Introduction: Navigating the Global Market for leather for auto upholstery

Navigating the global market for leather for auto upholstery presents a unique set of challenges for B2B buyers, particularly when it comes to sourcing high-quality materials that meet industry standards. In an era where consumers increasingly demand luxury and durability, understanding the nuances of leather types, finishes, and applications is essential. This guide serves as a comprehensive resource, providing insights into various leather options, supplier vetting processes, cost considerations, and the latest trends in automotive interiors.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—will find valuable information tailored to their specific needs. By delving into the intricacies of leather sourcing, this guide empowers businesses to make informed purchasing decisions that enhance their product offerings while ensuring compliance with regional standards and consumer preferences.

With a focus on actionable insights and strategic recommendations, readers will learn how to evaluate suppliers effectively, assess material quality, and navigate the complexities of pricing structures. This guide is not just about purchasing leather; it’s about understanding the landscape of the auto upholstery market, enabling businesses to thrive in a competitive environment while delivering exceptional value to their customers.

Table Of Contents

- Top 7 Leather For Auto Upholstery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather for auto upholstery

- Understanding leather for auto upholstery Types and Variations

- Key Industrial Applications of leather for auto upholstery

- 3 Common User Pain Points for ‘leather for auto upholstery’ & Their Solutions

- Strategic Material Selection Guide for leather for auto upholstery

- In-depth Look: Manufacturing Processes and Quality Assurance for leather for auto upholstery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for auto upholstery’

- Comprehensive Cost and Pricing Analysis for leather for auto upholstery Sourcing

- Alternatives Analysis: Comparing leather for auto upholstery With Other Solutions

- Essential Technical Properties and Trade Terminology for leather for auto upholstery

- Navigating Market Dynamics and Sourcing Trends in the leather for auto upholstery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather for auto upholstery

- Strategic Sourcing Conclusion and Outlook for leather for auto upholstery

- Important Disclaimer & Terms of Use

Understanding leather for auto upholstery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains the natural grain, highly durable, ages beautifully | Luxury automotive interiors, OEMs | Pros: Excellent durability, natural aesthetics. Cons: Higher cost, may have natural imperfections. |

| Top Grain Leather | Sanded and finished for a smooth surface, more affordable | Mid-range automotive upholstery | Pros: Good balance of quality and price. Cons: Less durable than full grain, can show wear over time. |

| Split Leather | Made from the fibrous part of the hide, less expensive | Budget vehicles, non-premium models | Pros: Cost-effective, lightweight. Cons: Lower durability, less luxurious feel. |

| Couro Nappa | Soft, supple, and smooth; often dyed for vibrant colors | High-end cars, luxury interiors | Pros: Exceptional comfort and look. Cons: Prone to scratches, higher maintenance. |

| Alcantara | Synthetic suede-like material, offers a unique texture | Sports cars, specialty vehicles | Pros: Lightweight, easy to clean. Cons: Less traditional feel, may not appeal to all customers. |

What are the Characteristics of Full Grain Leather for Auto Upholstery?

Full grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This type of leather is highly durable and develops a rich patina over time, making it ideal for luxury automotive interiors and OEM applications. B2B buyers should consider the initial investment as it is typically higher, but the longevity and aesthetic appeal can justify the cost. Its natural characteristics can enhance the vehicle’s value and appeal to discerning customers.

How Does Top Grain Leather Compare in Quality and Cost?

Top grain leather is sanded and finished to create a smooth surface, which makes it more affordable than full grain leather while still providing a high-quality look. It is commonly used in mid-range automotive upholstery, striking a balance between luxury and cost-effectiveness. Buyers should note that while it offers good durability, it is less resistant to wear and tear than full grain leather, making it essential to assess the intended use and customer expectations when selecting this material.

Why Choose Split Leather for Budget-Friendly Options?

Split leather is derived from the fibrous part of the hide, making it a more economical option for budget vehicles or non-premium models. While it is lightweight and cost-effective, B2B buyers should be aware that it lacks the durability and luxurious feel of higher-grade leathers. This type is suitable for applications where budget constraints are paramount, but it may not meet the expectations of customers looking for premium quality.

Illustrative image related to leather for auto upholstery

What Makes Nappa Leather a Preferred Choice for Luxury Interiors?

Nappa leather is known for its soft, supple texture and vibrant color options, making it a popular choice for high-end cars and luxury interiors. This type of leather offers exceptional comfort and visual appeal, enhancing the overall customer experience. However, B2B buyers must consider its susceptibility to scratches and the need for regular maintenance, which may affect long-term satisfaction and cost of ownership.

How Does Alcantara Fit into Specialty Vehicle Upholstery?

Alcantara is a synthetic material that mimics the look and feel of suede, offering a unique texture that is particularly appealing in sports cars and specialty vehicles. Its lightweight and easy-to-clean properties make it a practical choice for automotive applications. However, buyers should consider that while it provides a modern aesthetic, it may not appeal to traditionalists who prefer genuine leather. Understanding the target market’s preferences is crucial when selecting Alcantara for upholstery projects.

Key Industrial Applications of leather for auto upholstery

| Industry/Sector | Specific Application of leather for auto upholstery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Leather seats and interior trims | Enhances vehicle aesthetics and resale value | Sourcing high-quality, durable leather that meets safety standards. |

| Luxury Vehicle Customization | Custom leather interiors for high-end vehicles | Provides unique, personalized interior design options | Availability of diverse colors and textures to match client specifications. |

| Classic Car Restoration | Upholstery for vintage and classic cars | Maintains authenticity and adds value to restored vehicles | Access to historically accurate leather types and finishes. |

| Marine Industry | Leather upholstery for luxury yachts | Adds elegance and comfort, enhancing customer experience | Consideration for water-resistant treatments and durability in marine environments. |

| Aviation | Leather seating and interiors in private jets | Ensures luxury and comfort for high-net-worth individuals | Compliance with aviation safety regulations and lightweight options. |

How is Leather for Auto Upholstery Used in Automotive Manufacturing?

In the automotive manufacturing sector, leather is predominantly utilized for seats and interior trims, providing a luxurious feel that appeals to consumers. Leather seats not only enhance the aesthetic appeal of vehicles but also improve their resale value significantly. For international buyers, particularly in regions like the Middle East and Europe, sourcing leather that meets stringent safety and durability standards is crucial. This includes ensuring the leather is treated to withstand UV exposure and wear over time.

What Role Does Leather Play in Luxury Vehicle Customization?

For luxury vehicle customization, leather serves as a canvas for creating bespoke interiors tailored to individual client preferences. This application allows for a range of colors, textures, and finishes, which can transform a standard vehicle into a personalized masterpiece. Buyers from Africa and South America should consider suppliers that offer extensive customization options and the ability to meet unique design requests, ensuring the final product aligns perfectly with their vision.

Illustrative image related to leather for auto upholstery

Why is Leather Important in Classic Car Restoration?

In the classic car restoration industry, leather is essential for upholstery that maintains the vehicle’s authenticity. Using high-quality leather that matches the original specifications can significantly enhance the value of restored cars. International buyers must focus on sourcing historically accurate materials, which may involve working with specialized suppliers who understand the nuances of vintage vehicles and can provide leather that meets historical standards.

How is Leather Used in the Marine Industry?

In the marine industry, leather upholstery is applied to luxury yachts, where it adds an element of sophistication and comfort. The use of leather in this context enhances the overall customer experience, making it an attractive feature for high-end clients. Buyers should prioritize sourcing leather that has been treated for water resistance and durability, ensuring it can withstand the harsh marine environment while maintaining its luxurious appearance.

What is the Application of Leather in Aviation?

In aviation, leather is commonly used for seating and interior finishes in private jets, where luxury and comfort are paramount. High-net-worth individuals expect premium materials that not only look good but also comply with aviation safety regulations. International buyers in this sector must consider lightweight leather options that meet these regulations while ensuring that the material retains its aesthetic appeal and comfort during flight.

3 Common User Pain Points for ‘leather for auto upholstery’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Diverse Automotive Needs

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets specific automotive requirements. This can be particularly challenging when catering to diverse markets, such as luxury vehicles in Europe and rugged off-road models in South America. Buyers may encounter issues with inconsistent quality, inadequate product descriptions, or suppliers who do not understand the unique needs of their market segments. Additionally, the risk of obtaining inferior materials that do not meet automotive-grade specifications could lead to costly reworks and dissatisfied customers.

The Solution: To effectively source quality leather, buyers should establish a network of reputable suppliers who specialize in automotive upholstery. Conduct thorough research to identify suppliers with a strong track record and industry certifications. Look for suppliers who provide detailed product specifications, including information on leather grades (e.g., full-grain, top-grain), finishes, and durability characteristics. Request samples to assess quality firsthand before making larger purchases. Furthermore, consider leveraging trade shows and industry expos to connect with suppliers and explore a range of products that can meet diverse automotive needs.

Scenario 2: Understanding Leather Specifications for Different Markets

The Problem: Many B2B buyers face confusion regarding the various specifications and terminologies used in the leather industry, which can lead to miscommunication with suppliers and, ultimately, poor purchasing decisions. For instance, terms like “genuine leather” can be misleading, often indicating lower quality than full-grain leather. This confusion is exacerbated when dealing with international suppliers who may have different standards and expectations, complicating the procurement process for buyers in regions like Africa and the Middle East.

The Solution: To navigate this complexity, buyers should invest time in understanding leather specifications and industry standards relevant to their target markets. Enroll in training programs or workshops that focus on automotive leather, or consult industry experts who can provide insights into the differences between leather types and their applications. When communicating with suppliers, be specific about the desired characteristics, such as UV resistance, stain repellency, and breathability. Developing a clear set of criteria for leather selection will ensure that buyers can make informed decisions that align with their customers’ expectations and market demands.

Scenario 3: Managing Inventory and Waste in Leather Procurement

The Problem: B2B buyers often deal with the challenge of managing inventory levels while minimizing waste associated with leather procurement. Because leather is typically sold by square footage and comes in irregular shapes, precise calculations are necessary to avoid over-ordering or under-ordering, which can lead to financial losses. In regions with fluctuating demand, such as the Middle East and South America, maintaining the right stock levels can be particularly daunting.

The Solution: To manage inventory effectively, buyers should implement a robust inventory management system that tracks usage patterns and forecasts future demand based on historical data. Utilize tools that allow for precise calculations of leather requirements based on specific project needs, helping to minimize waste. Additionally, consider establishing relationships with suppliers who can accommodate smaller orders or offer flexible purchasing options, such as half or quarter hides. This approach not only helps in reducing waste but also provides the agility needed to respond to changing market conditions without incurring unnecessary costs.

Strategic Material Selection Guide for leather for auto upholstery

What Are the Key Properties of Full Grain Leather for Auto Upholstery?

Full grain leather is considered the highest quality leather available for automotive applications. It retains the natural grain and imperfections of the hide, contributing to its unique aesthetic. Key properties include excellent durability and resistance to wear, making it suitable for high-traffic areas. It also offers good temperature regulation, ensuring comfort in various climates, which is particularly important for international markets like Saudi Arabia and Brazil.

Pros: Full grain leather is highly durable, ages beautifully, and provides a luxurious feel. Its natural breathability makes it ideal for climates with high temperatures.

Cons: The cost of full grain leather is typically high, which may not align with budget constraints for some buyers. Additionally, its maintenance requires regular conditioning to prevent drying and cracking.

How Does Top Grain Leather Compare for Auto Upholstery?

Top grain leather is slightly less durable than full grain but is still a popular choice for automotive upholstery. It is sanded and treated to remove imperfections, resulting in a more uniform appearance. This leather type also has good resistance to stains and is easier to clean, which is beneficial for vehicle interiors exposed to spills.

Pros: Top grain leather is more affordable than full grain while still offering a high-end look. Its stain resistance and ease of cleaning make it suitable for family vehicles.

Cons: It is less durable than full grain leather and may not age as gracefully. Additionally, it can be more susceptible to scratches and wear over time.

What Are the Benefits of Bonded Leather in Auto Upholstery?

Bonded leather consists of leather scraps and fibers that are bonded together with polyurethane. While it is a more economical option, its properties vary significantly based on the quality of the bonding process. Bonded leather can provide a decent aesthetic for budget-conscious projects.

Pros: The main advantage of bonded leather is its cost-effectiveness, making it an attractive option for budget-sensitive markets. It can mimic the look of genuine leather while being easier to produce.

Cons: Bonded leather lacks the durability and longevity of full or top grain leather. It is more prone to peeling and wear, which can lead to a less appealing appearance over time.

Illustrative image related to leather for auto upholstery

How Does Synthetic Leather Perform in Automotive Applications?

Synthetic leather, often made from polyvinyl chloride (PVC) or polyurethane (PU), is another alternative for automotive upholstery. It offers a wide range of colors and textures, making it a versatile option for various design preferences.

Pros: Synthetic leather is generally more affordable and easier to clean than natural leather. It is also resistant to moisture and stains, making it suitable for regions with high humidity.

Cons: While synthetic leather can mimic the look of real leather, it often lacks the breathability and comfort that natural leather provides. Additionally, it may not hold up as well under extreme temperatures, which could be a concern in hotter climates.

Summary Table of Material Options for Auto Upholstery

| Material | Typical Use Case for leather for auto upholstery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury vehicles, high-end models | Exceptional durability and aesthetics | High cost and requires maintenance | Elevado |

| Top Grain Leather | Mid-range vehicles, family cars | Affordable luxury and stain resistance | Less durable than full grain | Medium |

| Bonded Leather | Budget vehicles, entry-level models | Cost-effective and visually appealing | Prone to wear and peeling | Low |

| Couro sintético | Mass-market vehicles, custom designs | Easy to clean and moisture resistant | Lacks breathability and long-term durability | Low |

This strategic material selection guide provides B2B buyers with essential insights into various leather types for automotive upholstery, helping them make informed purchasing decisions that align with their specific market needs and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for leather for auto upholstery

What Are the Main Stages of Manufacturing Leather for Auto Upholstery?

The manufacturing process of leather for auto upholstery involves several critical stages, each designed to ensure that the final product meets the high standards required for automotive applications. The primary stages are material preparation, forming, assembly, and finishing.

Illustrative image related to leather for auto upholstery

How Is Material Prepared for Leather Production?

The journey begins with the selection of raw hides, typically sourced from cattle. The hides are carefully inspected for quality and defects. Once selected, they undergo several treatments, including soaking, liming, and fleshing, to remove hair and fat. This process is essential for preserving the integrity of the leather and preparing it for tanning.

Tanning is the next pivotal step. There are various tanning methods, such as vegetable tanning, chrome tanning, and synthetic tanning. Chrome tanning is most prevalent in the automotive industry due to its efficiency and the durability it imparts to the leather. The tanning process not only preserves the leather but also enhances its color and texture.

What Techniques Are Used in the Forming and Assembly of Leather?

Once tanned, the leather is cut into specific shapes and sizes based on design specifications. This is often done using advanced cutting technology, including die cutting and laser cutting, to ensure precision and reduce waste.

In the assembly stage, the cut leather pieces are stitched together. High-performance threads and CNC stitching techniques are commonly used to enhance durability and aesthetic appeal. This step is crucial in ensuring that the seams are strong enough to withstand the wear and tear of automotive interiors.

What Finishing Techniques Enhance the Quality of Automotive Leather?

The finishing stage involves applying various coatings and treatments to achieve the desired look and feel. This can include dyeing, embossing, and applying protective finishes that enhance UV resistance and stain repellency. These treatments not only improve the leather’s aesthetic appeal but also contribute to its longevity and maintenance ease.

What Are the International Quality Standards for Leather in Automotive Applications?

Quality assurance in leather manufacturing is vital, particularly for B2B buyers looking to ensure that they are sourcing high-quality materials. Various international standards govern the quality of leather, including ISO 9001, which outlines requirements for a quality management system.

In addition to ISO certifications, automotive-specific standards such as the Automotive Product Quality Planning (APQP) and the ISO/TS 16949 are also relevant. These standards ensure that manufacturers adhere to strict quality control processes throughout production.

How Is Quality Control Implemented During Leather Production?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to monitor the quality of the leather at different stages, including dimensional checks and visual inspections.

- Final Quality Control (FQC): Before shipping, the finished leather undergoes rigorous inspections to verify that it meets all specifications and quality standards.

What Common Testing Methods Are Used to Ensure Leather Quality?

Testing methods for leather include physical tests, such as tensile strength, abrasion resistance, and color fastness. Chemical tests are also performed to check for harmful substances, ensuring compliance with regulations such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe.

B2B buyers should be aware of these testing methods as they provide insight into the durability and safety of the leather products they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should engage in thorough due diligence. This includes:

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. It is advisable to request access to audit reports or certifications from third-party organizations.

- Reports: Buyers should request quality control reports that detail the outcomes of various tests conducted on the leather. This transparency helps in assessing the reliability of the supplier.

- Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices, ensuring that the leather meets the required specifications.

What Nuances Should International B2B Buyers Consider in Quality Control?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate several nuances when assessing quality control. Variations in local regulations, cultural expectations regarding quality, and differences in manufacturing capabilities can all impact the final product.

Illustrative image related to leather for auto upholstery

Understanding the specific compliance requirements for automotive leather in different countries is crucial. For instance, automotive standards in Europe may be more stringent compared to those in South America or Africa. Buyers should familiarize themselves with these differences to ensure that the leather sourced meets both local and international quality standards.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance practices for leather used in auto upholstery is essential for B2B buyers. By understanding the stages of production, quality standards, testing methods, and verification processes, buyers can make informed decisions that align with their quality expectations and market requirements. This proactive approach not only enhances supply chain reliability but also fosters long-term partnerships with reputable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for auto upholstery’

This sourcing guide serves as a practical checklist for B2B buyers looking to procure leather for auto upholstery. Whether you’re in Africa, South America, the Middle East, or Europe, this step-by-step process will help you navigate the complexities of sourcing high-quality leather that meets automotive standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the leather meets your project requirements. Consider factors such as thickness, grain type, and finish. It’s essential to specify whether you need full-grain leather, which offers durability and a luxurious appearance, or top-grain leather, which provides a balance of quality and cost-effectiveness.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the automotive leather market. Utilize industry directories, trade shows, and online platforms to gather a list of candidates. Focus on suppliers known for their quality standards and customer service, as these will significantly impact your purchasing experience.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers hold relevant certifications. Look for compliance with automotive industry standards, such as ISO 9001 or IATF 16949. Certifications indicate a commitment to quality management and can assure you of the leather’s durability and performance in automotive applications.

Step 4: Request Material Samples

Always request material samples before finalizing your order. This step allows you to physically assess the leather’s texture, color, and overall quality. Pay attention to how the leather feels and looks under different lighting conditions, as this can significantly influence the final product’s appearance in vehicles.

Step 5: Understand Pricing Structures

Clarify the pricing structure with potential suppliers, including minimum order quantities and available discounts for bulk purchases. This understanding will help you budget effectively and avoid unexpected costs. Be aware of additional charges for shipping and handling, especially when importing materials from international suppliers.

Illustrative image related to leather for auto upholstery

Step 6: Review Terms and Conditions

Scrutinize the terms and conditions of the purchase agreement. Pay close attention to aspects such as delivery timelines, return policies, and warranties. A clear understanding of these terms will protect your interests and ensure a smooth transaction.

Step 7: Establish a Communication Plan

Finally, establish a communication plan with your chosen supplier. Regular updates and open channels of communication can facilitate problem-solving and ensure that you stay informed about your order status. This proactive approach can lead to a more collaborative relationship and better outcomes for your upholstery projects.

By following this checklist, B2B buyers can navigate the sourcing process for automotive leather with confidence, ensuring they procure materials that meet their specific needs and uphold quality standards.

Comprehensive Cost and Pricing Analysis for leather for auto upholstery Sourcing

What Are the Key Cost Components in Leather for Auto Upholstery Sourcing?

When sourcing leather for auto upholstery, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of raw leather can vary significantly based on quality and type. For instance, full-grain leather, known for its durability and aesthetic appeal, commands a higher price than corrected-grain or synthetic alternatives. Prices typically range from $17 to $34 per square foot, depending on the supplier and material specifications.

-

Labor: Skilled labor is required for cutting, sewing, and finishing the leather upholstery. Labor costs can vary based on the region and the complexity of the work involved. For high-quality finishes, expect labor costs to be a significant part of the overall expenditure.

-

Manufacturing Overhead: This encompasses the costs associated with running the production facility, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Depending on the customization required, tooling costs can be substantial. Custom dies or molds may be necessary for unique designs or specifications, impacting the overall price.

-

Quality Control (QC): Ensuring that the leather meets specific automotive standards requires a robust QC process. This involves testing for durability, colorfastness, and other relevant factors, adding to the overall cost.

-

Logistics: Transporting leather from suppliers to manufacturing facilities or end-users can incur significant expenses, particularly for international shipments. Factors such as shipping method, distance, and customs duties play a vital role in logistics costs.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. This margin can vary based on market conditions, competition, and the supplier’s unique value proposition.

What Influences Pricing for Leather Upholstery Materials?

Several factors influence the pricing of leather for auto upholstery:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms and reduce costs per unit.

-

Specifications and Customization: Customized leather solutions tailored to specific vehicle models or customer preferences can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Leather sourced from reputable suppliers often comes with certifications that guarantee quality, such as UV resistance and durability. These certifications can justify higher prices but also ensure a long-lasting product.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to their quality assurance and service levels.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping, influencing overall costs.

What Tips Can Help B2B Buyers Negotiate Better Prices?

To optimize costs when sourcing leather for auto upholstery, consider the following strategies:

-

Negotiate Volume Discounts: Leverage bulk purchasing to negotiate lower prices. Building long-term relationships with suppliers can also lead to favorable terms over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and potential replacement costs. Investing in higher-quality leather may yield savings in the long run.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. This knowledge can empower buyers during negotiations and help identify the right time to purchase.

-

Explore Alternative Suppliers: While it’s essential to work with reputable suppliers, exploring new suppliers may uncover cost-effective options without compromising quality.

-

Understand International Pricing Nuances: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and tariffs that may impact pricing.

Conclusion

Sourcing leather for auto upholstery involves navigating a complex landscape of costs and pricing influences. By understanding the cost components, pricing influencers, and employing effective negotiation strategies, B2B buyers can make informed decisions that align with their budget and quality requirements. Always consider the total cost of ownership to ensure a sustainable investment in leather upholstery materials.

Alternatives Analysis: Comparing leather for auto upholstery With Other Solutions

Exploring Alternatives to Leather for Auto Upholstery

In the automotive upholstery industry, leather has long been regarded as a premium material due to its durability, aesthetic appeal, and comfort. However, with the rise of alternative materials, buyers are increasingly evaluating options that may offer comparable benefits at a lower cost or with unique features. This section analyzes leather for auto upholstery in comparison to synthetic leather and high-performance textiles, providing insights into their respective advantages and limitations.

| Comparison Aspect | Couro para estofos de automóveis | Couro sintético | High-Performance Textiles |

|---|---|---|---|

| Performance | Excellent durability, natural feel, and breathability | Good durability, less breathable than real leather | Highly durable, water-resistant, and often UV resistant |

| Cost | Higher initial investment | Generally lower cost | Variable, often mid-range |

| Ease of Implementation | Requires skilled labor for installation | Easier to work with, often pre-cut | Specialized installation may be needed |

| Maintenance | Requires regular conditioning to maintain appearance | Easy to clean, resistant to stains | Low maintenance, machine washable options available |

| Best Use Case | Luxury vehicles, custom restorations | Mass-market vehicles, budget options | Performance vehicles, off-road applications |

Understanding Synthetic Leather as an Alternative

Synthetic leather, commonly known as faux leather or vegan leather, is a popular alternative that mimics the appearance and texture of real leather. Made from polyurethane (PU) or polyvinyl chloride (PVC), synthetic leather is generally more affordable and easier to clean, making it a practical choice for mass-market vehicles. However, it lacks the breathability and luxurious feel of genuine leather, which may be a drawback for high-end applications. Additionally, while it is resistant to stains and spills, synthetic leather can be less durable over time, especially in extreme temperatures.

Evaluating High-Performance Textiles for Auto Upholstery

High-performance textiles, such as those made from advanced fibers like Cordura or Dyneema, offer remarkable durability and resistance to wear and tear. These materials are particularly beneficial for performance and off-road vehicles, where exposure to harsh conditions is common. High-performance textiles can also be designed to be water-resistant and UV resistant, providing added protection for automotive interiors. However, they may require specialized installation and can have a higher upfront cost than traditional upholstery materials. While these fabrics excel in performance, they may not provide the same aesthetic appeal as leather or even synthetic alternatives.

Conclusion: Choosing the Right Upholstery Material for Your Needs

When selecting upholstery materials for automotive applications, B2B buyers must consider various factors including performance, cost, maintenance, and intended use. Leather remains the top choice for luxury and custom vehicles due to its timeless appeal and durability. However, synthetic leather and high-performance textiles present viable alternatives for budget-conscious buyers or those seeking specific functional advantages. Ultimately, understanding the unique characteristics of each option will empower buyers to make informed decisions that align with their project requirements and customer expectations.

Essential Technical Properties and Trade Terminology for leather for auto upholstery

What Are the Essential Technical Properties of Leather for Auto Upholstery?

When sourcing leather for auto upholstery, understanding its technical properties is crucial for ensuring quality and longevity. Here are some of the key specifications to consider:

1. Material Grade

Material grade refers to the quality of the leather based on its source and processing. Automotive leather is typically classified into grades such as full-grain, top-grain, and corrected grain. Full-grain leather is the highest quality, retaining the natural grain and characteristics of the hide, making it more durable and luxurious. Understanding material grades helps buyers select the appropriate leather that meets their quality standards and budget.

2. Tolerance and Thickness

Tolerance indicates the acceptable variation in thickness and dimensions of leather hides. This is vital in auto upholstery, where precise measurements are necessary for a perfect fit. Standard thickness for automotive leather ranges from 1.0 to 1.4 mm. A consistent thickness ensures durability and ease of handling during the upholstery process, impacting the final aesthetic and functionality.

3. UV Resistance

UV resistance measures the leather’s ability to withstand sunlight exposure without fading or degrading. This property is essential for automotive applications, as vehicles are often exposed to sunlight. High UV resistance ensures that the leather retains its color and structural integrity over time, thus prolonging its lifespan and maintaining the vehicle’s resale value.

4. Stain Resistance

Stain resistance is a critical property that affects the maintenance and longevity of leather upholstery. Many automotive leathers are treated with protective coatings that repel stains and make cleaning easier. This is particularly important for buyers in regions with harsh climates or those catering to families and commercial fleets where wear and tear is more pronounced.

5. Breathability

Breathability refers to the leather’s ability to allow air circulation, which helps in regulating temperature and moisture. This property is particularly important for comfort in automotive interiors, ensuring that seats remain comfortable over long periods, especially in hot climates. Breathable leather can also reduce the likelihood of mold and mildew, enhancing hygiene.

What Are Common Trade Terms Used in the Leather Upholstery Industry?

Understanding the jargon used in the leather upholstery industry can facilitate smoother transactions and clearer communications between buyers and suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to manufacturers that produce components or products that are used in another company’s end product. In the context of leather upholstery, it indicates that the leather is suitable for use in original vehicle manufacturing. Buyers should prioritize OEM-certified leather to ensure it meets industry standards for quality and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For leather suppliers, MOQs can vary significantly based on the type of leather and the supplier’s policies. Understanding MOQs is crucial for B2B buyers to plan their inventory and budget accordingly, ensuring they meet production needs without excessive surplus.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent by a buyer to suppliers to provide pricing and terms for specific products. This process is essential for establishing competitive pricing and ensuring that buyers receive the best possible deal. Crafting a clear RFQ can lead to better responses from suppliers and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international buyers, as they dictate who is responsible for costs and risks during transportation, impacting overall pricing and logistics strategies.

5. Full Hide vs. Half Hide

These terms refer to the size of the leather hide being purchased. A full hide typically ranges from 40 to 45 square feet, while a half hide is about half that size. Understanding these terms helps buyers accurately assess their needs and avoid over or under-purchasing materials for upholstery projects.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing leather for auto upholstery, ensuring high-quality outcomes that meet both aesthetic and functional requirements.

Illustrative image related to leather for auto upholstery

Navigating Market Dynamics and Sourcing Trends in the leather for auto upholstery Sector

What Are the Current Market Dynamics and Key Trends in the Leather for Auto Upholstery Sector?

The leather for auto upholstery market is witnessing robust growth driven by several global factors. The increasing consumer preference for luxury and comfort in vehicles has led to a surge in demand for high-quality leather upholstery. As the automotive industry continues to evolve with advancements in design and technology, leather remains a preferred choice for enhancing vehicle aesthetics and durability. Key trends include the adoption of innovative manufacturing processes, such as digital printing and laser cutting, which allow for customization and reduced waste, appealing to eco-conscious buyers.

Moreover, the rise of electric vehicles (EVs) has created new opportunities for leather suppliers. With EV manufacturers seeking to differentiate their products, the demand for premium, sustainable materials is on the rise. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note the importance of sourcing from manufacturers who can provide traceable and high-quality materials, as this can significantly impact brand reputation and consumer loyalty.

Emerging technologies such as blockchain are also influencing sourcing trends, providing transparency and authenticity in supply chains. This is particularly relevant in regions where buyers are increasingly scrutinizing the origins of the materials they purchase. Thus, staying abreast of these technological advancements is crucial for B2B buyers in making informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Leather for Auto Upholstery Industry?

Sustainability and ethical sourcing have become paramount in the leather for auto upholstery sector, driven by increasing consumer awareness and regulatory pressures. The environmental impact of leather production, including deforestation and water pollution, is prompting brands to seek sustainable alternatives. B2B buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using vegetable-tanned leather or sourcing hides from certified farms that adhere to ethical animal treatment standards.

Illustrative image related to leather for auto upholstery

Green certifications, such as the Global Organic Textile Standard (GOTS) or Leather Working Group (LWG) certification, are essential indicators of a supplier’s commitment to sustainability. These certifications not only enhance the marketability of products but also reassure consumers of the ethical implications behind their purchases. As buyers from regions like Europe and the Middle East increasingly demand transparency, aligning with suppliers who prioritize sustainability can create a competitive edge.

Furthermore, the trend toward circular economy models is gaining traction, with companies exploring ways to recycle and repurpose leather materials. B2B buyers should consider partnerships with suppliers who are actively engaged in these practices, as this will not only contribute to environmental conservation but also appeal to a growing segment of eco-conscious consumers.

What Is the Historical Context of Leather in Auto Upholstery?

Historically, leather has been a symbol of luxury and quality in automotive interiors, tracing back to the early 20th century when it was predominantly used in high-end vehicles. The craftsmanship involved in leather upholstery offered durability and comfort, setting a standard in the automotive industry. Over the decades, advancements in tanning and finishing techniques have improved the quality and variety of leather available, making it a staple in both luxury and mass-market vehicles.

However, the industry’s evolution has not been without challenges. The rise of synthetic materials in the late 20th century posed significant competition, leading to a decline in leather use in some segments. Nonetheless, the unique qualities of leather, such as its breathability and aesthetic appeal, have allowed it to maintain a strong foothold in the market.

Today, as the focus shifts towards sustainability and ethical sourcing, the leather for auto upholstery sector is once again transforming. This historical context underscores the importance of adaptability and innovation in meeting the changing demands of consumers while upholding the traditional values of quality and craftsmanship that leather represents.

Frequently Asked Questions (FAQs) for B2B Buyers of leather for auto upholstery

-

How do I choose the right leather for automotive upholstery?

Selecting the appropriate leather for automotive upholstery involves considering factors such as durability, color, texture, and ease of maintenance. Full-grain leather is highly recommended for its strength and natural appearance. It’s essential to assess the specific needs of the vehicle, including climate conditions, as some leathers are more resistant to UV damage and staining. Collaborating with a supplier who can provide samples and technical specifications can help ensure you make an informed decision. -

What are the common types of leather used in auto upholstery?

The most commonly used types of leather for auto upholstery include full-grain, top-grain, and corrected grain leathers. Full-grain leather is the highest quality, offering durability and a luxurious finish. Top-grain leather, while slightly less durable, is more affordable and easier to work with. Corrected grain leather is often treated to mask imperfections and is generally the least expensive option. The choice depends on budget, desired aesthetics, and the intended use of the vehicle. -

What is the minimum order quantity (MOQ) for automotive leather?

Minimum order quantities for automotive leather can vary significantly between suppliers, typically ranging from half a hide (approximately 25 square feet) to full hides (40-45 square feet). It’s essential to confirm the MOQ with potential suppliers as this can affect your purchasing strategy and inventory management. Some suppliers may offer flexibility for larger orders or ongoing partnerships, so negotiating terms can be beneficial. -

How do I ensure the quality of leather before purchasing?

To ensure the quality of leather, request samples from potential suppliers before making a bulk purchase. Examine the leather for texture, color consistency, and any natural markings that may affect its appearance. Additionally, inquire about the tanning process and certifications that verify the leather meets automotive-grade standards. Establishing a relationship with reputable suppliers who have a history of quality assurance can also help mitigate risks. -

What payment terms should I expect when sourcing leather internationally?

Payment terms can vary widely based on the supplier and your business relationship. Common options include advance payments, letters of credit, or net terms (e.g., net 30, net 60). It is advisable to clarify these terms upfront to avoid misunderstandings. Additionally, consider the impact of currency fluctuations and potential fees associated with international transactions. Establishing trust with your supplier can also lead to more favorable payment conditions. -

How can I customize leather for specific automotive applications?

Customization options for automotive leather may include color matching, embossing, and specific finishes to enhance durability or aesthetics. When discussing customization, provide detailed specifications to your supplier and request samples to ensure the final product meets your expectations. Many suppliers are equipped to handle custom orders, but lead times may vary, so it’s essential to plan ahead. -

What logistics considerations should I keep in mind when importing leather?

When importing leather, consider factors such as shipping methods, customs regulations, and potential tariffs. Collaborate with logistics providers familiar with international trade to ensure compliance with all regulations. It’s crucial to accurately declare the value and type of leather to avoid delays. Additionally, factor in lead times for production and shipping when planning your inventory to ensure timely delivery to your clients. -

How can I vet suppliers for leather sourcing effectively?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Request references and verify their ability to meet your quality standards and delivery timelines. Conduct direct communications to assess their responsiveness and willingness to collaborate. If possible, visit their facilities or request virtual tours to gain insights into their operations and quality control processes.

Top 7 Leather For Auto Upholstery Manufacturers & Suppliers List

1. Leather Hide Store – Quality Auto Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Quality auto upholstery leather for cars and trucks. Offers many leathers that meet or exceed color fastness standards (UV resistance) for aftermarket auto use. Key product lines include: Essentials Line (durable, soft, supple), Market Street (smooth, buttery feel, rich color), Urban (heavier weight, extra lux, rich grain), Dakota (high performance distressed leathers). Special note: aftermarket a…

2. Relicate – Full Grain Leather Options

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Full Grain Leather options include Solid Color Leather, Nappa Italia Leather, Napali Leather, and various Black Leather types. OEM Auto Leather Colors available for brands like BMW®, Ferrari®, Lamborghini®, Porsche®, Rolls Royce®, and American Cars. Distressed & Heritage Leather types include Legacy Distressed Leather, Heritage Hide Leather, Matte Distressed Leather, Vintage Distressed Leather, an…

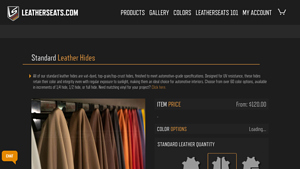

3. LeatherSeats.com – Automotive Leather Hides

Domain: leatherseats.com

Registered: 2000 (25 years)

Introduction: Automotive Leather Hides for interior car upholstery available at LeatherSeats.com. Includes Standard Leather Hides and Ecstasy Leather Hides. Various matching materials and upholstery supplies are offered, including vinyl by the yard, thread by the cone/spool, and acrylic stitch templates. The site provides options for DIY installation tools and accessories, as well as custom upholstery configura…

4. Apex Leather – Auto Upholstery Supplies

Domain: apexleather.com

Registered: 2005 (20 years)

Introduction: Apex Leather offers a variety of auto upholstery supplies including high performance auto leather, square weave carpet, microsuede, and thread. The types of auto leather available are smooth grain leather, distressed leather, natural grain leather, and heavyweight leather. Additional services include CNC panels, CNC perforation, custom color matching, and standard perforation samples. Apex Leather…

5. Hydes Leather – Automotive, Marine & Aviation Leather

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather offers a diverse collection of automotive, marine, and aviation leather, including:

– Automotive Leather: Astro Bomber, Distressed Buffalo, OEM Leather, Pelle Fresco, Prima Nappa, Roser 2 Tone, Royal Steering Wheel Leather, Thema Vintage, Vintage OEM Leather, Vision Woven Leather.

– Alcantara Products: Automotive Alcantara Cover (backed), Panel (unbacked), Multilayer (steering wheel…

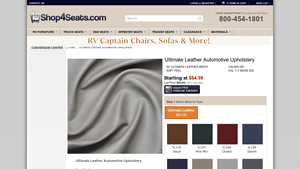

6. Shop4Seats – Ultimate Leather Automotive Upholstery

Domain: shop4seats.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Ultimate Leather Automotive Upholstery”, “Width”: “54 inches”, “Thickness”: “50 ga”, “Weight”: “25 oz per linear yard”, “Abrasion Resistance”: “100,000 DR”, “Flame Resistance”: “CAL 117 SECT E MVSS 302”, “UV Resistance”: “1000 Hours”, “Mildew Resistance”: “Back and face conforms with ASTM G21”, “Material Composition”: “100% premium polyurethane”, “Price”: “$64.99”, “List Price”: …

7. Katzkin – Custom Leather Seat Covers

Domain: katzkin.com

Registered: 1998 (27 years)

Introduction: Katzkin offers custom leather seat covers and interiors for a wide range of vehicles, including popular models like Ford F-150, Jeep Wrangler, Toyota Tacoma, Chevy Silverado, and Ram 1500. They provide over 3,000 interior designs in 120 colors and materials, allowing for extensive customization. Katzkin’s products are not just seat covers; they replace existing cloth upholstery with high-quality l…

Strategic Sourcing Conclusion and Outlook for leather for auto upholstery

In today’s competitive automotive market, strategic sourcing of leather for upholstery is essential for international buyers aiming to enhance product quality and customer satisfaction. High-quality leather not only elevates the aesthetic appeal of vehicles but also offers functional advantages such as allergy resistance and ease of maintenance. As the demand for luxury interiors continues to rise, leveraging diverse sourcing options can facilitate access to premium materials that meet both aesthetic and durability standards.

Moreover, understanding the nuances of leather types—such as full-grain and top-grain—allows buyers to make informed decisions that align with their brand’s positioning. This knowledge is crucial, especially in regions like Africa, South America, the Middle East, and Europe, where market preferences may vary significantly. By building relationships with reliable suppliers, buyers can ensure a consistent supply of high-quality leather tailored to their specific needs.

Looking ahead, the automotive upholstery sector is poised for innovation, driven by consumer demand for sustainability and luxury. International B2B buyers are encouraged to explore partnerships that not only meet immediate sourcing needs but also align with long-term sustainability goals. Embrace the opportunity to enhance your offerings with quality leather that resonates with the evolving expectations of today’s consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.