Introduction: Navigating the Global Market for custom leather stamp logo

Navigating the global market for a custom leather stamp logo presents unique challenges for B2B buyers, particularly those aiming to establish a distinctive brand identity in competitive sectors. The quest for sourcing high-quality custom leather stamps that align with specific branding needs requires careful consideration of various factors, including design complexity, material durability, and production timelines. This guide offers a comprehensive overview of the types and applications of custom leather stamps, alongside practical insights into supplier vetting, cost structures, and quality assurance.

For international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—understanding the nuances of the custom leather stamp market is essential for making informed purchasing decisions. This resource empowers businesses to navigate potential pitfalls by providing actionable strategies for evaluating suppliers, negotiating pricing, and ensuring that the final product meets their branding expectations.

By delving into the intricate details of custom leather stamp logos, this guide aims to equip B2B buyers with the knowledge necessary to enhance their brand visibility and craftsmanship, ultimately fostering successful partnerships in the global marketplace. Whether you are looking to create a unique logo for leather goods, enhance product branding, or explore innovative stamping techniques, our comprehensive insights will serve as your roadmap to success.

Table Of Contents

- Top 9 Custom Leather Stamp Logo Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamp logo

- Understanding custom leather stamp logo Types and Variations

- Key Industrial Applications of custom leather stamp logo

- 3 Common User Pain Points for ‘custom leather stamp logo’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamp logo

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp logo

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp logo’

- Comprehensive Cost and Pricing Analysis for custom leather stamp logo Sourcing

- Alternatives Analysis: Comparing custom leather stamp logo With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamp logo

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamp logo Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp logo

- Strategic Sourcing Conclusion and Outlook for custom leather stamp logo

- Important Disclaimer & Terms of Use

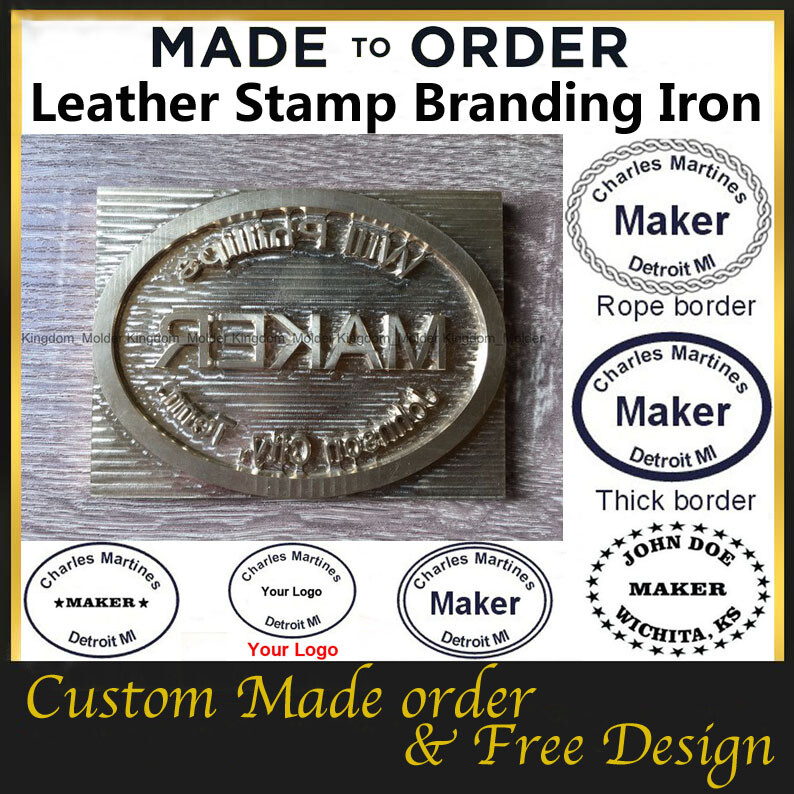

Understanding custom leather stamp logo Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Stamps | Durable, precision-engraved, reusable | Branding, product labeling | Pros: Long-lasting, high-quality impressions. Cons: Higher initial cost than resin. |

| Handheld Leather Stamps | Portable, versatile, various sizes available | Small batch production, crafting | Pros: Easy to use, no additional equipment needed. Cons: Limited to smaller designs. |

| Heated Branding Irons | Electric or manual, ideal for heat embossing | High-volume production, industrial use | Pros: Creates deep impressions, suitable for various materials. Cons: Requires additional setup and handling. |

| Custom Roll Dies | Continuous patterns, designed for repetitive stamping | Mass production, leather goods manufacturing | Pros: Efficient for large runs, consistent results. Cons: Higher upfront investment, not suitable for small batches. |

| Resin-Based Stamps | Lightweight, ideal for detailed designs | Prototyping, limited runs | Pros: Cost-effective, good for short-term use. Cons: Less durable, not suitable for high-volume applications. |

What Are the Characteristics of Custom Brass Stamps?

Custom brass stamps are renowned for their durability and precision. They are typically engraved using CNC technology, ensuring high accuracy in reproducing intricate designs. These stamps are suitable for various applications, including branding and product labeling. B2B buyers should consider the long-term benefits of brass stamps, as they can withstand repeated use without significant wear, making them a cost-effective option for businesses focused on quality branding.

How Do Handheld Leather Stamps Differ from Other Types?

Handheld leather stamps are designed for portability and ease of use, making them an excellent choice for small batch production and crafting. These stamps come in various sizes and can be used without complex machinery, appealing to artisans and small businesses. However, their limitations in size and design complexity may not meet the needs of larger companies or those requiring high-volume production.

Why Choose Heated Branding Irons for Leather Stamping?

Heated branding irons offer a unique method for creating deep impressions on leather and other materials through heat application. Ideal for high-volume production, these tools can efficiently mark items with logos or designs. B2B buyers should be aware that while heated branding irons provide high-quality results, they also necessitate proper setup and handling, which may involve additional training for staff.

What Are Custom Roll Dies Used For in Leather Stamping?

Custom roll dies are specifically designed for creating continuous patterns, making them essential for mass production in the leather goods industry. These dies allow manufacturers to produce consistent designs across large quantities of items, ensuring brand uniformity. However, the initial investment can be higher, and they may not be suitable for smaller production runs, making them a better fit for established businesses with significant output needs.

When Should Businesses Consider Resin-Based Stamps?

Resin-based stamps are lightweight and ideal for detailed designs, making them suitable for prototyping and limited runs. They are a cost-effective option for businesses that do not require the durability of brass stamps. However, B2B buyers should note that these stamps have a shorter lifespan and are not suited for high-volume applications, which could limit their effectiveness in larger-scale production environments.

Key Industrial Applications of custom leather stamp logo

| Industry/Sector | Specific Application of custom leather stamp logo | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Branding leather goods such as handbags, wallets, and belts | Enhances brand identity and adds a premium feel to products | Precision in stamp design, material durability, and production speed |

| Furniture & Upholstery | Custom branding on leather furniture and upholstery | Creates a unique selling proposition and fosters customer loyalty | Compatibility with various leather types and ease of application |

| Automotive | Stamping logos on leather car interiors and accessories | Strengthens brand recognition and adds value to luxury vehicles | Heat resistance, design complexity, and production lead times |

| Craft & DIY | Personalized stamps for artisan leather projects | Supports small businesses and enhances craftsmanship | Customization options, material selection, and ease of use |

| Promotional Products | Creating branded leather gifts and promotional items | Increases brand visibility and customer engagement | Minimum order quantities, design flexibility, and shipping options |

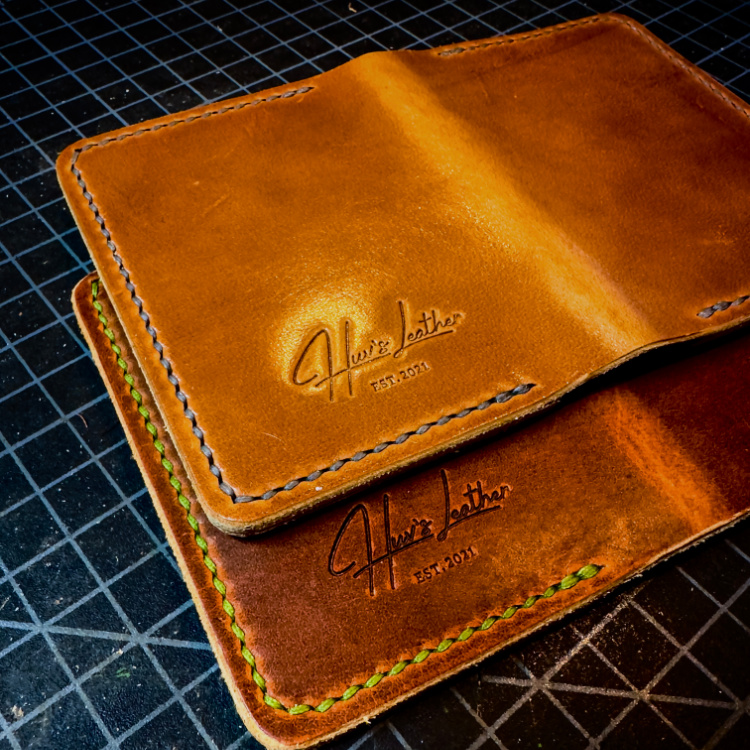

How is Custom Leather Stamp Logo Used in the Fashion & Accessories Sector?

In the fashion and accessories industry, custom leather stamp logos are extensively used to brand products such as handbags, wallets, and belts. This not only helps in establishing a strong brand identity but also adds a premium touch to the items, which is crucial for attracting discerning customers. For international buyers, especially from regions like Africa and South America, sourcing high-quality stamps that can create clear impressions on various leather types is essential. They must also consider the durability of the stamp to withstand frequent use in high-volume production.

What Role Does Custom Leather Stamp Logo Play in Furniture & Upholstery?

In the furniture and upholstery sector, custom leather stamp logos are applied to branded leather sofas and chairs, enhancing the uniqueness of each piece. This branding serves as a mark of quality, helping businesses stand out in a competitive market. For buyers in the Middle East and Europe, understanding the compatibility of stamps with different leather types is critical. They should also assess the ease of application, as this can influence production efficiency and turnaround times.

Illustrative image related to custom leather stamp logo

How is Custom Leather Stamp Logo Beneficial in the Automotive Industry?

The automotive industry utilizes custom leather stamp logos to mark leather seats, steering wheels, and other interior accessories. This branding not only reinforces brand recognition but also adds perceived value to luxury vehicles. Buyers from regions like Europe and Africa need to focus on sourcing stamps that can withstand high temperatures and pressure during the stamping process. Additionally, the complexity of the design may require advanced engraving techniques, which should be factored into the sourcing decision.

What Applications Exist for Custom Leather Stamp Logos in Craft & DIY?

Artisans and small businesses in the craft and DIY sector frequently use custom leather stamp logos to personalize leather goods. This practice supports craftsmanship and helps artisans build their brand identity. For international buyers, particularly from emerging markets, customization options and the ability to produce small batches are vital. They should also consider the ease of use of the stamps, as many artisans may not have access to professional stamping equipment.

How Do Custom Leather Stamp Logos Enhance Promotional Products?

Custom leather stamp logos are increasingly popular in the promotional products industry for creating branded leather gifts, such as keychains and coasters. This method of branding increases visibility and fosters customer engagement. B2B buyers should consider minimum order quantities and design flexibility when sourcing these stamps, as they often need to adapt designs for different promotional campaigns. Shipping options and lead times are also important, especially for businesses operating in fast-paced markets.

3 Common User Pain Points for ‘custom leather stamp logo’ & Their Solutions

Scenario 1: Delays in Custom Leather Stamp Production

The Problem: B2B buyers often experience frustration when custom leather stamps take longer to produce than anticipated. For businesses that rely on timely branding for product launches, promotional events, or fulfilling customer orders, delays can lead to lost revenue and damaged relationships. Buyers may also struggle with understanding the production timelines and how to communicate their urgent needs effectively to suppliers, resulting in further complications.

The Solution: To mitigate production delays, buyers should prioritize clear communication with suppliers regarding their timelines and urgency. When placing an order, it’s essential to specify the required delivery date upfront. Additionally, ask for a detailed production timeline, including mock-up approval and shipping times. Many suppliers offer expedited services for rush orders, which can be beneficial in critical situations. Establishing a strong relationship with your supplier can also facilitate better service and quicker turnaround times in the future. Lastly, consider suppliers who provide real-time updates on the production status, allowing you to plan accordingly.

Illustrative image related to custom leather stamp logo

Scenario 2: Quality Control Issues with Custom Designs

The Problem: One significant pain point for B2B buyers is ensuring that the quality of the custom leather stamp logo meets their brand standards. Inconsistent quality can occur due to variations in materials, engraving depth, or the manufacturing process, leading to dissatisfaction with the final product. Buyers may find themselves in a position where they have to reject a batch of stamps, resulting in wasted time and resources.

The Solution: To avoid quality control issues, buyers should conduct thorough research before selecting a supplier. Request samples of previous work to assess the quality of the materials used and the precision of the engraving. When submitting designs, provide high-resolution vector files to ensure clarity and accuracy in production. Additionally, consider requesting a mock-up before final production to visualize how the design will appear on leather. Establishing a clear set of quality expectations and communicating them to the supplier can help ensure that the final product aligns with your vision. Regular feedback and open dialogue throughout the production process can further enhance quality assurance.

Scenario 3: Difficulty in Sourcing the Right Material for Leather Stamps

The Problem: B2B buyers often face challenges in selecting the appropriate material for custom leather stamps that will yield optimal results for their branding needs. Different types of leather and materials may require specific stamp designs or techniques, and buyers may not fully understand how these factors affect the final outcome. This lack of clarity can lead to issues such as poor imprint quality or difficulty in applying the stamp.

The Solution: To navigate material selection effectively, buyers should educate themselves on the different types of leather and their compatibility with various stamping techniques. For example, vegetable-tanned leather is ideal for tooling and can handle deeper engravings, while other leathers may require more delicate stamping approaches. Engage with suppliers who offer expert guidance on material selection based on your specific branding needs. It’s also beneficial to request material recommendations based on the intended use of the stamp, whether for high-volume production or limited runs. Additionally, suppliers that provide comprehensive resources on material properties and stamping techniques can enhance your decision-making process, ensuring you choose the right combination for your brand.

Strategic Material Selection Guide for custom leather stamp logo

What Are the Key Materials for Custom Leather Stamp Logos?

When selecting materials for custom leather stamp logos, understanding the properties, advantages, and limitations of each option is crucial for international B2B buyers. This guide analyzes four common materials used in the production of leather stamps: brass, stainless steel, high-density resin, and aluminum. Each material offers unique characteristics that can influence the performance and suitability of the stamp for various applications.

Illustrative image related to custom leather stamp logo

How Does Brass Perform as a Material for Leather Stamps?

Brass is a popular choice for custom leather stamps due to its excellent durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for both heat embossing and traditional stamping methods. Brass stamps typically have a long lifespan and can be used for high-volume production without significant wear.

Pros: Brass offers exceptional durability and can produce detailed impressions on leather. It is also relatively easy to machine, allowing for intricate designs.

Cons: The initial cost of brass is higher than some alternatives, and it may require more complex manufacturing processes, particularly for custom designs. Additionally, brass can tarnish over time, necessitating regular maintenance.

Impact on Application: Brass is compatible with various types of leather, including vegetable-tanned and chrome-tanned leather, making it versatile for different branding needs.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards for metal products. Brass is widely accepted, but checking for any specific regulations is advisable.

What About Stainless Steel for Custom Leather Stamps?

Stainless steel is another robust option for leather stamps, known for its high corrosion resistance and strength. It can endure extreme conditions, making it suitable for both indoor and outdoor applications.

Pros: Stainless steel is highly durable and resistant to rust, ensuring longevity even in humid environments. It is also less likely to tarnish compared to brass.

Cons: The cost of stainless steel is generally higher than brass, and it can be more challenging to machine, which may lead to longer lead times for custom orders.

Impact on Application: Stainless steel is ideal for high-volume stamping applications where consistent quality is essential. It performs well with various leather types but may require higher pressure for effective stamping.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that meet international standards, such as ASTM or DIN, to ensure quality and compliance.

How Does High-Density Resin Compare for Leather Stamps?

High-density resin is a cost-effective alternative for custom leather stamps, particularly for short-run applications or less intricate designs. It is lightweight and easy to handle, making it suitable for smaller businesses or startups.

Illustrative image related to custom leather stamp logo

Pros: The primary advantage of resin is its lower cost and ease of production. It can be manufactured quickly and is suitable for lower-volume applications.

Cons: Resin stamps have a limited lifespan, typically lasting for about 1,000 uses, and they cannot withstand high temperatures or heavy pressure, which may restrict their application.

Impact on Application: Resin is best suited for light stamping on softer leathers and is not recommended for heat embossing. Its compatibility with various media is limited compared to metal options.

Considerations for International Buyers: Buyers should verify that the resin meets safety and environmental regulations in their respective countries, as standards can vary significantly.

Is Aluminum a Viable Option for Custom Leather Stamps?

Aluminum is a lightweight and cost-effective material that can be used for custom leather stamps. It offers a good balance between durability and affordability, making it an attractive option for many businesses.

Pros: Aluminum is easy to machine and can be produced quickly, allowing for fast turnaround times on custom orders. It is also resistant to corrosion.

Cons: While aluminum is durable, it is not as strong as brass or stainless steel, which may limit its use in high-pressure applications. It can also wear down more quickly than other metals.

Impact on Application: Aluminum stamps work well for lighter applications and can be effective for branding on various types of leather, but they may not hold up as well under heavy use.

Considerations for International Buyers: Buyers should ensure that aluminum products comply with local standards and regulations, particularly concerning material quality and safety.

Summary Table of Material Selection for Custom Leather Stamp Logos

| Material | Typical Use Case for custom leather stamp logo | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-volume stamping and heat embossing | Excellent durability and detail | Higher initial cost, tarnishes over time | Elevado |

| Stainless Steel | Consistent quality in harsh environments | High corrosion resistance | More expensive and harder to machine | Elevado |

| High-Density Resin | Short-run applications and simple designs | Cost-effective and quick production | Limited lifespan and heat sensitivity | Low |

| Aluminum | Light stamping and branding | Lightweight and fast production | Less durable under heavy use | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp logo

What Are the Key Stages in the Manufacturing Process of Custom Leather Stamp Logos?

The manufacturing of custom leather stamp logos involves several critical stages, each designed to ensure precision, durability, and quality. Understanding these stages is essential for B2B buyers looking to source high-quality leather stamps.

Material Preparation: What Materials Are Commonly Used?

The primary material for manufacturing custom leather stamps is solid brass, known for its durability and ability to withstand repeated use. Some manufacturers also offer options in high-density resin, which is less expensive but suitable for limited use cases. The preparation stage includes sourcing high-quality materials and verifying their compliance with international standards, which is crucial for ensuring the longevity and effectiveness of the stamps.

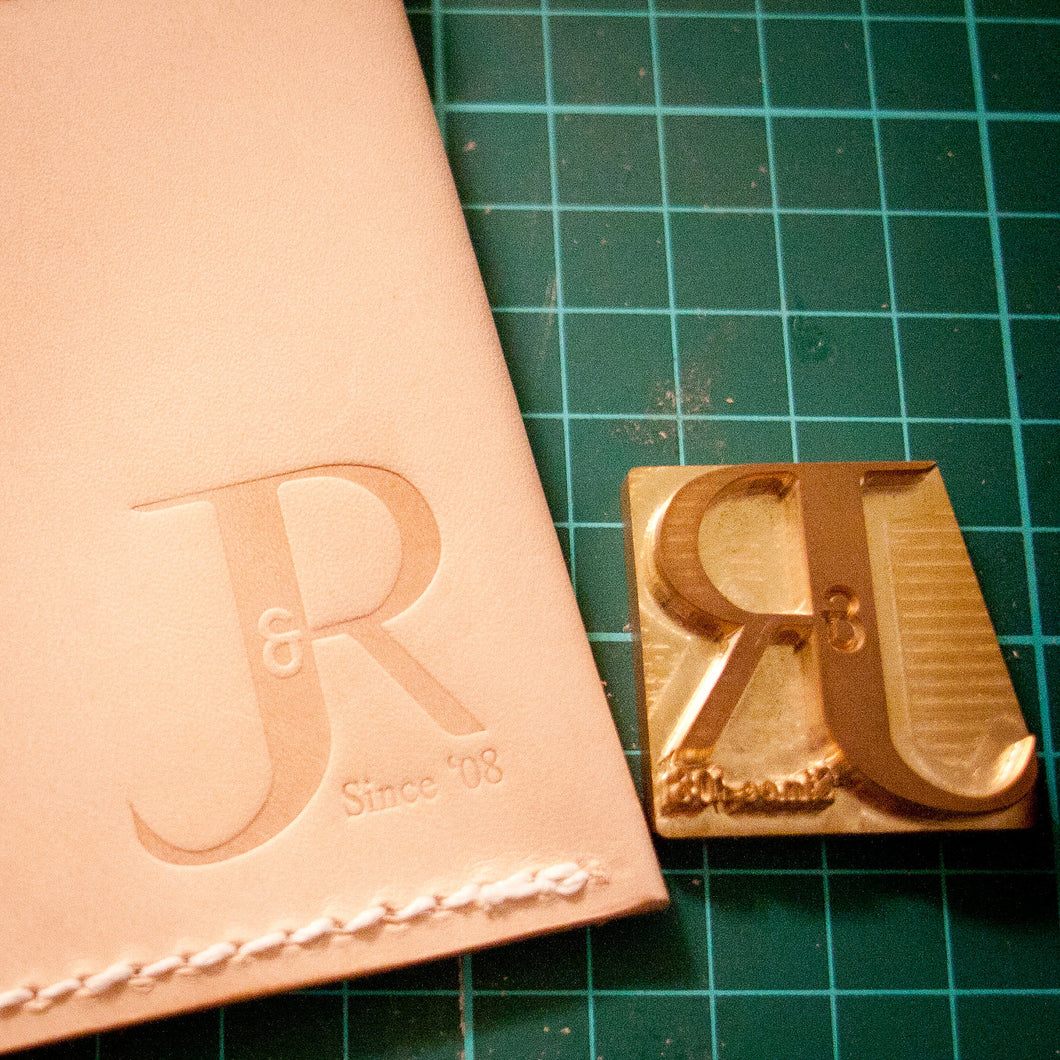

Forming: How Are Custom Designs Created?

Once the materials are ready, the forming stage begins. This typically involves the use of advanced techniques such as CNC (Computer Numerical Control) machining. CNC allows for precise engraving of designs onto the stamp surface, ensuring that intricate logos and markings are reproduced accurately. For B2B buyers, understanding the technology used in this stage can provide insights into the potential quality and detail of the final product.

Assembly: What Does This Process Entail?

After forming, the assembly stage may involve attaching handles or other components, especially if the stamp is designed for handheld use. Manufacturers might offer different options, such as electric branding irons or manual handles, depending on the end-use requirements. This flexibility can be an essential factor for buyers who need specific applications for their leather stamps.

Finishing: How Is Quality Enhanced in This Stage?

The finishing stage is where the final touches are applied to the stamp. This includes polishing and possibly applying protective coatings to enhance durability. The quality of the finishing can significantly affect the stamp’s performance, particularly regarding its resistance to wear and tear. B2B buyers should inquire about the finishing processes used by suppliers to ensure they meet their quality expectations.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance is a critical component of the manufacturing process, ensuring that the final product meets the required standards and specifications.

What International Standards Are Relevant for Custom Leather Stamp Production?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer is committed to maintaining quality throughout the production process. Additionally, industry-specific certifications may be relevant, depending on the intended use of the leather stamps.

Illustrative image related to custom leather stamp logo

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential for maintaining product standards. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, inspections are conducted to monitor the production process and identify any defects early.

- Final Quality Control (FQC): This final inspection assesses the finished product against quality standards before shipping.

B2B buyers should ask suppliers about their QC processes and the frequency of these inspections to gauge their commitment to quality.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods may vary by manufacturer, but some standard practices include:

- Dimensional Inspection: Ensuring that the stamp dimensions match the specifications provided.

- Visual Inspection: Checking for any surface defects or inconsistencies.

- Functional Testing: Assessing the stamp’s performance on leather to confirm it produces the desired results.

These tests help ensure that the product meets the intended quality before it reaches the buyer.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is crucial for mitigating risk and ensuring product satisfaction.

What Should B2B Buyers Look for in Supplier Audits and Reports?

Buyers should request access to quality control reports and audit results to understand a supplier’s QC processes better. A reputable supplier will be transparent about their practices and willing to share relevant documentation. This transparency is a good indicator of reliability and commitment to quality.

Illustrative image related to custom leather stamp logo

How Important Are Third-Party Inspections in the B2B Supply Chain?

In many cases, buyers may opt for third-party inspections to further validate the quality of products. These inspections can provide an unbiased assessment of the manufacturer’s processes and final products. Buyers should consider engaging third-party services, especially when dealing with new suppliers or large orders.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control can be complex, particularly when dealing with suppliers from regions like Africa, South America, the Middle East, and Europe.

How Do Cultural and Regional Differences Affect Quality Assurance?

Cultural and regional differences can impact how quality assurance is perceived and implemented. For instance, manufacturers in different regions may have varying levels of access to technology and training, affecting their ability to meet international standards. Buyers should conduct thorough research on potential suppliers, considering these factors when assessing quality.

What Should Buyers Know About Import Regulations and Compliance?

International buyers must also be aware of import regulations and compliance requirements in their home countries. Ensuring that products meet local standards is essential to avoid delays and additional costs. Buyers should engage with legal and compliance experts to navigate these complexities effectively.

Conclusion: Ensuring Quality in Custom Leather Stamp Logo Manufacturing

By understanding the manufacturing processes and quality assurance practices involved in creating custom leather stamps, B2B buyers can make informed decisions when selecting suppliers. Emphasizing quality control at every stage—from material preparation to final inspection—can help ensure that the products meet the required standards, ultimately leading to successful business outcomes.

Illustrative image related to custom leather stamp logo

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp logo’

Introdução

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for procuring custom leather stamp logos. Whether you are a business looking to enhance your brand identity or a craftsman aiming to create unique leather products, following these steps will ensure you make informed decisions, achieve high-quality results, and foster beneficial supplier relationships.

Step 1: Define Your Technical Specifications

Before approaching suppliers, it’s essential to clarify your requirements. Specify the dimensions, material (e.g., brass, resin), and depth of engraving for the stamp.

– Consider the type of leather you will be working with, as different materials may require specific stamp characteristics for effective branding.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers who specialize in custom leather stamps. This is vital to ensure quality and reliability.

– Look for customer reviews, testimonials, and case studies that showcase the supplier’s previous work.

– Check their website for detailed product offerings and their ability to meet your specific needs.

Step 3: Evaluate Supplier Capabilities

Once you have shortlisted potential suppliers, assess their manufacturing capabilities.

– Inquire about production times and their ability to handle rush orders, which is crucial if you have tight deadlines.

– Ask about the technology they use (e.g., CNC machining) and the materials available to ensure they can deliver a product that meets your specifications.

Step 4: Request Samples and Mock-ups

Before finalizing an order, it’s prudent to request samples or mock-ups of the stamp.

– This step allows you to evaluate the quality of the stamp and how well it reproduces your design.

– Review the mock-up for accuracy, and don’t hesitate to ask for revisions if necessary to achieve the desired outcome.

Illustrative image related to custom leather stamp logo

Step 5: Verify Certifications and Compliance

Ensure that the suppliers you are considering comply with industry standards and regulations.

– Request certifications related to quality management (e.g., ISO certifications) to guarantee that the supplier adheres to best practices.

– Inquire about environmental compliance if your business values sustainable practices, particularly important in regions focusing on eco-friendly production.

Step 6: Clarify Terms and Conditions

Before proceeding with an order, clarify all terms and conditions with the supplier.

– Discuss payment terms, shipping costs, and return policies to avoid any misunderstandings later.

– Ensure that you understand their warranty or guarantee policies for defective items, which can save you from potential losses.

Step 7: Establish Communication Channels

Finally, set up effective communication channels with your chosen supplier.

– Regular updates regarding the production process can help you stay informed about timelines and any potential issues.

– Establish a point of contact for any queries or concerns that may arise during the production process, ensuring smooth and transparent interactions.

Illustrative image related to custom leather stamp logo

By following this checklist, you can confidently navigate the sourcing process for custom leather stamp logos, ensuring that you partner with suppliers who align with your quality standards and business needs.

Comprehensive Cost and Pricing Analysis for custom leather stamp logo Sourcing

What Are the Key Cost Components for Custom Leather Stamp Logo Production?

When sourcing custom leather stamps for branding, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The most significant portion of the cost comes from the materials used. Brass is a popular choice due to its durability and precision, typically ranging from $68 to $89 for standard sizes. Alternative materials like high-density resin are available but may be less durable and more cost-effective for short-term uses.

-

Labor: Labor costs are influenced by the complexity of the design and the precision required. Custom designs may require skilled artisans for engraving, which can increase labor costs.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. These are generally fixed but can vary based on the supplier’s location and operational efficiency.

-

Tooling: Custom tooling costs may be incurred for unique designs, especially if specialized equipment is necessary. This can add to the initial investment but is often amortized over larger production runs.

-

Quality Control (QC): Ensuring the quality of the stamps is essential, especially for high-volume orders. QC processes may add to the labor costs but help prevent costly errors in the final product.

-

Logistics: Shipping costs can vary significantly based on location, shipping method, and order size. International buyers should consider these expenses when calculating total costs.

-

Margin: Suppliers typically apply a markup to cover their costs and profit margins, which can vary widely. Understanding the margin can help buyers negotiate better pricing.

How Do Price Influencers Affect Custom Leather Stamp Sourcing?

Several factors influence the pricing of custom leather stamps:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Suppliers may offer discounts for larger quantities, making it cost-effective for businesses with higher demand.

-

Specifications and Customization: More intricate designs or larger sizes often result in higher costs. Buyers should clearly define their specifications to receive accurate quotes.

-

Material Quality and Certifications: Higher-quality materials or certifications (e.g., for eco-friendliness) can increase costs. Buyers should weigh the importance of these factors against their budget and branding needs.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can all impact pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is essential for accurately calculating total costs. Different terms can influence who bears the shipping costs and risks.

What Are Effective Buyer Tips for Negotiating Custom Leather Stamp Prices?

International B2B buyers should consider several strategies to optimize their purchasing process:

-

Negotiate for Better Terms: Always seek to negotiate pricing, especially for larger orders. Discussing payment terms and delivery schedules can also lead to cost savings.

-

Evaluate Total Cost of Ownership: Beyond the purchase price, consider the longevity and durability of the stamp. A higher upfront cost may be justified if the product lasts longer and requires fewer replacements.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and import duties that may impact final costs. Engaging in discussions about these factors can lead to more favorable terms.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and priority service. Long-term partnerships often yield better negotiation leverage.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can prevent costly mistakes and ensure the product meets expectations.

By understanding these cost components, pricing influencers, and negotiation strategies, B2B buyers can make informed decisions when sourcing custom leather stamp logos, ensuring they achieve both quality and cost-effectiveness.

Illustrative image related to custom leather stamp logo

Alternatives Analysis: Comparing custom leather stamp logo With Other Solutions

Exploring Alternatives to Custom Leather Stamp Logos

In the realm of branding and personalization, a custom leather stamp logo serves as a distinctive tool for businesses aiming to leave a lasting impression on their products. However, various alternative solutions exist that can achieve similar branding goals. This analysis aims to compare the custom leather stamp logo with other viable methods, allowing B2B buyers to make informed decisions based on their specific needs.

| Comparison Aspect | Custom Leather Stamp Logo | Laser Engraving | Branding Iron |

|---|---|---|---|

| Performance | High-quality, detailed impressions; suitable for various leather types. | Precision engraving on multiple materials, including leather, wood, and metal. | Effective for deep impressions; best for high-volume applications. |

| Cost | Approximately $68-$89 per stamp. | Initial investment higher; costs vary by project size and complexity. | Costs range from $50 to over $200, depending on the design and materials. |

| Ease of Implementation | Requires manual stamping; straightforward process. | Requires technical expertise and setup; software needed for design. | Simple to use but may require heating for best results. |

| Maintenance | Minimal maintenance; durable if properly used. | Low maintenance but may require software updates and machine care. | Requires regular cleaning and maintenance of heating elements. |

| Best Use Case | Ideal for small-scale operations or artisanal brands. | Best suited for intricate designs and larger production runs. | Ideal for businesses needing consistent branding on leather goods. |

Understanding the Alternatives: Pros and Cons

Laser Engraving

Laser engraving offers a high level of precision and versatility, making it a strong alternative to custom leather stamps. It can engrave on a variety of materials beyond leather, such as wood and metal, which can be advantageous for businesses with diverse product lines. However, the initial investment in laser equipment can be substantial, and the operational complexity may require specialized training. While it excels in detailed and intricate designs, it may not provide the tactile quality that a physical stamp offers.

Branding Iron

Branding irons are another alternative that can create deep, lasting impressions on leather products. They are particularly effective for high-volume applications, as they can quickly and efficiently brand multiple items. While the setup is relatively simple, the necessity for heating can introduce complications, particularly in terms of temperature management. Branding irons are suitable for businesses focused on a consistent brand image across various leather goods, but they may not achieve the same level of detail as custom stamps.

Conclusion: Choosing the Right Solution for Your Business

When selecting between a custom leather stamp logo and its alternatives, B2B buyers should consider their specific branding needs, production scale, and budget. Custom leather stamps are ideal for small businesses or artisans focusing on quality and detail. In contrast, laser engraving may be more suitable for companies seeking versatility and precision across different materials. Branding irons work best for businesses that require a consistent and efficient branding process. Ultimately, aligning the chosen method with business objectives and production capabilities will ensure the most effective branding solution.

Illustrative image related to custom leather stamp logo

Essential Technical Properties and Trade Terminology for custom leather stamp logo

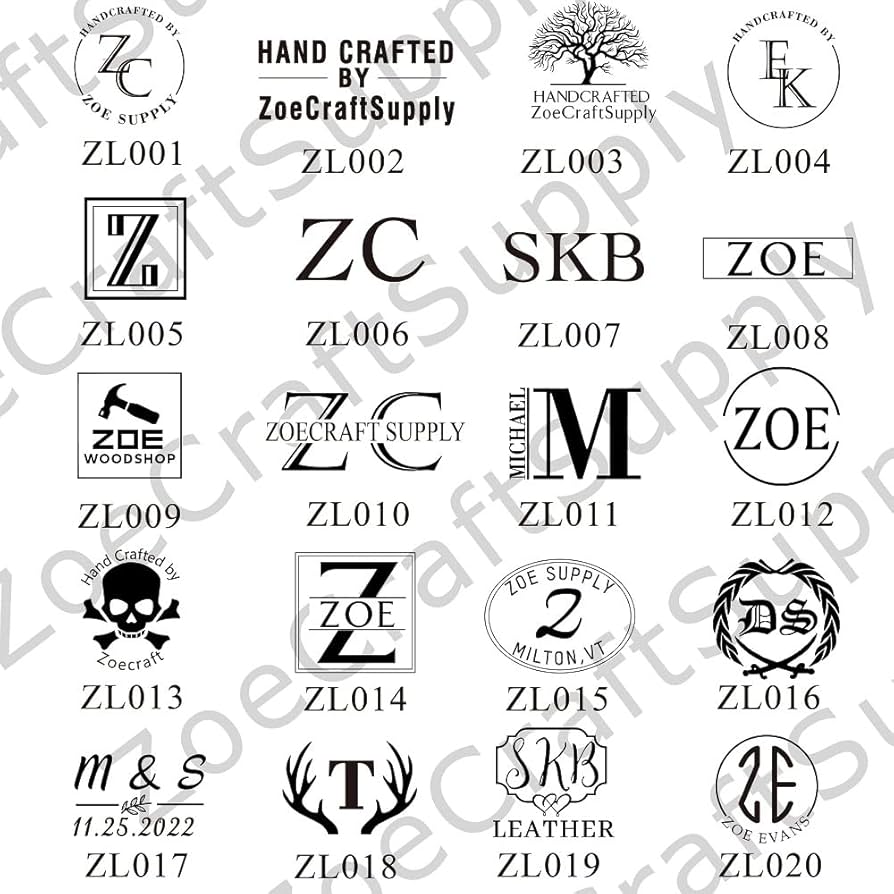

What Are the Key Technical Properties of Custom Leather Stamp Logos?

When investing in custom leather stamp logos, understanding the technical specifications is crucial for ensuring product quality and suitability for your business needs. Here are some essential properties to consider:

1. Material Grade

The most common materials for leather stamps include solid brass and high-density resin. Brass is preferred for high-volume applications due to its durability and ability to withstand repeated use, while resin stamps are more cost-effective but less durable, suitable for limited applications. Choosing the right material impacts the lifespan of the stamp and the quality of the impressions it produces.

2. Engraving Depth

The engraving depth typically ranges from 2mm to 3mm, which affects how deeply the stamp will imprint the leather. A deeper engraving is necessary for clearer, more defined logos, especially when working with thicker leather types. In B2B contexts, a precise engraving depth ensures that the branding remains legible and aesthetically pleasing over time.

3. Stamp Thickness

Standard stamp thickness is around 8mm. This thickness provides stability during use, preventing bending or warping that can occur with thinner stamps. For businesses, a thicker stamp can lead to more consistent impressions and reduce the need for frequent replacements, thus optimizing operational efficiency.

4. Size Specifications

Custom stamps are often priced based on the size of the design, typically with a standard maximum area of 10 cm². Understanding size specifications is vital for budgeting and ensuring the stamp fits the intended application. Larger designs may incur additional costs, so it’s important to plan accordingly.

5. Heat Resistance

For stamps designed for heat embossing, the material must withstand high temperatures without degrading. This is particularly relevant for businesses that utilize heat embossing techniques for branding on leather products. Choosing a heat-resistant material ensures that the stamp maintains its integrity during the embossing process.

6. Die Type

Stamps can come in male or female die formats. The choice between these die types affects the way the logo is applied to the leather. Male dies push the design into the leather, while female dies create an indented impression. Understanding these differences allows businesses to select the right type based on their branding needs.

Which Trade Terms Are Important for Custom Leather Stamp Logos?

Familiarity with industry terminology can streamline the purchasing process and facilitate better communication with suppliers. Here are some common trade terms to know:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather stamps, understanding OEM relationships can help businesses ensure they are sourcing from reputable manufacturers who meet quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses that may need to balance cost efficiency with stock levels.

Illustrative image related to custom leather stamp logo

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. Using RFQs allows businesses to compare prices and terms across multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk transfer, and delivery obligations, especially for businesses involved in cross-border trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times helps businesses manage expectations regarding delivery and production schedules, which is critical for maintaining supply chain efficiency.

Illustrative image related to custom leather stamp logo

6. Customs Clearance

This term describes the process of passing goods through customs so they can enter or leave a country. For international buyers, understanding customs clearance procedures is vital to avoid delays and additional costs during shipping.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing custom leather stamp logos, ensuring they achieve the best results for their branding needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamp logo Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Stamp Logo Sector?

The global custom leather stamp logo market is experiencing notable growth, driven by the rising demand for personalized products across various sectors, including fashion, craft, and promotional items. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to differentiate their brands, custom leather stamps offer a unique solution for branding and personalization. Key trends include the integration of advanced technologies such as CNC machining, which allows for high-precision designs, and the growing popularity of e-commerce platforms that facilitate direct ordering and customization.

Additionally, rapid turnaround times have become a significant competitive advantage, with many suppliers offering expedited services for urgent orders. International buyers are increasingly looking for suppliers who can provide quick shipping options, often within 2-3 business days. This demand for speed, combined with the ability to customize designs through digital file uploads, reflects a broader trend towards greater flexibility and responsiveness in the B2B marketplace.

Illustrative image related to custom leather stamp logo

Moreover, the rise of eco-conscious consumers is prompting suppliers to offer sustainable options, such as vegetable-tanned leather and eco-friendly packaging. As a result, B2B buyers are encouraged to consider suppliers who prioritize sustainability, aligning their branding efforts with ethical practices that resonate with their customer base.

How Is Sustainability Shaping the Sourcing of Custom Leather Stamps?

Sustainability is becoming a cornerstone of sourcing strategies in the custom leather stamp logo sector. The environmental impact of leather production, particularly concerning water usage, chemical treatment, and waste, is under scrutiny. As such, B2B buyers are increasingly seeking partners who demonstrate a commitment to ethical sourcing and environmental stewardship.

Suppliers are responding by offering ‘green’ certifications and materials. For instance, vegetable-tanned leather is gaining traction due to its less harmful production process compared to chrome-tanned options. Furthermore, many manufacturers are adopting sustainable practices in their operations, such as using recycled materials for packaging and implementing energy-efficient production methods.

Ethical supply chains are crucial for enhancing brand reputation and building trust with customers. Buyers are advised to engage with suppliers who can provide transparency regarding their sourcing methods and production processes. This not only aligns with growing consumer expectations for corporate responsibility but also positions businesses as leaders in sustainability within their respective markets.

What Is the Brief Evolution and History of Custom Leather Stamps in B2B?

The history of custom leather stamps can be traced back to ancient civilizations, where artisans used simple tools to mark leather goods for identification and authenticity. Over the centuries, as leathercraft evolved into a recognized art form, so did the methods of branding and stamping.

In the modern era, the introduction of precision machinery and digital technologies has revolutionized the production of custom leather stamps. CNC engraving, for example, enables the creation of intricate designs with unparalleled accuracy, catering to the sophisticated demands of today’s B2B buyers.

As the market continues to evolve, the blend of traditional craftsmanship with modern technology is paving the way for innovative branding solutions, making custom leather stamps a vital tool for businesses looking to establish their identity in a competitive landscape. This evolution reflects a broader trend of personalization and quality that resonates strongly with contemporary consumer preferences, especially in markets across Africa, South America, the Middle East, and Europe.

In summary, the custom leather stamp logo sector is rapidly adapting to market demands, driven by technological advancements, sustainability considerations, and the timeless appeal of personalized branding. For B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that align with both their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp logo

-

How do I ensure the quality of my custom leather stamp logo?

To ensure the quality of your custom leather stamp logo, begin by researching potential suppliers. Look for manufacturers with positive reviews and a portfolio showcasing their previous work. Request samples or mock-ups before finalizing your order to verify the craftsmanship and material quality. Additionally, inquire about the production process, including the engraving technique and materials used. Establish clear communication regarding your expectations, and consider requesting a quality assurance protocol that the supplier follows to maintain consistent standards. -

What is the best material for a custom leather stamp logo?

The best material for a custom leather stamp logo depends on your intended use and volume. Brass is highly recommended for its durability and ability to withstand high-pressure stamping, making it ideal for high-volume applications. For lighter or less frequent use, high-density resin can be a cost-effective option, though it has a limited lifespan. Always discuss your specific requirements with the supplier to ensure you choose the right material that aligns with your branding and operational needs. -

How can I customize my leather stamp logo design?

Customization of your leather stamp logo design can be achieved by providing your supplier with high-quality vector files (AI or PDF preferred) of your logo. Most suppliers offer design services and can assist in refining your concept. You may also request mock-ups to visualize how your design will appear on leather. Be clear about any specific elements you want to include, such as size, shape, and engraving depth, to ensure the final product meets your branding standards. -

What are the typical minimum order quantities (MOQs) for custom leather stamps?

Minimum order quantities for custom leather stamps can vary significantly between suppliers. Some may accept orders for a single stamp, while others might have a MOQ of 10 or more. It’s essential to clarify MOQs during your initial discussions with potential suppliers. If you’re looking to order in bulk, inquire about price breaks or discounts that may apply, as this can be beneficial for scaling your production and reducing overall costs. -

What payment terms should I expect when ordering custom leather stamps internationally?

Payment terms for international orders of custom leather stamps typically involve a deposit upfront, often ranging from 30% to 50% of the total order value, with the balance due upon completion or shipment. Some suppliers may offer payment via credit card, bank transfer, or platforms like PayPal. Always confirm payment methods accepted and consider any additional fees related to international transactions. It’s advisable to establish a clear agreement on payment terms to avoid misunderstandings. -

How long does it take to receive my custom leather stamp order?

The production and shipping time for custom leather stamps can vary based on the supplier and order complexity. Generally, expect production to take between 2 to 6 business days after design approval. Shipping times will depend on your location and the chosen shipping method—standard shipping may take longer, while express options can expedite delivery. Always ask your supplier for estimated timelines to plan your branding activities accordingly and accommodate any urgent needs. -

What should I consider when vetting suppliers for custom leather stamps?

When vetting suppliers for custom leather stamps, assess their experience, quality of work, and customer service. Look for reviews and testimonials from previous clients, and check their portfolio for examples of similar projects. Communication is key; ensure they respond promptly and are willing to accommodate your specific needs. Additionally, inquire about their production capabilities, turnaround times, and quality assurance processes to ensure they align with your business requirements. -

How can I handle logistics for international shipping of my custom leather stamps?

To manage logistics for international shipping of custom leather stamps, first, confirm the shipping options provided by your supplier. Choose a reliable carrier that offers tracking and insurance for valuable shipments. Understand customs regulations and potential duties or taxes that may apply to your order in your country. It’s advisable to maintain open communication with the supplier regarding shipping status and any potential delays, ensuring you receive your order in a timely manner.

Top 9 Custom Leather Stamp Logo Manufacturers & Suppliers List

1. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “regular_price”: “US$68.00”, “size_options”: [“Up to 1.25 x 1.25 inch / 3 x 3 cm”, “Up to 1.5 x 1.5 inch / 4 x 4 cm”, “Up to 2 x 2 inch / 5 x 5 cm”, “Up to 3 x 3 inch / 7.5 x 7.5 cm”, “Up to 4 x 4 inch / 10 x 10 cm”], “lead_time”: “2-5 working days”, “material”: “Solid Brass”, “stamp_thickness”: “8mm”, “engraving_depth”: “3mm”, “applications”: [“Leather emb…

2. Infinity Stamps Inc. – Leather Stamping Products

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. The company is family-owned and has been in business for over 25 years, emphasizing their products are made in the USA.

3. Custom Brand – Leather Embossing Stamp

4. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

5. Tandy Leather – Custom Logo Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Custom Logo Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps available at Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, and Farriers, as well as Custom Locksmith Stamps and Industrial Markings. The product range features Leather Design Stamps, including Sheridan Flowers/Leaves, Leather State Stamps, and Jewelry Design Stamps. There are also Pro Series Desi…

7. Buckeye Engraving – Custom Leather Stamps

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Buckeye Engraving offers custom leather stamps, dies, and branding irons made in the USA. The stamps can be crafted from aluminum, steel, or brass, with brass being the most popular choice due to its durability and resistance to rust. The company provides high-detail stamps tailored to customer specifications, including options for wet stamping and heat stamping. Customization includes the ability…

8. Leatherstampstools – Custom Leather Stamps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options from Leatherstampstools on Etsy, Springfield Leather, leatherstampmaker, TyraCraftTools.

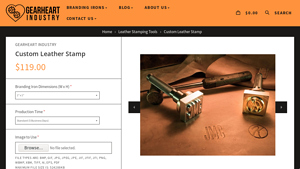

9. Gearheart Industry – Custom Leather Stamp

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “price”: “$119.00”, “dimensions”: [“1” x “1””, “1” x “1.5””, “1.5” x “1.5””], “production_time”: [“Standard (5 Business Days)”, “RUSH (1 Business Day)”], “file_types”: [“bmp”, “gif”, “jpg”, “jpeg”, “jpe”, “jif”, “jfif”, “jfi”, “png”, “wbmp”, “xbm”, “tiff”, “ai”, “eps”, “pdf”], “max_file_size”: “524288KB”, “features”: [“Custom made per your specifications”, …

Strategic Sourcing Conclusion and Outlook for custom leather stamp logo

In the competitive landscape of custom leather stamp logos, strategic sourcing emerges as a vital practice for international B2B buyers. By prioritizing quality materials, such as solid brass and high-density resin, businesses can ensure durability and effectiveness in branding efforts. Fast turnaround times, often as short as 2-3 working days, enable companies to respond swiftly to market demands, enhancing their agility in a dynamic marketplace.

Illustrative image related to custom leather stamp logo

Moreover, investing in customization options allows brands to create unique identities that resonate with their target audiences. This personalization not only strengthens brand recognition but also fosters customer loyalty. Buyers from regions like Africa, South America, the Middle East, and Europe should leverage local suppliers to minimize shipping costs and support regional economies, while also considering global vendors for specialized products.

As you navigate your sourcing strategy, remember that the quality of your branding tools directly impacts your business image. Embrace the opportunity to innovate and differentiate your brand through custom leather stamps. Take action today by reaching out to trusted suppliers to explore how these products can elevate your brand presence in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.