Introduction: Navigating the Global Market for leather manufacturers in usa

In the dynamic world of international trade, sourcing high-quality leather manufacturers in the USA presents both opportunities and challenges for B2B buyers. With the growing demand for premium leather goods across various industries, from fashion to automotive, understanding the intricacies of the US leather market is crucial. This guide serves as an essential resource for international buyers, particularly those from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Saudi Arabia.

The comprehensive scope of this guide encompasses various aspects of the leather manufacturing sector, including types of leather, applications in different industries, effective supplier vetting processes, and insights into cost structures. By addressing common challenges such as identifying reliable suppliers and understanding material specifications, this guide equips buyers with the knowledge needed to make informed purchasing decisions.

With detailed insights into the nuances of the US leather market, buyers can navigate supplier landscapes with confidence, ensuring they source products that meet their quality standards and business needs. Whether you are seeking handcrafted items or mass-produced goods, this guide aims to streamline your procurement process and enhance your strategic sourcing capabilities in the competitive global marketplace.

Table Of Contents

- Top 4 Leather Manufacturers In Usa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather manufacturers in usa

- Understanding leather manufacturers in usa Types and Variations

- Key Industrial Applications of leather manufacturers in usa

- 3 Common User Pain Points for ‘leather manufacturers in usa’ & Their Solutions

- Strategic Material Selection Guide for leather manufacturers in usa

- In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturers in usa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturers in usa’

- Comprehensive Cost and Pricing Analysis for leather manufacturers in usa Sourcing

- Alternatives Analysis: Comparing leather manufacturers in usa With Other Solutions

- Essential Technical Properties and Trade Terminology for leather manufacturers in usa

- Navigating Market Dynamics and Sourcing Trends in the leather manufacturers in usa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturers in usa

- Strategic Sourcing Conclusion and Outlook for leather manufacturers in usa

- Important Disclaimer & Terms of Use

Understanding leather manufacturers in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains the natural grain and texture, highest quality | Luxury goods, high-end fashion accessories | Pros: Durability, luxurious appearance. Cons: Higher cost, limited availability. |

| Top Grain Leather | Sanded and finished surface, softer than full grain | Apparel, handbags, and furniture | Pros: Soft feel, less expensive than full grain. Cons: Less durable than full grain. |

| Genuine Leather | Made from layers of lower-quality leather, often bonded | Budget-friendly products like wallets and bags | Pros: Cost-effective, widely available. Cons: Shorter lifespan, less luxurious feel. |

| Suede Leather | Soft, napped finish, typically made from the underside of leather | Apparel, shoes, and accessories | Pros: Unique texture, lightweight. Cons: Less water-resistant, requires more care. |

| Exotic Leather | Derived from non-traditional sources (e.g., alligator, ostrich) | High-end fashion, luxury goods | Pros: Unique aesthetic, high value. Cons: Ethical concerns, high cost, and limited supply. |

What are the Characteristics and Suitability of Full Grain Leather for B2B Buyers?

Full grain leather is the pinnacle of leather quality, retaining the hide’s natural texture and imperfections. It is often used in luxury goods, such as high-end handbags and wallets, due to its durability and aesthetic appeal. For B2B buyers, sourcing full grain leather can signal a commitment to quality, making it suitable for brands aiming to position themselves in the luxury market. However, the higher cost and limited availability may require buyers to establish strong relationships with reputable suppliers.

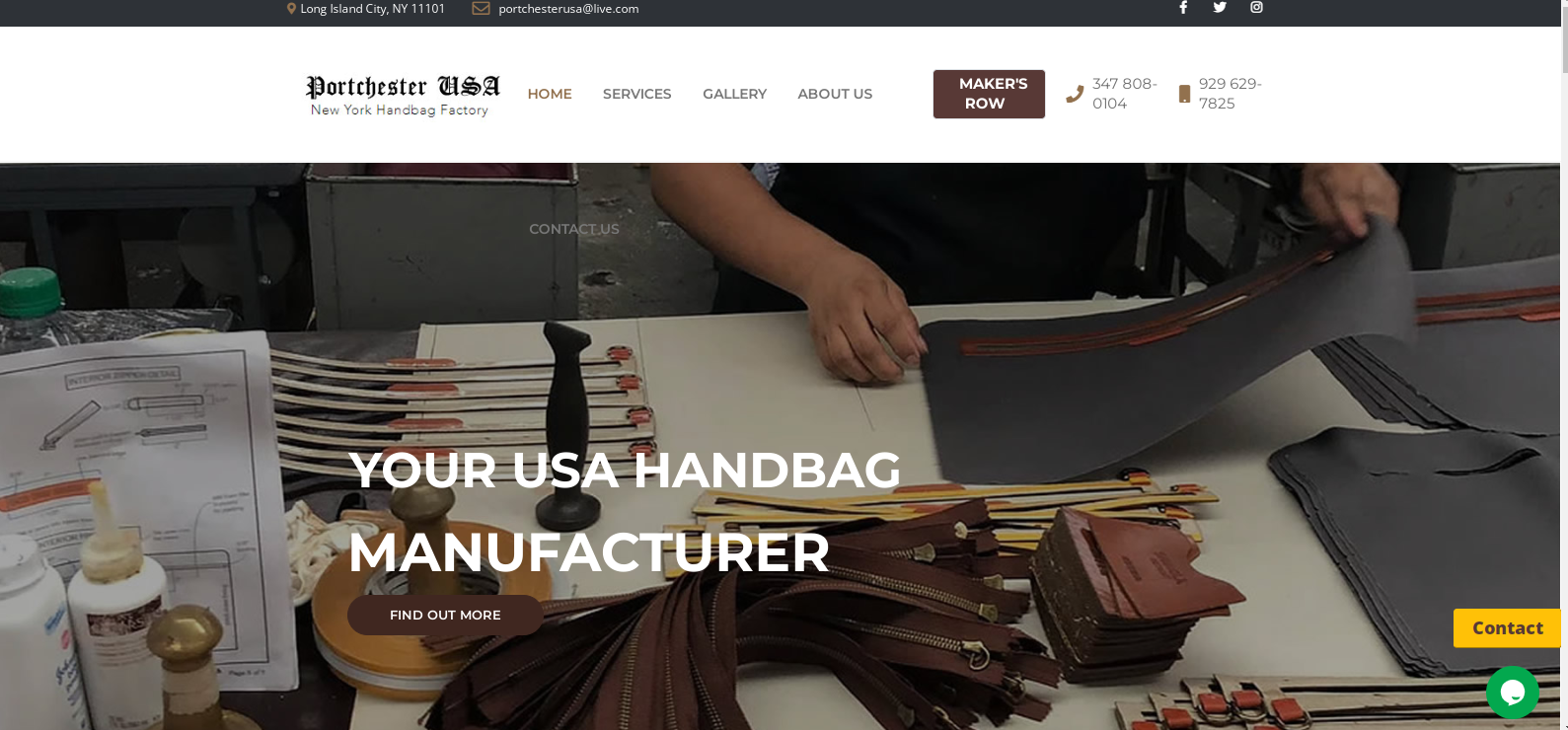

Illustrative image related to leather manufacturers in usa

How Does Top Grain Leather Compare for Various B2B Applications?

Top grain leather is slightly lower in quality than full grain, as it undergoes sanding and finishing, which gives it a softer texture. This type is commonly used in apparel, handbags, and furniture. For businesses focused on a balance of quality and price, top grain leather offers a compelling option. It is more accessible than full grain leather and can be ideal for brands looking to produce premium products without the associated costs of the highest-quality materials.

Why Choose Genuine Leather for Budget-Friendly Products?

Genuine leather is made from the layers of lower-quality leather and is often bonded together, making it a more affordable option. It is widely used for budget-friendly products like wallets, bags, and belts. B2B buyers may find genuine leather appealing for entry-level product lines or promotions. However, they should be aware of its shorter lifespan and less luxurious feel compared to higher-grade leathers, which could affect brand perception.

What Makes Suede Leather a Unique Choice for B2B Buyers?

Suede leather is characterized by its soft, napped finish, typically made from the underside of the hide. It is often used in apparel, shoes, and accessories, providing a unique texture that can enhance product appeal. For B2B buyers, suede can attract consumers looking for fashionable, lightweight options. However, it requires more maintenance and care, and its lower water resistance may limit its applications, particularly in outdoor or rugged environments.

What Should Buyers Consider When Sourcing Exotic Leather?

Exotic leather, sourced from non-traditional animals such as alligators and ostriches, offers a unique aesthetic and high value, making it desirable for high-end fashion and luxury goods. For B2B buyers, exotic leather can enhance brand prestige and attract affluent customers. However, ethical concerns surrounding sourcing and the high costs associated with these materials may pose challenges. Buyers must navigate these considerations carefully while ensuring compliance with regulations and consumer expectations.

Key Industrial Applications of leather manufacturers in usa

| Industry/Sector | Specific Application of leather manufacturers in usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather garments and accessories | High-quality, durable products that enhance brand image | Material sourcing, craftsmanship, lead times |

| Automotive | Leather upholstery for vehicles | Improved aesthetic appeal and luxury feel | Material quality, compliance with safety standards |

| Footwear | Production of leather shoes | Comfort and durability that meets consumer demands | Sizing options, style variations, production timelines |

| Home Furnishings | Leather upholstery for furniture | Adds luxury and comfort to living spaces | Color options, texture preferences, maintenance requirements |

| Sporting Goods | Leather goods for sports equipment (e.g., gloves) | Enhanced performance and durability for athletes | Customization options, material performance standards |

How Are Leather Manufacturers in the USA Applied in the Fashion & Apparel Industry?

In the fashion and apparel sector, leather manufacturers in the USA produce custom garments and accessories that are tailored to meet specific client needs. This includes high-end fashion items that require exceptional craftsmanship and unique designs. For international buyers, especially from regions like Africa and South America, the emphasis on sourcing ethically produced leather can enhance brand reputation. Buyers must consider material quality, craftsmanship, and lead times, ensuring that the final product aligns with their brand’s image and market expectations.

What Role Does Leather Play in the Automotive Sector?

Leather manufacturers supply the automotive industry with premium upholstery materials that elevate vehicle interiors. This application not only enhances the aesthetic appeal of cars but also contributes to a luxurious feel that consumers seek. For B2B buyers in the Middle East and Europe, understanding compliance with local safety and environmental standards is crucial when sourcing leather. Factors such as material quality and durability, alongside the manufacturer’s ability to meet specific design requirements, are essential considerations.

Why is Leather Important for Footwear Production?

The footwear industry leverages leather for the production of high-quality shoes that combine style with durability. Leather shoes provide comfort and longevity, meeting the demands of discerning consumers. International buyers, particularly from Europe and Brazil, should focus on sourcing options that offer various sizing and style variations. Additionally, production timelines are important to ensure timely market entry, especially during peak fashion seasons.

How is Leather Utilized in Home Furnishings?

In home furnishings, leather is a popular choice for upholstery in furniture items such as sofas and chairs. It adds a touch of luxury and comfort, appealing to consumers looking for high-end home decor. Buyers from diverse markets must consider factors like color options, texture preferences, and maintenance requirements when sourcing leather upholstery. Understanding the durability and care needed for different leather types can influence purchasing decisions significantly.

Illustrative image related to leather manufacturers in usa

What Are the Applications of Leather in Sporting Goods?

Leather is a vital material in the sporting goods sector, particularly for items like gloves and protective gear. These products benefit from leather’s durability and ability to withstand rigorous use. For international buyers, customization options and adherence to material performance standards are key considerations. Ensuring that the leather used meets specific performance requirements can enhance the quality and appeal of sporting goods, making them more attractive to consumers.

3 Common User Pain Points for ‘leather manufacturers in usa’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality Consistency Across Orders

The Problem: B2B buyers often face challenges with the consistency of leather quality when sourcing from manufacturers in the USA. Variability in materials, craftsmanship, and finishing processes can lead to discrepancies between orders. This inconsistency can jeopardize product quality and customer satisfaction, especially for businesses that rely on uniformity in their product lines, such as fashion brands or furniture manufacturers.

The Solution: To ensure quality consistency, B2B buyers should establish a robust quality assurance protocol with their chosen leather manufacturers. This involves creating a detailed specification document that outlines the expected standards for leather quality, including grain texture, color, and finish. Additionally, it’s advisable to request samples before placing large orders. Implementing regular audits of the manufacturing process can also help maintain quality control. Building a strong, communicative relationship with the supplier and providing feedback can further ensure that expectations are consistently met.

Scenario 2: Navigating Complex Shipping and Import Regulations

The Problem: International buyers often encounter complex shipping and import regulations when sourcing leather products from the USA. Different countries have varying import duties, tariffs, and environmental regulations concerning leather goods. This can lead to unexpected delays, additional costs, and even confiscation of goods if regulations are not adequately followed.

The Solution: B2B buyers should conduct thorough research on their country’s import regulations regarding leather products before engaging with manufacturers. Engaging a customs broker can significantly streamline this process. They can provide insights into necessary documentation, tariffs, and shipping methods. Additionally, buyers should consider manufacturers who offer comprehensive shipping services, including assistance with customs clearance. This proactive approach will mitigate risks and ensure smoother logistics from the USA to the buyer’s destination.

Scenario 3: Limited Customization Options for Unique Designs

The Problem: Many B2B buyers require customized leather products tailored to their specific design needs. However, some manufacturers may have limited capabilities when it comes to customization, resulting in a lack of flexibility that can hinder a buyer’s ability to create unique products that stand out in the market.

The Solution: To overcome this limitation, buyers should seek out leather manufacturers that specialize in bespoke services. When approaching potential suppliers, it’s crucial to clearly communicate design expectations and flexibility in terms of materials and processes. Providing detailed sketches or prototypes can help manufacturers understand the buyer’s vision better. Additionally, buyers should ask about the manufacturer’s experience with custom orders and request a portfolio of past projects. Building a partnership with manufacturers who are open to innovation can lead to fruitful collaboration and unique product offerings that resonate with target markets.

Strategic Material Selection Guide for leather manufacturers in usa

What Are the Key Materials Used by Leather Manufacturers in the USA?

When selecting materials for leather manufacturing, several options stand out due to their unique properties and applications. Understanding these materials is crucial for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. Here, we analyze four common materials used in leather production, focusing on their properties, advantages, disadvantages, and considerations for international trade.

What Are the Key Properties of Full Grain Leather?

Full grain leather is renowned for its durability and natural appearance. It retains the animal’s original grain, making it less processed than other types. This type of leather is highly resistant to wear and tear, providing excellent temperature stability and moisture resistance, which is vital for products exposed to varying environmental conditions.

Illustrative image related to leather manufacturers in usa

Pros: Full grain leather is exceptionally durable, develops a beautiful patina over time, and is suitable for high-end products such as luxury handbags and wallets.

Cons: The cost is relatively high due to the quality and sourcing of the hides, and it may require more complex manufacturing processes, including specialized stitching and finishing techniques.

Impact on Application: Full grain leather is ideal for high-quality goods that demand longevity and aesthetic appeal, making it a preferred choice for luxury brands.

Illustrative image related to leather manufacturers in usa

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM for leather quality. Additionally, regions like Europe may have specific regulations regarding animal welfare and sourcing practices.

How Does Top Grain Leather Compare?

Top grain leather is another popular choice, often used in a variety of leather goods. It is slightly processed, which makes it more uniform in appearance compared to full grain leather. It offers good resistance to stains and is easier to clean.

Pros: It provides a balance between quality and cost, making it suitable for a wide range of products, from furniture to fashion accessories.

Cons: While durable, top grain leather is not as robust as full grain leather and may show signs of wear more quickly. It also lacks the unique character and aging qualities of full grain leather.

Impact on Application: This material is versatile and can be used in both casual and formal products, appealing to a broad market segment.

Considerations for International Buyers: Buyers should be aware of the varying quality grades and ensure that the leather meets local standards for durability and safety.

What Are the Advantages of Suede Leather?

Suede leather, known for its soft texture, is derived from the inner layer of the animal hide. It is often used in garments, shoes, and accessories due to its luxurious feel.

Illustrative image related to leather manufacturers in usa

Pros: Suede offers a unique aesthetic and is lightweight, making it ideal for fashion items that require comfort and style.

Cons: It is less durable than full grain or top grain leather and is more susceptible to stains and water damage, which can limit its applications.

Impact on Application: Suede is often used in fashion-forward products but may not be suitable for items requiring high durability.

Considerations for International Buyers: Buyers should consider the environmental conditions of their market, as suede may require specific care and maintenance to preserve its quality.

Illustrative image related to leather manufacturers in usa

How Does Synthetic Leather Fit into the Market?

Synthetic leather, or faux leather, is made from various materials, including polyurethane and polyvinyl chloride (PVC). It is increasingly popular due to its cost-effectiveness and ethical considerations.

Pros: Synthetic leather is often cheaper, easier to maintain, and available in a variety of colors and textures. It is also cruelty-free, appealing to environmentally conscious consumers.

Cons: It typically lacks the durability and breathability of genuine leather and may not age as gracefully.

Impact on Application: Synthetic leather is suitable for budget-friendly products and can be used in a variety of applications, from casual wear to upholstery.

Considerations for International Buyers: Buyers must ensure that synthetic materials comply with local regulations regarding chemical safety and environmental impact.

Summary Table of Material Selection

| Material | Typical Use Case for leather manufacturers in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury handbags, wallets, high-end goods | Exceptional durability and aesthetic | High cost and complex manufacturing | Elevado |

| Top Grain Leather | Fashion accessories, furniture | Good balance of quality and cost | Less durable than full grain | Medium |

| Suede Leather | Garments, shoes, fashion accessories | Soft texture and lightweight | Susceptible to stains and water damage | Medium |

| Couro sintético | Budget-friendly products, upholstery | Cost-effective and cruelty-free | Lacks durability and breathability | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to navigate the diverse landscape of leather manufacturing in the USA. Understanding these materials will aid in making informed purchasing decisions that align with market demands and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturers in usa

What Are the Key Stages in Leather Manufacturing for B2B Buyers?

The manufacturing of leather products involves a series of meticulous processes that ensure high-quality outcomes suitable for various applications. Understanding these stages can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed decisions when sourcing leather goods.

Material Preparation: How Is Leather Sourced and Treated?

The first step in leather manufacturing is material preparation, which typically involves sourcing raw hides from livestock. The quality of the leather begins with the selection of hides, which should be free from blemishes and defects. After sourcing, the hides undergo preservation through salting or drying to prevent decay.

Once preserved, the hides are soaked in water to rehydrate them, followed by a process known as liming. This step involves treating the hides with lime to remove hair and other unwanted substances. Following liming, the hides are fleshed to remove excess fat and connective tissues, ensuring a clean surface for tanning.

What Techniques Are Used in Forming Leather Products?

The next stage is forming, where the treated hides are cut into specific shapes based on product designs. This step often employs advanced cutting techniques, such as die-cutting and laser cutting, to ensure precision and minimize waste.

Illustrative image related to leather manufacturers in usa

After cutting, the leather pieces are skived to adjust their thickness and are sometimes dyed at this stage to achieve the desired color. Techniques like airbrushing and hand-dyeing are common, allowing for a range of finishes that cater to diverse market preferences.

How Are Leather Goods Assembled?

Once the leather is prepared and cut, assembly begins. This stage involves stitching or bonding the leather pieces together. Skilled artisans often hand-stitch high-end products, providing durability and a unique finish. For mass-produced items, industrial sewing machines are employed to enhance efficiency.

Quality assurance starts during assembly, where skilled workers inspect stitching and alignment to ensure consistency with design specifications. This attention to detail is crucial for maintaining the brand’s reputation and meeting customer expectations.

What Finishing Techniques Enhance Leather Quality?

The finishing stage is where leather products are treated to enhance their durability, appearance, and feel. Techniques such as polishing, waxing, and applying protective coatings are commonly used to achieve the desired finish. These processes not only improve aesthetics but also contribute to the leather’s resistance to wear and moisture.

Illustrative image related to leather manufacturers in usa

Additionally, embossing or debossing techniques can be employed to add branding or decorative elements, further personalizing the product for clients.

What International Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance in leather manufacturing is vital, especially for international B2B buyers who expect consistent quality across suppliers. The ISO 9001 standard is widely recognized and ensures that manufacturers maintain quality management systems to enhance customer satisfaction.

Moreover, industry-specific certifications such as CE marking (for compliance with European safety standards) and API standards (for specific applications) are also crucial. Buyers should verify that suppliers hold these certifications, indicating adherence to international quality and safety norms.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints are integral to the leather manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to catch defects early. This includes checking stitching quality, color consistency, and material integrity.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure they meet all quality requirements.

B2B buyers should inquire about these QC checkpoints when evaluating potential suppliers, as they reflect the manufacturer’s commitment to quality.

Illustrative image related to leather manufacturers in usa

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to quality control standards, B2B buyers can take several proactive steps:

- Request Audits and Reports: Buyers should ask for documentation of past quality audits and reports to gauge the supplier’s quality management practices.

- Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures.

- Conduct On-Site Visits: If feasible, visiting the manufacturing facility can offer valuable insights into the production processes and quality assurance practices in place.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international B2B buyers, understanding the nuances of quality control in different regions is essential. Some countries may have varying standards and practices, which can impact product quality. For instance, buyers from Brazil and Saudi Arabia may encounter differing expectations regarding leather grades and treatments.

Moreover, cultural factors can influence quality perceptions. Buyers should communicate clearly about their quality expectations and ensure that suppliers understand the specific requirements of their target markets.

By being informed about manufacturing processes and quality assurance practices, B2B buyers can make educated decisions when sourcing leather products from manufacturers in the USA. This knowledge not only enhances supplier relationships but also ensures that the final products meet the necessary standards for their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturers in usa’

Introdução

Sourcing leather manufacturers in the USA can be a complex process, especially for international B2B buyers. This step-by-step checklist is designed to guide you through the essential actions needed to identify and engage with reliable leather manufacturers. By following these steps, you can ensure quality, compliance, and a good fit for your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline your technical requirements for leather products. This includes specifying the type of leather (e.g., full-grain, top-grain, or genuine leather), thickness, finish, and intended use (e.g., apparel, accessories, upholstery). A well-defined specification helps streamline communication and ensures that manufacturers can meet your expectations.

Illustrative image related to leather manufacturers in usa

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential leather manufacturers in the USA. Utilize online directories, trade shows, and industry publications to compile a list. Pay attention to factors such as their production capacity, specialization, and reputation in the market. This groundwork will save you time and effort in the later stages of sourcing.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of shortlisted manufacturers by reviewing their production processes and technology. Look for manufacturers that utilize modern machinery and techniques, as this can impact quality and lead times. Inquire about their experience with international orders and their ability to scale production according to your needs.

Step 4: Verify Supplier Certifications

Ensure that the manufacturers you consider have relevant certifications that demonstrate compliance with industry standards. Certifications such as ISO 9001 for quality management systems or environmental standards (e.g., Leather Working Group certification) indicate a commitment to quality and sustainability. This verification helps mitigate risks associated with subpar suppliers.

Illustrative image related to leather manufacturers in usa

Step 5: Request Samples and Prototypes

Before making a commitment, request samples or prototypes of the leather products you intend to order. This step is crucial for assessing the quality of materials, craftsmanship, and overall design. Evaluate the samples against your specifications and consider testing them for durability and performance under real-world conditions.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable manufacturer, engage in negotiations regarding pricing, payment terms, minimum order quantities, and lead times. Clarity on these points is essential to avoid misunderstandings later in the process. Ensure that all agreements are documented in a formal contract to protect both parties.

Step 7: Establish Communication Channels

Set up clear communication channels with your chosen manufacturer. Regular communication is vital for maintaining transparency and addressing any issues that may arise during production. Consider utilizing project management tools to facilitate updates and collaboration, ensuring that both parties are aligned throughout the sourcing process.

By following this checklist, you will be well-equipped to navigate the sourcing landscape for leather manufacturers in the USA, ensuring a successful partnership that meets your business requirements.

Comprehensive Cost and Pricing Analysis for leather manufacturers in usa Sourcing

What Are the Key Cost Components for Leather Manufacturing in the USA?

When sourcing leather products from manufacturers in the USA, understanding the cost structure is essential for international B2B buyers. The primary components include:

-

Materials: The type of leather used significantly impacts costs. Full-grain leather is generally more expensive due to its superior quality and durability compared to corrected grain or synthetic alternatives. Leather prices can fluctuate based on market demand, animal husbandry practices, and sourcing regions.

-

Labor: Skilled labor is a critical factor in the leather manufacturing process. The USA has higher labor costs than many other countries, reflecting the quality of craftsmanship. Handcrafted items, which are common in premium segments, will naturally command higher prices.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and equipment maintenance. Manufacturers with advanced machinery may have higher initial costs, but this can lead to greater efficiency and lower long-term production costs.

-

Tooling: Custom tooling for specialized products can be a significant upfront cost. Buyers should inquire about these costs, especially when ordering bespoke items or large volumes.

-

Quality Control (QC): Implementing strict QC measures adds to the manufacturing cost but ensures that products meet the required standards. This is especially crucial for international buyers who may have specific certification requirements.

-

Logistics: Shipping costs can vary widely based on the destination, weight, and dimensions of the leather goods. International buyers should factor in customs duties and taxes, which can add significantly to the total cost.

-

Margin: Manufacturers will include a profit margin in their pricing, which can vary based on market competition, brand reputation, and product uniqueness.

What Influences Pricing for Leather Goods from US Manufacturers?

Several factors can influence pricing structures, particularly for international buyers:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Manufacturers typically have minimum order quantities (MOQs), and negotiating these can yield better pricing.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly outline their requirements to get accurate quotes.

-

Quality and Certifications: Products that meet specific quality standards or certifications (like sustainable sourcing or organic leather) may have higher price points. Buyers should assess the value of these certifications against their needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands may charge a premium due to their track record of quality and service.

-

Incoterms: The agreed terms of trade (like FOB, CIF) can significantly impact the total landed cost. Understanding these terms is essential to avoid unexpected expenses.

How Can International Buyers Optimize Costs When Sourcing Leather Products?

For buyers from regions like Africa, South America, the Middle East, and Europe, several strategies can help optimize costs:

-

Negotiation: Engaging in open discussions about pricing, payment terms, and delivery schedules can lead to better deals. Manufacturers often appreciate buyers who show commitment to long-term partnerships.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the initial purchase price. Consider factors like durability, maintenance, and potential resale value.

-

Pricing Nuances: Be aware of currency fluctuations, tariffs, and trade agreements that could affect pricing. Understanding the economic landscape can help you negotiate better terms.

-

Supplier Relationships: Building strong relationships with suppliers can lead to preferential pricing, early access to new products, and more flexible terms.

Disclaimer

The prices mentioned herein are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always consult directly with manufacturers for accurate and up-to-date pricing information tailored to your needs.

Illustrative image related to leather manufacturers in usa

Alternatives Analysis: Comparing leather manufacturers in usa With Other Solutions

Exploring Alternative Solutions to Leather Manufacturing in the USA

In the dynamic world of leather production, international B2B buyers often seek alternatives that can meet their specific needs while providing quality, cost-effectiveness, and sustainability. Understanding these alternatives is crucial for making informed decisions, especially when sourcing leather goods or materials. This analysis compares leather manufacturers in the USA with two viable alternatives: synthetic leather production and textile-based solutions.

| Comparison Aspect | Leather Manufacturers In USA | Synthetic Leather Production | Textile-Based Solutions |

|---|---|---|---|

| Performance | High durability, classic appeal, and natural aesthetics | Good durability, versatile designs, and lighter weight | Varies by fabric; may lack durability compared to leather |

| Cost | Generally higher due to craftsmanship and material quality | Often lower than genuine leather; price varies based on quality | Typically lower, but performance and longevity can be inconsistent |

| Ease of Implementation | Established supply chains and experienced artisans | Rapid production capabilities, but quality control can be a challenge | Easy to source, with a wide range of suppliers available |

| Maintenance | Requires regular care to maintain appearance; can last decades | Low maintenance; easy to clean but may wear out faster | Depends on the fabric; some may require special care |

| Best Use Case | Luxury goods, fashion accessories, and durable items | Fashion items, affordable alternatives, and eco-friendly options | Casual wear, promotional items, and cost-sensitive projects |

What are the Pros and Cons of Synthetic Leather Production?

Synthetic leather, often made from polyurethane or PVC, serves as a popular alternative to genuine leather. One of its main advantages is cost-effectiveness; it is generally cheaper to produce, allowing businesses to offer competitive pricing. Additionally, synthetic leather can be manufactured in various colors and textures, appealing to diverse consumer preferences. However, the durability of synthetic leather can be a drawback; it may not withstand wear and tear as effectively as natural leather. Furthermore, while some synthetic options are marketed as eco-friendly, the production process can still involve harmful chemicals.

How Do Textile-Based Solutions Compare to Leather Manufacturing?

Textile-based solutions encompass a broad range of materials, including cotton, polyester, and blends. These alternatives are often more affordable and accessible, making them an attractive option for budget-conscious buyers. They can also be produced in large quantities and offer a variety of design possibilities. However, textile materials may not provide the same durability or aesthetic appeal as leather, especially for high-end products. Moreover, they often lack the timeless quality that leather embodies, which can be a significant factor for brands aiming to convey luxury.

Conclusion: How Should B2B Buyers Choose the Right Leather Solution?

When selecting between leather manufacturers in the USA and alternative solutions, B2B buyers should consider several factors tailored to their specific needs. If quality, craftsmanship, and a luxury image are paramount, partnering with reputable leather manufacturers is advisable. Conversely, for projects where budget constraints or rapid production timelines are more critical, synthetic leather or textile options may offer viable solutions. Ultimately, understanding the unique benefits and limitations of each alternative will empower buyers to make informed decisions that align with their brand identity and market demands.

Illustrative image related to leather manufacturers in usa

Essential Technical Properties and Trade Terminology for leather manufacturers in usa

What Are the Key Technical Properties Important for Leather Manufacturers in the USA?

Understanding the essential technical properties of leather is crucial for B2B buyers, as these specifications directly impact product quality, durability, and suitability for various applications. Below are some critical specifications to consider:

1. Material Grade

Material grade indicates the quality of the leather, which can range from full-grain to corrected grain. Full-grain leather retains the natural grain and imperfections, making it the highest quality available. It is more durable and develops a patina over time. On the other hand, corrected grain leather undergoes sanding and finishing, which can diminish its natural characteristics. Knowing the material grade helps buyers assess the longevity and aesthetic appeal of leather goods.

2. Tolerance

Tolerance refers to the acceptable variations in thickness and dimensions of leather hides. For instance, a tolerance of ±1mm in thickness ensures that the leather meets the specific requirements for various products. Accurate tolerances are critical for manufacturers to ensure consistent quality, especially when producing components that must fit together precisely. This is particularly important for sectors like automotive or fashion, where precision impacts both functionality and visual appeal.

3. Weight

Leather weight is measured in ounces per square foot (oz/sq ft) and indicates the thickness and sturdiness of the material. For example, lighter leathers (2-3 oz) are often used for garments, while heavier leathers (4-6 oz) are suitable for bags and furniture. Understanding leather weight helps buyers choose the right type for their intended application, ensuring that the final product meets performance standards.

4. Finish Type

The finish type refers to the surface treatment applied to the leather, which can affect its texture, appearance, and durability. Common finishes include aniline (natural look), semi-aniline (slightly protected), and pigmented (highly durable). Each finish type serves different market needs, so understanding the implications of each is essential for buyers looking to meet specific aesthetic or functional requirements.

Illustrative image related to leather manufacturers in usa

5. Breathability

Breathability refers to the ability of leather to allow air and moisture to pass through it. This property is particularly important for garments and footwear, as it affects comfort and moisture management. High-quality leather typically offers better breathability, which can enhance the product’s overall performance and wearer satisfaction.

What Trade Terminology Should B2B Buyers Know in the Leather Industry?

Familiarity with industry jargon can significantly streamline communication and negotiations between manufacturers and buyers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this can refer to companies that create leather products under another brand’s name. Understanding OEM relationships can help buyers navigate sourcing and branding strategies effectively.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand, as it can impact inventory management and cash flow. Knowing the MOQ helps buyers plan their purchases and avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. It is commonly used in the procurement process to compare costs and terms. Providing a clear RFQ can ensure that buyers receive accurate and comparable quotes, facilitating better decision-making.

Illustrative image related to leather manufacturers in usa

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. They define who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks in international transactions, ensuring smoother trade processes.

5. ASTM (American Society for Testing and Materials)

ASTM standards define the specifications and testing methods for various materials, including leather. Knowledge of relevant ASTM standards can help buyers ensure compliance with industry regulations and quality benchmarks, enhancing product reliability.

By understanding these technical properties and industry terms, international B2B buyers can make informed decisions, ensuring that they source high-quality leather products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the leather manufacturers in usa Sector

What Are the Current Market Dynamics and Key Trends in the Leather Manufacturing Sector in the USA?

The leather manufacturing sector in the USA is experiencing significant transformations driven by global economic shifts, consumer preferences, and technological advancements. Key trends include the increasing demand for high-quality, handcrafted leather goods, which are particularly appealing to international markets seeking unique and durable products. B2B buyers from Africa, South America, the Middle East, and Europe are increasingly sourcing from US manufacturers due to their reputation for quality and innovation. The rise of e-commerce platforms has further facilitated this trend, enabling buyers to access a wider range of products from different suppliers without geographical constraints.

Emerging technologies such as automation and digital supply chain management are reshaping the sourcing landscape. Manufacturers are leveraging advanced analytics to optimize inventory levels and enhance production efficiency, which is vital for meeting the evolving demands of international buyers. Additionally, the adoption of blockchain technology is gaining traction for its potential to increase transparency and traceability in supply chains, a critical factor for businesses aiming to ensure product authenticity and compliance with international standards.

Illustrative image related to leather manufacturers in usa

How Is Sustainability and Ethical Sourcing Shaping the Leather Industry?

Sustainability and ethical sourcing have become paramount concerns in the leather manufacturing sector. The environmental impact of leather production, particularly in terms of water usage and chemical waste, has prompted a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers who adopt eco-friendly methods, such as vegetable tanning and the use of recycled materials. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential benchmarks for assessing the environmental credentials of manufacturers.

Moreover, ethical supply chains are gaining importance as consumers worldwide demand greater accountability from brands. For international buyers, partnering with manufacturers who prioritize fair labor practices and responsible sourcing can enhance brand reputation and customer loyalty. This trend is particularly relevant in markets like Europe, where regulations surrounding sustainability are stringent, making it crucial for US manufacturers to align with these expectations to remain competitive.

What Is the Historical Context of Leather Manufacturing in the USA?

The leather manufacturing industry in the USA has a rich history that dates back to the colonial era. Initially, the sector thrived on local resources and craftsmanship, with tanneries and leather goods manufacturers establishing themselves in various regions, particularly in the Northeast and Midwest. Over the years, the industry has evolved, influenced by technological advancements and changing consumer preferences.

Illustrative image related to leather manufacturers in usa

In the 20th century, mass production techniques began to dominate, leading to a decline in artisanal craftsmanship. However, the recent resurgence of interest in handmade and bespoke leather goods has reinvigorated the sector, pushing manufacturers to adopt a blend of traditional techniques and modern technology. This evolution is not just historical; it reflects a broader shift in consumer values towards quality and sustainability, positioning the USA as a leader in premium leather goods on the global stage.

Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturers in usa

-

How do I choose the right leather manufacturer in the USA?

When selecting a leather manufacturer, consider factors such as production capacity, specialization in leather types, and previous client reviews. Look for manufacturers who can demonstrate expertise in your specific product needs, whether it’s handbags, wallets, or garments. It’s also crucial to evaluate their compliance with international quality standards and ethical sourcing practices. Engaging in direct communication to discuss your requirements and assess their responsiveness can provide insights into their reliability and willingness to collaborate. -

What is the minimum order quantity (MOQ) when sourcing leather products?

Minimum order quantities can vary significantly between manufacturers. While some may offer flexible MOQs for custom orders, others might require larger quantities to optimize production efficiency. Typically, MOQs range from 50 to 500 units depending on the complexity of the product and customization options. It’s advisable to clarify MOQs upfront to align your sourcing strategy with your business needs, especially if you’re entering new markets or testing product demand. -

What customization options are available when working with US leather manufacturers?

Most US leather manufacturers offer a range of customization options, including leather type, color, size, and branding elements such as embossing or screen printing. It’s essential to communicate your specific design requirements clearly. Request samples to ensure the quality meets your standards before placing a larger order. Some manufacturers may also provide design assistance, which can be beneficial if you’re looking to create unique products that stand out in the market. -

What payment terms should I expect when sourcing from leather manufacturers in the USA?

Payment terms can vary widely among manufacturers. Common practices include deposits ranging from 30% to 50% upfront, with the balance due upon completion or before shipment. Some manufacturers might offer net payment terms, allowing a period (e.g., 30, 60, or 90 days) to settle the invoice after delivery. Ensure to discuss and negotiate payment terms early in your discussions to avoid any misunderstandings later in the process. -

How can I ensure quality assurance when sourcing leather products?

Quality assurance should be a critical aspect of your sourcing strategy. Request detailed information about the manufacturer’s quality control processes, including inspections at various production stages. It’s advisable to ask for product samples before committing to a larger order. Additionally, consider third-party quality inspections, especially if you are importing goods, to ensure they meet your specifications and international standards. -

What are the shipping and logistics considerations for importing leather goods from the USA?

When importing leather goods, consider factors such as shipping costs, timelines, and customs regulations in your country. Collaborate with your manufacturer to determine the most efficient shipping methods, whether by air or sea, and understand the associated costs. Familiarize yourself with import duties and taxes, as these can significantly impact your total landed cost. Establishing a reliable logistics partner can also streamline the shipping process and mitigate delays. -

How do I verify the credibility of a leather manufacturer in the USA?

To verify a manufacturer’s credibility, start by checking their business credentials, including registration, certifications, and industry affiliations. Look for reviews and testimonials from other B2B clients to gauge their reputation. Engaging in direct conversations can also reveal a lot about their professionalism and willingness to cooperate. If possible, visit the manufacturing facility to conduct a firsthand assessment of their operations and quality standards. -

What are the common challenges faced when sourcing leather from US manufacturers?

Common challenges include navigating varying quality standards, understanding lead times, and dealing with higher costs compared to other regions. Communication barriers may also arise, especially regarding technical specifications. To mitigate these challenges, maintain open lines of communication, set clear expectations from the outset, and be proactive in addressing any issues as they arise. Building a strong relationship with your supplier can significantly enhance the sourcing experience.

Top 4 Leather Manufacturers In Usa Manufacturers & Suppliers List

1. Garrett Leather – Cielo & Cestino

Domain: garrettleather.com

Registered: 1996 (29 years)

Introduction: Garrett Leather offers a variety of leather products categorized by color, type, and application. Key product lines include:

1. **Cielo** – Olive tanned leather, climate neutral, combining sustainability and luxury for aviation.

2. **Cestino** – Roller-embossed leather with a natural texture and hand-tipped finish, inspired by artisan baskets.

3. **Espiga** – Features a braided motif with a high …

2. Hide & Leather House – Premium Leather Hides

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: The Hide & Leather House, Inc. offers a wide range of leather products including:

– Leather Hides for various applications such as bags, personal leather gear, belting, strapping, chaps, motorcycle gear, footwear, garments, upholstery, saddlery, and more.

– Eco-friendly tanning options available.

– More than 3,000 types of leather in stock, sourced from the U.S. and imported globally.

– Contra…

3. Stonestreet Leather – Premium Leather Products

Domain: stonestreetleather.com

Registered: 2019 (6 years)

Introduction: Stonestreet Leather offers a variety of leather products including cowhide, vegetable tanned leather, chrome tanned leather, water buffalo leather, and embossed leather. The product categories include strips, straps, belt blanks, scrap bags, leather shapes, and finished goods such as knife sheaths, wallets, bags, cases, valet trays, coaster sets, and pencil cups. They also provide acrylic template…

4. Cromwell Leather Group – Quality Leather Solutions

Domain: cromwellgroup.com

Registered: 1996 (29 years)

Introduction: Cromwell Leather Group offers a variety of leather products including Bonded Leather, Eurobond®, Excel-Tan®, Taratan II®, and ReNatura®. They provide over 300 sample items available for immediate shipment and have a commitment to quality and reliability. Their products are in stock and ready to ship from warehouses in North America, Asia, and Europe. They also offer custom production made to speci…

Strategic Sourcing Conclusion and Outlook for leather manufacturers in usa

As the leather industry continues to evolve, strategic sourcing remains critical for international buyers aiming to capitalize on the high-quality offerings of U.S. manufacturers. The diverse range of products, from handcrafted luxury items to industrial leather goods, presents a wealth of opportunities for businesses looking to enhance their supply chains. By partnering with reputable manufacturers in the U.S., buyers can leverage superior craftsmanship, ethical production practices, and innovative designs that cater to various markets.

Understanding regional preferences and consumer trends is essential for international buyers, particularly those from Africa, South America, the Middle East, and Europe. Establishing strong relationships with U.S. manufacturers not only ensures access to premium materials but also enhances brand reputation through quality assurance.

Looking ahead, the demand for sustainable and ethically sourced leather products is expected to rise. This presents a prime opportunity for B2B buyers to align their sourcing strategies with these emerging trends. Now is the time to explore partnerships with U.S. leather manufacturers to stay ahead of the competition and meet the evolving needs of your customers. Engage with the U.S. leather market today and unlock the potential for growth and innovation in your offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.