Catalog

Material Insight: What’S Faux Leather

B2B Product Guide: Understanding Faux Leather for Modern Applications

What is Faux Leather?

Faux leather, also known as synthetic leather, artificial leather, or vegan leather, is a human-engineered material designed to replicate the look, feel, and performance characteristics of genuine animal leather. Modern faux leather is predominantly manufactured using performance-driven substrates like polyurethane (PU) or polyvinyl chloride (PVC), bonded to durable textile backings (typically polyester or recycled fibers). Crucially, advanced formulations now prioritize eco-conscious inputs, including water-based PU systems, plant-based polyols, and recycled content, significantly reducing environmental impact compared to earlier generations. It is a purpose-built solution engineered for specific functional and aesthetic requirements across diverse industries.

Why Faux Leather is the Optimal Choice for Modern B2B Applications

Faux leather delivers decisive advantages that align with the strategic imperatives of forward-thinking businesses, making it the superior material selection for numerous commercial applications:

- Consistent Quality & Supply Chain Reliability: Eliminates the natural variations inherent in animal hides, ensuring uniform color, texture, and thickness batch after batch. This guarantees predictable manufacturing outcomes and mitigates supply chain disruptions common in the volatile genuine leather market.

- Enhanced Sustainability Credentials: Offers a tangible pathway to reduce environmental footprint. Modern eco-faux options utilize recycled materials (e.g., rPET), bio-based components, and solvent-free/water-based production processes, directly supporting corporate ESG goals and meeting stringent regulatory requirements without compromising performance.

- Superior Design Flexibility & Customization: Provides unparalleled freedom in color, texture, embossing, and performance characteristics (e.g., enhanced abrasion resistance, UV stability, flame retardancy). This enables brands to achieve unique aesthetics and meet exacting technical specifications for specific product needs.

- Ethical Sourcing Assurance: Provides a guaranteed animal-free alternative, addressing growing consumer and regulatory demands for cruelty-free products and simplifying ethical compliance verification for global brands.

- Cost-Effectiveness & Performance: Delivers competitive total cost of ownership through material yield optimization, reduced waste, and often lower processing costs. Advanced formulations match or exceed genuine leather in critical performance metrics like durability, cleanability, and resistance to wear in controlled environments.

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

For over 20 years, WINIW has been at the forefront of innovation in the synthetic leather industry, serving as a strategic B2B partner to leading brands and manufacturers worldwide. We specialize in developing and producing high-performance, eco-responsible faux leather solutions tailored to the exacting demands of furniture, automotive, fashion accessories, electronics, and specialty industrial applications. Our deep expertise spans material science, sustainable manufacturing, and global supply chain management. WINIW invests continuously in R&D to pioneer next-generation materials that balance exceptional aesthetics, rigorous functionality, and genuine environmental stewardship. Partnering with WINIW means accessing not just a material supplier, but a solutions provider committed to driving your product success through reliability, innovation, and shared sustainability values.

Technical Performance & Standards

WINIW Faux Leather – Technical Product Guide for B2B Partners

WINIW specializes in high-performance synthetic leather engineered for industrial and commercial applications across furniture, automotive, fashion, and accessories. Our faux leather solutions combine advanced material science with sustainable manufacturing to deliver cost-effective, durable, and compliant materials tailored to your production needs.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s faux leather reduces material waste and processing time compared to genuine leather. Its consistent thickness and defect-free surface minimize cutting losses and rework, resulting in lower overall production costs. Additionally, reduced maintenance and no need for animal sourcing enhance long-term savings. -

Superior Durability

Engineered with high-density polyurethane (PU) and reinforced backings, WINIW’s synthetic leather offers excellent abrasion resistance (tested up to 50,000+ double rubs), tear strength, and colorfastness. It maintains integrity under high-stress conditions, making it ideal for high-traffic environments. -

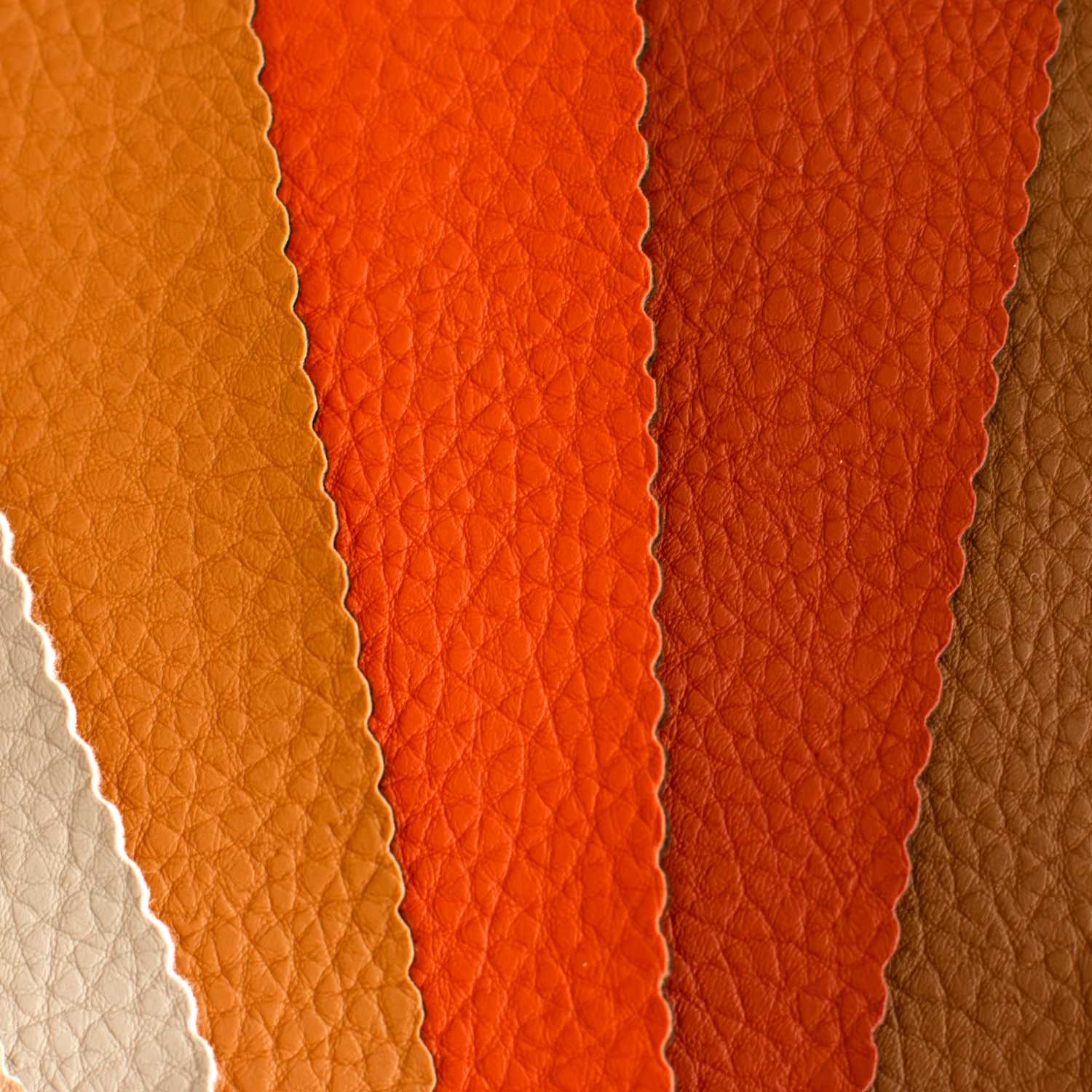

Customizable Color & Finish Options

WINIW supports full customization of color, texture, and surface finish. With digital color matching (Pantone® and RAL compatibility), clients can achieve precise aesthetic outcomes. Over 1,000 standard colors are available, with rapid turnaround for custom batches. -

REACH Compliance

All WINIW products are fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our materials are free from SVHCs (Substances of Very High Concern), phthalates, heavy metals, and other hazardous substances, ensuring safe handling and end-use. -

ISO 9001 Certified Manufacturing

WINIW operates under ISO 9001-certified quality management systems. This ensures consistent product quality, traceability, and process control across all production batches, meeting the highest international standards for reliability and performance.

Technical Specifications – WINIW Faux Leather Series

| Property | Especificação |

|---|---|

| Material Composition | Polyurethane (PU) + Polyester Knit or Scrim Backing |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight | 200 – 450 g/m² (depending on thickness) |

| Abrasion Resistance | ≥ 50,000 cycles (Martindale, ISO 12947) |

| Color Fastness to Rubbing | Grade 4–5 (ISO 105-X12) |

| Light Fastness | ≥ 4–6 (ISO 105-B02, 40+ hours Xenon) |

| Tear Strength | ≥ 25 N (Elmendorf, ISO 13937) |

| Tensile Strength | ≥ 80 N/5cm (ISO 13934-1) |

| Cold Crack Resistance | Passes -20°C (ISO 4646) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, roll width (1.37m standard), roll length (30m, 50m) |

WINIW’s faux leather delivers a balanced combination of economic efficiency, technical resilience, and environmental responsibility. With scalable production capacity and responsive R&D support, we enable B2B clients to innovate sustainably while meeting global regulatory and performance benchmarks.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Understanding Faux Leather vs. Real Leather

As a leader in sustainable material innovation, WINIW provides clarity on material selection for discerning B2B partners. Understanding the fundamental differences between faux (synthetic) leather and real (genuine) leather is critical for aligning product specifications with performance, cost, and sustainability goals. This guide offers a concise, objective comparison to support informed sourcing decisions.

Defining the Materials

- Real Leather: A natural product derived from the tanned hides or skins of animals (primarily bovine, ovine, or porcine). It undergoes processes like tanning, dyeing, and finishing to achieve desired aesthetics and functionality. Real leather features unique grain patterns, breathability, and develops a patina over time.

- Faux Leather (Synthetic Leather): A human-engineered material designed to replicate the look, feel, and performance of real leather. WINIW’s advanced formulations primarily utilize polyurethane (PU) or polyvinyl chloride (PVC) applied to textile backings (e.g., polyester, recycled PET). Modern synthetics offer superior consistency, design flexibility, and enhanced eco-performance compared to early generations.

Core Comparison: Cost, Durability & Eco-Friendliness

The table below summarizes key differentiators relevant to commercial and industrial applications:

| Criteria | Real Leather | Faux Leather (WINIW Advanced PU) |

|---|---|---|

| Cost | Higher initial cost (premium hides); significant price volatility due to raw material scarcity and tanning complexity. | Lower, stable upfront cost; consistent pricing due to controlled manufacturing. Reduces waste in cutting/processing. |

| Durabilidade | Excellent longevity with proper care; susceptible to UV fading, water damage, and cracking. Requires conditioning. Performance varies significantly by hide grade. | High resistance to abrasion, UV exposure, stains, and moisture. Uniform performance across batches. No conditioning needed. Ideal for high-traffic or demanding environments. |

| Eco-Friendliness | Resource-intensive: requires land/water for livestock, generates tannery wastewater (often high in chromium), and has significant carbon footprint. Limited circularity. | WINIW’s eco-optimized PU: Uses water-based, solvent-free production; incorporates recycled content (e.g., r-PET); zero chromium; lower water/energy use. Fully recyclable in WINIW’s closed-loop programs. Significantly reduced carbon footprint. |

Strategic Advantages for B2B Partners

WINIW’s advanced faux leather solutions deliver compelling value for forward-thinking manufacturers:

– Sustainability Compliance: Meet stringent ESG targets and regulations (e.g., REACH, ZDHC) with traceable, low-impact materials.

– Design & Operational Efficiency: Achieve consistent color, texture, and thickness for streamlined production. Reduced material waste due to precise engineering.

– Performance Tailoring: Customize properties (e.g., fire resistance, antimicrobial finish, extreme weather resilience) for automotive, furniture, or tech applications.

– Ethical Sourcing Assurance: Eliminate supply chain complexities and ethical concerns associated with animal agriculture.

WINIW empowers brands to future-proof their portfolios with synthetics that exceed real leather in performance consistency and environmental stewardship—without compromising aesthetics. Partner with us to develop solutions aligned with your sustainability mandates and market demands.

WINIW: Engineered Elegance, Responsibly Realized.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, eco-friendly materials. Our vertically integrated production capabilities and commitment to quality have positioned us as a trusted partner in industries ranging from automotive and furniture to fashion and sports.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive production base enables us to maintain high output capacity while ensuring flexibility for customized solutions and large-volume orders. The facility is equipped with advanced production lines that support a wide range of synthetic leather types, including PU, PVC, and eco-conscious alternatives.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, sustainability, and performance enhancement. The team continuously develops new textures, finishes, and functional properties such as abrasion resistance, UV stability, and low-VOC emissions.

- Comprehensive in-house testing laboratories that simulate real-world conditions to ensure durability and compliance with international standards.

- Strict quality control (QC) protocols implemented at every stage of production—from raw material inspection to final product verification. Our QC system follows ISO 9001 standards and includes automated monitoring and manual inspections to maintain consistency and precision.

- Certified environmental management systems (ISO 14001) supporting sustainable manufacturing practices, including waste reduction, energy efficiency, and the use of eco-friendly raw materials.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products meet stringent regional requirements, including REACH, RoHS, and CA Proposition 65, ensuring safe and compliant materials for global brands.

Through advanced manufacturing, relentless innovation, and rigorous quality assurance, WINIW delivers synthetic leather solutions that combine performance, sustainability, and aesthetic excellence for forward-thinking businesses.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Solutions for Sustainable Manufacturing

WINIW delivers next-generation microfiber leather engineered for B2B partners demanding uncompromising quality, ethical production, and environmental responsibility. Our advanced PU/polyester composite material replicates the luxury, durability, and tactile experience of premium genuine leather while eliminating ecological and ethical concerns. As a leader in sustainable synthetics since 2003, WINIW serves global automotive, furniture, fashion, and accessories manufacturers seeking future-proof material partnerships.

What Is Faux Leather? (Beyond Basic Vinyl)

Faux leather encompasses synthetic alternatives to animal hide, but not all are equal. WINIW specializes in high-performance microfiber leather – a sophisticated non-woven substrate bonded with polyurethane resin. This differs fundamentally from low-grade PVC/vinyl or thin PU-coated fabrics:

- Microfiber base: Ultra-fine polyester fibers (0.1–0.3 denier) create a dense, breathable structure mimicking真皮’s collagen matrix

- Advanced PU coating: Proprietary formulations deliver superior abrasion resistance, flexibility, and color retention

- Eco-engineered: Zero heavy metals, phthalates, or DMF; 30–60% lower carbon footprint vs. bovine leather

- Performance parity: Matches or exceeds genuine leather in tear strength, seam slippage, and lightfastness

Why WINIW Outperforms Traditional Alternatives

Our closed-loop production and R&D focus yield measurable advantages for your supply chain:

- Sustainability without compromise: OEKO-TEX® STANDARD 100 Class I certified; 40% post-consumer recycled content options

- Manufacturing efficiency: Consistent roll goods (1.37m–1.52m width) with minimal waste; compatible with standard cutting/sewing lines

- End-product longevity: 50,000+ Martindale rubs (vs. 15,000–25,000 for standard PU); UV-stable for automotive interiors

- Customization agility: Rapid color matching (Pantone®/RAL), embossing, and texture development (suede, pebble, exotic)

Performance Comparison: WINIW vs. Industry Standards

| Property | WINIW Microfiber Leather | Standard PU Leather | PVC Vinyl | Genuine Leather |

|---|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles | 15,000–25,000 | 5,000–10,000 | 20,000–40,000 |

| Tear Strength (N) | 80–120 | 40–60 | 30–50 | 60–90 |

| VOC Emissions (μg/g) | < 50 | 150–300 | 500–1,000 | 100–200 |

| Recycled Content | Up to 60% | 0–10% | 0% | 0% |

| Water Absorption (24h) | < 5% | 8–15% | < 1% | 20–30% |

Partner With WINIW for Scalable Eco-Innovation

Reduce supply chain risk while advancing ESG goals with materials trusted by Tier-1 automotive suppliers and luxury furniture brands. Our technical team collaborates on:

- Material specification for extreme environments (e.g., -30°C to 85°C stability)

- Compliance with global regulations (REACH, CA Prop 65, UL ECOLOGO®)

- Waste-reduction programs via precision digital printing and roll optimization

Request Technical Dossiers & Free Samples

Discover how WINIW microfiber leather elevates product performance and sustainability credentials. Contact our B2B solutions team for:

– Custom swatch books with physical performance test reports

– Application-specific case studies (seating, handbags, footwear)

– Zero-cost material samples for qualification testing

→ Clarify “what’s faux leather” for your next collection: MKT88@MicrofiberLeather.com

Free samples available to qualified manufacturers. MOQs from 500m per design.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.