Waist Band, Cross Draw, Law Enforcement/Duty Holsters, New Shoulder/Chest Holsters, Field Hunting Holsters, Cowboy Holsters (Cowboy/Western Holsters, Cowboy Fast Draw Holsters), Classic Hollywood/Movie Inspired Holsters, Wild Bunch Holsters, The Walking Dead Inspired Holsters. Additional o…

2. Falco – Leather Gun Holsters

Domain: falcoholsters.com

Registered: 2009 (16 years)

Introduction: Leather Gun Holsters (183 products) | Falco includes various types of holsters such as IWB (Inside the Waistband), OWB (Outside the Waistband), Shoulder Holsters, Thigh Holsters, Chest Holsters, Ankle Holsters, Magazine & Speedloader Pouches, Gun Belts, and more. The materials used include Leather (183), Kydex (35), Nylon (174), Hybrid (24), and Carbon (10). Key features include different carry st…

Strategic Sourcing Conclusion and Outlook for custom leather gun holster

In the competitive landscape of custom leather gun holsters, strategic sourcing emerges as a critical factor for B2B buyers seeking quality, reliability, and aesthetics. Understanding the nuances of craftsmanship, materials, and design is essential for making informed purchasing decisions. As international buyers from Africa, South America, the Middle East, and Europe navigate this market, they should prioritize suppliers with a proven track record in quality craftsmanship, such as those that leverage American leather and time-honored techniques.

The value of strategic sourcing extends beyond cost savings; it encompasses the alignment of supplier capabilities with the specific needs of diverse markets. Buyers must consider not only the functional attributes of holsters—such as security and comfort—but also the supplier’s commitment to sustainability and ethical practices.

Looking ahead, the demand for custom leather gun holsters is poised to grow, driven by increasing awareness of firearm safety and personal protection. Now is the time for B2B buyers to engage with reputable manufacturers and explore partnerships that emphasize quality and craftsmanship. By doing so, they can ensure a competitive advantage in their respective markets while meeting the evolving needs of their customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather gun holster

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.