Catalog

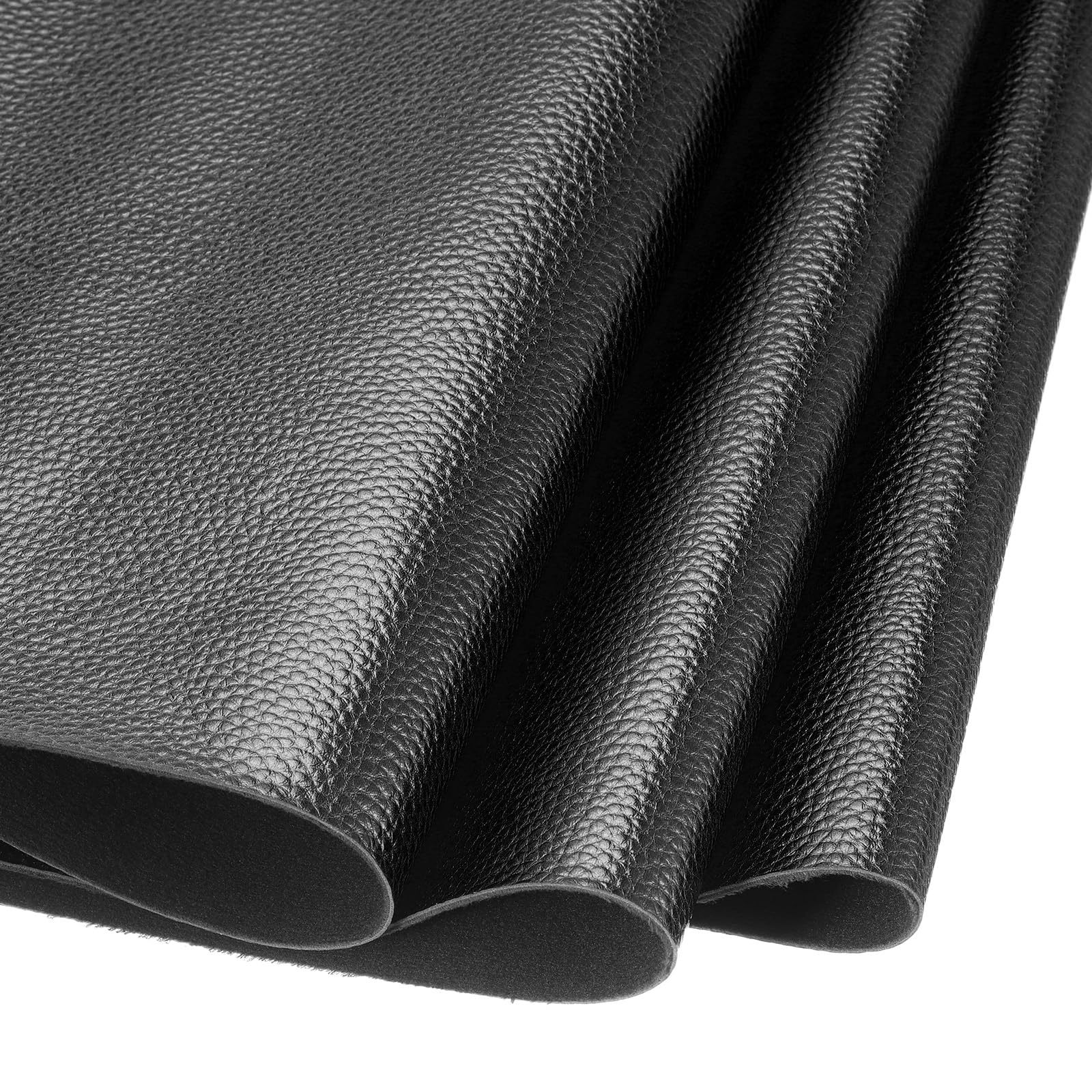

Material Insight: Bulk Leather

B2B Product Guide: Bulk Synthetic Leather Solutions

For manufacturers and designers requiring consistent, high-volume material supply, bulk synthetic leather represents a strategic cornerstone for modern production. Unlike natural leather, which faces inherent limitations in uniformity, ethical sourcing, and scalability, synthetic alternatives deliver unparalleled reliability for large-scale applications—from automotive interiors and furniture manufacturing to fashion accessories and contract furnishings. The volatility of rawhide markets, coupled with growing regulatory pressures on tanning processes and animal welfare, makes traditional leather increasingly impractical for cost-effective, sustainable bulk procurement.

Why Faux Leather is the Optimal Choice for Bulk Applications:

– Consistent Quality & Performance: Eliminates natural leather’s grain variations, scars, and thickness inconsistencies, ensuring uniform aesthetics and mechanical properties across millions of linear meters.

– Scalable Production: Engineered for high-volume output without seasonal or supply chain bottlenecks, guaranteeing on-time delivery for global manufacturing schedules.

– Ethical & Traceable Sourcing: Fully complies with international labor and animal welfare standards, mitigating reputational risks and meeting corporate sustainability mandates.

– Resource Efficiency: Uses up to 90% less water and generates significantly lower carbon emissions versus bovine leather, aligning with ESG reporting requirements.

– Design Flexibility: Offers customizable textures, colors, thicknesses, and performance attributes (e.g., abrasion resistance, UV stability) tailored to specific end-uses.

Introducing WINIW: Your Trusted Bulk Synthetic Leather Partner

With over 20 years of specialized expertise in high-performance synthetic materials, WINIW has pioneered innovations that redefine bulk material procurement for B2B clients worldwide. We combine advanced polymer science with rigorous eco-manufacturing protocols to deliver premium faux leather engineered for industrial-scale demand. Our vertically integrated production ecosystem—spanning R&D, raw material sourcing, and automated finishing—ensures unmatched batch-to-batch repeatability while adhering to REACH, OEKO-TEX® STANDARD 100, and ISO 14001 certifications. For brands committed to scaling sustainably without compromising quality, WINIW provides the technical partnership, supply chain resilience, and environmental accountability essential for tomorrow’s market leadership.

Engineered for volume. Certified for responsibility.

Technical Performance & Standards

WINIW B2B Product Guide: Bulk Synthetic Leather

WINIW’s bulk synthetic leather is engineered for industrial and commercial partners seeking high-performance, sustainable, and cost-effective materials. Designed for applications in furniture, automotive interiors, apparel, and accessories, our bulk leather delivers exceptional value through advanced manufacturing, rigorous quality control, and compliance with international standards.

Technical Advantages

-

Cost-Effective Production

WINIW utilizes optimized manufacturing processes that reduce material waste and energy consumption, enabling competitive pricing without compromising quality. Our bulk production model supports large-volume orders with consistent cost efficiency, ideal for B2B clients scaling operations. -

Superior Durability

Engineered with high tensile strength, abrasion resistance, and excellent color fastness, WINIW’s synthetic leather withstands rigorous use in demanding environments. Resistant to cracking, peeling, and UV degradation, it ensures long-term performance across diverse climates and applications. -

Customizable Colors & Finishes

We offer full color customization with Pantone matching and a wide range of surface textures (suede, grain, smooth, embossed). Clients can specify unique aesthetics to align with brand identity or design requirements, supported by quick sampling and batch consistency. -

REACH Compliance

WINIW’s bulk leather is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our products are free from SVHCs (Substances of Very High Concern) and restricted substances, ensuring safety for end-users and environmental responsibility. -

ISO 9001 Certified Quality Management

Our production facilities are ISO 9001 certified, ensuring standardized processes, continuous improvement, and stringent quality control at every stage—from raw material sourcing to final inspection. This certification guarantees reliability, traceability, and consistent product performance.

Technical Specifications

| Property | Especificação |

|---|---|

| Material Base | High-density polyurethane (PU) or composite |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Width (Roll) | 137 cm, 140 cm, or 150 cm (custom available) |

| Weight | 200 – 450 g/m² (based on thickness) |

| Tensile Strength | ≥ 60 N/5cm (warp & weft) |

| Elongation at Break | ≥ 80% |

| Color Fastness (Rubbing) | Dry: Grade 4–5; Wet: Grade 4 |

| Light Fastness | ≥ Grade 4 (ISO 105-B02) |

| Cold Crack Resistance | Passes -20°C test |

| REACH SVHC Status | None detected |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, width, texture, backing |

WINIW’s bulk synthetic leather combines performance, sustainability, and flexibility to meet the evolving demands of global B2B markets. Partner with us for reliable supply, technical innovation, and eco-conscious materials that support your brand’s growth and compliance goals.

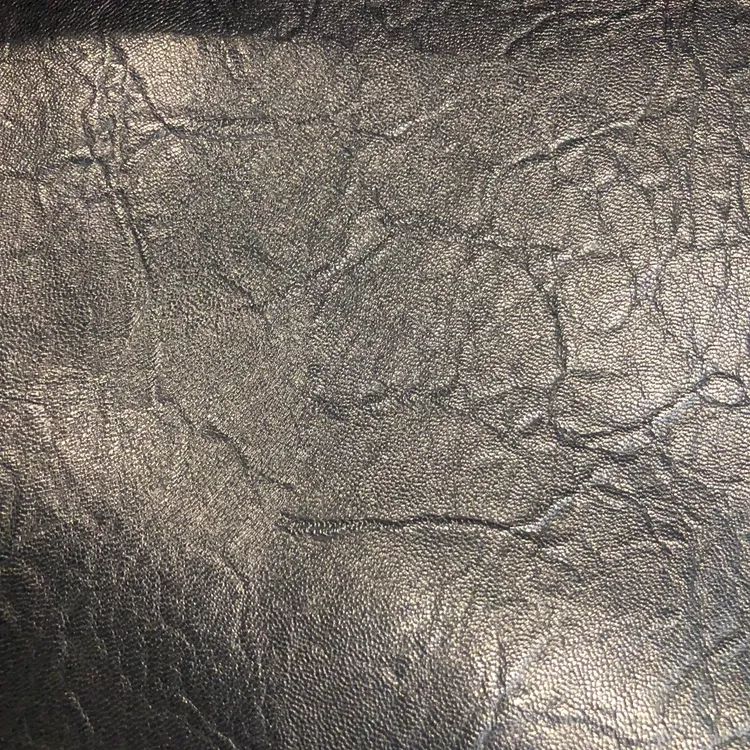

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Bulk Leather vs. Real Leather Comparison

As a leader in sustainable material innovation, WINIW provides this objective analysis to support informed procurement decisions. “Bulk leather” refers to high-performance synthetic leather (primarily PU or PVC-based), engineered for commercial scalability and environmental responsibility. This guide contrasts it with traditional bovine leather (“Real Leather”) across critical operational metrics.

Key Differentiators for Commercial Applications

- Supply Chain Resilience: Bulk leather offers consistent global availability with reduced lead times, mitigating livestock market volatility and geopolitical disruptions affecting real leather.

- Design Flexibility: Customizable thickness, texture, and color batching ensures brand alignment without minimum order constraints common in tanneries.

- Processing Efficiency: Pre-calendared surfaces and uniform thickness reduce cutting waste by 15-25% compared to variable real leather hides.

- Regulatory Compliance: WINIW’s bulk leather meets REACH, OEKO-TEX® STANDARD 100, and RoHS without hazardous tanning chemicals (e.g., chromium VI).

Performance & Sustainability Comparison

| Attribute | Bulk Leather (WINIW Standard) | Real Leather (Full-Grain Bovine) |

|---|---|---|

| Cost | 30-50% lower upfront cost per sqm; no grading losses. Predictable pricing unaffected by hide quality fluctuations. | High variability (up to 200% between grades). 30-40% material waste due to scars/defects requiring manual sorting. |

| Durabilidade | 50,000+ double-rub cycles (Martindale); UV-stable; waterproof; consistent abrasion resistance. No delamination under industrial cleaning protocols. | 20,000-30,000 double-rub cycles; susceptible to water damage, staining, and fading. Performance varies by hide section and tanning method. |

| Eco-Friendliness | 60-100% recycled content options; 90% lower water usage; zero land/water pollution from tanning. Carbon footprint 65% lower (ISO 14067 verified). Fully recyclable via WINIW Reclaim Program. | Requires 15,000-20,000L water per hide; generates toxic sludge (chromium, formaldehyde). High methane emissions from livestock. Non-recyclable at end-of-life; slow biodegradation with chemical leaching. |

Strategic Advantages for B2B Partners

- Sustainability Reporting: WINIW bulk leather delivers auditable reductions in Scope 3 emissions and water stress, directly supporting ESG targets.

- Waste Reduction: Uniform sheet goods optimize nesting efficiency in automated cutting systems, lowering material costs by 18-22%.

- Circularity: End-of-life take-back program ensures closed-loop recycling into new material streams, eliminating landfill liability.

- Ethical Assurance: Zero animal sourcing; certified conflict-free supply chain compliant with EU deforestation regulations.

For applications demanding reliability, cost control, and verifiable sustainability—furniture manufacturing, automotive interiors, and commercial upholstery—WINIW bulk leather delivers superior lifecycle value. Request our technical datasheets or material samples to validate performance against your specifications.

WINIW: Engineering Responsibility into Every Fiber™

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong foundation in research, production excellence, and international compliance, WINIW delivers premium solutions tailored to diverse industry needs.

Strategically positioned for scale and innovation, WINIW operates from a 100,000 sqm state-of-the-art manufacturing facility. This expansive campus integrates advanced production lines with sustainable practices, enabling high-volume output without compromising quality or environmental responsibility.

Key strengths of WINIW’s factory operations include:

-

Advanced R&D Team: A dedicated research and development team drives continuous innovation, focusing on eco-conscious materials, enhanced durability, and application-specific formulations. The team ensures WINIW stays ahead of market trends and regulatory standards.

-

Strict Quality Control (QC) System: Every production stage follows a rigorous QC protocol, from raw material selection to finished goods. WINIW adheres to international standards, including ISO and REACH compliance, ensuring consistent product reliability and safety.

-

Sustainable Manufacturing: The factory implements low-emission processes, water-saving technologies, and recyclable material integration, supporting clients’ ESG goals and reducing environmental impact.

WINIW proudly exports to demanding markets worldwide, with established distribution channels in Europe and the USA. Our products meet the stringent requirements of these regions, including environmental regulations and performance benchmarks across industries such as fashion, automotive, and furniture.

By combining large-scale production capacity, technical expertise, and a commitment to sustainability, WINIW stands as a trusted partner for global brands seeking high-quality, responsible synthetic leather solutions.

Contact Us for Samples

WINIW Synthetic Leather: Premium Eco-Conscious Solutions for Industrial Applications

WINIW is a global leader in sustainable synthetic leather manufacturing, delivering high-performance microfiber materials engineered for durability, aesthetics, and environmental responsibility. Our B2B-focused portfolio meets rigorous industry standards while reducing ecological impact—ideal for furniture, automotive, fashion, and technical textiles. All products are certified under GRSC™, OEKO-TEX® STANDARD 100, and ISO 14001 frameworks.

Core Product Lines for Industrial Partnerships

- WINIW EcoPure™: Petroleum-free PU leather with 30% bio-based content; ideal for luxury upholstery and accessories requiring soft hand feel and color stability.

- WINIW RecycledPro™: Made from 50%+ post-consumer recycled PET bottles; features superior tear strength (≥50N) for automotive seating and contract furniture.

- WINIW TechFlex™: PVC-free technical grade with enhanced abrasion resistance (≥50,000 cycles Martindale); optimized for marine, aviation, and healthcare applications.

Technical Specifications Comparison

| Property | WINIW EcoPure™ | WINIW RecycledPro™ | WINIW TechFlex™ |

|---|---|---|---|

| Composição | Bio-based PU | Recycled PET fiber | PU/Polyester |

| Width (cm) | 137 ± 2 | 140 ± 2 | 145 ± 2 |

| Thickness (mm) | 0.8–1.8 | 1.0–2.2 | 1.2–2.5 |

| Abrasion Resistance | ≥35,000 cycles | ≥45,000 cycles | ≥50,000 cycles |

| Tear Strength | ≥35 N | ≥50 N | ≥45 N |

| Eco-Certifications | GRS, OEKO-TEX® | GRS, Global Recycled Standard | OEKO-TEX®, ISO 14001 |

Why Industrial Partners Choose WINIW

- Circular Economy Integration: Traceable supply chain with 92% reduction in water usage vs. conventional leather.

- Customization Capabilities: Tailored thickness, color matching (Pantone®), embossing, and functional coatings (anti-microbial, flame-retardant).

- Scalable Production: Dedicated 50,000m² facility ensuring 15-day lead times for orders ≥5,000m.

Streamlined Partnership Process

- Submit technical requirements for rapid feasibility assessment

- Receive compliance documentation and digital swatch library within 48 hours

- Validate performance with complimentary physical samples (no cost, no obligation)

- Transition to bulk production with dedicated account management

Optimize your sustainability metrics without compromising performance. WINIW’s engineered microfiber leathers deliver lifecycle value for forward-thinking manufacturers.

→ Request bulk pricing and technical datasheets for your next production run: MKT88@MicrofiberLeather.com

Free samples available to qualified B2B partners. Minimum order: 500m per style.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.