Introduction: Navigating the Global Market for diamond stitch leather fabric roll

In today’s competitive global market, sourcing high-quality diamond stitch leather fabric rolls can be a daunting challenge for B2B buyers, particularly when aiming to meet diverse industry needs. This versatile material, characterized by its luxurious quilted design and durable construction, is increasingly sought after in various applications, from automotive interiors to upscale upholstery. With the rise in demand for both genuine and faux leather options, it is essential for international buyers—especially those from regions like Africa, South America, the Middle East, and Europe (including Vietnam and Germany)—to navigate this complex landscape effectively.

This guide serves as a comprehensive resource, designed to empower B2B buyers by addressing key aspects of the diamond stitch leather fabric roll market. Within these pages, you will find detailed insights into the different types of fabric available, their applications across various sectors, and critical considerations for supplier vetting. Furthermore, we delve into cost factors, enabling you to make informed purchasing decisions that align with your business objectives. By equipping you with actionable knowledge, this guide aims to streamline your sourcing process, ensuring you acquire high-quality materials that enhance your product offerings and satisfy your clients’ demands.

Table Of Contents

- Top 5 Diamond Stitch Leather Fabric Roll Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for diamond stitch leather fabric roll

- Understanding diamond stitch leather fabric roll Types and Variations

- Key Industrial Applications of diamond stitch leather fabric roll

- 3 Common User Pain Points for ‘diamond stitch leather fabric roll’ & Their Solutions

- Strategic Material Selection Guide for diamond stitch leather fabric roll

- In-depth Look: Manufacturing Processes and Quality Assurance for diamond stitch leather fabric roll

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘diamond stitch leather fabric roll’

- Comprehensive Cost and Pricing Analysis for diamond stitch leather fabric roll Sourcing

- Alternatives Analysis: Comparing diamond stitch leather fabric roll With Other Solutions

- Essential Technical Properties and Trade Terminology for diamond stitch leather fabric roll

- Navigating Market Dynamics and Sourcing Trends in the diamond stitch leather fabric roll Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of diamond stitch leather fabric roll

- Strategic Sourcing Conclusion and Outlook for diamond stitch leather fabric roll

- Important Disclaimer & Terms of Use

Understanding diamond stitch leather fabric roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Diamond Stitch | Made from real animal hides; luxurious feel and durability | High-end automotive interiors, luxury furniture | Pros: Premium quality, longevity. Cons: Higher cost, requires maintenance. |

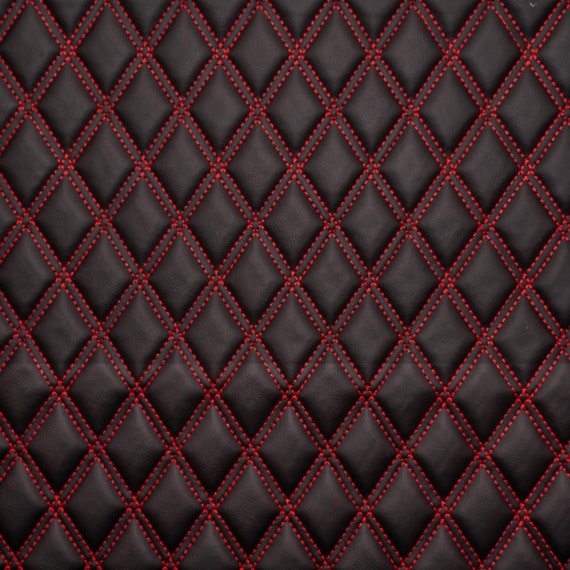

| Faux Leather Diamond Stitch | Synthetic material mimicking leather; often more affordable | Budget-friendly automotive interiors, casual furniture | Pros: Cost-effective, easy to clean. Cons: Less durable than genuine leather. |

| Foam Backed Diamond Stitch | Includes a foam layer for added comfort and insulation | Automotive seating, headliners, wall coverings | Pros: Enhanced comfort, sound insulation. Cons: Heavier material, potential for wear over time. |

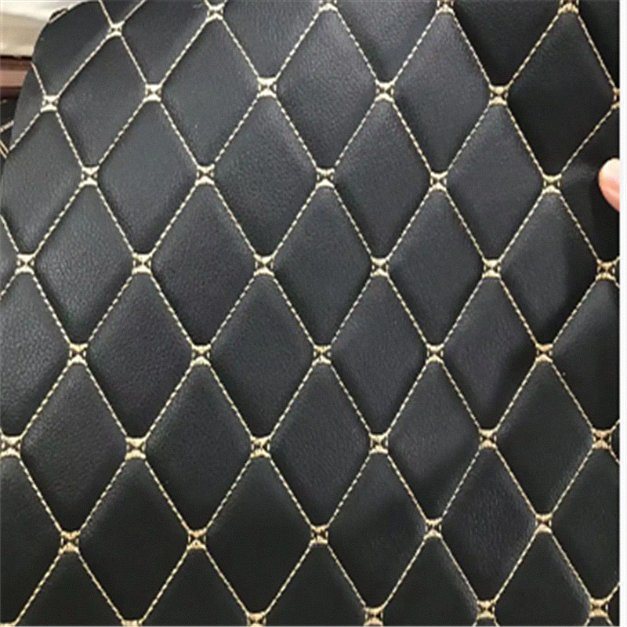

| Burnished Finish Diamond Stitch | Features a polished, slightly glossy appearance | Premium upholstery, fashion accessories | Pros: Aesthetic appeal, unique texture. Cons: May show wear and tear more visibly. |

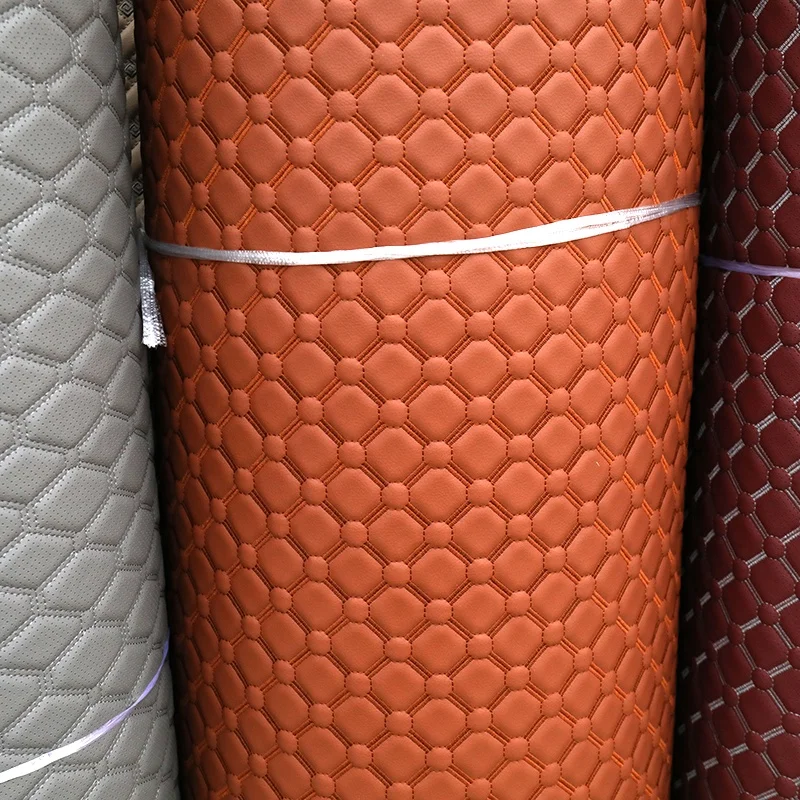

| Color Variants Diamond Stitch | Available in a wide range of colors and textures | Custom projects, themed interiors | Pros: Versatile for design needs, enhances branding. Cons: Color matching may be challenging. |

What are the Characteristics of Genuine Leather Diamond Stitch?

Genuine leather diamond stitch fabric rolls are crafted from real animal hides, offering a luxurious texture and unmatched durability. This type is particularly suitable for high-end automotive interiors and luxury furniture applications, where quality is paramount. B2B buyers should consider the investment in genuine leather, as it often comes at a higher price point but provides longevity and a prestigious aesthetic that can justify the cost.

How Does Faux Leather Diamond Stitch Compare?

Faux leather diamond stitch fabric rolls mimic the appearance of genuine leather while being more budget-friendly. This material is ideal for automotive interiors and casual furniture, making it a popular choice for businesses targeting cost-conscious consumers. Buyers should weigh the lower durability against the initial savings, as faux leather may require more frequent replacement in high-use environments.

What Benefits Does Foam Backed Diamond Stitch Provide?

Foam backed diamond stitch fabrics incorporate a foam layer that enhances comfort and provides insulation, making them ideal for automotive seating and headliners. This added cushioning can significantly improve the user experience in vehicles. B2B purchasers should consider the weight of this material, as it may impact shipping costs and installation processes.

Why Choose Burnished Finish Diamond Stitch?

Burnished finish diamond stitch fabrics present a polished look, making them suitable for premium upholstery and fashion accessories. Their unique texture adds a sophisticated touch to any design. However, B2B buyers should be mindful that while burnished finishes are visually appealing, they may show wear more readily than matte finishes, potentially affecting longevity in high-traffic areas.

How Do Color Variants Enhance Customization?

Diamond stitch fabrics come in a variety of colors and textures, allowing for extensive customization. This versatility is particularly beneficial for themed interiors and branding projects, where color matching is essential. Buyers should ensure that their suppliers can provide consistent color quality and availability to meet their specific design needs, as this can greatly impact project timelines and outcomes.

Key Industrial Applications of diamond stitch leather fabric roll

| Industry/Sector | Specific Application of diamond stitch leather fabric roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats, dashboards, and door panels | Enhances luxury feel and comfort; durable and easy to clean | Material specifications, fire retardant treatments, and color options |

| Furniture Manufacturing | Upholstery for sofas, chairs, and headboards | Adds aesthetic value and structural integrity to furniture | Availability of custom colors and patterns, bulk purchasing options |

| Marine Industry | Boat interiors and upholstery | Water-resistant properties; enhances overall aesthetic of boats | UV resistance, material durability in marine environments |

| Hospitality | Wall coverings and decorative elements in hotels | Creates a luxurious ambiance, easy maintenance | Fire safety certifications, color palette compatibility |

| Fashion and Accessories | Handbags and fashion items | Offers a high-end look and feel; customizable for branding | Material sourcing for faux vs. genuine leather, trend alignment |

How is Diamond Stitch Leather Fabric Roll Used in the Automotive Industry?

In the automotive sector, diamond stitch leather fabric roll is widely utilized for upholstery in seats, dashboards, and door panels. The quilted design not only enhances the aesthetic appeal but also provides added comfort and durability, making it an ideal choice for both luxury and standard vehicles. International buyers should consider specific requirements such as fire retardant treatments and the availability of diverse color options to meet regional regulations and consumer preferences.

What Role Does Diamond Stitch Leather Fabric Play in Furniture Manufacturing?

Furniture manufacturers leverage diamond stitch leather fabric rolls for upholstering sofas, chairs, and headboards. This material elevates the aesthetic value of furniture pieces while ensuring structural integrity and longevity. For B2B buyers, sourcing considerations include the availability of custom colors and patterns, as well as bulk purchasing options to meet production needs efficiently. The ability to customize can also align with market trends in various regions.

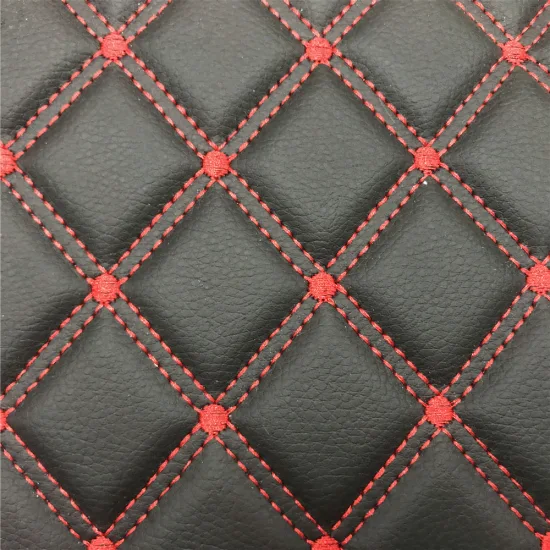

Illustrative image related to diamond stitch leather fabric roll

Why is Diamond Stitch Leather Fabric Important in the Marine Industry?

In the marine industry, diamond stitch leather fabric is essential for boat interiors and upholstery due to its water-resistant properties. This fabric enhances the overall aesthetic of boats while providing durability in challenging marine environments. Buyers in this sector must ensure that the sourced materials have UV resistance and are suitable for prolonged exposure to water, which is crucial for maintaining quality and appearance over time.

How Can Hospitality Benefit from Diamond Stitch Leather Fabric?

The hospitality industry uses diamond stitch leather fabric for wall coverings and decorative elements in hotels, contributing to a luxurious ambiance. This fabric is not only visually appealing but also easy to maintain, making it a practical choice for high-traffic areas. B2B buyers should prioritize sourcing materials that meet fire safety certifications and offer a compatible color palette to enhance the overall design theme of their establishments.

What Are the Advantages of Using Diamond Stitch Leather in Fashion and Accessories?

In the fashion industry, diamond stitch leather fabric rolls are used for crafting handbags and other fashion items. The high-end look and feel of this material can significantly enhance brand appeal, making it a popular choice among luxury brands. Buyers should focus on sourcing materials that align with current fashion trends and consider the differences between faux and genuine leather options to cater to diverse consumer preferences.

3 Common User Pain Points for ‘diamond stitch leather fabric roll’ & Their Solutions

Scenario 1: Sourcing Quality Diamond Stitch Leather Fabric for Automotive Applications

The Problem: B2B buyers in the automotive sector often struggle to find high-quality diamond stitch leather fabric rolls that meet specific durability and aesthetic standards. This challenge is exacerbated when suppliers provide inconsistent quality, leading to potential issues in manufacturing and customer satisfaction. Buyers may encounter fabrics that do not hold up under wear and tear, affecting the overall quality of the vehicle interiors they are producing.

The Solution: To ensure a reliable supply of diamond stitch leather fabric, buyers should establish strong relationships with reputable manufacturers who specialize in automotive materials. Request samples of the fabric before making bulk purchases to assess quality firsthand. Additionally, buyers should inquire about the material’s specifications, such as fire retardancy, foam backing thickness, and durability ratings. Collaborating with suppliers who offer customization options can also help in obtaining fabrics that align perfectly with the buyer’s design and functional requirements. Setting clear expectations and specifications upfront can minimize discrepancies and enhance the quality of the final product.

Scenario 2: Understanding the Versatility of Diamond Stitch Leather Fabric in Various Markets

The Problem: Many B2B buyers are unaware of the full range of applications for diamond stitch leather fabric rolls, which can limit their market reach. Buyers in regions like Africa or South America may primarily focus on automotive uses, neglecting other lucrative sectors such as furniture, marine, or hospitality industries. This narrow focus can result in missed opportunities for diversification and increased revenue.

The Solution: Conducting thorough market research can help buyers identify the diverse applications of diamond stitch leather fabric. Buyers should consider reaching out to industry experts or attending trade shows to gather insights on emerging trends and applications in different markets. Furthermore, collaborating with suppliers that offer a variety of fabric finishes and colors can enable buyers to target multiple sectors effectively. Creating marketing materials that highlight the versatility of diamond stitch leather fabric can also attract a broader clientele, ultimately leading to enhanced business growth.

Scenario 3: Managing Inventory and Minimizing Waste in Fabric Procurement

The Problem: A common pain point for B2B buyers is managing inventory effectively, particularly with materials like diamond stitch leather fabric rolls. Overestimating demand can lead to excess inventory and increased storage costs, while underestimating can result in project delays and unmet customer needs. This balancing act is especially challenging for businesses operating in regions with fluctuating market demands.

The Solution: Implementing a robust inventory management system can significantly mitigate these challenges. Buyers should analyze historical sales data to forecast demand more accurately and adjust their orders accordingly. Partnering with suppliers who offer just-in-time delivery can also help reduce the need for large inventories, allowing businesses to respond flexibly to market changes. Additionally, establishing a clear communication channel with suppliers regarding lead times and minimum order quantities can help streamline the procurement process and reduce the likelihood of overstocking or shortages. Emphasizing sustainable practices by finding ways to repurpose leftover fabric can also enhance brand reputation and reduce waste, contributing to a more environmentally friendly business model.

Strategic Material Selection Guide for diamond stitch leather fabric roll

What Are the Key Materials for Diamond Stitch Leather Fabric Rolls?

When selecting materials for diamond stitch leather fabric rolls, B2B buyers must consider various options, each with distinct properties, advantages, and limitations. The following analysis focuses on four common materials: genuine leather, faux leather, vinyl, and foam-backed options, providing insights relevant to international buyers.

Illustrative image related to diamond stitch leather fabric roll

Genuine Leather: What Are Its Properties and Suitability?

Genuine leather is a natural material known for its durability and aesthetic appeal. It typically exhibits excellent temperature resistance and can withstand significant wear and tear, making it suitable for high-traffic areas such as automotive interiors. The natural fibers provide a breathable quality, enhancing comfort in seating applications.

Pros: Genuine leather offers superior durability and a luxurious feel, making it ideal for high-end applications. It can also be treated for fire resistance, which is crucial for compliance with safety standards.

Cons: The primary drawbacks include higher costs and the need for specialized maintenance to prevent damage from moisture and sunlight. Additionally, sourcing genuine leather may raise ethical concerns, which some buyers may wish to avoid.

Impact on Application: Genuine leather is compatible with various upholstery applications, including automotive seats and luxury furniture. However, buyers must ensure compliance with environmental regulations regarding leather sourcing and processing.

Faux Leather: Is It a Viable Alternative?

Faux leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to genuine leather. It is available in a variety of textures and colors, making it versatile for different design needs. Faux leather is also resistant to moisture and easy to clean, which is advantageous in many applications.

Pros: The primary advantage of faux leather is its affordability and lower maintenance requirements. It can mimic the appearance of genuine leather while being more resistant to stains and fading.

Cons: However, faux leather may not offer the same level of durability or breathability as genuine leather. It can also be less environmentally friendly, depending on the manufacturing processes used.

Impact on Application: Faux leather is commonly used in automotive interiors and furniture, but buyers should verify that the material meets relevant safety standards, particularly in fire resistance.

Vinyl: What Are Its Key Characteristics?

Vinyl is a synthetic material that provides excellent durability and is often used in applications requiring high resistance to moisture and chemicals. It is particularly popular in automotive upholstery and marine applications due to its water-resistant properties.

Pros: Vinyl is highly durable and easy to clean, making it suitable for environments that require frequent maintenance. It is also available in various colors and finishes, allowing for customization.

Illustrative image related to diamond stitch leather fabric roll

Cons: The main limitation of vinyl is its lower breathability compared to leather, which can affect comfort in seating applications. Additionally, it may not have the same luxurious feel as genuine leather.

Impact on Application: Vinyl is ideal for automotive interiors and commercial applications, but international buyers must ensure compliance with local standards for material safety and environmental impact.

Foam-Backed Options: How Do They Enhance Performance?

Foam-backed leather fabric rolls combine a layer of foam with leather or synthetic materials, enhancing comfort and support. This type of fabric is commonly used in automotive interiors, providing both aesthetic appeal and functional benefits.

Pros: The foam backing adds cushioning, making it suitable for applications where comfort is a priority. It also enhances the fabric’s durability and can improve insulation properties.

Cons: The complexity of manufacturing foam-backed materials can increase costs. Additionally, the quality of the foam can vary, affecting the overall performance of the fabric.

Impact on Application: Foam-backed options are particularly suited for automotive seating and high-end furniture. Buyers should consider the foam’s specifications to ensure it meets their performance needs, including fire resistance and durability.

Summary Table of Material Selection for Diamond Stitch Leather Fabric Rolls

| Material | Typical Use Case for diamond stitch leather fabric roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Automotive interiors, luxury furniture | Superior durability and luxury feel | Higher cost, requires maintenance | Elevado |

| Couro sintético | Automotive interiors, furniture, bags | Cost-effective, easy to clean | Less durable, potential ethical concerns | Medium |

| Vinyl | Automotive upholstery, marine applications | Highly durable, water-resistant | Lower breathability, less luxurious feel | Medium |

| Foam-Backed | Automotive seating, high-end furniture | Enhanced comfort and support | Increased manufacturing complexity | Medium |

This comprehensive analysis equips B2B buyers with essential insights into material properties, advantages, and limitations, facilitating informed purchasing decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for diamond stitch leather fabric roll

What Are the Main Stages in the Manufacturing Process of Diamond Stitch Leather Fabric Roll?

The manufacturing process of diamond stitch leather fabric rolls is multifaceted, involving several critical stages that ensure the final product meets the quality and aesthetic standards expected by B2B buyers.

Illustrative image related to diamond stitch leather fabric roll

Material Preparation: How Is the Raw Material Selected and Processed?

The first step in manufacturing involves the careful selection of raw materials, which can include genuine leather, faux leather, or vinyl. The choice of material directly impacts the durability, appearance, and cost of the finished product. For example, genuine leather offers a luxurious feel but may require more extensive processing to ensure quality. In contrast, faux leather is often more affordable and easier to work with but may not provide the same level of durability.

Once the raw material is selected, it undergoes a treatment process that may include dyeing, finishing, and conditioning to enhance its properties. This stage also involves cutting the leather into sheets that will be used for stitching. The thickness and texture of the leather are important considerations, as they will affect the final look and feel of the diamond stitch pattern.

Forming: What Techniques Are Used to Create the Diamond Stitch Pattern?

In the forming stage, the prepared leather is subjected to various techniques to create the distinctive diamond stitch pattern. This typically involves the use of specialized machinery that can perform the stitching accurately and consistently. The quilting process not only adds aesthetic value but also enhances the structural integrity of the fabric.

Techniques such as wireless quilting may be employed for added efficiency, particularly when large quantities are being produced. The use of scrim foam backing is common, as it provides additional padding and comfort, which is particularly desirable in applications like automotive interiors.

Illustrative image related to diamond stitch leather fabric roll

Assembly: How Are the Fabric Rolls Prepared for Distribution?

After the diamond stitch pattern is formed, the fabric rolls are assembled. This includes quality checks to ensure that the stitching is uniform and that there are no defects in the material. The rolls are then cut to specific lengths based on customer specifications, often sold by the meter to accommodate various project needs.

At this stage, any additional treatments—such as water resistance or fire retardancy—may be applied to enhance the fabric’s performance in specific environments.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage involves a final inspection of the product, where any imperfections are addressed, and the fabric is prepared for shipment. This may include cleaning, folding, and packaging to ensure that the rolls arrive in pristine condition. Labels and certifications are also affixed to the packaging, providing buyers with essential information about the product’s specifications and compliance with industry standards.

What Quality Control Measures Are Implemented During Manufacturing?

Quality control (QC) is a critical component of the manufacturing process for diamond stitch leather fabric rolls. To ensure that the final product meets international standards and client expectations, manufacturers typically implement a comprehensive QC system.

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for quality management systems. Compliance with ISO standards signifies that a manufacturer has established processes that consistently produce products meeting customer and regulatory requirements.

Additionally, industry-specific certifications, such as CE marking for products sold in Europe or API standards for automotive applications, may also apply. These certifications can provide further assurance of the product’s quality and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch any defects early. Key checkpoints typically include:

- Incoming Quality Control (IQC): This initial stage checks the raw materials for quality and consistency before they enter the production line.

- In-Process Quality Control (IPQC): Continuous checks during the manufacturing process ensure that the production adheres to set specifications. This includes monitoring stitching accuracy and material integrity.

- Final Quality Control (FQC): Before the product is packaged for shipment, a thorough inspection ensures that the finished fabric meets all quality criteria, including appearance, durability, and compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable strategies to verify QC practices:

What Steps Can Buyers Take to Audit Suppliers?

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control measures. This direct observation allows buyers to assess compliance with international standards and best practices.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that include testing results, compliance documentation, and any certifications that the supplier holds. This documentation can help validate the supplier’s commitment to quality.

-

Third-party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes. These organizations can conduct random checks during production and provide comprehensive reports on findings.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality assurance and certifications can be challenging for international buyers. Different regions may have varying standards and compliance requirements, so understanding these nuances is essential.

For example, buyers in the European market may prioritize CE marking and compliance with REACH regulations, while those in the Middle East may focus on local certifications specific to their industry needs. Buyers should familiarize themselves with the relevant standards in their target markets and ensure that their suppliers can meet these requirements.

By understanding the manufacturing processes and quality assurance measures involved in diamond stitch leather fabric rolls, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diamond stitch leather fabric roll’

When sourcing diamond stitch leather fabric rolls, it’s essential to follow a structured approach to ensure you obtain high-quality materials that meet your specific needs. This guide outlines the critical steps to streamline your procurement process, catering to B2B buyers across various international markets.

Illustrative image related to diamond stitch leather fabric roll

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define what you need from the diamond stitch leather fabric. Consider factors such as the type of leather (genuine vs. faux), thickness, backing material, and color options. This clarity will help you communicate effectively with suppliers and ensure that the products meet your project requirements.

- Key Considerations:

- Desired applications (automotive, upholstery, etc.)

- Specific size requirements (width and length per roll)

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of diamond stitch leather fabric rolls. Look for manufacturers and distributors with a solid reputation in the industry, particularly those with experience in your target markets such as Africa, South America, the Middle East, and Europe.

- Action Items:

- Check online reviews and ratings.

- Review their product range and certifications.

Step 3: Request Samples

Once you have shortlisted suppliers, request samples of the diamond stitch leather fabric. This allows you to assess the quality, texture, and color accuracy before making a bulk purchase. Evaluate the samples against your defined specifications.

- Why It Matters:

- Samples help you verify the material’s durability and aesthetic appeal.

- They enable you to gauge how well the fabric fits into your project or product line.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers hold relevant certifications and comply with industry standards. This is particularly important when sourcing from international markets, as regulations may vary significantly.

- What to Look For:

- ISO certifications for quality management.

- Certifications related to sustainability and safety, such as fire retardancy.

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, minimum order quantities (MOQs), and payment terms. Understanding the total cost of procurement, including shipping and tariffs, is crucial to maintaining your budget.

- Negotiation Tips:

- Be clear about your volume needs to leverage better pricing.

- Consider long-term partnerships for more favorable terms.

Step 6: Assess Shipping and Logistics Options

Discuss shipping options and logistics with your supplier to ensure timely delivery. Factor in lead times, shipping methods, and costs. Understanding these logistics is vital, especially for international shipments.

- Considerations:

- Customs regulations for importing leather products into your region.

- Potential delays and how to mitigate them.

Step 7: Establish a Quality Control Process

Once the order is placed, set up a quality control process to ensure that the received materials meet your standards. This could involve inspecting the fabric upon arrival and comparing it against the samples you approved.

- Quality Control Steps:

- Check for consistency in color and texture.

- Assess the stitching quality and overall finish.

By following these steps, you can effectively navigate the procurement process for diamond stitch leather fabric rolls, ensuring that you secure high-quality materials that align with your business needs.

Comprehensive Cost and Pricing Analysis for diamond stitch leather fabric roll Sourcing

What Are the Key Cost Components for Sourcing Diamond Stitch Leather Fabric Rolls?

When sourcing diamond stitch leather fabric rolls, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of leather—genuine or faux—significantly impacts cost. Genuine leather typically commands a higher price due to its durability and luxury appeal. Faux leather options, while more affordable, can vary based on the quality of PVC or other synthetic materials used.

-

Labor: Labor costs encompass the workforce involved in cutting, stitching, and finishing the leather. Regions with lower labor costs may offer more competitive pricing, but it’s vital to ensure that quality standards are maintained.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Manufacturers with advanced machinery for diamond stitching may have higher overheads, but they can also achieve better precision and efficiency.

-

Tooling: Initial tooling costs for molds or specialized stitching equipment can be significant, particularly for custom designs. These costs may be amortized over larger production runs, making it beneficial for buyers to order in bulk.

-

Quality Control: Rigorous QC processes ensure that the final product meets industry standards. Suppliers who invest in quality assurance may charge higher prices, but this often results in fewer defects and returns.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the shipping method chosen. International buyers should consider customs duties and taxes, which can add to the overall cost.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary widely based on market conditions, competition, and the supplier’s positioning in the market.

What Influences Pricing for Diamond Stitch Leather Fabric Rolls?

Several factors can influence the pricing of diamond stitch leather fabric rolls, especially for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit prices. Many suppliers have MOQs that can significantly affect pricing; negotiating lower MOQs can help smaller buyers access competitive rates.

-

Specifications and Customization: Custom designs or specific color requests can increase costs. Buyers should be clear about their requirements upfront to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of material and any associated certifications (e.g., fire retardant, eco-friendly) can impact pricing. Buyers should assess whether the additional cost for certified materials aligns with their market needs.

-

Supplier Factors: Reputation, reliability, and service quality of suppliers can affect pricing. Established suppliers may charge a premium but often provide better service, reliability, and product quality.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential. Incoterms determine who bears the costs and risks during shipping, which can significantly impact the total landed cost.

What Are the Best Practices for Negotiating Prices in International B2B Transactions?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and more favorable terms. Regular communication helps in understanding the supplier’s position and flexibility.

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term value rather than just upfront costs. Consider factors like durability, maintenance, and potential returns, as these can justify higher initial prices.

-

Research Market Prices: Knowledge of market rates for diamond stitch leather fabric rolls allows buyers to negotiate effectively. Being informed about competitors’ pricing can provide leverage.

-

Be Transparent About Needs: Clearly communicate your requirements, expected delivery times, and payment terms. This transparency can foster trust and lead to better pricing arrangements.

-

Consider Local Partnerships: Collaborating with local distributors or agents who understand the market can streamline the sourcing process and potentially reduce costs.

Conclusion: Why Understanding Pricing Nuances is Essential for B2B Buyers

Understanding the cost structure and pricing influencers for diamond stitch leather fabric rolls is critical for B2B buyers. By considering the various cost components, recognizing the factors that influence pricing, and employing effective negotiation strategies, buyers can make informed decisions that enhance their sourcing efficiency and overall profitability. As the global market evolves, staying updated on these nuances will be key to successful procurement practices.

Disclaimer: The prices mentioned throughout this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements.

Alternatives Analysis: Comparing diamond stitch leather fabric roll With Other Solutions

When evaluating upholstery materials for automotive or furniture applications, the diamond stitch leather fabric roll is a popular choice due to its luxurious appearance and durability. However, it’s important to consider alternative solutions that might better suit specific project requirements or budgets. Below, we will compare the diamond stitch leather fabric roll against two viable alternatives: quilted vinyl fabric and traditional leather.

Illustrative image related to diamond stitch leather fabric roll

| Comparison Aspect | Diamond Stitch Leather Fabric Roll | Quilted Vinyl Fabric | Traditional Leather |

|---|---|---|---|

| Performance | High durability with a premium feel; fire retardant options available. | Good durability, easy to clean; less expensive but may lack the same premium feel. | Excellent durability, natural breathability; can be more expensive and requires care. |

| Cost | Moderate to high, depending on leather type (genuine vs. faux). | Generally lower cost; budget-friendly option. | Higher initial investment; long-term value due to durability. |

| Ease of Implementation | Requires specialized tools for cutting and installation. | Easy to cut and sew; can be used for DIY projects without special tools. | Requires skilled labor for best results; can be challenging to work with. |

| Maintenance | Easy to clean; resistant to stains and spills. | Very easy to maintain; wipeable surface. | Requires regular conditioning and care to maintain appearance. |

| Best Use Case | Ideal for high-end automotive interiors and luxury furniture. | Best for budget-conscious projects needing a stylish look. | Suitable for high-quality furniture and custom upholstery projects. |

What Are the Advantages and Disadvantages of Using Quilted Vinyl Fabric?

Quilted vinyl fabric serves as a cost-effective alternative to the diamond stitch leather fabric roll. It offers a similar aesthetic with a quilted pattern, making it visually appealing for automotive interiors and furniture. The material is lightweight and easy to clean, which is a significant advantage for applications in environments prone to spills and stains. However, while it is durable, it may not provide the same luxurious feel and longevity as leather options. This makes quilted vinyl more suitable for temporary or budget-sensitive projects rather than high-end applications.

How Does Traditional Leather Compare to Diamond Stitch Leather Fabric Roll?

Traditional leather is revered for its durability and timeless appeal. It provides a premium look and feel, making it an excellent choice for luxury automotive interiors and high-end furniture. Unlike diamond stitch leather fabric rolls, traditional leather has natural breathability, which adds to comfort. However, it comes with a higher price tag and requires more maintenance, including conditioning to prevent drying and cracking. While traditional leather may offer superior quality, the additional care and cost may not align with every buyer’s budget or project scope.

How Can B2B Buyers Choose the Right Upholstery Solution?

When selecting the right upholstery material, B2B buyers should carefully consider their specific needs, including budget constraints, intended use, and desired aesthetics. The diamond stitch leather fabric roll is ideal for projects that demand a blend of luxury and durability, particularly in high-end automotive applications. In contrast, quilted vinyl fabric may be suitable for those looking for a stylish yet budget-friendly option, while traditional leather is best for buyers willing to invest in quality and longevity. By evaluating these aspects, buyers can make informed decisions that align with their project goals and customer expectations.

Illustrative image related to diamond stitch leather fabric roll

Essential Technical Properties and Trade Terminology for diamond stitch leather fabric roll

What Are the Key Technical Properties of Diamond Stitch Leather Fabric Roll?

When considering diamond stitch leather fabric rolls for B2B applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

The quality of leather used—whether genuine or synthetic—affects durability, appearance, and cost. Genuine leather typically offers superior durability and a premium aesthetic, making it suitable for high-end applications like automotive interiors. Synthetic options provide cost-effective alternatives while still offering aesthetic appeal and durability. -

Foam Backing Thickness

The thickness of the foam backing, usually ranging from 6mm to 8mm, plays a vital role in comfort and support. A thicker backing enhances the fabric’s cushioning properties, making it more suitable for applications requiring prolonged use, such as automotive seats. Buyers should assess their specific needs to determine the appropriate thickness. -

Fire Retardant Treatment

Many diamond stitch leather fabrics are treated to be fire retardant, a critical specification for safety compliance, especially in automotive and commercial applications. This treatment minimizes the risk of ignition and can be a significant selling point for products aimed at safety-conscious markets. -

Width and Length Tolerance

The standard width for diamond stitch leather fabric rolls is typically 54 inches, with lengths sold by the meter. Understanding length tolerance is essential for ensuring that the fabric meets specific project requirements without excess waste. Consistent width and length help maintain uniformity across large orders, which is vital for manufacturers. -

Color Fastness

The ability of the fabric to maintain its color when exposed to light and other environmental factors is crucial, especially for outdoor or heavily used applications. High color fastness ensures that the product remains visually appealing over time, reducing the need for replacement. -

Double Rub Count

This measure indicates the durability of the fabric, particularly in upholstery applications. A higher double rub count signifies greater resistance to wear and tear, making it suitable for high-traffic areas. Buyers should seek fabrics with an appropriate double rub count for their intended use to ensure longevity.

What Are Common Trade Terms Related to Diamond Stitch Leather Fabric Roll?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common trade terms associated with diamond stitch leather fabric rolls:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that can be branded by another company. In the context of diamond stitch leather, OEMs may produce custom materials for automotive manufacturers or furniture makers. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest order size that a supplier is willing to accept. Understanding MOQ is crucial for buyers to determine if a supplier can meet their project needs without incurring excessive costs or inventory. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. It’s an essential step in the procurement process, allowing buyers to compare costs and conditions before making purchasing decisions. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international transactions. Knowing the applicable Incoterms helps clarify shipping costs, insurance, and liability, which are vital for international buyers sourcing diamond stitch leather. -

Lead Time

This term refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is critical for inventory planning and ensuring that production schedules are met. -

Color Variants

This term refers to the different colors and finishes available for diamond stitch leather fabric rolls. Buyers should inquire about color variants to ensure that the materials align with their brand and project specifications.

Understanding these technical properties and trade terms empowers B2B buyers to navigate the complexities of sourcing diamond stitch leather fabric rolls effectively, ensuring they make informed decisions that align with their business objectives.

Illustrative image related to diamond stitch leather fabric roll

Navigating Market Dynamics and Sourcing Trends in the diamond stitch leather fabric roll Sector

What Are the Key Trends Shaping the Diamond Stitch Leather Fabric Roll Market?

The diamond stitch leather fabric roll market is experiencing significant growth, driven by a surge in demand across various sectors, including automotive, furniture, and fashion industries. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, aesthetically appealing materials that offer durability and comfort. The automotive sector is a major contributor, as manufacturers and restorers look for materials that enhance the interior aesthetics of vehicles while providing comfort and safety.

Emerging trends in technology are shaping sourcing strategies, with digital platforms facilitating easier access to suppliers and enabling buyers to compare prices and quality with just a few clicks. E-commerce has become a vital channel, allowing suppliers to reach global markets efficiently. Additionally, innovations in manufacturing processes, such as the use of foam backing for enhanced comfort and fire retardant treatments, are gaining traction. Buyers are increasingly prioritizing versatile materials that can be customized for various applications, including upholstery, wall coverings, and accessories.

How Is Sustainability Influencing the Sourcing of Diamond Stitch Leather Fabric Rolls?

Sustainability is a critical consideration for B2B buyers in the diamond stitch leather fabric roll market. The environmental impact of leather production has prompted many companies to adopt ethical sourcing practices and seek out sustainable materials. Buyers are increasingly looking for suppliers that adhere to stringent environmental standards and offer certified sustainable options.

The introduction of eco-friendly faux leather alternatives is also reshaping the landscape. These materials often come with certifications that guarantee they are made from recycled or non-toxic substances, appealing to a market segment that values sustainability. Additionally, companies are embracing transparency in their supply chains, enabling buyers to trace the origins of materials and ensuring ethical practices throughout the production process. As consumers and businesses alike become more environmentally conscious, incorporating sustainability into sourcing strategies is not just beneficial; it is becoming essential for maintaining competitive advantage.

Illustrative image related to diamond stitch leather fabric roll

What Is the Historical Context of Diamond Stitch Leather Fabric Rolls in B2B Markets?

The use of diamond stitch leather fabric rolls has evolved significantly over the years, initially gaining popularity in the automotive industry for its luxurious aesthetic and durability. The diamond quilting technique dates back to traditional upholstery practices, where it was used to enhance both the appearance and structural integrity of leather goods. As consumer preferences shifted towards more customized and stylish options, manufacturers began incorporating this distinctive pattern into a broader range of applications, from furniture to fashion accessories.

In recent years, advancements in production technology have expanded the versatility of diamond stitch leather fabrics, allowing for a variety of textures, colors, and finishes. This evolution has positioned diamond stitch leather as a sought-after material in international markets, appealing to B2B buyers looking for high-quality, visually striking solutions for their products. As the market continues to grow, understanding the historical context of this fabric can provide valuable insights for buyers navigating current trends and sourcing options.

Frequently Asked Questions (FAQs) for B2B Buyers of diamond stitch leather fabric roll

-

How do I determine the right thickness for diamond stitch leather fabric roll?

When selecting the thickness of diamond stitch leather fabric, consider the intended application. Thicker options, such as those with 6mm or 8mm foam backing, provide enhanced durability and comfort, making them ideal for automotive upholstery and heavy-use furniture. Conversely, thinner materials may be more suitable for decorative applications or light-duty uses. Always request samples to assess the feel and performance before finalizing your order. -

What is the best diamond stitch leather fabric for automotive applications?

For automotive interiors, look for diamond stitch leather fabric with a durable foam backing and fire-retardant properties. This ensures safety and longevity, especially in high-traffic areas like seats and dashboards. Additionally, consider options that offer UV resistance to prevent fading in sunny climates. Fabrics that are easy to clean and maintain will also enhance the overall user experience. -

How can I ensure the quality of the diamond stitch leather fabric I’m sourcing?

To ensure quality, request samples from potential suppliers before making bulk purchases. Verify that the fabric meets industry standards, such as ISO certifications, and inquire about their quality assurance processes. Reviews and testimonials from other B2B buyers can also provide insights into the supplier’s reliability and product quality. Establishing a quality control checklist that aligns with your specific requirements can further safeguard your investment. -

What are the common minimum order quantities (MOQs) for diamond stitch leather fabric rolls?

Minimum order quantities can vary significantly by supplier, typically ranging from 10 to 100 meters. It’s essential to communicate your needs clearly during negotiations, as some suppliers may accommodate smaller orders at a higher price per meter. Additionally, consider the implications of MOQ on your inventory management and cash flow, especially if you are entering a new market. -

What payment terms should I expect when sourcing diamond stitch leather fabric from international suppliers?

Payment terms can vary widely among suppliers. Common practices include a deposit (usually 30%) upfront, with the balance due before shipping. Some suppliers may offer letters of credit or payment upon delivery for established relationships. Always clarify terms in advance and consider using secure payment methods to mitigate risks associated with international transactions. -

How do I handle customs and logistics when importing diamond stitch leather fabric?

When importing fabric, familiarize yourself with the customs regulations in your country, including tariffs and duties applicable to textile imports. Partnering with a freight forwarder can streamline logistics, ensuring that your shipment complies with all regulations and arrives on time. Additionally, maintaining clear communication with your supplier regarding shipping methods and documentation will facilitate smoother customs clearance. -

Can I customize the diamond stitch pattern and color for my order?

Many suppliers offer customization options for diamond stitch leather fabric, allowing you to select specific patterns, colors, and finishes that align with your branding. However, customization may come with additional lead times and costs. Be sure to discuss your requirements upfront and confirm any minimum order sizes for custom designs to avoid delays in your project. -

What are the best practices for maintaining diamond stitch leather fabric?

To maintain the quality of diamond stitch leather fabric, regular cleaning is essential. Use a damp cloth with mild soap to wipe away dirt and stains, avoiding harsh chemicals that could damage the material. For long-term care, consider applying a protective leather conditioner to keep the fabric supple and prevent cracking. Educating your end users on proper care will enhance the longevity of the product and maintain its aesthetic appeal.

Top 5 Diamond Stitch Leather Fabric Roll Manufacturers & Suppliers List

1. Diamond Stitch – Leather Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Diamond Stitch Leather Fabric available in various colors including Beige, Black, Blue, Brown, Gray, Multicolor, Pink, Purple, Red, and White. Suitable for upholstery, car upholstery, motorcycle upholstery, bedding, quilting, crafts, and accessories like bags and purses. Features include embroidered, waterproof, quilted, and 3D options. Fabric weight ranges from light to heavy, with widths availab…

2. Barbarossa Leather – Diamond Stitch Embossed Leather

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: {“design_name”: “Diamond Stitch”, “description”: “A quilted design that creates a stunning visual effect on soft leather.”, “finish”: “Available in a burnished finish.”, “specifications”: {“raw_material”: “Bovine hide”, “weight”: “2.5 – 3.5 oz.”, “type”: “Embossed Leather”, “hide_size”: “Full 40-50 sqft.”, “thickness”: “1.0 – 1.4mm”, “flammability”: “Meets CA 117E”}, “color_options”: [“Bolero Ceme…

3. Carmatroll – Diamond Stitch Leather Fabric Roll

Domain: carmatroll.com

Registered: 2019 (6 years)

Introduction: Diamond Stitch Leather Fabric Roll is a highly popular material used in automotive interiors, featuring a distinctive quilted design with diamond-shaped stitching for a luxurious appearance. Available in genuine and faux leather options, it offers versatility for various applications. Key features include:

– Durability and Aesthetic Appeal: The diamond stitch pattern enhances visual appeal and add…

4. Etsy – Diamond Stitch Leather Fabric

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Diamond Stitch Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

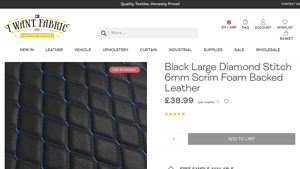

5. I Want Fabric – Black Large Diamond Stitch Foam Backed Leather

Domain: iwantfabric.com

Registered: 2012 (13 years)

Introduction: Black Large Diamond Stitch 6mm Scrim Foam Backed Leather

– Price: £38.99 per metre

– Width: 150 cm

– Thickness: 6mm

– Backing: 8mm scrim foam

– Fire Retardant: Yes

– Feel: Smooth vinyl feel

– Usage: Suitable for car upholstery, embellishments, camper vans, home upholstery projects, sofas, foot stools, bags, and widely used in car interiors.

– Stitch Colors Available: Black, White, Blue, Red, Black…

Strategic Sourcing Conclusion and Outlook for diamond stitch leather fabric roll

In conclusion, strategic sourcing of diamond stitch leather fabric rolls presents a myriad of opportunities for international B2B buyers. This versatile material not only enhances the aesthetic appeal of automotive interiors and upholstery but also boasts durability and functional benefits, such as fire resistance and comfort due to its foam backing. Buyers should prioritize suppliers that offer a range of color options and quality assurances, ensuring they meet specific project requirements.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality leather products will only grow. Engaging with reliable suppliers who can provide consistent quality and service is essential for maintaining a competitive edge in these regions.

Looking ahead, embracing innovations in leather sourcing and production will be critical. By leveraging the benefits of diamond stitch leather, businesses can not only meet current market demands but also anticipate future trends. We encourage international buyers to explore partnerships with reputable manufacturers and distributors to elevate their product offerings. The time to invest in diamond stitch leather fabric rolls is now—position your business for success in this thriving sector.

Illustrative image related to diamond stitch leather fabric roll

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.