Catalog

Material Insight: Automotive Vinyl Material

B2B Product Guide: Automotive Vinyl Material

Automotive vinyl materials play a critical role in modern vehicle interior design, offering durability, aesthetic flexibility, and cost-effective performance across a wide range of applications—from seating and door panels to dashboards and trim components. As the automotive industry evolves with a growing emphasis on sustainability, comfort, and design innovation, the demand for high-performance synthetic leather has surged. Among the available options, automotive synthetic leather—specifically engineered vinyl materials—stands out as a superior alternative to both natural leather and conventional PVC-based vinyls.

Why Automotive Synthetic Leather Is the Best Choice

- Durability & Performance: Engineered to withstand extreme temperatures, UV exposure, abrasion, and repeated mechanical stress, automotive synthetic leather maintains its integrity and appearance over the lifetime of the vehicle.

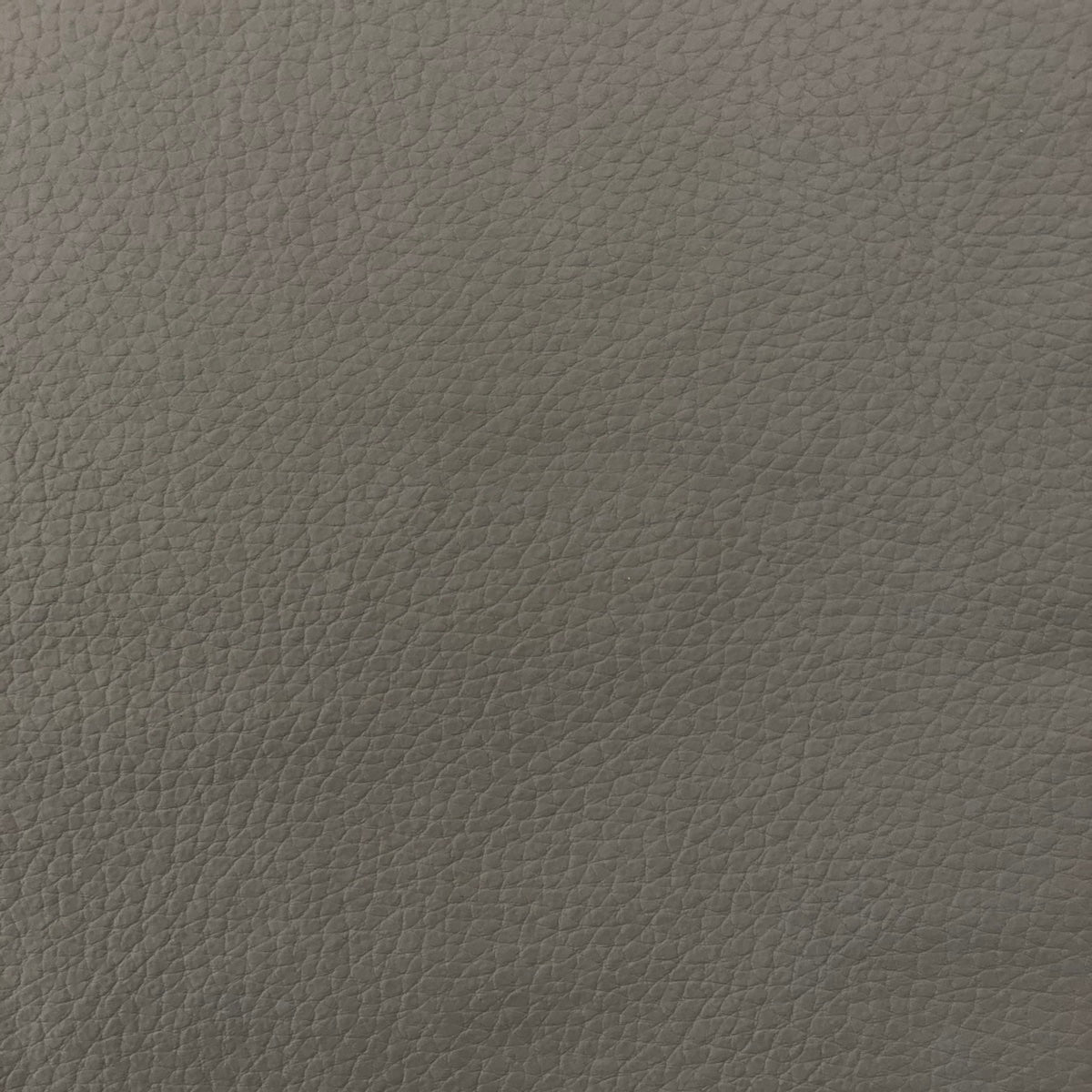

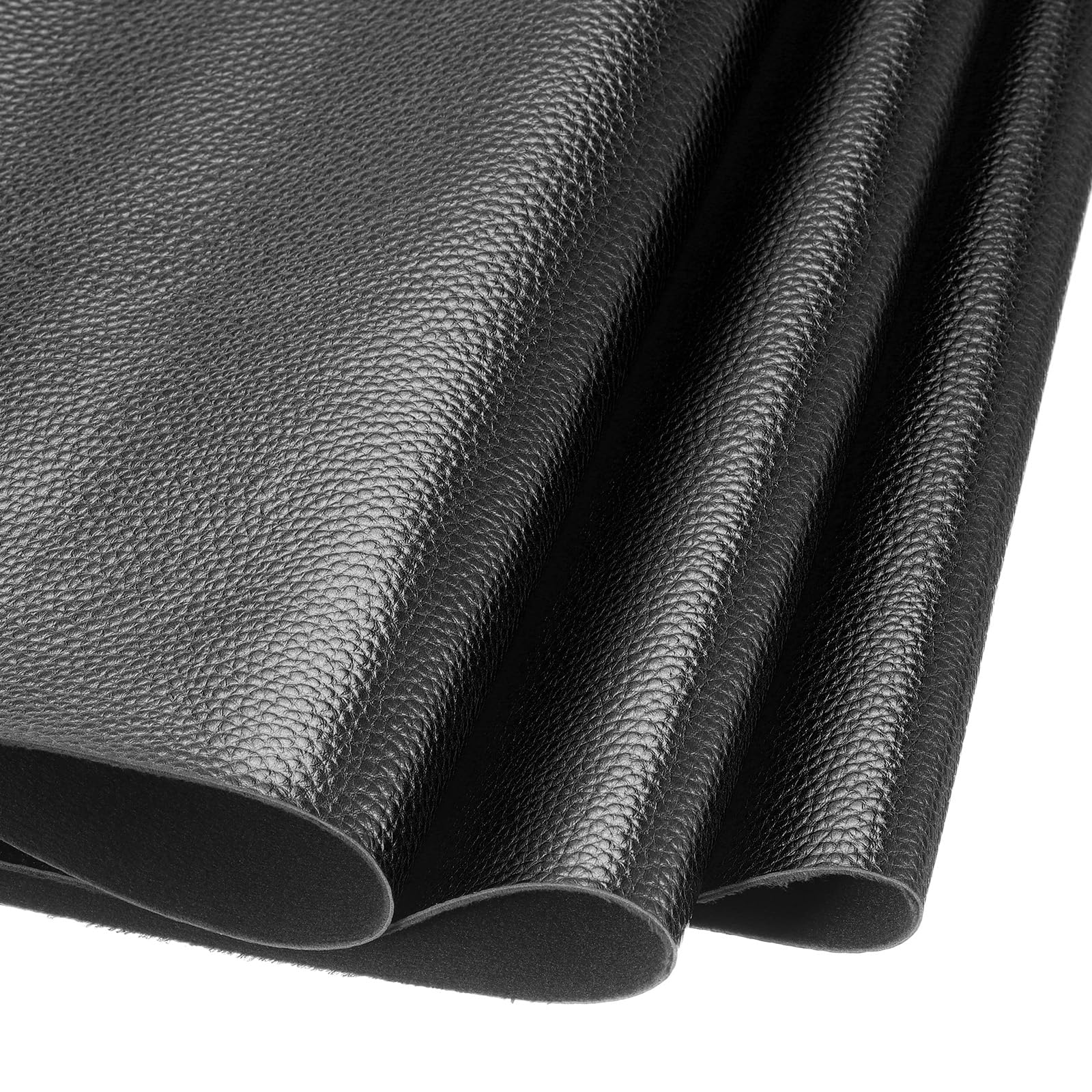

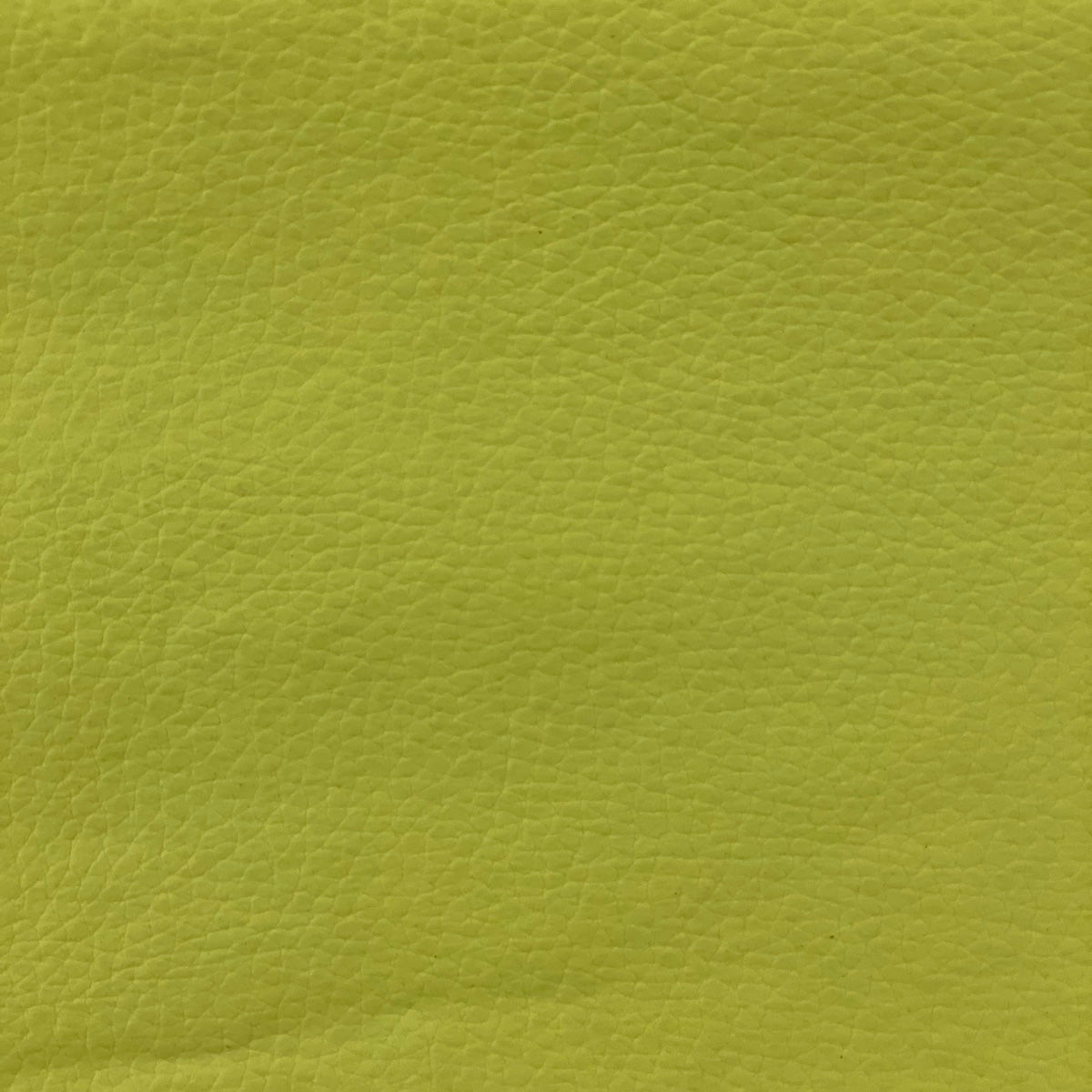

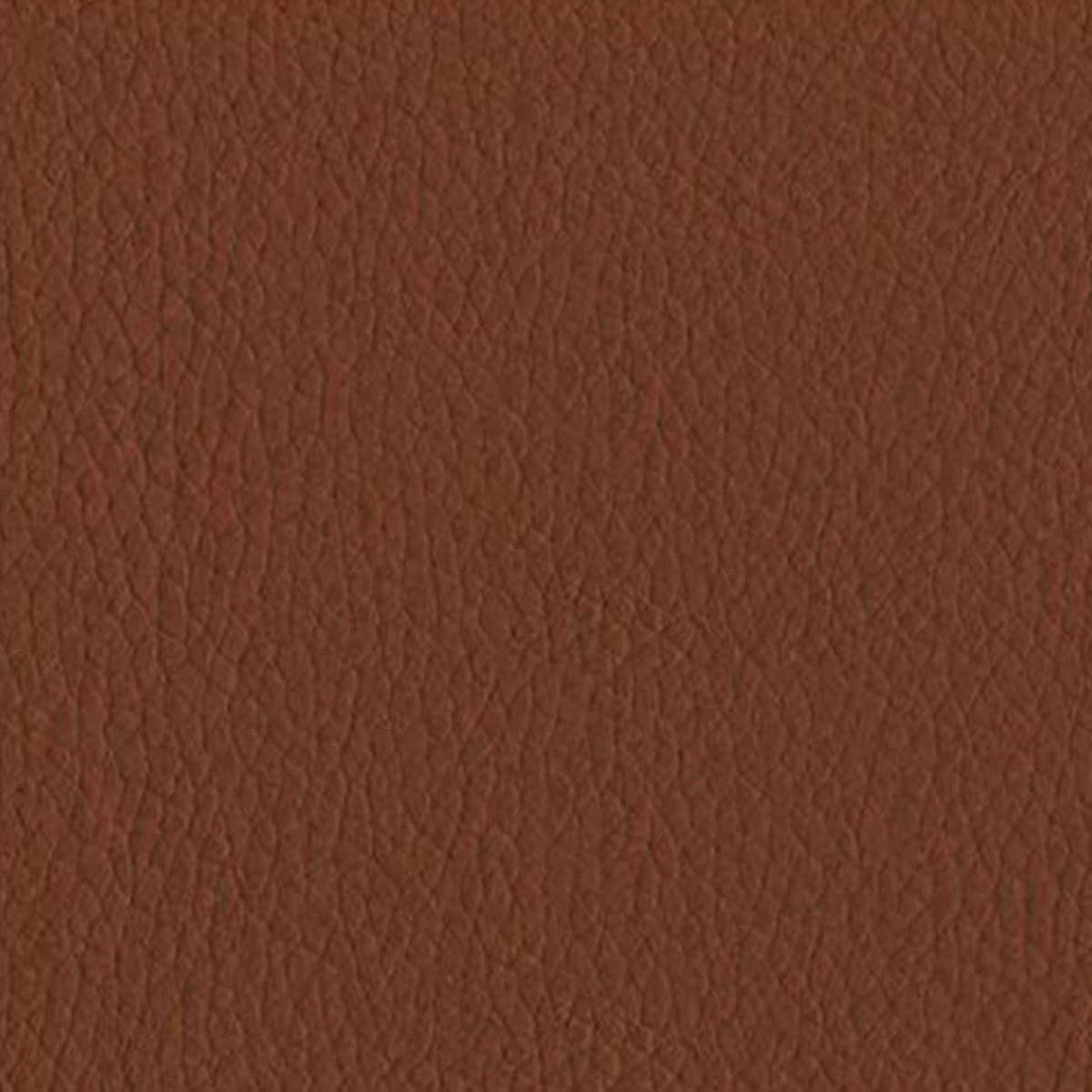

- Design Versatility: Available in a wide range of textures, colors, and finishes, synthetic leather can replicate the look and feel of premium natural leather while enabling custom design solutions tailored to brand identity.

- Eco-Friendly Solutions: Modern polyurethane (PU)-based vinyls reduce environmental impact through lower VOC emissions, recyclability, and reduced reliance on animal products—aligning with global sustainability standards.

- Cost Efficiency: Offers a high-end aesthetic at a more predictable and scalable cost compared to natural leather, which is subject to supply volatility and inconsistent grading.

- Regulatory Compliance: Meets stringent automotive industry standards for flammability, fogging, odor, and fog resistance, ensuring safety and comfort across global markets.

Introducing WINIW: Trusted Expertise in Synthetic Leather

WINIW is a leading global manufacturer of high-performance synthetic leather, with over 20 years of specialized experience in developing innovative materials for the automotive sector. Our R&D-driven approach combines advanced coating technologies, sustainable raw materials, and rigorous quality control to deliver products that meet the evolving needs of OEMs and Tier 1 suppliers.

- We specialize in PU and PVC-based automotive vinyls engineered for superior wear resistance, soft touch, and long-term colorfastness.

- Our production facilities adhere to international environmental and quality standards, including ISO 9001, IATF 16949, and REACH compliance.

- WINIW partners with automotive designers and manufacturers worldwide to provide customizable, scalable, and eco-conscious material solutions that enhance both vehicle interiors and brand value.

With a commitment to innovation, sustainability, and performance, WINIW is the trusted choice for automotive vinyl materials in the new era of mobility.

Technical Performance & Standards

WINIW Automotive Vinyl Material: Technical Advantages for Premium Interiors

WINIW’s advanced automotive vinyl material is engineered specifically for the demanding requirements of modern vehicle interiors. Combining exceptional durability with stringent environmental and safety compliance, our solution delivers long-term performance while supporting sustainable manufacturing goals. Designed for OEMs and Tier-1 suppliers, WINIW vinyl minimizes lifecycle costs and enhances brand reputation through certified quality and eco-conscious innovation.

Core Technical Advantages

- Superior Abrasion Resistance: Engineered with a proprietary cross-linked polymer matrix, WINIW vinyl withstands rigorous daily use. Validated to exceed 100,000 cycles in Martindale testing (ASTM D4966), it resists wear from friction, scuffs, and repeated contact, ensuring seat and trim surfaces maintain aesthetic integrity throughout the vehicle’s lifespan.

- Exceptional UV Stability: Formulated with high-performance UV absorbers and Hindered Amine Light Stabilizers (HALS), WINIW vinyl resists fading, cracking, and embrittlement. It consistently passes 2,000+ hours of accelerated weathering per SAE J2527, guaranteeing colorfastness and structural resilience under prolonged sun exposure.

- True VOC-Free Composition: WINIW vinyl is manufactured using a water-based, solvent-free process. It achieves VOC emissions below 10 μg/g (as measured by ISO 12219-2), significantly below automotive industry thresholds. This ensures cabin air purity, eliminates odor issues, and protects occupant health without compromising material flexibility.

- Full REACH Compliance: Our material is rigorously screened and certified free of Substances of Very High Concern (SVHCs) listed under REACH Regulation (EC) No 1907/2006 at concentrations above 0.1%. Comprehensive chemical documentation is provided, simplifying your supply chain due diligence and import compliance.

- ISO 9001-Certified Quality Control: Every batch is produced under WINIW’s ISO 9001-certified quality management system. This ensures strict adherence to dimensional tolerances (thickness, width), color consistency (ΔE < 0.5), and physical properties, guaranteeing reliability for high-precision automotive cutting and assembly processes.

Technical Specifications Overview

| Property | WINIW Specification | Test Standard | Automotive Relevance |

|---|---|---|---|

| Abrasion Resistance | > 100,000 cycles | ASTM D4966 | Ensures long-term upholstery durability |

| UV Resistance | > 2,000 hours (no fade) | SAE J2527 | Maintains color/appearance in sunlight |

| VOC Emissions | < 10 μg/g | ISO 12219-2 | Meets strict cabin air quality standards |

| REACH Compliance | SVHC-free (<0.1%) | EC 1907/2006 | Simplifies regulatory documentation |

| Thickness Tolerance | ±0.05 mm | ISO 2422 | Enables precise cutting & assembly |

| Color Consistency (ΔE) | < 0.5 | ISO 105-A02 | Guarantees uniform interior aesthetics |

WINIW automotive vinyl material provides a strategic advantage: uncompromising performance validated by global standards, coupled with transparent environmental stewardship. Our solution directly addresses OEM priorities for sustainable, low-VOC interiors that meet evolving global regulations while delivering the premium feel expected in modern vehicles. Partner with WINIW to integrate certified quality and durability into your next-generation automotive interiors.

Why Choose Synthetic over Real Leather

B2B Product Guide: Automotive Vinyl Material vs. Real Leather

In the automotive interior market, material selection plays a critical role in balancing performance, cost, and sustainability. Two of the most widely used materials are automotive vinyl and real leather. While both offer distinct advantages, their differences in cost, durability, and environmental impact are key considerations for manufacturers and suppliers.

Overview of Materials

Automotive vinyl material is a synthetic alternative typically made from polyvinyl chloride (PVC) or polyurethane (PU). It is engineered to mimic the appearance and feel of real leather while offering enhanced resistance to wear, UV exposure, and moisture. Real leather, derived from animal hides (usually bovine), is valued for its natural texture, breathability, and premium aesthetic.

Key Comparisons

The following table compares automotive vinyl material and real leather across three essential criteria for B2B decision-making: cost, durability, and eco-friendliness.

| Criteria | Automotive Vinyl Material | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher production cost |

| Durabilidade | High resistance to stains, fading, and cracking; ideal for high-use environments | Prone to cracking and fading over time; requires regular conditioning |

| Eco-Friendliness | Varies by formulation; modern PU-based vinyls are more sustainable, recyclable, and animal-free; lower carbon footprint in production | Resource-intensive; involves animal agriculture and chemical tanning processes; limited biodegradability |

Advantages of Automotive Vinyl Material

- Cost-effective for large-scale production and commercial vehicle fleets

- Consistent texture and color batch-to-batch

- Resistant to UV rays, making it suitable for sun-exposed interiors

- Easy to clean and maintain

- Available in a wide range of colors, textures, and finishes

- Supports eco-conscious branding with animal-free, low-emission options

Advantages of Real Leather

- Premium tactile feel and luxury perception

- Natural breathability enhances comfort in climate-controlled environments

- Develops a unique patina over time, valued in high-end automotive segments

- Long-standing market preference in luxury vehicle categories

Sustainability Considerations

As environmental regulations and consumer demand for sustainable materials grow, automotive vinyl—especially PU-based synthetic leather—has emerged as a responsible alternative. WINIW’s advanced microfiber synthetic leather solutions offer high performance with reduced environmental impact, supporting OEMs in meeting ESG goals without compromising on quality.

Conclusion

While real leather maintains its position in luxury automotive design, automotive vinyl material offers a competitive, sustainable, and cost-efficient solution for a broad range of vehicle types. For B2B partners focused on scalability, durability, and eco-friendly innovation, high-performance synthetic leather is increasingly the material of choice.

WINIW Factory Capabilities

WINIW Factory Capabilities: Engineered for Global B2B Excellence

WINIW operates a state-of-the-art manufacturing facility spanning 100,000 square meters, strategically designed to deliver high-volume, precision-engineered synthetic leather solutions for discerning international partners. Our vertically integrated production ecosystem ensures end-to-end control over quality, sustainability, and innovation, meeting the rigorous demands of global supply chains.

Key operational strengths include:

– Advanced Manufacturing Scale: 100,000 sqm facility equipped with automated production lines for consistent output of 50+ million meters annually, supporting just-in-time delivery for large-scale B2B contracts.

– Dedicated R&D Innovation Hub: 80+ member technical team holding 120+ patents, specializing in eco-material development (including water-based PU, recycled PET, and bio-based polymers) compliant with EU REACH, OEKO-TEX® STANDARD 100, and CPSIA.

– Zero-Defect Quality Assurance: Triple-stage QC protocol (raw material screening, in-line process control, final product validation) with ISO 9001-certified testing labs, achieving <0.3% customer defect rates.

– Global Compliance & Logistics: Direct export infrastructure serving Tier-1 automotive, furniture, and fashion brands across Europe and North America, with full documentation for customs clearance (including SCIP database submissions and LCA reports).

Our facility’s LEED-certified operations and closed-loop water recycling system underscore WINIW’s commitment to reducing environmental impact without compromising industrial throughput—delivering reliable, sustainable performance for global B2B partnerships.

Contact Us for Samples

WINIW Automotive Vinyl Material – B2B Product Guide

WINIW specializes in high-performance, eco-friendly synthetic leather solutions designed for the evolving demands of the automotive industry. Our automotive vinyl materials combine durability, aesthetic versatility, and sustainable manufacturing practices to meet the rigorous standards of OEMs and Tier-1 suppliers worldwide.

Engineered for both interior and exterior applications, WINIW’s automotive vinyl offers excellent resistance to abrasion, UV exposure, temperature fluctuations, and chemical cleaners—making it ideal for seating, door panels, dashboards, armrests, and trim components.

Key Features & Benefits

- Superior Durability: Tested to exceed 50,000 double rubs (Martindale), ensuring long-term performance in high-wear environments.

- Eco-Conscious Production: PVC-free and REACH-compliant formulations with low VOC emissions; suitable for sustainable vehicle programs.

- Design Flexibility: Available in a wide range of textures (suede, grain, matte, embossed), colors, and finishes—customizable to brand specifications.

- Weather & UV Resistance: Maintains integrity and appearance after prolonged exposure to sunlight and extreme temperatures (-30°C to +85°C).

- Easy Maintenance: Stain-resistant surface with simple cleaning requirements, ideal for consumer and commercial vehicle interiors.

- Lightweight Composition: Contributes to vehicle weight reduction, supporting fuel efficiency and EV range optimization.

Technical Specifications

| Property | Especificação |

|---|---|

| Thickness Range | 0.8 mm – 2.0 mm |

| Weight | 300 – 650 g/m² |

| Backing Fabric | Knit polyester or non-woven |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness (ISO 105) | ≥ Grade 4 (Xenon arc light) |

| Cold Crack Resistance | Passes at -30°C |

| Flame Resistance | Meets FMVSS 302, ISO 3795 |

| VOC Emissions | < 10 μg/g (cabin air quality compliant) |

Aplicações

- Car seat upholstery

- Center consoles and dashboards

- Door and armrest trim

- Steering wheel wraps

- Commercial fleet and shared mobility interiors

Sustainability Commitment

WINIW is committed to reducing environmental impact across the supply chain. Our automotive vinyl materials are manufactured using energy-efficient processes, water-based coatings, and recyclable components. We support circular economy initiatives and provide full traceability documentation upon request.

Request Free Samples Today

Experience the quality and performance of WINIW automotive vinyl firsthand. We offer complimentary material samples tailored to your application needs.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your vehicle interiors with a partner dedicated to innovation, sustainability, and precision.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.