Catalog

Material Insight: Vinyl Leatherette Fabric

B2B Product Guide: Vinyl Leatherette Fabric

Vinyl leatherette fabric represents a sophisticated, high-performance synthetic alternative engineered to meet the demanding requirements of modern commercial and industrial applications. Combining the aesthetic appeal of genuine leather with enhanced functional properties, this material is constructed from a durable polyvinyl chloride (PVC) or polyurethane (PU) coating applied to a robust textile backing. It delivers exceptional consistency, design versatility, and operational efficiency for businesses seeking reliable, scalable upholstery and surface solutions across furniture, transportation, healthcare, and retail sectors.

Why Vinyl Leatherette is the Optimal Choice for Commercial Applications

Faux leather outperforms traditional materials in B2B environments due to its engineered advantages:

- Cost Efficiency & Predictability: Eliminates the price volatility and supply chain disruptions associated with genuine leather. Offers consistent pricing and reliable large-scale availability for project budgeting and production planning.

- Enhanced Durability & Performance: Superior resistance to abrasion, tearing, stains, and UV degradation ensures longevity in high-traffic settings. Easily withstands rigorous commercial use without compromising appearance.

- Simplified Maintenance & Hygiene: Non-porous surface prevents liquid absorption, enabling quick cleaning with standard disinfectants. Critical for healthcare, hospitality, and public transport where sanitation standards are paramount.

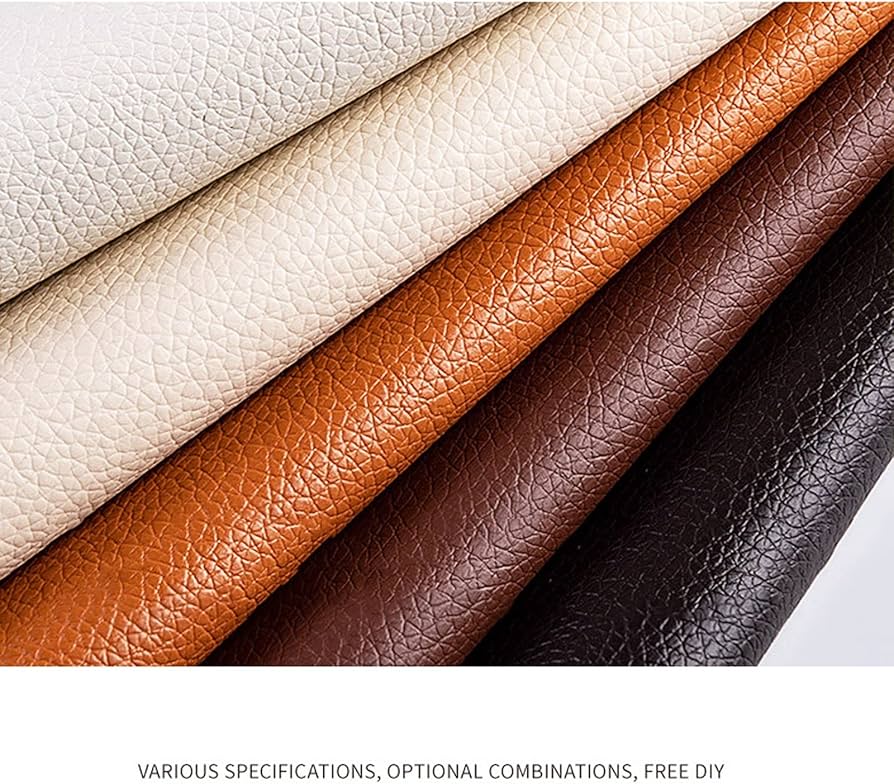

- Design Flexibility & Consistency: Available in an extensive spectrum of colors, textures, and finishes (matte, gloss, embossed) with uniform appearance across large production runs—unachievable with natural hide variations.

- Eco-Conscious Resource Management: Significantly reduces water consumption, land use, and chemical processing compared to bovine leather production. Modern formulations prioritize recyclability and reduced environmental footprint without sacrificing performance.

WINIW: Your Trusted Partner in Advanced Synthetic Leather

WINIW leverages over 20 years of specialized expertise in developing and manufacturing premium synthetic leather solutions for global B2B markets. We understand that commercial clients require materials that balance operational excellence with evolving sustainability mandates. Our R&D-driven approach focuses on:

- Engineering next-generation vinyl leatherette with enhanced eco-credentials, including PVC-free options and recycled content integration.

- Ensuring rigorous quality control to meet international safety (REACH, RoHS) and performance standards (Martindale, Taber abrasion, lightfastness).

- Providing scalable production capabilities and technical support to optimize material integration into your manufacturing processes.

By choosing WINIW, businesses gain a strategic partner committed to delivering innovative, responsible, and high-value synthetic leather that elevates product performance while supporting long-term environmental goals.

Technical Performance & Standards

WINIW Vinyl Leatherette Fabric – B2B Product Technical Guide

WINIW’s vinyl leatherette fabric is engineered to meet the demanding needs of commercial and industrial applications, offering a high-performance, sustainable alternative to genuine leather. Designed for manufacturers, designers, and procurement professionals, this synthetic leather combines cost efficiency with exceptional durability and environmental responsibility. Ideal for use in automotive interiors, furniture, luggage, footwear, and more, WINIW’s vinyl leatherette delivers consistent quality and broad customization capabilities without compromising on compliance or performance.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s vinyl leatherette reduces material and processing costs compared to genuine leather. With consistent roll yields and minimal waste, it supports high-efficiency manufacturing. The absence of natural defects (scars, insect bites, etc.) ensures uniform quality across large production runs, lowering rejection rates and rework. -

Superior Durability

Reinforced with high-tenacity polyester backing and wear-resistant surface coatings, the material offers excellent abrasion resistance (tested up to 50,000 cycles in Martindale testing), tear strength, and dimensional stability. It maintains integrity under repeated flexing and prolonged use, making it ideal for high-traffic applications. -

Customizable Color & Finish Options

WINIW supports full color customization via digital Pantone matching (PMS), with options for matte, glossy, soft-touch, embossed, and textured finishes. Batch-to-batch color consistency is maintained through automated dyeing systems and spectrophotometric quality control, ensuring brand accuracy across global supply chains. -

REACH Compliant Chemistry

The vinyl leatherette is manufactured without SVHC (Substances of Very High Concern) listed under REACH (EC 1907/2006). It is free from heavy metals (lead, cadmium), phthalates, and APEOs, ensuring safe handling and compliance with EU and international chemical regulations. -

ISO 9001-Certified Manufacturing

Produced in ISO 9001:2015 certified facilities, WINIW’s quality management system ensures strict process control, traceability, and continuous improvement. Each production batch undergoes rigorous in-line and final inspections to maintain performance standards.

Technical Specifications

| Property | Especificação | Test Method |

|---|---|---|

| Base Material | PVC-coated polyester fabric | Visual/Manufacturer |

| Thickness | 0.6 mm – 1.2 mm (customizable) | ISO 2589 |

| Weight | 280 – 450 g/m² | ISO 9073-1 |

| Tensile Strength (MD) | ≥ 90 N/25mm | ISO 1421 |

| Tensile Strength (CD) | ≥ 80 N/25mm | ISO 1421 |

| Elongation at Break (MD/CD) | ≤ 25% | ISO 1421 |

| Martindale Abrasion Resistance | ≥ 50,000 cycles (no breakdown) | ISO 12947-2 |

| Color Fastness to Rubbing | Dry: Class 4–5; Wet: Class 4 | ISO 105-X12 |

| Color Fastness to Light | ≥ Grade 6 (400 hours Xenon) | ISO 105-B02 |

| Cold Crack Temperature | ≤ -20°C | ASTM D1790 |

| REACH Compliance | Fully compliant, no SVHCs detected | Internal & 3rd Party |

| ISO Certification | ISO 9001:2015 | Certificate on file |

| Customization Lead Time | 7–15 days (sample); 20–30 days (bulk) | Production Schedule |

WINIW vinyl leatherette fabric delivers a balanced solution for B2B clients seeking performance, regulatory compliance, and economic efficiency. With scalable production capacity and dedicated technical support, WINIW enables seamless integration into diverse manufacturing workflows while supporting sustainable material transitions.

Why Choose Synthetic over Real Leather

B2B Material Comparison Guide: Synthetic Leather (PU/PVC) vs. Genuine Leather

As a leader in sustainable synthetic leather innovation, WINIW provides this objective comparison to support informed material selection for commercial upholstery, automotive interiors, fashion, and furnishings. Understanding the core differences in performance, economics, and environmental impact is critical for strategic sourcing decisions.

Key Distinctions

Genuine leather is a natural byproduct of the meat industry, requiring extensive tanning and finishing. Modern “vinyl leatherette” (a dated term) has evolved into advanced couro sintético, primarily using polyurethane (PU) or polyvinyl chloride (PVC) coatings on textile backings. WINIW specializes in high-performance, eco-engineered PU synthetics designed to meet rigorous commercial demands while addressing sustainability imperatives.

Comparative Analysis: Core Metrics

| Metric | Synthetic Leather (PU/PVC) | Genuine Leather |

|---|---|---|

| Cost | – 30-50% lower raw material cost – Consistent pricing (unaffected by hide grades) – Reduced waste during cutting (uniform surface) |

– High volatility (subject to hide supply/quality) – Significant waste (15-25% due to scars/inconsistencies) – Premium pricing for top-grain hides |

| Durabilidade | – Superior abrasion resistance (50,000+ double rubs) – Excellent UV/colorfastness – Uniform performance across batches – Resistant to moisture & microbial growth |

– Variable durability (dependent on hide quality) – Prone to fading/staining without treatment – Natural stretch/sag over time – Vulnerable to moisture damage |

| Eco-Friendliness | – WINIW Advantage: Water-based PU systems (near-zero VOCs) – Recyclable components (mechanical/chemical) – 60-70% lower carbon footprint vs. chrome-tanned leather – No animal husbandry land/water use |

– High water consumption (15,000+ liters per hide) – Toxic chrome tanning (waste management challenges) – Methane emissions from livestock – Limited recyclability (landfill dominant) |

Strategic Advantages of Modern Synthetic Leather for B2B Applications

- Supply Chain Resilience: Eliminate hide scarcity risks and ethical sourcing complexities.

- Design Flexibility: Achieve consistent color, texture, and width (up to 200cm) for seamless large-scale production.

- Performance Customization: Engineer for specific needs (flame retardancy, antimicrobial, extreme abrasion).

- ESG Compliance: Meet corporate sustainability targets with traceable, low-impact materials (WINIW’s Eco Series certified by OEKO-TEX® STeP).

- Total Cost of Ownership: Lower waste, faster processing, and reduced maintenance offset initial material savings.

When to Consider Genuine Leather

Reserved for ultra-luxury segments where natural patina and heritage storytelling justify higher costs and sustainability trade-offs. Not viable for applications requiring strict hygiene (healthcare), uniformity (mass transit), or moisture resistance (marine).

WINIW’s synthetic leathers deliver uncompromised performance while future-proofing your supply chain against resource scarcity and tightening environmental regulations. We partner with brands to develop custom solutions that align profitability with planetary responsibility—without greenwashing. Request our technical datasheets for lifecycle assessment (LCA) data on specific product lines.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our vertically integrated production capabilities and commitment to quality have established us as a trusted partner across industries such as automotive, furniture, fashion, and technical textiles.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus enables large-scale production while maintaining flexibility for customized solutions and rapid turnaround times. The facility integrates advanced production lines with automated systems to ensure consistency, efficiency, and environmental sustainability.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and eco-conscious development. Our team continuously develops next-generation synthetic leather with improved breathability, abrasion resistance, and low-VOC emissions.

- Strict quality control protocols implemented at every stage of production. From raw material selection to final inspection, each batch undergoes rigorous testing for color fastness, tensile strength, environmental compliance, and other critical performance indicators.

- Compliance with international standards, including REACH, ROHS, and OEKO-TEX® certifications, ensuring our products meet the regulatory demands of highly selective markets.

- Advanced environmental management systems that support sustainable manufacturing, including water-based coating technologies and recycling initiatives to minimize ecological impact.

WINIW exports to over 50 countries, with a strong presence in Europe and the USA. Our global logistics network ensures reliable delivery and consistent supply chain performance. We partner with leading brands and manufacturers who value high-quality, sustainable alternatives to genuine leather.

By combining scale, innovation, and uncompromising quality, WINIW delivers synthetic leather solutions that meet the evolving needs of modern industries—driving performance, sustainability, and long-term value for our business partners worldwide.

Contact Us for Samples

WINIW Premium Synthetic Leather: Sustainable Performance for Industrial Applications

WINIW delivers next-generation synthetic leather solutions engineered for durability, sustainability, and seamless integration into high-volume manufacturing. As a global leader in eco-conscious material innovation, we provide B2B partners with traceable, high-performance alternatives to traditional leather—reducing environmental impact without compromising quality. Our closed-loop production process achieves 30% lower CO₂ emissions versus industry averages, with 92% of wastewater fully recycled.

Core Advantages for Industrial Buyers

- Certified Sustainability: OEKO-TEX® STANDARD 100 Class I (safe for infant products), ISO 14001 compliant, and 40% post-consumer recycled content available.

- Performance Engineered: 50,000+ double-rub abrasion resistance (Martindale), UV-stable color retention (Grade 7-8), and consistent thickness tolerance (±0.1mm).

- Supply Chain Security: 150+ global production facilities ensure 99.3% on-time delivery, with customizable roll widths (1.38m–2.05m) and MOQs from 500m.

- Regulatory Ready: REACH, RoHS, and Proposition 65 compliant; free from DMF, AZO dyes, and heavy metals.

WINIW Vinyl Leatherette Fabric: Technical Specifications

| Property | WINIW Standard | Industry Average | Performance Benefit |

|---|---|---|---|

| Thickness | 0.6mm–1.2mm | 0.8mm–1.5mm | Weight reduction for transport savings |

| Tensile Strength | 28–35 N/mm² | 20–25 N/mm² | Resists tearing during cutting/sewing |

| Color Fastness (Light) | ISO 105-B02: Grade 7-8 | Grade 5-6 | Maintains appearance in sun-exposed applications |

| Cold Crack Resistance | -30°C | -20°C | Suitable for automotive interiors in extreme climates |

| VOC Emissions | <10 μg/m³ | 25–50 μg/m³ | Meets strict indoor air quality standards (CA 01350) |

Why Industrial Partners Choose Vinyl Leatherette

- Cost Efficiency: Eliminates wet-processing costs; 22% faster cutting yield vs. genuine leather.

- Design Flexibility: 200+ stock colors/patterns; custom embossing and digital printing options.

- End-Use Versatility: Ideal for automotive seating, medical furniture, luggage, and contract interiors requiring wipe-clean surfaces.

- Eco-Transparency: Full LCA reports available; 100% recyclable at end-of-life via WINIW Take-Back Program.

Drive sustainable innovation with materials that meet rigorous industrial demands. Request free A4 samples of our flagship vinyl leatherette fabric to validate performance in your production workflow.

→ Contact WINIW Material Solutions

Email: MKT88@MicrofiberLeather.com

Specify: “Vinyl Leatherette Sample Request” + your target application (e.g., automotive, furniture).

Samples dispatched within 48 business hours. Global logistics support included.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.