Introduction: Navigating the Global Market for alcantara material

In an increasingly competitive landscape, international B2B buyers face the pressing challenge of sourcing high-quality Alcantara material that meets the diverse demands of their industries. Whether you are looking to enhance automotive interiors, elevate fashion collections, or enrich interior design projects, understanding the nuances of Alcantara can significantly impact your purchasing decisions. This guide serves as a comprehensive resource, detailing the various types of Alcantara, its extensive applications, and critical considerations for supplier vetting and cost evaluation.

Alcantara is not just a material; it represents a fusion of luxury and functionality, making it a preferred choice across multiple sectors. Our guide will empower you with actionable insights into the sourcing process, helping you navigate supplier networks in regions like Africa, South America, the Middle East, and Europe, including key markets such as Brazil and Vietnam. You will gain a clear understanding of what to look for in quality Alcantara, how to assess suppliers effectively, and strategies to negotiate favorable terms.

By equipping yourself with this knowledge, you will be better positioned to make informed purchasing decisions that align with your business objectives, ultimately enhancing the quality of your products and the satisfaction of your customers. Explore the multifaceted world of Alcantara and unlock the potential it holds for your ventures.

Table Of Contents

- Top 7 Alcantara Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara material

- Understanding alcantara material Types and Variations

- Key Industrial Applications of alcantara material

- 3 Common User Pain Points for ‘alcantara material’ & Their Solutions

- Strategic Material Selection Guide for alcantara material

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara material’

- Comprehensive Cost and Pricing Analysis for alcantara material Sourcing

- Alternatives Analysis: Comparing alcantara material With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara material

- Navigating Market Dynamics and Sourcing Trends in the alcantara material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara material

- Strategic Sourcing Conclusion and Outlook for alcantara material

- Important Disclaimer & Terms of Use

Understanding alcantara material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Classic | Standard version with a soft, suede-like texture | Automotive interiors, luxury fashion | Pros: Premium feel, versatile applications. Cons: Requires regular maintenance to preserve appearance. |

| Alcantara Eco | Eco-friendly variant made from recycled materials | Sustainable fashion, eco-conscious products | Pros: Sustainable, aligns with green branding. Cons: May have a different texture compared to traditional Alcantara. |

| Alcantara Sport | High-grip texture designed for performance use | Automotive racing, sports equipment | Pros: Enhanced grip, moisture-resistant. Cons: Can wear down faster in high-use areas. |

| Alcantara Flame Retardant | Treated for flame resistance | Aviation, high-risk environments | Pros: Safety compliance, durable. Cons: Limited color options due to treatment process. |

| Alcantara Velvet | Luxurious finish with a plush texture | High-end furniture, luxury interiors | Pros: Aesthetic appeal, soft touch. Cons: Higher cost, more delicate than standard variants. |

What Are the Key Characteristics of Alcantara Classic?

Alcantara Classic is the flagship variant known for its soft, suede-like texture and versatility. This material is widely utilized in automotive interiors, luxury fashion, and high-end consumer goods. When considering this type, B2B buyers should note its premium feel, which enhances the aesthetic value of products. However, it does require regular maintenance to maintain its appearance, making it essential for buyers to factor in cleaning protocols and costs.

How Does Alcantara Eco Stand Out in the Market?

Alcantara Eco is a sustainable alternative crafted from recycled materials, appealing to businesses focused on eco-friendly practices. This variant is suitable for sustainable fashion brands and products aimed at environmentally conscious consumers. While it aligns well with green branding and corporate responsibility initiatives, buyers should be aware that the texture may differ slightly from traditional Alcantara, potentially affecting customer satisfaction.

What Advantages Does Alcantara Sport Offer for Performance Applications?

Alcantara Sport is specifically designed for high-performance applications, featuring a textured surface that provides enhanced grip. This makes it ideal for automotive racing and sports equipment, where performance is critical. B2B buyers will appreciate its moisture resistance, which helps maintain functionality in demanding environments. However, it’s important to consider that this variant can wear down more quickly in high-use areas, necessitating careful selection for long-term applications.

Why Choose Alcantara Flame Retardant for Safety Compliance?

Alcantara Flame Retardant is treated to meet safety standards in high-risk environments, such as aviation and industrial applications. This variant ensures compliance with fire safety regulations, making it a reliable choice for businesses prioritizing safety. While it offers durability and protection, buyers should note that the treatment process may limit color options, potentially restricting design choices.

What Makes Alcantara Velvet a Luxurious Choice for Interiors?

Alcantara Velvet features a plush, luxurious finish, making it an excellent choice for high-end furniture and luxury interior applications. Its soft touch and aesthetic appeal can significantly enhance the perceived value of products. However, B2B buyers should consider the higher cost and the material’s delicate nature, which may require special care to maintain its quality over time.

Key Industrial Applications of alcantara material

| Industry/Sector | Specific Application of alcantara material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for high-end vehicles | Enhances luxury perception, durability, and comfort | Ensure compliance with automotive standards and certifications. |

| Fashion and Apparel | High-end fashion items and accessories | Elevates brand image and offers unique texture | Consider sustainable sourcing and customization options. |

| Aviation | Cabin interiors and seating for commercial airlines | Improves passenger experience and reduces weight | Assess fire safety standards and maintenance requirements. |

| Furniture | Upholstery for luxury furniture and decor | Provides a premium feel and aesthetic appeal | Evaluate cleaning and maintenance solutions for long-term use. |

| Electronics | Covers for premium electronic devices | Offers a stylish and protective finish | Ensure compatibility with device specifications and durability. |

How is Alcantara Material Used in the Automotive Industry?

In the automotive sector, Alcantara is predominantly used for upholstery in high-end vehicles, including seats, dashboards, and steering wheels. This material not only enhances the luxury aesthetic but also provides superior grip and durability compared to traditional leather. For international buyers, particularly from regions like Africa and South America, it’s essential to consider local climate conditions that may affect the material’s longevity and maintenance. Compliance with automotive safety standards is also crucial when sourcing Alcantara for vehicle interiors.

What Role Does Alcantara Play in Fashion and Apparel?

In the fashion industry, Alcantara is utilized for creating high-end garments and accessories, such as handbags and shoes. Its unique texture and appearance elevate the perceived value of products, making them more appealing to luxury consumers. For B2B buyers in Europe and the Middle East, understanding the latest fashion trends and sustainable sourcing practices is vital. Collaborating with manufacturers who can offer customization in color and design can further enhance product differentiation in a competitive market.

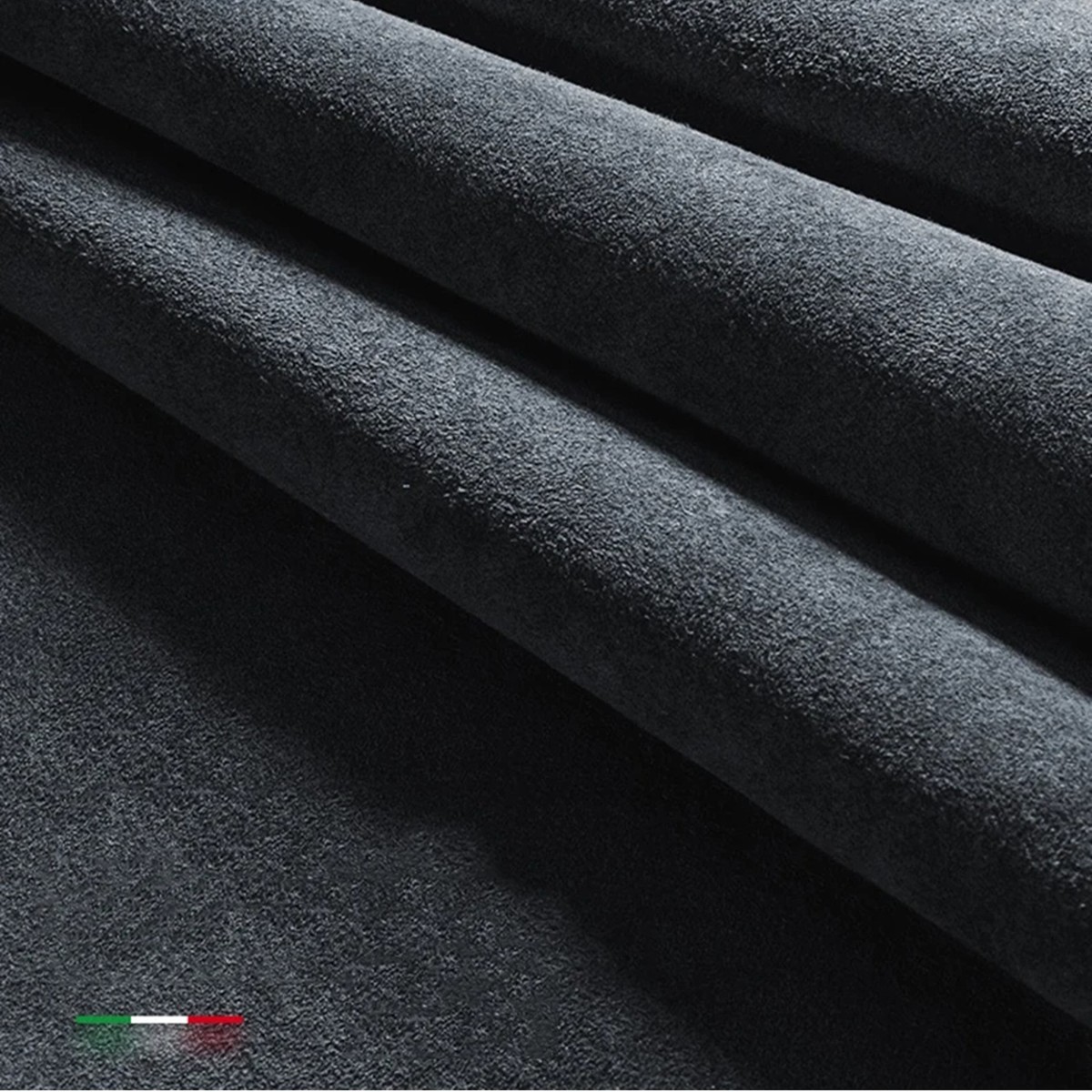

Illustrative image related to alcantara material

Why is Alcantara Important for Aviation Interiors?

Alcantara finds significant applications in the aviation industry, particularly for commercial airline cabin interiors and seating. Its lightweight properties contribute to fuel efficiency, while its soft texture improves passenger comfort. Buyers in the aviation sector must ensure that the sourced Alcantara meets stringent fire safety regulations and can withstand the rigors of high-traffic environments. Additionally, ease of cleaning and maintenance is a key consideration for maintaining a premium passenger experience.

How is Alcantara Used in Luxury Furniture?

In the furniture industry, Alcantara is employed for upholstery in luxury furniture pieces, such as sofas and chairs. This material provides a soft, luxurious feel that appeals to high-end consumers, enhancing both aesthetic and tactile experiences. For businesses in South America and Europe, sourcing Alcantara requires attention to the material’s durability and cleaning properties to ensure long-term satisfaction. Buyers should also explore options for eco-friendly production processes to align with growing sustainability trends.

What are the Applications of Alcantara in Electronics?

Alcantara is increasingly being used for covers and cases for premium electronic devices, offering a stylish yet protective finish. This application not only enhances the aesthetic appeal but also provides a soft touch that consumers appreciate. B2B buyers in Asia and Africa should prioritize sourcing Alcantara that meets durability standards and is compatible with electronic device specifications. Understanding consumer preferences for design and texture can also drive successful product offerings in this competitive sector.

3 Common User Pain Points for ‘alcantara material’ & Their Solutions

Scenario 1: Challenges in Cleaning and Maintaining Alcantara

The Problem:

B2B buyers often face challenges when it comes to the cleaning and maintenance of Alcantara. Given its unique texture and composition, this material can attract dirt and oils, especially in high-traffic areas like car interiors or office furnishings. Buyers may find that after a short period of use, the material appears worn or discolored, leading to dissatisfaction among clients or consumers. This not only affects the aesthetic appeal but can also diminish the perceived value of their products, resulting in potential losses.

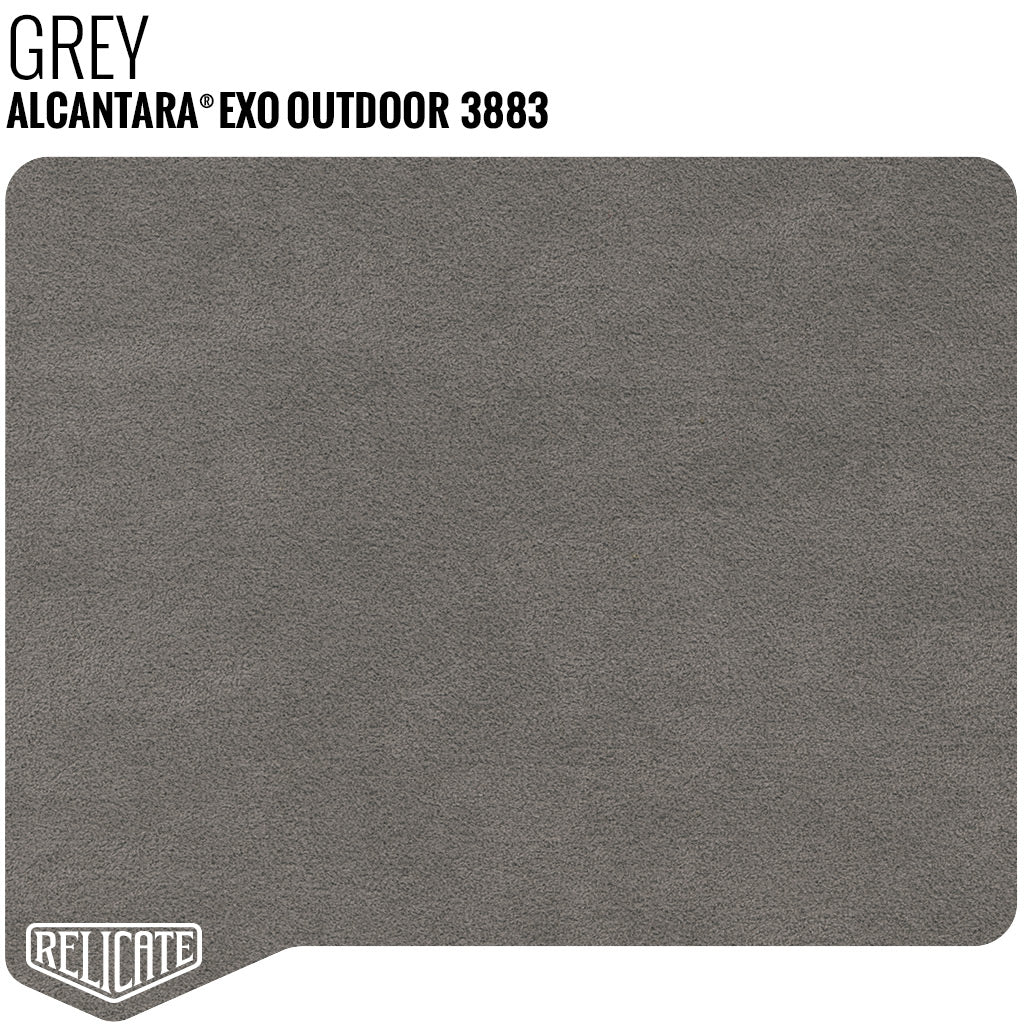

Illustrative image related to alcantara material

The Solution:

To effectively maintain Alcantara, it’s essential to establish a proactive cleaning routine. First, source cleaning products specifically designed for Alcantara, as standard cleaning agents may damage the fabric. Regularly using a soft brush to remove dust and debris can prevent dirt from settling deep into the fibers. Additionally, implementing a gentle cleaning solution that does not contain harsh chemicals will help maintain the fabric’s integrity. It is advisable to provide training for staff on proper cleaning techniques, emphasizing the importance of using a light touch to preserve the material’s nap. Buyers should also consider offering aftercare services or guides to their clients, ensuring longevity and satisfaction with Alcantara applications.

Scenario 2: Sourcing Quality Alcantara for Diverse Applications

The Problem:

When sourcing Alcantara, B2B buyers often struggle with ensuring the quality and authenticity of the material. Given the existence of various substitutes in the market, buyers may inadvertently purchase inferior products that do not meet the desired specifications or performance characteristics. This can lead to product failures, increased costs, and damage to the company’s reputation, particularly in industries like automotive or high-end fashion where quality is paramount.

The Solution:

To mitigate sourcing issues, buyers should establish relationships with reputable suppliers who are officially recognized distributors of Alcantara. Requesting certifications and samples before committing to large orders can help verify the material’s authenticity. Additionally, buyers should inquire about the production process and sustainability practices of the supplier, as these factors can significantly impact quality. Attending industry trade shows or exhibitions can provide opportunities to meet suppliers in person, assess their offerings, and build trust. By developing a robust supplier vetting process, buyers can ensure they are sourcing high-quality Alcantara that meets their application needs.

Scenario 3: Addressing the Perception of Wear and Tear

The Problem:

A common concern among B2B buyers is the perception that Alcantara shows signs of wear and tear more quickly than traditional materials like leather. As Alcantara is often used in high-visibility areas, any signs of fading or flattening can lead to customer dissatisfaction and complaints. This can be particularly detrimental in industries where aesthetics play a crucial role in branding and customer experience, such as luxury automotive and high-end interior design.

The Solution:

To combat the negative perception of wear and tear, buyers should communicate the benefits of Alcantara to their clients. Highlighting its superior grip, lightweight properties, and flame-retardant capabilities can shift focus from potential drawbacks to its functional advantages. Additionally, educating clients on proper care techniques can enhance the longevity of Alcantara, ensuring it retains its visual appeal over time. Offering warranties or guarantees on Alcantara products can further instill confidence in buyers, reassuring them that the material is a worthwhile investment. By proactively addressing concerns and emphasizing the unique qualities of Alcantara, businesses can foster greater customer satisfaction and loyalty.

Strategic Material Selection Guide for alcantara material

What Are the Key Properties of Alcantara Material?

Alcantara is a unique synthetic textile known for its suede-like appearance and feel, created from a blend of polyester and polyurethane. This proprietary material is recognized for its versatility, making it suitable for various applications, including automotive interiors, fashion, and furniture. Alcantara’s properties include excellent durability, moisture resistance, and a soft texture that provides a premium aesthetic. It is also flame retardant, which is critical for applications in the automotive and aviation industries.

What Are the Pros and Cons of Using Alcantara Material?

Pros:

1. Durabilidade: Alcantara is more resistant to wear and tear compared to traditional suede and leather, making it ideal for high-traffic areas in vehicles and public spaces.

2. Maintenance: Although it requires regular cleaning, Alcantara is easier to maintain than leather, as it can be cleaned with gentle solutions without the risk of damage.

3. Aesthetic Appeal: The luxurious look and feel of Alcantara enhance the overall design of products, making them more appealing to consumers.

Cons:

1. Cost: Alcantara can be as expensive as leather, which might deter some buyers, especially in price-sensitive markets.

2. Wear Over Time: While durable, Alcantara can lose its softness and appearance if not properly maintained, which can affect the long-term satisfaction of end-users.

3. Manufacturing Complexity: The production of Alcantara involves specific processes that may not be easily replicated, potentially leading to supply chain challenges.

How Does Alcantara Material Impact Specific Applications?

Alcantara’s unique properties make it suitable for various applications, particularly in the automotive industry. It provides superior grip for steering wheels and gear levers, enhancing driver control. Additionally, its non-reflective surface reduces glare, improving visibility for drivers. In the fashion and furniture sectors, Alcantara’s luxurious feel and wide range of colors allow for creative design possibilities, appealing to high-end markets.

What Should International B2B Buyers Consider When Selecting Alcantara Material?

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should consider several factors when selecting Alcantara. Compliance with local regulations and standards (such as ASTM, DIN, or JIS) is crucial. Buyers should also evaluate the availability of cleaning and maintenance products specific to Alcantara, as these can vary by region. Furthermore, understanding regional preferences for materials can guide product development and marketing strategies, ensuring alignment with consumer expectations.

Summary Table of Material Analysis

| Material | Typical Use Case for alcantara material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara | Automotive interiors, fashion, furniture | Durable and luxurious appearance | Requires regular maintenance | Elevado |

| Leather | Luxury goods, automotive upholstery | Classic aesthetic and durability | Expensive and less eco-friendly | Elevado |

| Polyester | Upholstery, clothing | Cost-effective and versatile | Less durable than Alcantara | Low |

| Microfibra | Cleaning products, upholstery | Highly absorbent and easy to clean | Can be less durable than Alcantara | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into the properties, advantages, and limitations of Alcantara and comparable materials, enabling informed decision-making in their procurement processes.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara material

What Are the Main Stages of the Manufacturing Process for Alcantara Material?

The manufacturing process of Alcantara material involves several critical stages that ensure its quality and performance. Understanding these stages is essential for B2B buyers looking to procure high-quality Alcantara for various applications.

Material Preparation: What Goes Into Alcantara Production?

Alcantara is a synthetic textile made from a blend of polyester and polyurethane. The manufacturing process begins with the careful selection and preparation of these raw materials. The polyester provides strength and durability, while polyurethane contributes to the material’s soft texture and flexibility. Once sourced, these components undergo a series of chemical treatments to enhance their properties, such as flame resistance and colorfastness.

Forming: How Is Alcantara Shaped and Structured?

The next step is the forming stage, where the prepared materials are combined and processed into sheets. This is done through a unique lamination technique that blends the polyester and polyurethane fibers, creating a cohesive fabric. The resulting sheets are then passed through rollers to achieve the desired thickness and texture, ensuring uniformity across the product. Advanced machinery and technology are employed to maintain precision during this stage, which is crucial for the final quality of the Alcantara.

Assembly: What Are the Key Techniques Used?

After forming, the Alcantara fabric is cut and assembled based on specific requirements for various applications. For automotive uses, for instance, the fabric may be tailored for seats, dashboards, or interior panels. Techniques such as ultrasonic welding or sewing are commonly used to assemble the Alcantara components securely. These methods not only enhance the aesthetic appeal but also ensure durability and performance in high-stress environments.

Finishing: How Is Alcantara Enhanced for Final Use?

The finishing stage involves several processes aimed at enhancing the appearance and performance of Alcantara. This includes dyeing to achieve vibrant colors, applying protective coatings to improve stain resistance, and conducting surface treatments to enhance tactile qualities. Quality control checks are integral during this stage to ensure that the finished product meets the specific standards required for various industries, from automotive to fashion.

What Quality Assurance Processes Are in Place for Alcantara Material?

Quality assurance is a cornerstone of Alcantara’s manufacturing ethos, ensuring that each product meets both international and industry-specific standards.

What International Standards Are Relevant to Alcantara Quality Assurance?

Alcantara adheres to several international quality standards, including ISO 9001, which outlines requirements for a quality management system. This certification ensures that the manufacturing process consistently meets customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for safety and environmental compliance are crucial for products used in various applications, particularly in the automotive and fashion sectors.

Illustrative image related to alcantara material

What Are the Key Quality Control Checkpoints in Alcantara Production?

Quality control checkpoints are strategically implemented throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to identify any deviations from established standards, allowing for immediate corrective actions.

- Final Quality Control (FQC): The finished Alcantara products undergo rigorous testing to verify that they meet performance, durability, and aesthetic standards before being shipped to clients.

What Common Testing Methods Are Used for Alcantara Quality Assurance?

Several testing methods are employed to ensure the quality of Alcantara. These include:

- Abrasion Resistance Testing: To assess the durability of the fabric under wear and tear.

- Color Fastness Testing: To evaluate how well the color holds up against washing, light exposure, and rubbing.

- Flame Retardancy Testing: To ensure compliance with safety standards, particularly in automotive applications.

- Tactile and Visual Inspections: To maintain the aesthetic and tactile quality of the material.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, need to ensure that their suppliers maintain high-quality standards.

What Auditing Processes Should Buyers Consider?

Conducting audits of potential suppliers is a vital step in verifying their quality control practices. Buyers should consider requesting:

- Quality Management System Documentation: Suppliers should provide documentation demonstrating compliance with ISO 9001 and other relevant standards.

- Audit Reports: Regularly conducted internal and external audits can provide insight into the supplier’s adherence to quality standards.

- Certifications: Confirm that suppliers possess the necessary certifications for their products, especially for specific industries.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can be beneficial for B2B buyers. These independent entities can conduct thorough evaluations of the manufacturing processes, material quality, and overall compliance with industry standards. Third-party inspections provide an unbiased assessment and can help mitigate risks associated with sourcing from international suppliers.

What Quality Control Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers must navigate various quality control nuances when sourcing Alcantara. This includes understanding the differences in regulatory requirements across regions, which can affect product specifications and testing methods. Buyers should also consider the cultural and logistical challenges that may arise when establishing quality assurance protocols with suppliers in different countries.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices related to Alcantara material is essential for B2B buyers. By focusing on these elements, companies can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Illustrative image related to alcantara material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara material’

To assist B2B buyers in procuring Alcantara material effectively, this guide provides a structured checklist. Alcantara is a premium synthetic fabric that is increasingly sought after in various industries, including automotive, fashion, and interior design. This checklist will help you navigate the sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Clearly outline what you need from Alcantara material. This includes understanding its intended application, required colors, textures, and any specific performance characteristics (e.g., flame resistance, water resistance). A detailed specification helps narrow down suppliers and ensures that the material meets your industry standards.

- Aplicações: Consider whether the material will be used for upholstery, fashion, or automotive interiors.

- Performance Requirements: Specify any durability or maintenance needs relevant to your project.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Alcantara. Look for manufacturers with a strong track record in the industry. A solid reputation often correlates with product quality and reliability in supply chains.

- Check Credentials: Ensure suppliers have relevant certifications that guarantee quality and sustainability practices.

- Industry Experience: Favor suppliers who have experience in your specific sector, as they will understand your unique needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a deeper investigation reveals their reliability and performance.

- Visit Facilities (if possible): If feasible, visit the supplier’s production facilities to assess their operations and quality control processes.

- Seek Testimonials: Reach out to current or past clients to gain insights into their experiences with the supplier.

Step 4: Request Samples

Always request samples of the Alcantara material before making a bulk order. Samples allow you to evaluate the texture, color, and quality firsthand, ensuring it aligns with your expectations.

Illustrative image related to alcantara material

- Test for Durability: Examine how the material responds to wear and tear, particularly if it will be used in high-traffic areas.

- Assess Maintenance Needs: Consider how easy the material is to clean and maintain, as this will impact its longevity and usability.

Step 5: Negotiate Terms and Conditions

Engage in discussions about pricing, delivery timelines, and payment terms. Clear agreements on these aspects can prevent misunderstandings later in the procurement process.

- Volume Discounts: Inquire about pricing structures for larger orders, as many suppliers offer discounts based on quantity.

- Lead Times: Confirm delivery schedules to ensure they align with your project timelines.

Step 6: Verify Compliance with Sustainability Standards

Given the growing emphasis on sustainability, ensure the supplier adheres to relevant eco-friendly practices. Alcantara has a reputation for sustainability, so it’s essential that your supplier aligns with these values.

- Check Certifications: Look for certifications related to environmental management and social responsibility.

- Sourcing Practices: Inquire about the sourcing of raw materials and the manufacturing process to ensure ethical practices.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance protocol to monitor the material upon delivery. This step is vital to ensure that the Alcantara received meets the agreed specifications.

- Inspect Deliveries: Conduct a thorough inspection of materials upon receipt to catch any discrepancies early.

- Feedback Loop: Establish a communication channel with the supplier for ongoing quality assessments and to address any issues promptly.

By following this checklist, B2B buyers can ensure a streamlined and effective sourcing process for Alcantara material, aligning their procurement strategies with quality and sustainability standards.

Comprehensive Cost and Pricing Analysis for alcantara material Sourcing

What Are the Key Cost Components in Sourcing Alcantara Material?

When considering Alcantara material for B2B applications, it is essential to understand the various cost components that contribute to its overall pricing. The primary cost elements include:

-

Raw Materials: Alcantara is a synthetic textile, primarily made from a blend of polyester and polyurethane. The cost of these raw materials can fluctuate based on market demand and supply chain stability.

-

Labor Costs: The manufacturing of Alcantara involves skilled labor for both production and quality assurance. Labor costs can vary significantly depending on the geographical location of the manufacturing facility, particularly between regions like Europe and South America.

-

Manufacturing Overhead: This includes expenses related to plant operations, utilities, equipment maintenance, and other indirect costs that support production. Efficiency in manufacturing processes can help reduce these overhead costs.

-

Tooling Costs: Depending on the specifications and customization required by the buyer, tooling costs can be substantial. Custom molds or machinery setups for unique Alcantara applications can impact the final price.

-

Quality Control (QC): Ensuring that Alcantara meets specific quality standards incurs additional costs. Rigorous testing and certification processes are necessary, especially for industries like automotive, where safety and durability are paramount.

-

Logistics: Transportation and shipping costs can significantly affect the total price. Factors such as distance, shipping methods, and the complexity of logistics (e.g., customs clearance) play a crucial role.

-

Supplier Margin: The profit margin applied by suppliers can vary widely based on their market position, brand reputation, and the added value they provide through customization or service.

What Influences the Pricing of Alcantara Material?

Several factors influence the pricing of Alcantara, making it crucial for buyers to understand these variables:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to better pricing due to economies of scale. Negotiating MOQs can yield more favorable terms.

-

Specifications and Customization: Custom colors, textures, and finishes can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality Certifications: Suppliers offering certified products (e.g., eco-friendly certifications) may charge a premium, but these certifications can enhance the material’s value.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record may command higher prices due to their quality assurance processes.

-

Incoterms: The agreed terms of shipping (e.g., FOB, CIF) affect the final cost. Understanding the implications of these terms can help buyers manage their logistics and total costs effectively.

How Can Buyers Negotiate for Better Prices on Alcantara Material?

Effective negotiation strategies can lead to cost efficiencies in sourcing Alcantara:

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, durability, and performance. This holistic view can guide better investment decisions.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication and trust can lead to more favorable negotiations.

-

Market Research: Understanding market trends, competitor pricing, and supplier capabilities can empower buyers during negotiations. Being informed about alternative materials can also provide leverage.

-

Consider Regional Variances: Pricing may vary significantly between regions such as Africa, South America, the Middle East, and Europe. Buyers should be aware of these differences and negotiate accordingly.

-

Explore Bulk Purchasing Options: If feasible, coordinating with other businesses to make bulk purchases can lower costs. This approach can enhance negotiating power with suppliers.

Disclaimer on Pricing

Pricing for Alcantara material can fluctuate based on various external factors, including raw material costs, geopolitical events, and market demand. As such, the prices discussed in this analysis are indicative and should be confirmed with suppliers during the procurement process. Always conduct thorough due diligence when sourcing materials to ensure the best value for your business.

Alternatives Analysis: Comparing alcantara material With Other Solutions

Exploring Alternatives to Alcantara Material: A Comparative Analysis

In the quest for high-performance materials in various applications, Alcantara has garnered attention for its unique properties and aesthetic appeal. However, buyers often face a dilemma when choosing the right material for their needs. This section will compare Alcantara with two viable alternatives: Microfiber and Natural Leather. By examining key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their specific requirements.

| Comparison Aspect | Alcantara Material | Microfibra | Natural Leather |

|---|---|---|---|

| Performance | High grip, soft texture, flame retardant | Good durability, soft feel, water-resistant | Excellent durability, natural aesthetics |

| Cost | Moderate to high (comparable to leather) | Generally lower than Alcantara | Higher initial cost, long-term value |

| Ease of Implementation | Easy to work with, widely available | Simple to sew and maintain | Requires specialized skills for upholstery |

| Maintenance | Needs regular cleaning, sensitive to oils | Easy to clean, stain-resistant | Requires conditioning and upkeep |

| Best Use Case | Automotive interiors, luxury fashion | Upholstery, fashion accessories | High-end furniture, luxury goods |

In-Depth Analysis of Alternatives

What is Microfiber and How Does It Compare to Alcantara?

Microfiber is a synthetic material made from finely woven polyester and polyamide fibers. It offers a soft touch and is known for its durability and water resistance. When compared to Alcantara, microfiber presents a cost-effective alternative, generally being less expensive while still providing good performance. However, it may not deliver the same level of grip and luxurious feel that Alcantara offers, which can be a critical factor for applications in high-performance automotive interiors.

On the maintenance front, microfiber is easier to clean and is often treated to resist stains, making it a practical choice for everyday use. However, it may lack the unique aesthetic qualities of Alcantara, which can elevate the design of luxury items.

What are the Advantages of Using Natural Leather Over Alcantara?

Natural leather is a classic material known for its durability and premium appearance. It ages beautifully, developing a unique patina over time, which can enhance the aesthetic value of the product. In terms of performance, leather outshines Alcantara in long-term durability, particularly in environments where wear and tear are prevalent.

Illustrative image related to alcantara material

However, natural leather comes with a higher upfront cost and requires more meticulous maintenance, including conditioning and cleaning to prevent cracking and drying. Additionally, ethical considerations regarding animal welfare may deter some buyers. For applications that prioritize luxury and timeless appeal, leather remains a strong contender despite its drawbacks.

Making the Right Choice: How to Decide Between Alcantara and Its Alternatives

Choosing the right material depends on several factors, including the intended application, budget constraints, and maintenance capabilities. For automotive interiors or luxury fashion items where aesthetics and grip are paramount, Alcantara may be the optimal choice despite its higher maintenance needs. Alternatively, for applications requiring a balance of cost-effectiveness and durability, microfiber presents a solid option. If long-term investment and classic appeal are priorities, natural leather stands out as the best choice, albeit with higher initial costs and maintenance requirements.

Ultimately, B2B buyers should evaluate their specific needs and consider how each material aligns with their brand values, customer expectations, and product lifecycle. By carefully weighing these factors, buyers can confidently select the material that best fits their strategic objectives.

Essential Technical Properties and Trade Terminology for alcantara material

What Are the Key Technical Properties of Alcantara Material?

Alcantara is a synthetic textile that combines aesthetics with performance, making it an increasingly popular choice across various industries, particularly in automotive, fashion, and interior design. Understanding its technical properties is essential for B2B buyers to ensure they are making informed decisions.

1. Composition and Material Grade

Alcantara is primarily composed of a blend of polyester and polyurethane, which gives it its unique suede-like appearance and feel. The specific ratios can vary, affecting its performance characteristics such as durability, softness, and maintenance requirements. For B2B buyers, knowing the material grade is crucial as it directly influences the product’s quality and longevity, particularly in high-use applications like automotive interiors.

2. Flame Retardancy

Many Alcantara products can be treated to be flame retardant, making them suitable for environments where safety is paramount, such as automotive and aviation. This property is vital for compliance with industry standards and regulations. B2B buyers should consider flame retardancy when sourcing materials for applications that may require adherence to safety guidelines.

3. Weight and Density

Alcantara is lighter than traditional leather, which is a significant advantage in applications where weight reduction is critical, such as in automotive design. The density of the material affects its handling and application methods. This property is particularly important for manufacturers looking to optimize performance without compromising on luxury and aesthetics.

4. Moisture Resistance

Unlike traditional fabrics, Alcantara has enhanced moisture resistance, which prevents degradation over time in humid or wet environments. This property is particularly beneficial in automotive applications where exposure to spills and sweat is common. B2B buyers should evaluate moisture resistance to ensure the material meets the performance expectations of their specific use cases.

5. Durability and Wear Resistance

Alcantara is known for its excellent durability and wear resistance, making it suitable for high-traffic areas. However, it can show signs of wear over time, especially in areas that experience frequent contact. Understanding the wear characteristics helps businesses set realistic expectations for product lifespan and maintenance needs.

Illustrative image related to alcantara material

What Are Common Trade Terms Associated with Alcantara Material?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some key terms relevant to Alcantara:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Alcantara, it often pertains to automotive manufacturers that utilize Alcantara in their vehicle interiors. Understanding OEM relationships can help buyers identify reliable suppliers and assess compatibility with their product lines.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For Alcantara materials, MOQs can vary based on the supplier and the specific product. Recognizing MOQs is essential for B2B buyers to plan inventory and budget effectively while ensuring they meet production requirements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific quantities of products. When dealing with Alcantara, submitting an RFQ helps buyers understand costs and terms, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers importing Alcantara to clarify shipping, insurance, and delivery responsibilities.

Illustrative image related to alcantara material

5. Sustainability Certification

This term refers to standards and certifications that indicate a product’s environmental sustainability. Alcantara has a strong commitment to sustainability, and understanding these certifications can help buyers align with eco-friendly practices and meet consumer demands for responsible sourcing.

Incorporating these properties and terms into your procurement strategy will enhance your understanding of Alcantara material and facilitate more effective business transactions.

Navigating Market Dynamics and Sourcing Trends in the alcantara material Sector

Market Overview & Key Trends

The Alcantara material sector is experiencing notable growth driven by diverse global trends and consumer demands. As a synthetic textile renowned for its versatility and premium feel, Alcantara has found applications across various industries, including automotive, fashion, and interior design. The increasing preference for sustainable and ethically produced materials is a significant factor influencing market dynamics, particularly among international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

Emerging technologies are reshaping sourcing strategies, with a growing emphasis on digital platforms for procurement. B2B buyers are leveraging online marketplaces and supply chain management software to streamline their sourcing processes. This shift not only enhances efficiency but also provides access to a broader range of suppliers and innovative designs. Additionally, the trend towards customization is gaining traction, as buyers seek tailor-made solutions that align with their brand values and customer expectations.

In the automotive sector, Alcantara’s use is expanding beyond luxury vehicles to include mainstream models, making it more accessible to a wider audience. This shift reflects a broader trend of integrating high-quality materials into everyday products, thereby enhancing perceived value. As a result, international buyers must stay attuned to these evolving market dynamics to effectively navigate the competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a cornerstone of the Alcantara material sector, with increasing scrutiny on environmental impact and ethical sourcing practices. Alcantara is produced using a proprietary blend of polyester and polyurethane, and the company places a strong emphasis on reducing its carbon footprint throughout the manufacturing process. This commitment resonates particularly well with B2B buyers who prioritize sustainability in their procurement decisions.

Ethical supply chains are becoming non-negotiable for many businesses, driven by consumer demand for transparency and accountability. Buyers are encouraged to seek suppliers that offer certifications demonstrating adherence to environmental standards and responsible sourcing practices. Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® are increasingly relevant, as they provide assurance of a material’s sustainability credentials.

Illustrative image related to alcantara material

Moreover, Alcantara’s vegan-friendly nature and absence of animal-derived components align with the values of many brands aiming to appeal to eco-conscious consumers. By prioritizing suppliers who adhere to ethical sourcing practices, international buyers can not only enhance their brand reputation but also contribute positively to the global push for sustainability.

Brief Evolution/History of Alcantara Material

Developed in the 1970s by a Japanese chemist, Alcantara material has undergone significant evolution since its inception. Originally designed as a synthetic alternative to suede, Alcantara quickly gained popularity in the automotive industry, particularly for its superior grip and durability. The Italian company Alcantara S.p.A. has since positioned itself as a global leader in the production of this versatile textile.

Over the decades, Alcantara has expanded its applications into various sectors, including fashion, interior design, and luxury goods. The brand’s commitment to innovation and sustainability has been pivotal in maintaining its relevance and appeal in a competitive market. As Alcantara continues to evolve, it remains a benchmark for quality and design, making it an attractive choice for international B2B buyers seeking cutting-edge materials that align with contemporary consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara material

1. How do I evaluate the quality of Alcantara material when sourcing?

To assess the quality of Alcantara, request samples from potential suppliers. Examine the texture, color consistency, and durability. A high-quality Alcantara should have a soft, suede-like feel and maintain its appearance over time. Additionally, inquire about the manufacturing process and any certifications related to sustainability and compliance with international standards. Quality assurance protocols should be in place, including testing for wear resistance and colorfastness, which are crucial for applications in automotive and fashion industries.

2. What are the typical minimum order quantities (MOQs) for Alcantara material?

Minimum order quantities for Alcantara can vary significantly based on the supplier and specific product requirements. Generally, MOQs range from 50 to 200 meters for bulk purchases. However, it’s advisable to negotiate with suppliers, especially if you are a new buyer or need custom specifications. Discussing your project scope and potential for repeat orders can help in securing more favorable terms. Always confirm MOQs upfront to align your sourcing strategy with your production needs.

3. How do I ensure sustainable sourcing of Alcantara material?

To ensure sustainable sourcing, partner with suppliers who adhere to environmental and ethical standards. Verify that the Alcantara is produced using eco-friendly processes and materials. Request documentation regarding sustainability certifications, such as ISO 14001 or similar. Additionally, inquire about the supplier’s commitment to reducing carbon footprints and waste management practices. Engaging with suppliers who prioritize sustainability can enhance your brand’s reputation and appeal to environmentally-conscious consumers.

4. What payment terms should I expect when sourcing Alcantara?

Payment terms for Alcantara can vary based on supplier policies, order size, and buyer history. Common arrangements include net 30, 60, or 90 days, requiring a deposit upfront—typically 30%—with the balance due upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms during negotiations to avoid misunderstandings and ensure smooth financial transactions.

5. How do I vet potential suppliers of Alcantara material?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with industry standards. Start by researching their history and customer reviews. Request references from previous clients and inquire about their experience with the supplier. It’s also crucial to evaluate their production processes, quality control measures, and delivery timelines. Conducting factory visits or audits can further enhance your confidence in their reliability and operational efficiency.

Illustrative image related to alcantara material

6. What customization options are available for Alcantara material?

Most suppliers offer a variety of customization options for Alcantara, including color selection, texture variations, and specific finishes. You can also request bespoke patterns or branding elements for unique applications in automotive, fashion, or interior design. Discuss your requirements with suppliers to explore available options and lead times for customization. Be clear about your project specifications to ensure the final product meets your design vision and functional needs.

7. How does Alcantara compare to other materials in terms of durability?

Alcantara is known for its superior durability compared to traditional suede and leather. It is resistant to wear, staining, and fading, making it ideal for high-traffic applications. However, it requires regular maintenance to preserve its aesthetic appeal, as it can absorb oils and dirt. In contrast, while leather may offer a premium feel, it can be more susceptible to damage from moisture and requires more intensive care. Evaluate your specific use case to determine the best material choice for longevity and performance.

8. What logistics considerations should I keep in mind when importing Alcantara?

When importing Alcantara, consider factors such as shipping costs, customs duties, and delivery timelines. Work with suppliers who have experience in international logistics to ensure smooth handling of documentation and compliance with local regulations. It’s advisable to select reliable shipping partners and discuss potential risks, including delays or damage during transit. Establishing clear communication regarding shipping terms can facilitate a seamless procurement process and help manage expectations effectively.

Top 7 Alcantara Material Manufacturers & Suppliers List

1. Alcantara – Versatile Luxury Material

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its versatility and excellence. It combines aesthetics and performance, making it suitable for various applications in art, design, fashion, and luxury. The material is characterized by its technology, functionality, emotion, and commitment to sustainability. Alcantara is involved in numerous collaborations, including capsule collections with Japanese fa…

2. Keyston Bros – Alcantara Suede Automotive Fabric

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Pricing requires login to view. Features include various roll sizes, cleaning codes, abrasion ratings, and UFAC class specifications.

3. Alcantara – Synthetic Suede Fabric

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic suede-like fabric made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is commonly used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame retardant…

4. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor of Alcantara in North America, offering a comprehensive range of Alcantara products used by luxury auto brands in Europe. Alcantara is 100% made in Italy and is known for its style, elegance, and functionality while being environmentally friendly. The product range includes: 1. Alcantara Panel: Unbacked, thin, and workable fabric for headliners, doors, and…

5. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Pricing starts at $134.99 for various colors, including Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, R…

6. Upholstery Supply USA – Alcantara for Panels – Anthracite Black

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Alcantara for Panels – Anthracite Black (#9002)”, “Price”: {“1 to 9 yards”: “$135.00”, “10 to 24 yards”: “$130.00”, “25+ yards”: “$125.00”}, “Roll Width”: “56 inches”, “Thickness”: “1.0 mm”, “Material Type”: “Unbacked Alcantara Textile”, “Origin”: “Made in Italy”, “Applications”: [“Automotive Interior”, “Door Panels”, “Headliners”, “Interior Trim Surfaces”], “Care Instructions”: …

7. Alcantara – Synthetic Suedelike Material

Domain: motortrend.com

Registered: 1998 (27 years)

Introduction: Alcantara is a synthetic suedelike material made up of 68% polyester and 32% non-fibrous polyurethane. It was invented in the early 1970s by Miyoshi Okamoto and is produced in Italy by Alcantara S.p.A. The fabric is commonly used in high-end automobile interiors and aftermarket parts, often replacing or complementing leather on seats, dashboards, and other surfaces. Alcantara has a matte finish th…

Strategic Sourcing Conclusion and Outlook for alcantara material

As businesses navigate the complexities of sourcing materials, Alcantara stands out as a premium choice that marries aesthetics with functionality. This versatile synthetic textile not only enhances the design of automotive interiors and luxury goods but also aligns with sustainability goals, making it an attractive option for environmentally-conscious companies. The unique properties of Alcantara, including its durability and ease of maintenance, underscore its value proposition, particularly in high-end applications across various industries.

Strategic sourcing of Alcantara can lead to significant advantages, including improved brand perception and customer satisfaction. As international buyers from regions such as Africa, South America, the Middle East, and Europe explore innovative materials, leveraging Alcantara can set them apart in competitive markets. The continued evolution of this material, driven by technological advancements and creative collaboration, promises to open new avenues for application and differentiation.

Illustrative image related to alcantara material

Looking ahead, businesses are encouraged to consider Alcantara not just as a material but as a strategic asset. Engage with suppliers to explore tailored solutions that meet your specific needs, thereby enhancing your product offerings and brand identity. Embrace the future of design with Alcantara, where luxury meets sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to alcantara material