Introduction: Navigating the Global Market for how to make a hole in a leather belt

In the world of leather goods, understanding how to make a hole in a leather belt is essential for both functionality and aesthetics. Whether you’re a manufacturer looking to enhance your product range or a retailer aiming to offer customization options to customers, knowing the various methods to create belt holes can be a game-changer. This comprehensive guide delves into multiple techniques, from traditional leather punches to innovative DIY solutions, ensuring you can cater to diverse customer needs without compromising quality.

Navigating the global market requires a keen awareness of local preferences and the tools available in different regions. For B2B buyers in Africa, South America, the Middle East, and Europe, including Brazil and Vietnam, this guide addresses critical aspects such as supplier vetting, cost analysis, and the application of different methods based on regional materials and practices. By leveraging this information, you can make informed purchasing decisions that align with your business strategy and customer demands.

Ultimately, this guide empowers you to enhance your product offerings and streamline your operations. Whether you are seeking efficient production methods or aiming to provide exceptional customer service through bespoke solutions, understanding how to effectively make a hole in a leather belt is an invaluable skill that can lead to increased customer satisfaction and business growth.

Table Of Contents

- Top 5 How To Make A Hole In A Leather Belt Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a hole in a leather belt

- Understanding how to make a hole in a leather belt Types and Variations

- Key Industrial Applications of how to make a hole in a leather belt

- 3 Common User Pain Points for ‘how to make a hole in a leather belt’ & Their Solutions

- Strategic Material Selection Guide for how to make a hole in a leather belt

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a hole in a leather belt

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a hole in a leather belt’

- Comprehensive Cost and Pricing Analysis for how to make a hole in a leather belt Sourcing

- Alternatives Analysis: Comparing how to make a hole in a leather belt With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a hole in a leather belt

- Navigating Market Dynamics and Sourcing Trends in the how to make a hole in a leather belt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a hole in a leather belt

- Strategic Sourcing Conclusion and Outlook for how to make a hole in a leather belt

- Important Disclaimer & Terms of Use

Understanding how to make a hole in a leather belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Hole Punch | Uses a specialized tool to create precise holes. | Retailers, leather goods manufacturers, repair shops | Pros: Consistent quality; easy to use. Cons: Requires investment in tools. |

| Power Drill Method | Utilizes a power drill with a specific bit for quick holes. | Workshops, DIY stores, manufacturing facilities | Pros: Fast; effective for bulk applications. Cons: Risk of uneven holes; needs careful handling. |

| Heated Nail Technique | Employs a heated nail for a quick, makeshift hole. | Small businesses, emergency repairs | Pros: Low-cost; minimal tools needed. Cons: Less precision; potential for damage if not careful. |

| Scissors or Sharp Object Method | Uses sharp objects to create holes through rotation. | DIY enthusiasts, craft businesses | Pros: Commonly available tools; versatile. Cons: Inconsistent hole size; requires skill. |

| Professional Services | Engaging a professional to punch holes in belts. | Retailers, boutiques, and specialty shops | Pros: High-quality results; saves time. Cons: Costs may vary; reliant on external services. |

What are the Characteristics of Using a Leather Hole Punch?

The leather hole punch is a tool specifically designed for creating clean, uniform holes in leather. It is favored by retailers and manufacturers for its precision, ensuring that the holes are evenly spaced and sized for optimal functionality. B2B buyers should consider the initial investment in this tool, which can enhance production quality and efficiency in leather goods manufacturing.

How Does the Power Drill Method Work for Making Holes?

Using a power drill is a practical approach for businesses that require speed in producing leather goods. This method involves using a drill bit tailored for leather, allowing for quick hole creation. While it is efficient for bulk operations, B2B buyers must be cautious about the potential for uneven holes and the need for skilled personnel to operate the equipment safely.

Why Choose the Heated Nail Technique for Quick Repairs?

The heated nail technique is an innovative, low-cost method for creating holes in leather belts. This approach is particularly useful for small businesses or emergency repairs, where tools may be limited. While it offers the advantage of requiring minimal investment, B2B buyers should be aware that this method may result in less precision and could damage the leather if not executed carefully.

What are the Advantages of Using Scissors or Sharp Objects?

Employing scissors or other sharp objects for hole-making is a versatile option for DIY enthusiasts and craft businesses. This method can be executed with tools readily available in most settings. However, it demands a certain level of skill to achieve consistent results, which can be a consideration for B2B buyers focused on quality control in leather products.

How Can Professional Services Benefit Leather Goods Businesses?

Engaging professional services to punch holes in leather belts offers businesses high-quality results without the need for investing in tools. This option is particularly appealing for retailers and boutiques that prioritize craftsmanship. However, B2B buyers should evaluate the cost implications and the reliability of the service providers to ensure that their needs are met efficiently.

Key Industrial Applications of how to make a hole in a leather belt

| Industry/Sector | Specific Application of how to make a hole in a leather belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Customizing leather belts for customers | Enhances customer satisfaction and personalization | Quality of leather, availability of tools, and skilled labor |

| Leather Goods Manufacturing | Production of belts and leather accessories | Streamlined manufacturing process and cost savings | Sourcing durable leather, efficient hole-punching tools, and machinery |

| Automotive | Adjusting leather seat belts for comfort and safety | Improved customer safety and product adaptability | Compliance with safety standards, material specifications, and durability |

| E-commerce | Offering DIY leather belt customization kits | Increased product range and customer engagement | Quality of instructional materials, sourcing tools, and leather quality |

| Craft and Hobby Supplies | Supplying tools and materials for DIY leather crafting enthusiasts | Expands market reach and customer loyalty | Variety of tools, quality of leather, and educational resources |

How is ‘how to make a hole in a leather belt’ utilized in the fashion retail sector?

In the fashion retail sector, customizing leather belts is a common practice to meet customer preferences. Retailers can offer personalization options, such as adding holes to adjust the fit of the belt. This not only enhances customer satisfaction but also drives sales by providing a unique shopping experience. Buyers in this sector should consider sourcing high-quality leather and reliable tools, ensuring that staff are trained in proper hole-making techniques to maintain product integrity.

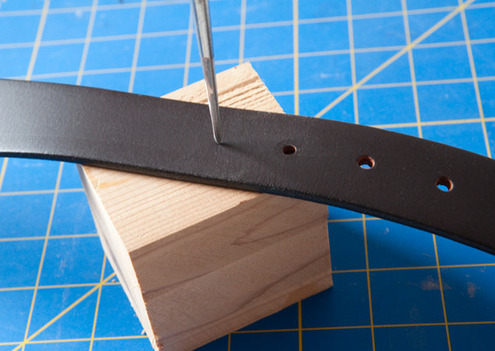

Illustrative image related to how to make a hole in a leather belt

What role does ‘how to make a hole in a leather belt’ play in leather goods manufacturing?

In leather goods manufacturing, the ability to efficiently create holes in belts and accessories is crucial for production. Manufacturers can optimize their workflow by using specialized tools, such as hydraulic or manual hole punches, which ensure consistent and precise hole sizes. This improves production efficiency and reduces material waste. Buyers must focus on sourcing durable leather and reliable machinery, while also considering the training of personnel in proper usage to maintain quality standards.

How is ‘how to make a hole in a leather belt’ important for the automotive industry?

In the automotive industry, customizing leather seat belts for enhanced comfort and safety is essential. Adjusting these belts often requires creating additional holes to fit various body sizes. This practice not only improves the driving experience but also adheres to safety regulations. Buyers in this sector should prioritize sourcing materials that meet industry safety standards and ensure that any adjustments are performed by skilled technicians to guarantee product reliability.

How does ‘how to make a hole in a leather belt’ enhance e-commerce offerings?

E-commerce platforms can capitalize on the DIY trend by offering leather belt customization kits that include tools and materials for customers to make their own holes. This approach increases product variety and customer engagement, appealing to those interested in crafting. To be successful, e-commerce businesses should focus on providing high-quality instructional materials and sourcing durable leather and tools that enable customers to achieve professional results.

Why is ‘how to make a hole in a leather belt’ significant in craft and hobby supplies?

In the craft and hobby supplies sector, providing tools and materials for DIY leather crafting enthusiasts is a growing market. Offering products that enable customers to create their own leather belts fosters creativity and enhances customer loyalty. Suppliers should ensure they offer a diverse range of tools and high-quality leather, as well as educational resources that help customers learn proper techniques. This not only boosts sales but also builds a community around crafting.

3 Common User Pain Points for ‘how to make a hole in a leather belt’ & Their Solutions

Scenario 1: Difficulty in Achieving Clean Cuts for New Belt Holes

The Problem: B2B buyers in the leather goods industry often face the challenge of creating precise holes in leather belts without compromising the material’s integrity. When working with high-quality leather, a poorly made hole can lead to fraying, tearing, or an unprofessional appearance, which is detrimental in a competitive market. Furthermore, many buyers may not have access to specialized tools such as leather punches, making it even harder to achieve clean cuts.

The Solution: To ensure clean cuts without investing in expensive tools, B2B buyers can utilize a power drill with a sharp drill bit specifically designed for leather. Before starting, it’s essential to secure the belt on a stable surface and place a piece of scrap wood underneath. This provides support and helps maintain the shape of the leather while drilling. Buyers should select a drill bit that matches the desired hole size and drill at a moderate speed to avoid damaging the leather. Additionally, using a Forstner bit can provide a cleaner finish. This approach not only ensures a professional look but also enables buyers to efficiently produce belts that meet their quality standards.

Scenario 2: Limited Access to Specialized Tools for Hole Creation

The Problem: In regions with limited access to specialized leatherworking tools, such as leather punches or hole chisels, B2B buyers may find it challenging to create additional holes in belts. This situation is particularly common in emerging markets where resources are scarce, leading to frustration and delays in production.

Illustrative image related to how to make a hole in a leather belt

The Solution: B2B buyers can adapt by employing alternative methods that utilize common household tools. For instance, a heated nail can serve as an effective substitute for a leather punch. By heating the nail with pliers until it is hot enough to pierce the leather, buyers can create clean holes without needing specialized equipment. It’s crucial to ensure that the belt is held firmly during this process to maintain control and prevent accidents. Additionally, leveraging local craftsmen or workshops that offer leatherworking services can provide a sustainable solution for those lacking the necessary tools. This approach not only solves the immediate problem but also fosters community connections and supports local economies.

Scenario 3: Need for Versatile Solutions Across Different Leather Types

The Problem: B2B buyers often work with various types of leather, each requiring different techniques for hole creation. For example, softer leathers may puncture easily, while thicker, more rigid leathers can resist simple piercing methods. This variability can lead to inconsistency in product quality and customer dissatisfaction if not addressed properly.

The Solution: To accommodate different leather types, B2B buyers should first assess the specific characteristics of the leather they are working with. For thinner leathers, a simple sharp object like a screwdriver or the point of scissors can suffice for making holes. However, for thicker materials, employing a rotary tool with a specialized leather bit or a manual leather punch can yield better results. Additionally, buyers can consider investing in a multi-tool that includes various attachments for different leather thicknesses. This versatility ensures that they can adapt their methods according to the material at hand, maintaining product quality and satisfying customer expectations. Regular training on proper techniques for different leather types can also help staff become more proficient in making adjustments on the fly, further enhancing operational efficiency.

Illustrative image related to how to make a hole in a leather belt

Strategic Material Selection Guide for how to make a hole in a leather belt

When selecting materials for making a hole in a leather belt, it is essential to consider the tools and techniques that will yield the best results while meeting the demands of international B2B buyers. Below, we analyze several common materials used in the process, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse markets.

What Are the Key Properties of Steel for Making Holes in Leather Belts?

Steel, particularly high-carbon steel, is often used for tools like hole punches and awls. This material boasts excellent hardness and durability, making it ideal for penetrating tough leather. Steel can withstand high temperatures and pressures, ensuring that it maintains its shape even under repeated use.

Pros and Cons: The primary advantage of steel tools is their longevity and effectiveness in creating clean holes. However, they can be prone to rust if not properly maintained, which can be a significant drawback in humid environments. Additionally, the manufacturing complexity can lead to higher costs compared to simpler materials.

Impact on Application: Steel tools are compatible with various leather types, including full-grain and top-grain leather, making them versatile for different applications. However, they may not be suitable for softer leathers, as they can cause tearing.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local regulations regarding tool safety and quality standards. Familiarity with ASTM standards can also guide purchasing decisions.

How Does Plastic Compare as a Material for Leather Hole Making?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is used in some less conventional hole-making tools. While not as durable as steel, plastic is lightweight and resistant to corrosion, making it a viable option for specific applications.

Pros and Cons: The significant advantage of plastic tools is their affordability and ease of use. However, they may not provide the same level of precision or durability as steel. Over time, plastic can wear down more quickly, leading to less effective hole-making.

Illustrative image related to how to make a hole in a leather belt

Impact on Application: Plastic tools are best suited for softer leathers or synthetic materials, where precision is less critical. They are less effective on tougher leathers, which require more robust tools.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of compliance with environmental regulations regarding plastics. Understanding the implications of using plastic tools in various markets can influence purchasing decisions.

What Role Does Aluminum Play in Leather Hole Punching?

Aluminum is another material used for making lightweight hole-making tools. It offers a good balance between weight and strength, making it easier to handle than steel while still being durable enough for occasional use.

Pros and Cons: The primary advantage of aluminum tools is their lightweight nature, making them easy to transport and use. However, they may not be as durable as steel, especially under heavy use. Aluminum can also be prone to bending, which may affect the precision of the hole.

Impact on Application: Aluminum tools are suitable for various leather types but may struggle with thicker materials. They are ideal for lighter applications where portability is a priority.

Considerations for International Buyers: Buyers should consider the cost-effectiveness of aluminum tools in comparison to steel. Additionally, understanding local preferences for tool materials can help in making informed decisions.

How Effective Are Wood Tools for Making Holes in Leather?

Wood, particularly hardwoods, can also be utilized in DIY leather hole-making applications. While not as common as metal tools, wooden dowels or punches can provide a unique approach.

Pros and Cons: The advantage of wood tools is their availability and ease of customization. However, they lack the durability of metal tools and may not provide clean holes, especially in tougher leather.

Impact on Application: Wooden tools are best suited for light-duty applications or crafting projects where precision is less critical. They may not be suitable for commercial-grade leatherwork.

Considerations for International Buyers: Buyers should consider the sustainability of wood sources and compliance with local forestry regulations. Understanding the market demand for eco-friendly tools can influence purchasing decisions.

Summary Table of Material Selection for Leather Hole Making

| Material | Typical Use Case for how to make a hole in a leather belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Professional-grade hole punches and awls | Excellent durability and precision | Prone to rust; higher manufacturing complexity | Elevado |

| Plastic | Lightweight, less frequent use tools | Affordable and easy to use | Less durable; not suitable for tough leather | Low |

| Aluminum | Lightweight tools for occasional use | Easy to handle and transport | Less durable; can bend under pressure | Medium |

| Wood | DIY applications and crafting | Easy to customize and source | Lacks durability; may not provide clean holes | Low |

This strategic material selection guide provides insights into the various materials available for making holes in leather belts, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a hole in a leather belt

What Are the Key Stages in the Manufacturing Process of Leather Belts?

The manufacturing process for leather belts involves several critical stages, each essential to ensuring the final product meets quality standards.

1. Material Preparation

The first step in manufacturing leather belts is the selection and preparation of materials. High-quality leather is sourced from reputable tanneries, ensuring it meets specific standards for durability, texture, and aesthetics. Once the leather is selected, it undergoes a conditioning process to enhance its pliability and prevent cracking. This may include treatments with oils or waxes that also add to the leather’s waterproofing and overall longevity.

Illustrative image related to how to make a hole in a leather belt

2. Cutting and Forming

After preparation, the leather is cut into strips of the desired width and length. This cutting process typically uses precision dies to ensure uniformity, which is crucial for maintaining consistency across production. The strips are then shaped into the belt form, where the buckle and holes will be integrated. This shaping can involve techniques such as edge finishing, where the edges are smoothed and rounded to enhance comfort and aesthetics.

3. Punching Holes

Creating holes in the leather belt is a vital step. This is often achieved using hydraulic or manual leather punches that ensure clean, precise holes without damaging the material. The placement of these holes is critical for functionality and style, requiring careful planning and measuring.

4. Assembly

Once the belt is cut and holes are punched, the next step is assembly. This involves attaching the buckle, which can be done through stitching or riveting, depending on the design specifications. Quality stitching is crucial for durability, with techniques such as double stitching often employed for added strength.

5. Finishing

The final stage of manufacturing is finishing, where the belts are treated with additional coatings to enhance their appearance and durability. This may involve applying dyes, protective finishes, or polishes. Quality control checks are performed to ensure that each belt meets the aesthetic and functional standards expected by B2B buyers.

How Is Quality Assurance Implemented in Leather Belt Manufacturing?

Quality assurance (QA) is a critical aspect of the leather belt manufacturing process, ensuring that each product meets international standards and customer expectations.

What Are the Relevant International Standards for Leather Products?

Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This standard helps ensure that processes are efficient and products are consistently of high quality. Additionally, specific industry standards like CE marking for safety and compliance with environmental regulations may also apply, particularly in the European market.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Leather quality is assessed for texture, thickness, and any defects.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure processes are being followed correctly. This includes checking the precision of hole punching and stitching quality.

-

Final Quality Control (FQC): Once the belts are finished, a thorough inspection is conducted. This includes checking for defects in stitching, hole placement, and overall aesthetics.

What Testing Methods Are Commonly Used?

Common testing methods in leather belt manufacturing include tensile strength tests, which assess the durability of the leather, and colorfastness tests to ensure dyes do not bleed. Some manufacturers may also conduct wear tests to evaluate how the belt performs over time under typical usage conditions.

Illustrative image related to how to make a hole in a leather belt

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to ensure they receive high-quality products.

What Steps Can Buyers Take to Verify Supplier QC?

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s quality management systems and production processes. This allows buyers to assess compliance with international standards directly.

-

Quality Reports: Requesting detailed quality control reports can help buyers understand the procedures and metrics suppliers use to maintain quality. These reports should detail the outcomes of IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of products before shipment. These independent inspections help mitigate risks associated with product defects and ensure adherence to agreed specifications.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial. Different regions may have varying standards and expectations, which can impact product suitability. Buyers should familiarize themselves with local regulations regarding leather goods, including any specific certifications required in their markets.

Additionally, language barriers and cultural differences can affect communication regarding quality standards. Establishing clear expectations through detailed contracts and specifications can help mitigate misunderstandings.

By focusing on robust manufacturing processes and stringent quality assurance practices, suppliers can ensure that their leather belts not only meet but exceed the expectations of B2B buyers across diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a hole in a leather belt’

Introdução

This guide provides a practical checklist for B2B buyers interested in procuring tools and methods for making holes in leather belts. Understanding the various techniques and tools available can enhance your product offerings and ensure customer satisfaction. This checklist will help you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before sourcing tools or services for making holes in leather belts, outline your specific requirements. Consider factors such as the type of leather (thickness and finish), the desired size of the hole, and the volume of production.

- Example Specifications:

- Hole diameter (e.g., 1/4 inch, 3/8 inch).

- Leather thickness (e.g., 1mm, 2mm).

- This clarity will guide your supplier selection and ensure compatibility with your production processes.

Step 2: Research Available Tools and Techniques

Explore the various tools and methods used to create holes in leather. Common options include leather punches, drills, heated nails, and awls.

- Key Considerations:

- Durability and precision of tools.

- Suitability for different types of leather.

- Knowing the pros and cons of each method will help you select the right tools for your needs.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request company profiles, case studies, and references from buyers in similar industries or regions.

- What to Look For:

- Supplier experience in leather goods manufacturing.

- Customer reviews and testimonials.

- This evaluation will help ensure that you choose a reliable supplier who understands your specific needs.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold necessary certifications for quality and safety standards. This is particularly important in regions with stringent regulations regarding materials and manufacturing processes.

- Certifications to Check:

- ISO 9001 for quality management.

- Environmental certifications (e.g., REACH, RoHS).

- Verified certifications can enhance trust and reduce the risk of compliance issues.

Step 5: Request Samples for Testing

Before finalizing your supplier, request samples of the tools or services they offer. Testing these samples will allow you to assess their effectiveness in creating holes in leather.

- Testing Criteria:

- Ease of use and efficiency.

- Quality of the hole produced (clean edges, proper sizing).

- This hands-on evaluation can prevent future production issues and ensure that the tools meet your standards.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in discussions about pricing, delivery times, and payment terms.

- Important Negotiation Points:

- Bulk order discounts and payment flexibility.

- Warranty or return policies for defective products.

- A clear agreement on these terms will help prevent misunderstandings and foster a positive supplier relationship.

Step 7: Plan for Ongoing Support and Maintenance

After procurement, ensure that you have a plan for ongoing support and maintenance of the tools. This is crucial for maintaining productivity and quality in your operations.

- Support Considerations:

- Availability of replacement parts or service.

- Supplier responsiveness to inquiries or issues.

- Establishing a solid support plan will enhance operational efficiency and customer satisfaction.

By following these steps, B2B buyers can successfully navigate the sourcing process for tools and methods related to making holes in leather belts, ensuring they meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for how to make a hole in a leather belt Sourcing

What Are the Key Cost Components in Making a Hole in a Leather Belt?

When sourcing solutions for adding holes to leather belts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of leather, which can vary significantly based on quality, type (genuine leather vs. synthetic), and sourcing location. High-quality leather from renowned suppliers can command a premium price, impacting the overall budget.

-

Labor: Skilled labor is often necessary for precision work. Labor costs may vary based on the region, with labor-intensive countries potentially offering lower rates. However, the expertise level required to maintain quality can influence this cost.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and salaries for non-direct labor. In regions where manufacturing is prevalent, overhead may be lower due to economies of scale.

-

Tooling: Investing in specialized tools like leather punches or drills can add to initial costs. However, these tools can enhance efficiency and reduce labor costs in the long run.

-

Quality Control (QC): Ensuring that the finished product meets specifications incurs additional costs. This includes testing for durability and aesthetics, especially for high-quality leather belts.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier, the mode of transport, and the Incoterms agreed upon. International shipping can introduce complexities that affect pricing.

-

Margin: Suppliers will typically mark up prices to ensure profitability. This margin can vary based on market competition, brand reputation, and demand for leather products.

How Do Price Influencers Impact the Cost of Making a Hole in a Leather Belt?

Several factors can influence the pricing structure for adding holes to leather belts:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to achieve more favorable pricing.

-

Specifications and Customization: Custom designs or specific hole sizes may increase costs. Providing detailed specifications can help suppliers offer accurate quotes without unexpected charges.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly, sustainable sourcing) can increase costs but may be essential for market positioning, especially in regions with stringent regulations.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can significantly affect pricing. Established suppliers may charge higher rates due to their reliability and quality assurance.

-

Incoterms: The agreed terms of shipping and delivery can impact overall costs. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for calculating total landed costs.

What Negotiation Tips Can Help B2B Buyers Achieve Cost Efficiency?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies are essential:

-

Research and Benchmarking: Before negotiations, conduct thorough market research to understand standard pricing for similar products. This information can serve as leverage during discussions.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with sourcing, including maintenance, potential repairs, and quality-related issues. Emphasizing TCO in negotiations can lead to better pricing agreements.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to preferential pricing and terms. Regular communication fosters trust and opens doors for better deals.

-

Flexibility in Orders: Be willing to adjust order sizes or specifications to meet suppliers’ needs, which can result in lower prices.

-

Understanding Local Market Dynamics: Awareness of local economic conditions, currency fluctuations, and trade tariffs can inform negotiation tactics and help avoid unexpected costs.

Conclusion

In conclusion, comprehending the cost structure and pricing influencers involved in making a hole in a leather belt is vital for B2B buyers. By strategically negotiating and considering total costs, buyers can secure favorable deals while ensuring high-quality products. It’s essential to remain informed and adaptable to navigate the complexities of international sourcing effectively.

Illustrative image related to how to make a hole in a leather belt

Alternatives Analysis: Comparing how to make a hole in a leather belt With Other Solutions

Exploring Alternatives to Making a Hole in a Leather Belt

In the world of leather craftsmanship, creating a hole in a leather belt is often necessary for adjustments. However, there are multiple methods and tools available that can accomplish this task, each with its own advantages and drawbacks. Understanding these alternatives can help businesses make informed decisions based on their specific needs.

| Comparison Aspect | How To Make A Hole In A Leather Belt | Alternative 1: Power Drill Method | Alternative 2: Heated Nail Technique |

|---|---|---|---|

| Performance | High precision with a dedicated tool | Quick, but may lack precision | Effective for small holes |

| Cost | Moderate (cost of a leather punch) | Low (if drill is already owned) | Very low (utilizes common items) |

| Ease of Implementation | Requires training for optimal use | Requires some skill | Simple, but safety precautions needed |

| Maintenance | Minimal (occasional sharpening) | Regular maintenance of drill bits | None (disposable tools) |

| Best Use Case | Professional leatherwork | Fast adjustments | Quick fixes in a pinch |

What Are the Benefits and Drawbacks of Using a Power Drill to Make a Hole in a Leather Belt?

Using a power drill to make a hole in a leather belt is a method that leverages existing tools in a workshop. This approach can yield a clean hole if executed properly. However, it does require a degree of skill to ensure the belt remains stationary and that the drill bit is appropriate for the leather. The main advantage is speed; a power drill can create holes quickly, which is beneficial for high-volume production. On the downside, it may lack the precision of a dedicated leather hole punch, which can result in uneven holes if not handled carefully.

How Does the Heated Nail Technique Compare for Creating Holes in Leather Belts?

The heated nail technique involves heating a nail until it can easily penetrate the leather. This method is particularly effective for creating small holes and can be a lifesaver in emergency situations where tools are limited. The primary benefits are its low cost and simplicity, as it requires minimal equipment. However, it does come with safety risks, as handling heated objects can lead to burns or accidents. Additionally, this method may not be suitable for larger holes or for use in professional settings where consistency and precision are paramount.

Conclusion: Which Method Should B2B Buyers Choose for Their Leather Belt Needs?

Choosing the right method for creating holes in leather belts depends on various factors, including the scale of production, the desired precision, and the available tools. For businesses focused on high-quality craftsmanship, investing in a leather hole punch is advisable for its precision and durability. Conversely, companies looking for quick fixes or operating on a tight budget may find the power drill or heated nail methods more appealing. Ultimately, B2B buyers should evaluate their specific needs, budget constraints, and operational capabilities to select the most effective solution for their leatherworking requirements.

Essential Technical Properties and Trade Terminology for how to make a hole in a leather belt

What Are the Essential Technical Properties When Making a Hole in a Leather Belt?

When considering the process of making a hole in a leather belt, several technical properties are critical for ensuring quality and durability. Understanding these specifications can help B2B buyers make informed decisions about the tools and methods they choose for this task.

-

Material Grade: The type of leather used in belts can vary significantly in quality, with grades typically categorized as full-grain, top-grain, corrected-grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and durability, making it ideal for belts that require frequent adjustment. Choosing the right material grade affects the longevity of the belt and the effectiveness of the hole-making process.

-

Thickness: Leather thickness is measured in ounces or millimeters. A standard leather belt is usually around 8 to 10 ounces thick (approximately 3.2 to 4 mm). The thickness directly impacts the choice of tools for creating holes. Thicker leather may require specialized tools like a heavy-duty leather punch or drill, whereas thinner leather could be more manageable with simpler tools.

-

Tensile Strength: This property refers to the maximum amount of tensile (pulling) stress a material can withstand before failure. For leather belts, tensile strength is crucial, especially in applications where the belt will bear significant weight or stress. Understanding tensile strength helps in selecting appropriate techniques for hole-making to avoid compromising the belt’s integrity.

-

Finish Type: Leather can be treated with various finishes, such as aniline, semi-aniline, or pigmented finishes. The finish affects the leather’s surface properties, including its resistance to wear and moisture. Knowing the finish type is essential when deciding on the tools and methods for punching holes, as certain finishes may require different care to avoid damage.

-

Hole Tolerance: Tolerance refers to the permissible limit of variation in the size of the hole being made. For belts, the hole size must accommodate the buckle’s prong snugly to ensure functionality. Understanding the required tolerance helps in selecting the right size tools and methods to achieve precise results, which is crucial for both aesthetics and usability.

What Are Common Trade Terms Related to Making Holes in Leather Belts?

Familiarity with industry jargon can enhance communication and negotiation with suppliers and manufacturers. Here are some essential terms relevant to the process of making holes in leather belts.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather belts, an OEM might supply the leather or tools needed for hole-making, ensuring compatibility with specific product requirements.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can impact inventory management and cost-effectiveness when sourcing tools or materials for leather belts.

-

RFQ (Request for Quotation): An RFQ is a business document that solicits price bids from suppliers for specific products or services. For businesses needing leather belts or related tools, issuing an RFQ can help compare prices and establish relationships with multiple suppliers.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B transactions involving the importation or exportation of leather products.

-

CAD (Computer-Aided Design): CAD is a technology used for creating precision drawings or technical illustrations. In the context of leather belts, CAD can be used to design the layout for holes, ensuring accuracy and efficiency in the manufacturing process.

By understanding these technical properties and trade terms, B2B buyers can enhance their decision-making process, optimize their sourcing strategies, and improve their overall product quality when working with leather belts.

Navigating Market Dynamics and Sourcing Trends in the how to make a hole in a leather belt Sector

What Are the Key Drivers in the Global Leather Belt Market?

The global market for leather belts, particularly in the segment focusing on the addition of holes, is driven by a blend of fashion trends, consumer preferences, and practical needs. As fashion evolves, the demand for customizable accessories that allow consumers to adjust fit has become increasingly pronounced. This trend is particularly notable in regions such as Africa and South America, where local craftsmanship and artisanal production are gaining traction, creating unique opportunities for B2B partnerships. Moreover, the rise of online marketplaces has facilitated access to a broader range of suppliers and manufacturers, making it easier for international buyers to source high-quality leather belts and accessories.

Emerging technologies are also reshaping the sourcing landscape. For instance, advancements in e-commerce platforms and digital supply chain management tools enable seamless transactions and improved inventory management. Buyers can now utilize data analytics to forecast demand and optimize their purchasing strategies, thus enhancing their competitiveness in the market. Additionally, there is a growing emphasis on quick turnaround times and customization, prompting manufacturers to adopt agile production methodologies.

How Is Sustainability Shaping the Leather Belt Industry?

Sustainability has become a pivotal consideration for B2B buyers in the leather belt sector. The environmental impact of leather production, including deforestation and water usage, is prompting companies to seek ethically sourced materials. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as using vegetable-tanned leather or recycled materials, which significantly reduces the carbon footprint of production.

Ethical sourcing is not just a trend; it has become a necessity for companies aiming to enhance their brand image and meet consumer demand for transparency. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification are gaining importance. These credentials assure buyers that the leather is produced under environmentally friendly conditions and that workers are treated fairly. As a result, businesses that integrate sustainable practices into their operations are likely to attract more international customers, particularly from Europe and the Middle East, where consumer awareness regarding sustainability is high.

What Is the Historical Context of Leather Belt Production?

The production of leather belts can be traced back centuries, evolving from simple utilitarian items to fashion statements. Historically, belts were primarily functional, used to secure garments and carry tools. As societies progressed, especially during the industrial revolution, leatherworking techniques advanced, allowing for more intricate designs and the incorporation of decorative elements.

In recent decades, the leather belt market has experienced significant transformation. The rise of fast fashion has led to increased production rates and a shift toward mass production. However, this has also sparked a counter-movement emphasizing craftsmanship, quality, and sustainability. Today, the leather belt industry reflects a blend of tradition and innovation, catering to a diverse range of consumer preferences while addressing the pressing need for sustainable practices.

Conclusion

Navigating the dynamics of the leather belt market requires an understanding of both current trends and historical contexts. As international B2B buyers increasingly prioritize sustainability and ethical sourcing, those engaged in the leather belt sector must adapt to these evolving demands. By leveraging technological advancements and maintaining a focus on responsible production, businesses can position themselves favorably in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a hole in a leather belt

-

1. How do I add a hole to a leather belt without specialized tools?

If you lack a leather punch, several alternatives can help. A heated nail or screwdriver can be effective; simply heat the nail and press it into the leather where you want the hole. Alternatively, use a power drill with a small bit, ensuring to place a piece of wood underneath the belt to avoid damage. For a more manual approach, a sharp knife can also create a hole, but be cautious to avoid injury. Always ensure the belt is secured while working to maintain safety. -

2. What is the best method for making a hole in a leather belt?

The most effective method for creating a hole in a leather belt is to use a leather hole punch, as it offers precision and reduces the risk of damage. If a punch is unavailable, using a drill with a sharp bit or a heated nail can yield satisfactory results. For consistent outcomes, ensure that the tools used are appropriate for leather and maintain a steady hand to create clean holes. -

3. How can I ensure the quality of leather belts sourced from suppliers?

To ensure quality, start by vetting suppliers through reviews and certifications. Request samples to assess the leather’s texture, durability, and stitching quality. It’s also beneficial to inquire about the tanning process and materials used, as these factors significantly impact longevity. Establishing a clear quality assurance (QA) process with your supplier can help maintain standards across shipments. -

4. What are the typical minimum order quantities (MOQs) for leather belts?

Minimum order quantities for leather belts can vary widely depending on the supplier and the specifics of the order. Generally, MOQs can range from 50 to several hundred pieces. It is essential to communicate your needs and negotiate MOQs with suppliers, especially if you are looking for customization. Some suppliers may offer lower MOQs for new clients or bulk orders. -

5. How should I approach payment terms when sourcing leather belts internationally?

When sourcing internationally, payment terms can vary, but common practices include upfront deposits and balance payments upon shipment. Using secure payment methods like letters of credit can protect both parties. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the supplier has a vested interest in fulfilling the order properly. Clear communication about payment schedules is crucial for building trust. -

6. What are the logistics considerations when importing leather belts?

Logistics for importing leather belts involve understanding shipping methods, tariffs, and customs regulations. Choose a reliable freight forwarder familiar with handling leather goods to streamline the process. Ensure you have all necessary documentation ready, including invoices and certificates of origin, to avoid delays. Additionally, factor in lead times for production and shipping to meet your market demand. -

7. Can I customize leather belts, and what should I know about the process?

Yes, many suppliers offer customization options, such as size, color, and design. When considering customization, discuss your specific requirements with the supplier early in the process. Be prepared to provide clear specifications, including designs or samples. Customization can affect MOQs and lead times, so it’s essential to factor these into your project timeline and budget. -

8. What quality assurance practices should I implement when sourcing leather products?

Implementing quality assurance practices involves establishing clear criteria for quality checks at various stages—initial samples, production, and pre-shipment. Conduct regular audits and maintain open communication with suppliers regarding quality expectations. Utilize third-party inspection services if necessary, especially for large orders. Document all QA processes to ensure accountability and consistency in quality across batches.

Top 5 How To Make A Hole In A Leather Belt Manufacturers & Suppliers List

1. Reddit – Household Hole Punching Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Household materials for punching holes in belts include: hammer and nail, awl, shoe repair shop services, 22 shell and hammer, small screwdriver, precision screwdriver, and drill with a sharp wood drill bit.

2. Facebook – Leather Hole Punch Tools

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: leather tools, hole punch for leather belts

3. Art of Manliness – Essential Leather Tools

Domain: artofmanliness.com

Registered: 2007 (18 years)

Introduction: 1. Rotary Punch: A tool specifically for leather, typically using #5 sized punch for standard holes. 2. Round Drive Punch: Sharp steel tubes available in various sizes, commonly using 3/16″ size for standard belt holes. 3. Power Drill: Common household tool, using a 3/16″ bit for drilling holes in leather. 4. Pocket Knife: Useful for finishing holes by rounding out and strengthening them after ini…

4. Lifehacks – DIY Belt Hole Solutions

Domain: lifehacks.stackexchange.com

Registered: 2009 (16 years)

Introduction: Substitute tools for adding a belt hole without a leather punch include: 1. Power drill with a small drill bit – use a piece of scrap wood underneath the belt. 2. Heated nail – hold with pliers, heat the tip, and push into the belt. 3. Sharp pointed knife – mark the spot and rotate gently to create a hole. 4. Screwdriver bit in an electric screwdriver. 5. Awl point from multitools or pocket knives…

5. WikiHow – Leather Belt Hole Punching Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: The article provides instructions on how to punch holes in a leather belt using various tools, including a rotary leather hole punch, a rod punch, an awl, or an electric drill. It emphasizes the importance of measuring the distance between existing holes and marking the new hole location accurately. The rotary leather hole punch is highlighted as the ideal tool due to its multiple punch sizes. The…

Strategic Sourcing Conclusion and Outlook for how to make a hole in a leather belt

How Can Strategic Sourcing Enhance Your Leather Belt Production?

In conclusion, mastering the art of adding a hole to a leather belt is a valuable skill for businesses in the leather goods industry. By understanding various methods—ranging from using specialized tools like leather punches to innovative alternatives such as drills or heated nails—businesses can enhance their operational efficiency and product offerings. This not only allows for customization but also caters to diverse customer needs, thereby strengthening client relationships.

Strategic sourcing plays a pivotal role in ensuring that your supply chain is equipped with the necessary tools and materials to execute these processes effectively. By sourcing high-quality leather and reliable tools from trusted suppliers, businesses can maintain product integrity and enhance their competitive edge.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to diversify their product lines, embracing these techniques can position your company as a forward-thinking leader in the leather industry. Invest in the right resources and partnerships today, and empower your business to meet the evolving demands of the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.