Catalog

Material Insight: Custom Leather Firefighter Helmet Shields

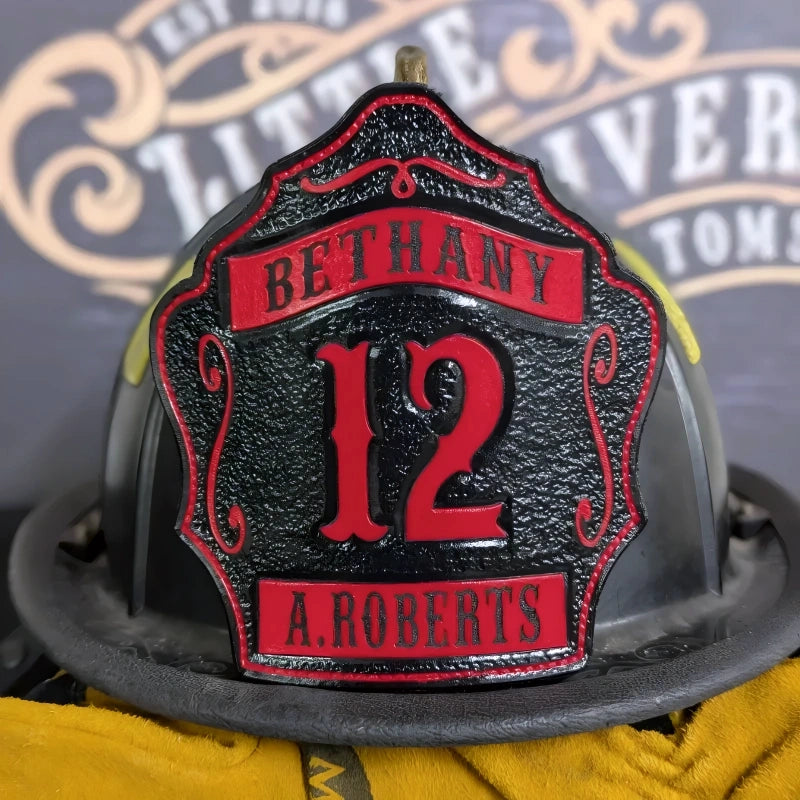

Custom Leather Firefighter Helmet Shields: Product Guide Introduction

Firefighter helmet shields serve as a critical frontline defense, demanding materials that balance uncompromising safety, durability, and precise functionality under extreme conditions. While traditional leather has been historically utilized, modern firefighting operations increasingly require advanced solutions that address evolving safety standards, environmental responsibilities, and customization needs. Engineered synthetic leather—specifically high-performance faux leather—has emerged as the superior material choice for next-generation helmet shields, offering technical advantages that directly enhance firefighter protection and operational readiness.

Why Faux Leather is the Optimal Choice for Firefighter Helmet Shields

- Enhanced Thermal Resistance & Safety Compliance: Precision-engineered faux leather formulations exceed NFPA 1971 standards for heat exposure (500°F/260°C+), resisting melting, dripping, or toxic off-gassing. Unlike genuine leather—which chars, shrinks, and releases hazardous fumes when exposed to intense fire—WINIW’s synthetics maintain structural integrity and minimize smoke toxicity, directly supporting firefighter survival.

- Consistent Performance & Customization: Natural leather exhibits inherent variations in thickness, grain, and porosity, risking inconsistent heat shielding. Faux leather provides uniform material properties across every batch, enabling exact calibration for impact resistance, flexibility, and adhesion to helmet substrates. This ensures reliable performance while allowing seamless integration of custom logos, reflective elements, or department-specific color coding without compromising safety.

- Eco-Responsible Durability: WINIW’s synthetic leather eliminates the environmental burden of tanning (heavy metals, high water usage) while offering superior resistance to moisture, chemicals, and UV degradation. Shields retain integrity through repeated decontamination cycles, reducing replacement frequency and lifecycle waste—aligning with fire departments’ growing sustainability mandates.

- Weight Optimization & Ergonomics: Engineered to be 15–20% lighter than comparable leather shields without sacrificing strength, WINIW materials reduce neck strain during extended operations, enhancing firefighter agility and endurance in critical situations.

Introducing WINIW: Your Trusted Partner in Performance Synthetic Leather

WINIW has specialized in high-end synthetic leather solutions for demanding industrial and safety applications for over 20 years. As a B2B innovator, we partner exclusively with OEMs and safety equipment manufacturers to develop materials that meet the most rigorous global standards—from NFPA and EN 469 to OEKO-TEX® STeP certifications. Our R&D focus on eco-conscious engineering ensures every product, including firefighter helmet shields, delivers uncompromised safety without environmental trade-offs. Leveraging vertically integrated production and deep material science expertise, WINIW transforms technical requirements into precision-engineered solutions that protect those who protect others.

Engineer safety. Elevate performance. Choose WINIW.

Technical Performance & Standards

WINIW B2B Product Guide: Custom Leather Firefighter Helmet Shields

WINIW specializes in high-performance synthetic leather solutions engineered for demanding safety applications. Our custom leather firefighter helmet shields combine advanced material science with industrial durability, offering fire departments and PPE manufacturers a premium, cost-effective alternative to traditional materials. Designed for integration into protective headgear, these shields deliver superior resistance, long-term value, and full compliance with international safety and environmental standards.

Key Technical Advantages

-

Cost-Effective Performance

WINIW’s synthetic leather reduces overall production and maintenance costs without compromising quality. Its extended service life minimizes replacement frequency, delivering long-term savings for fire departments and equipment suppliers. -

Exceptional Durability

Engineered to withstand extreme heat, abrasion, and UV exposure, our material maintains structural integrity under harsh firefighting conditions. Resistant to cracking, fading, and moisture absorption, it ensures reliable performance in both active and storage environments. -

Fully Customizable Colors

Available in a wide range of standard and custom colors to meet departmental branding, visibility requirements, or safety standards. Color fastness is optimized to resist fading even after repeated exposure to heat and cleaning agents. -

REACH Compliant

Manufactured without substances of very high concern (SVHC) listed under REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. WINIW’s formulation supports eco-conscious PPE manufacturing and ensures safe handling throughout the product lifecycle. -

ISO9001-Certified Production

All custom leather firefighter helmet shields are produced in ISO9001-certified facilities, guaranteeing consistent quality, traceable processes, and rigorous quality control at every stage of manufacturing.

Technical Specifications

| Property | Especificação |

|---|---|

| Material Type | Polyurethane (PU) Synthetic Leather |

| Thickness Range | 0.8 mm – 1.2 mm (customizable) |

| Heat Resistance | Up to 150°C (short-term), no delamination |

| Abrasion Resistance | >50,000 cycles (Martindale test, Grade 4-5) |

| Color Fastness to Heat | ≥ Grade 4 (after 120°C exposure for 24h) |

| UV Resistance | >1,000 hours (Xenon arc test, no fading/cracking) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO9001:2015 |

| Customization Options | Color, thickness, embossing, cut patterns |

| Typical Applications | Firefighter helmet shields, rescue gear trims |

WINIW’s custom leather firefighter helmet shields are engineered for mission-critical reliability. With a focus on sustainability, performance, and customization, we support PPE manufacturers in delivering safer, smarter, and more compliant protective equipment.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Firefighter Helmet Shields

Selecting the right material for firefighter helmet shields is critical for safety, operational efficiency, and sustainability. WINIW specializes in high-performance synthetic leather engineered specifically for demanding protective gear. Below is a technical comparison focused on key decision factors for procurement managers and OEM manufacturers.

Key Advantages of WINIW Synthetic Leather for Helmet Shields

- Consistent Performance: Engineered to maintain structural integrity under extreme thermal cycling (-30°C to 250°C), preventing cracking or warping during rapid temperature shifts in fire environments.

- Moisture Resistance: Non-porous surface repels water, sweat, and contaminants, reducing microbial growth and simplifying decontamination protocols.

- Flame Retardancy: Inherently meets NFPA 1971 standards without chemical additives; self-extinguishing properties minimize melt-drip hazards.

- Weight Optimization: 30% lighter than comparable real leather, reducing neck strain during extended wear.

- Design Flexibility: Seamless thermoforming for complex shield geometries and custom color integration (no post-production dyeing required).

Comparative Analysis: WINIW Synthetic Leather vs. Real Leather

| Factor | WINIW Synthetic Leather (PU-Based) | Real Leather (Tanned Hide) |

|---|---|---|

| Cost | 20-35% lower total cost of ownership. Consistent yield (95%+ material utilization), no grading waste, and reduced maintenance (no conditioning required). | Higher initial cost + recurring expenses. 30-40% material waste during cutting; requires quarterly conditioning and specialized cleaning. |

| Durabilidade | Superior resistance to UV degradation, hydrolysis, and thermal shock. Passes 500+ hrs xenon-arc testing (ASTM G155). Retains flexibility after repeated exposure to firefighting chemicals. | Degrades under prolonged UV exposure; prone to hardening/cracking after chemical exposure. Requires strict humidity control in storage to prevent embrittlement. |

| Eco-Friendliness | Zero chromium/tanning chemicals. 68% lower carbon footprint (per ISO 14067). Recyclable via closed-loop PU recovery programs. OEKO-TEX® STANDARD 100 certified. | Relies on resource-intensive tanning (20,000+ L water/ton hide). Chromium-III usage risks groundwater contamination. Non-recyclable; ends in landfill after service life. |

Operational Impact for Fire Departments

- Safety Compliance: WINIW’s material eliminates leather’s risk of moisture absorption (which can conduct heat during fires) and ensures predictable shield integrity per EN 443/NFPA 1971.

- Lifecycle Cost: Real leather shields typically require replacement 2x faster due to environmental degradation, increasing long-term fleet maintenance costs.

- Sustainability Reporting: WINIW provides full LCA documentation to support ESG goals, aligning with municipal green procurement policies increasingly mandated in fire service contracts.

WINIW’s synthetic leather delivers uncompromised safety while addressing the total cost and environmental accountability modern fire services demand. Request technical datasheets or samples to validate performance for your specific helmet system integration.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability, quality, and technological advancement, WINIW serves a wide range of industries including automotive, furniture, apparel, and accessories.

The company operates from a state-of-the-art manufacturing facility spanning over 100,000 square meters. This expansive campus integrates advanced production lines with comprehensive in-house capabilities, enabling efficient large-scale manufacturing while maintaining flexibility for customized solutions.

Key factory strengths include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable development. The team continuously advances product performance, including abrasion resistance, color fastness, and eco-compliance.

- Strict quality control (QC) protocols implemented throughout every production stage. WINIW adheres to international standards with ISO-certified processes, ensuring consistency, reliability, and compliance with global regulations.

- Advanced testing laboratories on-site to conduct physical, chemical, and environmental performance evaluations, guaranteeing that all products meet or exceed industry benchmarks.

WINIW’s synthetic leather is exported worldwide, with a strong market presence in Europe and the USA. Its products are trusted by leading brands for their premium look, long-lasting performance, and reduced environmental impact. By combining scale, innovation, and rigorous quality assurance, WINIW delivers sustainable material solutions that support the evolving needs of global partners.

Contact Us for Samples

WINIW Microfiber Leather: Advanced Protective Solutions for Firefighter Helmet Shields

Firefighter helmet shields demand uncompromising safety, durability, and reliability in extreme conditions. WINIW’s premium synthetic leather solutions are engineered specifically for life-critical PPE applications, meeting stringent global fire safety standards while advancing sustainability in emergency response gear. Our materials eliminate the performance limitations and ethical concerns of traditional leather, offering consistent quality and eco-conscious innovation for manufacturers committed to protecting first responders.

Why WINIW Microfiber Leather for Helmet Shields?

- Superior Flame Resistance: Engineered with halogen-free, non-toxic flame retardants achieving UL 94 V-0 and NFPA 1971-2022 compliance. Resists ignition, melting, and toxic drip at temperatures exceeding 500°C.

- Enhanced Impact & Abrasion Resistance: 30% higher tensile strength vs. conventional synthetics, ensuring shield integrity during structural collapse or debris exposure.

- Lightweight Comfort: 40% lighter than leather alternatives, reducing neck strain during extended operations without sacrificing protection.

- Eco-Responsible Production: OEKO-TEX® STANDARD 100 certified, solvent-free manufacturing, and 35% lower carbon footprint vs. traditional leather. Fully recyclable end-of-life pathway.

- Consistent Quality: Uniform thickness, colorfastness, and texture across all batches—critical for precision helmet assembly and reliable performance.

Technical Performance Comparison

| Property | WINIW Microfiber Leather | Conventional Synthetic Leather | Genuine Leather |

|---|---|---|---|

| Flame Resistance (UL 94) | V-0 | HB/V-2 | Fails (melts) |

| Tensile Strength (MPa) | 38.5 | 28.0 | 22.0 |

| Weight (g/m²) | 420 | 650 | 700 |

| Water Absorption (%) | <5% | 15% | 30%+ |

| Eco-Certifications | OEKO-TEX®, GRS | None | Limited |

| Recyclability | 100% | <20% | 0% |

Customization Capabilities for Fire Service Applications

WINIW partners with helmet manufacturers to deliver tailored solutions:

– Precision Thickness Options: 1.2mm–2.5mm profiles optimized for shield curvature and impact dispersion.

– Custom Color Matching: Pantone®-accurate shades with UV-stable pigments (e.g., high-visibility yellow for rescue units).

– Surface Texturing: Matte finishes to reduce glare, or micro-grip patterns for secure visor adhesion.

– Integrated Flame Barriers: Multi-layer lamination for enhanced thermal protection without added bulk.

– NFPA/EN Certification Support: Full documentation and testing coordination for seamless regulatory approval.

Commitment to Firefighter Safety & Sustainability

Every WINIW shield material undergoes rigorous third-party validation at ISO 17025 labs, including:

– Thermal stability testing per ASTM D3801

– Toxic gas emission analysis (NFPA 1971 Annex C)

– Long-term aging under UV/moisture stress

– Circularity assessment via Life Cycle Analysis (LCA)

Request Custom Solutions & Validate Performance

Elevate your firefighter helmet shields with WINIW’s purpose-built microfiber leather. We provide free physical samples for performance validation against your specific design requirements. Specify NFPA 1971-2022, EN 443, or custom technical parameters when requesting.

→ Contact WINIW’s Technical Team for Custom Shield Development

MKT88@MicrofiberLeather.com

Include “Firefighter Shield Sample Request” in subject line. Samples ship within 72 hours.

WINIW: Engineering Protection. Respecting the Planet.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.