Introduction: Navigating the Global Market for sueded microfiber fabric

In the competitive landscape of the global textile industry, sourcing high-quality sueded microfiber fabric can pose significant challenges for international B2B buyers. This synthetic material, celebrated for its luxurious feel and durability, is increasingly favored for various applications ranging from upholstery to fashion. However, navigating the complexities of supply chains, quality assurance, and pricing can be daunting, especially for businesses operating across diverse markets in Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Brazil.

This comprehensive guide aims to empower B2B buyers by providing in-depth insights into sueded microfiber fabric, including its types, applications, and the vital factors to consider when vetting suppliers. We will explore the advantages of this versatile material, such as its stain resistance, ease of maintenance, and affordability compared to genuine suede. Additionally, we will address cost considerations and best practices for procurement, ensuring that buyers can make informed purchasing decisions.

By equipping businesses with actionable knowledge and strategies, this guide serves as a valuable resource for navigating the global market for sueded microfiber fabric, helping you identify reliable suppliers and optimize your sourcing processes. Whether you are a manufacturer, retailer, or designer, understanding the nuances of this fabric will enhance your competitive edge and enable you to deliver high-quality products that meet your customers’ demands.

Table Of Contents

- Top 6 Sueded Microfiber Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sueded microfiber fabric

- Understanding sueded microfiber fabric Types and Variations

- Key Industrial Applications of sueded microfiber fabric

- 3 Common User Pain Points for ‘sueded microfiber fabric’ & Their Solutions

- Strategic Material Selection Guide for sueded microfiber fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for sueded microfiber fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sueded microfiber fabric’

- Comprehensive Cost and Pricing Analysis for sueded microfiber fabric Sourcing

- Alternatives Analysis: Comparing sueded microfiber fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for sueded microfiber fabric

- Navigating Market Dynamics and Sourcing Trends in the sueded microfiber fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sueded microfiber fabric

- Strategic Sourcing Conclusion and Outlook for sueded microfiber fabric

- Important Disclaimer & Terms of Use

Understanding sueded microfiber fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MicroSuede | Soft, velvety texture, high durability | Upholstery, clothing, accessories | Pros: Affordable, stain-resistant. Cons: Limited color options compared to genuine suede. |

| Heavy MicroSuede | Thicker, more robust fabric ideal for high-use areas | Furniture, automotive interiors | Pros: Excellent wear resistance, vegan-friendly. Cons: Heavier weight may limit design versatility. |

| Faux Suede | Mimics real suede, often made from polyester | Fashion, home décor, pet products | Pros: Cost-effective, easy maintenance. Cons: May not have the same luxurious feel as real suede. |

| Eco-Friendly MicroSuede | Made from recycled materials, sustainable production | Green furniture, eco-conscious fashion | Pros: Appeals to eco-conscious buyers, durable. Cons: Availability may be limited. |

| Performance MicroSuede | Enhanced stain and water resistance | High-traffic areas, commercial spaces | Pros: Easy to clean, long-lasting. Cons: Higher price point compared to standard options. |

What Are the Key Characteristics of MicroSuede Fabric?

MicroSuede is a synthetic fabric that closely resembles genuine suede but offers distinct advantages. Composed of ultra-fine polyester or nylon fibers, it boasts a soft, velvety texture that is both luxurious and durable. This fabric is particularly popular in upholstery and clothing, making it a versatile choice for B2B applications. Buyers should consider its affordability and ease of cleaning, as it often requires only mild soap and water for maintenance. However, the limited color palette may deter some buyers looking for unique design options.

Illustrative image related to sueded microfiber fabric

How Does Heavy MicroSuede Differ from Standard Options?

Heavy MicroSuede is characterized by its thicker, more robust composition, making it suitable for high-use applications such as furniture and automotive interiors. This fabric can withstand significant wear and tear, making it ideal for environments with heavy traffic or potential spills. B2B buyers should note its vegan-friendly nature, appealing to environmentally conscious markets. However, its heavier weight may limit its use in more delicate applications, which could be a consideration for certain projects.

In What Ways Does Faux Suede Serve B2B Needs?

Faux Suede provides a cost-effective alternative to genuine suede, making it a popular choice in fashion and home décor. This synthetic option is easy to maintain and resistant to stains, which is particularly beneficial for businesses catering to families or high-traffic environments. While it offers a similar aesthetic to real suede, buyers should be aware that it may lack the luxurious feel that some consumers desire. Nonetheless, its affordability and versatility make it a staple in many B2B sectors.

What Are the Benefits of Eco-Friendly MicroSuede?

Eco-Friendly MicroSuede is made from recycled materials, appealing to businesses focused on sustainability. This fabric not only provides durability but also aligns with the growing consumer demand for environmentally responsible products. B2B buyers should consider this option when targeting eco-conscious markets or when seeking to enhance their brand’s sustainability credentials. However, availability can sometimes be an issue, so sourcing may require additional effort.

Illustrative image related to sueded microfiber fabric

Why Choose Performance MicroSuede for High-Traffic Areas?

Performance MicroSuede features enhanced stain and water resistance, making it an excellent choice for high-traffic areas and commercial spaces. This fabric is designed to withstand the rigors of daily use while remaining easy to clean, which is a significant advantage for businesses in hospitality or retail. While it may come with a higher price tag than standard micro suede options, its longevity and low maintenance requirements can justify the investment for many B2B buyers.

Key Industrial Applications of sueded microfiber fabric

| Industry/Sector | Specific Application of sueded microfiber fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhanced durability and ease of maintenance, appealing to consumers seeking luxury at an affordable price | Look for suppliers that offer a wide range of colors and textures to match various design aesthetics. |

| Automotive | Interior car upholstery and trim | Lightweight, stain-resistant fabric that improves the vehicle’s aesthetic appeal and comfort | Ensure compliance with industry regulations regarding fire resistance and durability standards. |

| Fashion and Apparel | Clothing items such as jackets and accessories | Offers a luxurious look and feel while being cost-effective, appealing to eco-conscious consumers | Source from manufacturers that provide vegan options and sustainable production practices. |

| Home Decor | Decorative pillows, cushions, and throws | Versatile and stylish options that enhance home aesthetics while being easy to clean and maintain | Prioritize suppliers with robust quality control processes to ensure consistency in fabric quality. |

| Pet Products | Pet beds and accessories | Soft, durable, and easy-to-clean fabric, catering to pet owners’ desire for comfort and practicality | Seek suppliers that offer hypoallergenic and stain-resistant options to meet pet owners’ needs. |

How is Sueded Microfiber Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, sueded microfiber fabric is extensively used for upholstery on sofas and chairs. Its luxurious appearance mimics genuine suede while offering superior durability and ease of maintenance, making it an attractive option for high-traffic areas. For international buyers from regions like Africa and South America, sourcing this fabric allows them to provide end consumers with affordable yet elegant furniture solutions. It’s essential to partner with suppliers who can offer a diverse palette of colors and textures to cater to varying consumer preferences.

What Role Does Sueded Microfiber Fabric Play in the Automotive Industry?

In the automotive industry, sueded microfiber fabric is utilized for car interiors, including seats and trim. Its lightweight nature and stain-resistant properties not only enhance the vehicle’s aesthetic appeal but also contribute to overall passenger comfort. For businesses in Europe and the Middle East, ensuring compliance with automotive safety standards, such as fire resistance, is crucial when sourcing these materials. Buyers should prioritize suppliers with certifications that guarantee adherence to these industry regulations.

How is Sueded Microfiber Fabric Beneficial in Fashion and Apparel?

Sueded microfiber fabric has found its niche in the fashion and apparel industry, where it is used to create jackets, skirts, and various accessories. Its luxurious feel combined with affordability makes it an appealing choice for eco-conscious consumers looking for vegan alternatives to leather. B2B buyers from regions like Brazil and Saudi Arabia should focus on sourcing from manufacturers committed to sustainable practices, ensuring that their supply chain aligns with growing consumer demand for ethically produced materials.

Illustrative image related to sueded microfiber fabric

What Applications Does Sueded Microfiber Fabric Have in Home Decor?

In the home decor sector, sueded microfiber fabric is a popular choice for decorative pillows, cushions, and throws. Its versatility allows designers to create stylish and comfortable home accents that are easy to clean and maintain, appealing to modern consumers. International buyers should prioritize suppliers with stringent quality control measures to ensure fabric consistency, which is essential for maintaining brand reputation in competitive markets.

How is Sueded Microfiber Fabric Used in Pet Products?

Sueded microfiber fabric is increasingly being used in the pet products industry for items like pet beds and accessories. Its soft texture, durability, and ease of cleaning cater to the needs of pet owners who seek both comfort and practicality for their furry companions. Buyers should look for options that are hypoallergenic and stain-resistant, ensuring that the products meet the specific demands of pet owners across various international markets.

3 Common User Pain Points for ‘sueded microfiber fabric’ & Their Solutions

Scenario 1: Difficulty in Maintaining Sueded Microfiber Fabric in High-Traffic Areas

The Problem: B2B buyers in the hospitality or commercial furniture industries often face challenges when selecting upholstery materials for high-traffic areas. Sueded microfiber fabric, while luxurious and attractive, can be susceptible to staining and wear, particularly in environments where spills and heavy use are common. For instance, hotels and restaurants may find that their upholstered furniture shows signs of wear sooner than expected, leading to increased maintenance costs and diminished aesthetic appeal.

The Solution: To address maintenance challenges, it’s crucial to select high-quality, stain-resistant sueded microfiber fabric designed specifically for durability. Look for fabrics that have undergone treatments to enhance their stain resistance and durability, such as water-repellent finishes or those with high abrasion resistance ratings (like those above 50,000 double rubs). Additionally, establish a regular cleaning and maintenance schedule using appropriate cleaners that are compatible with microfiber. For example, mild soap and water solutions or specific microfiber fabric cleaners can effectively remove stains without damaging the material. Educating staff on quick response techniques to spills can also prevent long-term damage, ensuring the fabric retains its luxurious appearance.

Illustrative image related to sueded microfiber fabric

Scenario 2: Sourcing Quality Sueded Microfiber Fabric in Diverse Markets

The Problem: International buyers, particularly in regions such as Africa and South America, often encounter difficulties when sourcing quality sueded microfiber fabric. These challenges may arise from a lack of local suppliers, inconsistencies in product quality, or issues related to shipping and import regulations. Without reliable sourcing, businesses risk delays in project timelines and increased costs associated with shipping and customs.

The Solution: To effectively source quality sueded microfiber fabric, establish relationships with reputable manufacturers and suppliers who can provide consistent product quality and reliable shipping options. Attend industry trade shows or fabric expos to connect with suppliers who specialize in microfiber materials. Utilize online platforms that cater specifically to B2B transactions, offering detailed product specifications, samples, and customer reviews to inform purchasing decisions. Additionally, consider forming partnerships with local distributors who understand regional market dynamics and can facilitate smoother transactions. Always request samples prior to bulk purchases to assess fabric quality and performance firsthand.

Scenario 3: Ensuring Color Consistency in Bulk Orders of Sueded Microfiber Fabric

The Problem: B2B buyers often struggle with maintaining color consistency when ordering sueded microfiber fabric in bulk. This is particularly problematic for businesses that require matching fabrics across multiple orders, such as interior designers and furniture manufacturers. Variations in dye lots can lead to mismatched products, resulting in dissatisfaction from clients and wasted resources.

Illustrative image related to sueded microfiber fabric

The Solution: To mitigate color consistency issues, buyers should implement a stringent ordering process that includes specifying color codes and requesting detailed swatches before placing large orders. Establish clear communication with suppliers regarding dye lot variations and request guarantees on color matching for subsequent orders. It’s advisable to order all required fabric in one go to minimize discrepancies. Additionally, maintaining a record of previous orders and their corresponding dye lots can help in future sourcing decisions. Consider using digital color matching tools or Pantone references to ensure accuracy in color specifications when communicating with suppliers.

Strategic Material Selection Guide for sueded microfiber fabric

What Are the Key Materials Used in Sueded Microfiber Fabric?

Sueded microfiber fabric is primarily made from synthetic fibers, with polyester and nylon being the most common materials. Each of these materials has unique properties that can significantly influence the performance and application of the fabric in various industries. Below is an analysis of the key materials used in sueded microfiber fabric, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyester Impact the Performance of Sueded Microfiber Fabric?

Key Properties: Polyester is known for its excellent durability and resistance to shrinking and stretching. It can withstand a wide range of temperatures, making it suitable for various environments. Polyester fibers also exhibit good moisture-wicking properties, which can enhance comfort in upholstery applications.

Illustrative image related to sueded microfiber fabric

Pros & Cons: The primary advantage of polyester is its affordability and availability, making it a popular choice for mass production. However, it can be less breathable than natural fibers, which may limit its use in certain applications. Additionally, while polyester is generally durable, it may not perform as well under extreme conditions compared to other materials.

Impact on Application: Polyester-based sueded microfiber is often used in furniture upholstery and automotive interiors due to its durability and ease of maintenance. It can also be treated for stain resistance, making it suitable for high-traffic areas.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for performance testing. In regions like Europe, there is a growing preference for eco-friendly materials, so sourcing recycled polyester may be advantageous.

What Role Does Nylon Play in Sueded Microfiber Fabric?

Key Properties: Nylon is another synthetic fiber that offers high strength and elasticity. It is resistant to abrasion, making it ideal for applications requiring durability. Nylon also has a higher melting point compared to polyester, which can be beneficial in certain manufacturing processes.

Pros & Cons: The key advantage of nylon is its superior strength-to-weight ratio, making it suitable for applications where lightweight materials are essential. However, nylon can be more expensive than polyester, which may deter cost-sensitive buyers. Additionally, it is less resistant to UV light, which can lead to fading over time.

Impact on Application: Nylon-based sueded microfiber is often used in high-performance applications, including outdoor furniture and gear, where durability and resistance to wear are critical. Its elasticity also allows for a snug fit in clothing and accessories.

Considerations for International Buyers: Buyers in regions with high UV exposure, such as the Middle East, should consider the long-term durability of nylon in their applications. Compliance with local regulations regarding synthetic materials is also essential.

How Do Blended Fabrics Enhance Sueded Microfiber Performance?

Key Properties: Blended fabrics, typically combining polyester and nylon, leverage the strengths of both materials. This results in a fabric that is both durable and cost-effective, with improved performance characteristics.

Illustrative image related to sueded microfiber fabric

Pros & Cons: The primary advantage of blended fabrics is their versatility, allowing manufacturers to tailor properties such as softness, durability, and cost. However, the complexity of blending materials can lead to variations in quality, which requires careful quality control during manufacturing.

Impact on Application: Blended sueded microfiber is popular in a range of applications, from upholstery to fashion. The combination of materials allows for innovative designs and enhanced functionality.

Considerations for International Buyers: Buyers should verify the specific blend ratios and their implications on performance. Compliance with international standards for blended fabrics is crucial, particularly in regions with strict textile regulations.

Summary Table of Material Selection for Sueded Microfiber Fabric

| Material | Typical Use Case for sueded microfiber fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstery, automotive interiors | Cost-effective and durable | Less breathable than natural fibers | Low |

| Nylon | Outdoor furniture, high-performance gear | Superior strength and elasticity | More expensive and UV-sensitive | Medium |

| Blended Fabrics | Fashion, upholstery | Versatile with tailored properties | Quality variations due to complexity | Medium |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements.

Illustrative image related to sueded microfiber fabric

In-depth Look: Manufacturing Processes and Quality Assurance for sueded microfiber fabric

What Are the Key Stages in the Manufacturing Process of Sueded Microfiber Fabric?

The manufacturing of sueded microfiber fabric involves several critical stages, each designed to ensure the final product meets the high standards expected in the market.

-

Material Preparation: The process begins with the selection of high-quality synthetic fibers, primarily polyester or nylon. These fibers are processed to achieve the ultra-fine diameter necessary for creating a soft, suede-like texture. The fibers undergo a rigorous cleaning process to remove impurities and enhance their properties, ensuring they are ready for weaving.

-

Forming: Once the fibers are prepared, they are woven together using advanced weaving techniques. The twill weave is common in microfiber production, as it contributes to the fabric’s durability and softness. During this stage, the fibers are interlaced to create a dense, tightly packed structure that mimics the appearance and feel of real suede.

-

Assembly: After weaving, the fabric is cut to the required dimensions. This is typically done with precision cutting machines that ensure uniformity and reduce waste. The cut fabric pieces may be grouped based on color or texture for easier handling during the finishing process.

-

Finishing: The final stage involves several treatments to enhance the fabric’s appearance and performance. This may include dyeing, where environmentally friendly dyes are used to achieve vibrant colors. Additionally, the fabric is brushed to create the characteristic nap associated with suede. Treatments for stain resistance and durability, such as applying a protective coating, are also common. The finishing process ensures that the fabric not only looks good but is also practical for end-users.

How Is Quality Assurance Implemented in the Manufacturing of Sueded Microfiber Fabric?

Quality assurance (QA) is paramount in the production of sueded microfiber fabric to ensure the product meets international standards and customer expectations.

-

International Standards Compliance: Adhering to standards such as ISO 9001 is essential for manufacturers targeting global markets. This standard outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) may be relevant for exports to Europe, ensuring that products meet health and safety regulations.

-

Quality Control Checkpoints: Throughout the manufacturing process, various quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet specified standards. Any defective materials are rejected at this stage.

– In-Process Quality Control (IPQC): During the weaving and finishing processes, regular inspections are conducted to monitor quality. This helps identify and rectify any issues in real-time, ensuring consistency throughout production.

– Final Quality Control (FQC): Once the fabric is completed, a final inspection is performed. This includes checking for defects, color consistency, and adherence to specifications before the product is packaged and shipped.

What Testing Methods Are Commonly Used in the Quality Assurance of Sueded Microfiber Fabric?

To ensure that the fabric meets durability and performance standards, several testing methods are employed:

Illustrative image related to sueded microfiber fabric

-

Abrasion Resistance Testing: This test evaluates the fabric’s durability by subjecting it to repeated friction. The Wyzenbeek method is commonly used, with fabrics expected to withstand a minimum of 30,000 to 50,000 double rubs for upholstery applications.

-

Colorfastness Testing: This assesses how well the fabric retains its color under various conditions, such as exposure to light, washing, and rubbing. This is crucial for maintaining the aesthetic appeal of the fabric over time.

-

Stain Resistance Testing: Fabrics are tested for their ability to resist stains and spills, ensuring they are suitable for high-traffic areas and households with pets or children.

-

Environmental Testing: For international buyers, ensuring that the fabric is free from harmful chemicals and adheres to environmental regulations is vital. Tests for VOC (volatile organic compounds) emissions may be conducted to verify compliance with health and safety standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing sueded microfiber fabric, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, quality control measures, and overall production capabilities. This firsthand observation helps build confidence in the supplier’s commitment to quality.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality assurance reports that outline their testing methods, results, and compliance with international standards. These documents are crucial for verifying that the fabric meets the necessary specifications.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the fabric’s quality before shipment. This is especially important for international transactions where discrepancies can lead to significant financial losses.

-

Certifications and Compliance Documentation: Buyers should request copies of relevant certifications, such as ISO and CE, and any other compliance documentation that proves adherence to industry standards.

What Are the Quality Control Nuances for International Buyers from Africa, South America, the Middle East, and Europe?

International B2B buyers need to be aware of specific nuances in quality control when sourcing sueded microfiber fabric:

-

Understanding Local Regulations: Each region may have unique regulations regarding textile imports, including safety standards and environmental impact. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Considerations: Different markets may have varying preferences for fabric qualities, colors, and patterns. Understanding these cultural preferences can help buyers select the right product for their target market.

-

Logistical Challenges: International shipping can introduce complications in quality assurance. Buyers should ensure that suppliers have robust logistics and handling processes to maintain fabric quality throughout transportation.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and any potential issues that may arise during production. Regular communication and feedback loops can enhance overall quality assurance.

In conclusion, the manufacturing processes and quality assurance measures for sueded microfiber fabric are intricate and crucial for meeting the expectations of international B2B buyers. By understanding these processes and implementing thorough verification methods, buyers can ensure they receive high-quality products that meet their specific needs.

Illustrative image related to sueded microfiber fabric

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sueded microfiber fabric’

Introdução

Sourcing sueded microfiber fabric can be a strategic move for businesses looking to enhance their product offerings with a durable, cost-effective, and versatile material. This guide serves as a practical checklist to streamline your procurement process, ensuring that you make informed decisions while navigating the complexities of international suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your technical requirements for the sueded microfiber fabric. Consider factors such as fiber composition, weight, width, and intended applications (e.g., upholstery, clothing, or accessories).

– Fiber Composition: Ensure the fabric is made from high-quality polyester or nylon for durability.

– Weight and Width: Standard weights range from 250 g/m² to heavier options; choose based on your product’s needs.

Step 2: Research Potential Suppliers

Identifying potential suppliers is critical. Start by compiling a list of manufacturers and distributors known for high-quality microfiber products.

– Industry Reputation: Investigate online reviews, testimonials, and case studies to gauge supplier credibility.

– Geographical Considerations: Prioritize suppliers within your target regions (e.g., Africa, South America) to reduce shipping costs and lead times.

Step 3: Evaluate Supplier Certifications

Verify that your selected suppliers hold relevant certifications that demonstrate compliance with industry standards.

– Quality Certifications: Look for ISO certifications or other quality assurance indicators.

– Sustainability Practices: Assess whether the supplier adheres to eco-friendly practices, which can enhance your brand’s reputation.

Illustrative image related to sueded microfiber fabric

Step 4: Request Fabric Samples

Requesting samples is essential to evaluate the fabric’s quality and performance before placing bulk orders.

– Color and Texture: Ensure the sample accurately represents the desired color and texture, as these can vary significantly between batches.

– Durability Tests: Conduct preliminary tests for abrasion resistance and stain removal to confirm the fabric meets your expectations.

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and evaluated samples, engage in pricing negotiations.

– Bulk Pricing: Inquire about discounts for larger orders or long-term contracts to optimize your budget.

– Payment Terms: Establish clear payment terms that align with your cash flow, including deposits and payment schedules.

Step 6: Confirm Lead Times and Delivery Logistics

Understanding lead times and delivery logistics is crucial for planning your production schedule.

– Production Capacity: Confirm the supplier’s ability to meet your order volume within your required timeframe.

– Shipping Options: Discuss shipping methods, costs, and potential customs issues, especially for international transactions.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure that the received fabric meets your specifications and standards.

– Inspection Procedures: Define inspection criteria for incoming fabric, focusing on color consistency, texture, and any defects.

– Feedback Loop: Create a system for providing feedback to suppliers for continuous improvement in quality and service.

By following this checklist, B2B buyers can effectively navigate the sourcing process for sueded microfiber fabric, ensuring they partner with reliable suppliers while securing high-quality materials for their projects.

Comprehensive Cost and Pricing Analysis for sueded microfiber fabric Sourcing

What Are the Key Cost Components in Sueded Microfiber Fabric Sourcing?

When sourcing sueded microfiber fabric, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The fabric is primarily made from ultra-fine polyester or nylon fibers. Prices can vary based on the quality and type of fibers used. For instance, high-density fibers that provide better durability and stain resistance might be priced higher.

-

Labor: This involves the costs associated with manufacturing the fabric, including weaving, dyeing, and finishing processes. Labor costs can fluctuate based on the country of production, local wage rates, and labor laws.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment depreciation, and facility maintenance. Efficient production processes can help minimize these costs, which ultimately affects the price of the fabric.

-

Tooling: If custom designs or patterns are required, tooling costs for specialized machinery and molds can be significant. Customization can lead to higher initial investments but may provide a competitive edge in unique markets.

-

Quality Control (QC): Ensuring that the fabric meets specified standards involves QC processes that can increase costs. Buyers should consider certifications (e.g., ISO) that ensure product quality and compliance with international standards.

-

Logistics: Shipping costs depend on the origin and destination of the fabric, shipping method, and current fuel prices. Incoterms will also influence who bears these costs and the risk associated with transport.

-

Margin: Suppliers typically mark up the base costs to ensure profitability. This margin can vary widely based on market demand, competition, and supplier reputation.

How Do Price Influencers Impact Sueded Microfiber Fabric Costs?

Several factors can influence the pricing of sueded microfiber fabric:

-

Volume/MOQ: Suppliers often provide discounts for bulk orders. Minimum Order Quantities (MOQ) can significantly affect unit prices, making it essential for buyers to assess their needs against these requirements.

-

Specifications and Customization: Custom colors, patterns, or finishes may increase costs. Buyers should weigh the benefits of customization against the additional expenses it incurs.

-

Material Quality and Certifications: Fabrics that boast higher quality or specific certifications (like eco-friendliness) can command higher prices. Buyers should verify the certifications to ensure they align with their brand values and market demands.

-

Supplier Factors: Supplier reliability, reputation, and production capabilities can affect pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can influence total landed costs. Understanding these terms helps buyers manage risks and costs associated with shipping and customs.

What Are Essential Buyer Tips for Cost-Efficiency in Sueded Microfiber Fabric Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some strategic tips to enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules with suppliers. Establishing a good rapport can lead to better deals, especially for repeat orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost, including shipping, duties, and potential waste. This holistic view helps in making informed decisions.

-

Understand Pricing Nuances for International Sourcing: Be aware of currency fluctuations, tariffs, and trade agreements that may impact costs. This knowledge is crucial for budgeting and financial planning.

-

Request Samples: Before making large purchases, request samples to evaluate quality. This step can prevent costly mistakes associated with bulk orders of subpar fabric.

-

Stay Informed on Market Trends: Market conditions can shift rapidly, influencing prices. Keeping abreast of trends in the fabric market can help buyers time their purchases to achieve the best prices.

Conclusion

Navigating the cost and pricing landscape for sueded microfiber fabric sourcing requires a comprehensive understanding of various cost components and price influencers. By leveraging the provided insights and adopting strategic purchasing practices, B2B buyers can optimize their sourcing strategies and enhance their competitive edge in the market. Always remember that indicative prices may vary based on market conditions and supplier negotiations, so thorough research and planning are essential.

Illustrative image related to sueded microfiber fabric

Alternatives Analysis: Comparing sueded microfiber fabric With Other Solutions

When selecting materials for upholstery and other applications, it’s essential to consider the range of available options. Sueded microfiber fabric has gained popularity due to its unique blend of durability, aesthetic appeal, and ease of maintenance. However, understanding how it compares to other viable alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Sueded Microfiber Fabric | Couro sintético | Natural Suede |

|---|---|---|---|

| Performance | Highly durable, stain-resistant, and soft | Durable but can crack or peel over time | Luxurious feel but less durable |

| Cost | Affordable; typically lower than natural suede | Mid-range pricing; more expensive than microfiber | Higher cost due to sourcing and processing |

| Ease of Implementation | Easy to cut and sew; available by the yard | Requires specialized tools for installation | Requires careful handling and can be challenging to work with |

| Maintenance | Easy to clean; generally machine washable | Requires special cleaners; may be sensitive to heat | Needs regular conditioning and is prone to stains |

| Best Use Case | High-traffic areas, pet-friendly environments | Fashion items, furniture accents | Luxury items, bespoke upholstery |

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather, a synthetic alternative to genuine leather, offers a stylish look with a range of colors and finishes. Its durability makes it suitable for furniture and clothing, while its affordability appeals to budget-conscious buyers. However, faux leather can suffer from cracking and peeling, particularly in high-use environments, and may require special care to maintain its appearance. For applications where style is paramount but budget constraints exist, faux leather can be a good compromise.

How Does Natural Suede Compare to Sueded Microfiber Fabric?

Natural suede is renowned for its luxurious texture and aesthetic appeal, making it a popular choice for high-end upholstery and fashion items. However, it comes with a significantly higher price point and requires meticulous care to preserve its quality. Natural suede is susceptible to staining and water damage, making it less suitable for high-traffic or family environments. While it provides an unmatched look and feel, buyers must weigh the cost and maintenance requirements against their project needs.

Conclusion: How Should B2B Buyers Choose the Right Fabric Solution?

Selecting the right fabric solution hinges on understanding the specific requirements of the project. Sueded microfiber fabric stands out for its affordability, ease of maintenance, and durability, making it ideal for high-traffic areas or environments where pets and children are present. In contrast, faux leather and natural suede cater to different needs, with faux leather offering a stylish yet budget-friendly option, while natural suede provides a premium feel at a higher cost. By assessing the intended use, budget constraints, and maintenance capabilities, B2B buyers can make a well-informed decision that best aligns with their operational goals.

Essential Technical Properties and Trade Terminology for sueded microfiber fabric

What Are the Key Technical Properties of Sueded Microfiber Fabric?

Understanding the technical properties of sueded microfiber fabric is crucial for B2B buyers, especially when making decisions on material selection for various applications. Here are the essential specifications to consider:

Illustrative image related to sueded microfiber fabric

-

Material Composition

Sueded microfiber is typically made from 100% polyester or nylon fibers. This synthetic composition not only replicates the luxurious feel of genuine suede but also enhances durability and stain resistance. For buyers, this means selecting a fabric that offers a long lifespan and low maintenance, making it ideal for high-traffic areas or products exposed to spills. -

Weight (GSM)

The weight of microfiber fabric is often measured in grams per square meter (GSM). Common weights for sueded microfiber range from 200 to 300 GSM. A heavier fabric generally indicates greater durability and resistance to wear, which is particularly important for upholstery and furniture applications. Buyers should consider the intended use to ensure they select an appropriate weight that meets their project requirements. -

Abrasion Resistance

Abrasion resistance is a critical property measured using the Wyzenbeek method, which indicates how well the fabric withstands wear and tear. A high score (e.g., 50,000 double rubs) signifies excellent durability. This is vital for B2B buyers in industries like hospitality and automotive, where fabrics must endure rigorous daily use without significant degradation. -

Cleaning Codes

Understanding cleaning codes is essential for maintenance and longevity. Most sueded microfiber fabrics are categorized with codes such as “W” (water-based cleaning) or “S” (solvent-based cleaning). This information guides buyers on how to maintain the fabric properly, ensuring it remains aesthetically pleasing and functional over time, which is particularly important for end-user satisfaction. -

Width and Pattern Repeat

Sueded microfiber is typically available in widths of 58-60 inches, with specific designs that may have pattern repeats. Knowing the width helps buyers calculate the amount of fabric needed for their projects, minimizing waste and ensuring cost efficiency. This is especially important for large-scale applications like upholstery and drapery.

What Are Common Trade Terms Used in the Sueded Microfiber Fabric Industry?

Familiarizing yourself with industry jargon is essential for smooth transactions and negotiations. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are used in another company’s end products. In the context of sueded microfiber, an OEM might provide fabric to furniture manufacturers who then incorporate it into their products. Understanding OEM relationships can aid buyers in sourcing quality materials. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest order quantity that a supplier is willing to accept. For sueded microfiber, this could range from a few yards to thousands, depending on the supplier. Buyers should be aware of MOQs to plan their purchases effectively and manage inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific quantities of fabric. This is a critical step in the procurement process, allowing buyers to compare options and negotiate better deals based on their needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, such as shipping costs, insurance, and risk management. Familiarity with these terms helps buyers understand their obligations and negotiate better shipping arrangements. -

Dye Lot

A dye lot refers to a batch of fabric dyed together, which can result in slight color variations. This is significant for buyers, as reordering fabric from a different dye lot may not match the original order, potentially affecting the final product’s aesthetics.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing sueded microfiber fabric, ensuring they select the right materials for their specific applications while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the sueded microfiber fabric Sector

What Are the Current Market Dynamics and Key Trends in the Sueded Microfiber Fabric Sector?

The global sueded microfiber fabric market is witnessing significant growth, driven by rising consumer demand for affordable, durable, and easy-to-maintain materials. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Brazil) explore sourcing options, they are increasingly attracted to the versatility and aesthetic appeal of microsuede. This fabric’s ability to mimic the luxurious feel of genuine suede while offering superior durability and stain resistance makes it a preferred choice for upholstery, fashion, and accessories.

Current trends indicate a shift towards more sustainable practices, with manufacturers focusing on eco-friendly production methods. Innovations in textile technology are enabling the creation of microsuede made from recycled materials, appealing to environmentally conscious buyers. Furthermore, the rise of e-commerce platforms is transforming how businesses source fabrics, allowing buyers to compare prices, quality, and availability more efficiently. This trend is particularly beneficial for international buyers who can access a broader range of suppliers without geographical constraints.

In terms of market dynamics, fluctuating raw material prices and global supply chain disruptions continue to pose challenges. Buyers must remain vigilant about sourcing strategies, considering factors such as supplier reliability, lead times, and quality assurance processes. As the demand for microsuede fabric expands across multiple applications, from home décor to fashion, B2B buyers are advised to build strong relationships with suppliers who can provide consistent quality and timely delivery.

Illustrative image related to sueded microfiber fabric

How Can Sustainability and Ethical Sourcing Impact the Sueded Microfiber Fabric Market?

Sustainability has become a pivotal focus in the textile industry, and the sueded microfiber fabric sector is no exception. The environmental impact of fabric production, particularly in terms of water usage and chemical waste, is prompting businesses to seek sustainable sourcing options. B2B buyers are increasingly prioritizing suppliers that implement eco-friendly practices, such as using low-impact dyes, minimizing waste during production, and utilizing recycled materials.

Ethical sourcing is also gaining traction, with buyers demanding transparency in the supply chain. This includes ensuring fair labor practices and safe working conditions for those involved in the manufacturing process. By selecting suppliers who adhere to ethical standards, businesses not only enhance their brand reputation but also contribute to a more responsible industry.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can provide assurance that the materials are produced sustainably and ethically. Buyers looking to differentiate their offerings in a competitive market should consider sourcing microsuede fabrics that carry these certifications. This not only aligns with consumer preferences for sustainable products but also helps companies mitigate risks associated with unethical practices and regulatory compliance.

What Is the Evolution of Sueded Microfiber Fabric in the B2B Landscape?

The evolution of sueded microfiber fabric has been shaped by advancements in textile technology and shifting consumer preferences. Originally developed as a cost-effective alternative to genuine suede, microsuede gained popularity in the 1990s due to its luxurious appearance and ease of care. Over the years, manufacturers have refined the production process, resulting in a fabric that is not only durable but also highly versatile.

Today, microsuede is widely used across various sectors, from upholstery in residential and commercial spaces to fashion and accessories. The ongoing innovation in fabric blends and finishes continues to expand the possibilities for B2B applications. As businesses increasingly recognize the value of microsuede, its role in the global textile market is set to grow, driven by consumer demand for both quality and sustainability.

In conclusion, understanding the dynamics of the sueded microfiber fabric market, the importance of sustainable practices, and the fabric’s historical context can empower B2B buyers to make informed sourcing decisions that align with both their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of sueded microfiber fabric

-

How do I determine the right quality of sueded microfiber fabric for my project?

To choose the appropriate quality of sueded microfiber fabric, assess its weight, durability, and texture. Fabrics with a higher weight (measured in grams per square meter) typically offer increased durability, making them suitable for high-traffic applications like upholstery. Additionally, consider the fabric’s abrasion resistance, which is often tested by the Wyzenbeek method. Request samples from suppliers to evaluate the hand feel and visual appeal, ensuring it aligns with your project requirements. -

What is the best way to source sueded microfiber fabric suppliers internationally?

To source sueded microfiber fabric suppliers internationally, start by researching reputable fabric manufacturers and distributors through industry directories and trade shows. Utilize online platforms such as Alibaba or Global Sources, filtering results based on ratings and reviews. Verify suppliers by checking their certifications, production capacity, and previous client testimonials. Establish direct communication to discuss your specific needs and request samples, facilitating a more informed decision. -

What customization options are typically available for sueded microfiber fabric?

Many suppliers offer customization options for sueded microfiber fabric, including bespoke colors, patterns, and finishes. You may also request specific widths or weights tailored to your applications. Ensure to discuss minimum order quantities (MOQs) for custom designs, as these can vary significantly between suppliers. Additionally, inquire about lead times for production, as customized orders may require longer processing periods. -

What should I consider regarding minimum order quantities (MOQs) when sourcing?

When sourcing sueded microfiber fabric, be mindful of the supplier’s minimum order quantities (MOQs), as they can affect your purchasing strategy. MOQs can vary based on fabric type, color, and customization. Assess your project’s scale and budget to determine if the MOQ aligns with your needs. If MOQs are too high, consider negotiating with the supplier or exploring alternative suppliers that may offer lower MOQs, especially for smaller-scale projects. -

What payment terms are commonly offered by fabric suppliers?

Payment terms can vary widely among fabric suppliers. Common options include advance payment, partial payments (e.g., 30% deposit with the balance upon shipment), or net terms (e.g., net 30 or net 60 days). Always clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit. Establishing favorable payment terms can enhance cash flow management, so negotiate terms that work best for your business model. -

How can I ensure quality assurance (QA) for my sueded microfiber fabric order?

To ensure quality assurance for your order, establish clear quality specifications and communicate them to your supplier. Request pre-production samples to evaluate color, texture, and performance. Additionally, consider implementing third-party inspections during production or before shipment to verify compliance with your standards. This proactive approach minimizes the risk of receiving subpar materials and enhances overall project success. -

What logistics considerations should I keep in mind when importing fabric?

Logistics play a crucial role in the importation of sueded microfiber fabric. Be aware of shipping methods (air vs. sea), as they significantly impact costs and delivery times. Understand customs regulations and duties applicable to your region, particularly for imports from countries in Africa, South America, the Middle East, and Europe. Collaborate with a reliable freight forwarder who can navigate these complexities and ensure timely delivery while optimizing costs. -

What are the common applications for sueded microfiber fabric in various industries?

Sueded microfiber fabric is versatile and widely used across multiple industries. It is ideal for upholstery in furniture manufacturing, decorative pillows, and cushions. Additionally, it serves well in the fashion industry for clothing, accessories, and footwear. Its durability and easy maintenance make it suitable for automotive interiors and home décor items. Understanding these applications can help you target specific markets and maximize the fabric’s potential in your product offerings.

Top 6 Sueded Microfiber Fabric Manufacturers & Suppliers List

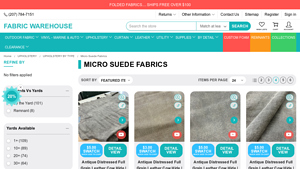

1. Fabric Warehouse – MicroSuede Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: MicroSuede Fabrics for Upholstery, available in various colors and weights. Options include: 1+ yards (109), 10+ yards (89), 20+ yards (74), 30+ yards (64). Colors include Beige, Black, Blue, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver, Tan. Fabric weights range from Extra Heavy (16), Heavy (35), Lightweight (5), Medium/Heavy (2), Medium (53). Designs include Solid Co…

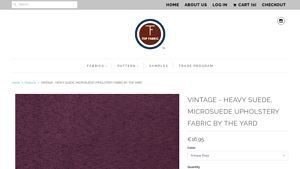

2. Top Fabric – Vintage Heavy Suede Upholstery Fabric

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: Product Name: Vintage – Heavy Suede, Microsuede Upholstery Fabric by the Yard

Price: $18.99 (originally $29.99)

Color Options: Antique Rose, Black, Buck Skin, Camel, Canary, Caramel, Celery, Charcoal, Chinese Red, Chocolate, Cinnabar, Cloud, Copper, Cream, Denim Blue, Earth, Espresso, Fawn, Gold, Green Bay, Herb, Hunter Green, Jalapeno, Khaki, Kiwi, Leather Brown, Lichen, Light Brown, Lipstick, Mi…

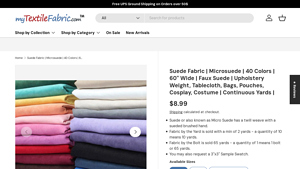

3. My Textile Fabric – Suede & Microsuede Fabrics

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: Suede Fabric | Microsuede | 40 Colors | 60″ Wide | Faux Suede | Upholstery Weight, Tablecloth, Bags, Pouches, Cosplay, Costume | Continuous Yards | Price: $8.99 per yard | Minimum order: 2 yards | Fabric by the Bolt: 65 yards | Available Sizes: Yards, Bolts, 3″x3″ Sample Swatch | Fabric Weight: Approximately 225 grams per square meter | Fabric Content: 100% Polyester | Fabric Width: 58/60″ | Clean…

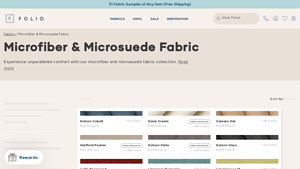

4. Folio Fabrics – Dotson Cobalt

Domain: foliofabrics.com

Registered: 2013 (12 years)

Introduction: Microfiber & Microsuede Fabric Collection: Ideal for upholstery, drapery, and decorative accents. Features a soft, luxurious feel with durability and easy care. Plush textures create an inviting ambiance. Key products include: 1. Dotson Cobalt – $40/yard 2. Davis Cream – $44/yard 3. Camaro Oat – $38/yard 4. Hartford Pewter – $46/yard 5. Dotson Slate – $40/yard 6. Dotson Onyx – $40/yard 7. Lydia Ro…

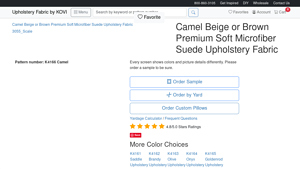

5. Kovi Fabrics – K4166 Camel Microsuede

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: {“Pattern number”: “K4166 Camel”, “Recommended use”: “Upholstery, Automotive, Contract, Home”, “Warranty”: “Limited lifetime warranty”, “Minimum order”: “1 yard”, “Collection”: “Microsuede, Ultimate Suede V”, “Color”: “Brown”, “Type”: “Fade Resistant, Performance Grade, Pet Friendly, Stain Resistant”, “Pattern”: “Plain & Solid”, “Material Contents”: “100% Woven Polyester”, “Cleaning”: “Solvent Bas…

6. Big Z Fabric – Microfiber Suede vs. Real Suede

Domain: blog.bigzfabric.com

Registered: 2010 (15 years)

Introduction: Microfiber Suede: Crafted from synthetic fibers like polyester or nylon; more affordable; durable and resistant to wear; easy to clean and maintain; better water resistance; hypoallergenic. Real Suede Fabric: Derived from the inner layer of animal hides (cows, sheep, goats); luxurious appearance; more expensive; durable but requires careful maintenance; sensitive to water; develops a desirable agi…

Strategic Sourcing Conclusion and Outlook for sueded microfiber fabric

In conclusion, the strategic sourcing of sueded microfiber fabric offers a multitude of advantages for B2B buyers across diverse international markets. This innovative fabric combines the luxurious appearance of genuine suede with enhanced durability, affordability, and ease of maintenance, making it an ideal choice for various applications, from upholstery to fashion. The ability to purchase fabric by the yard allows for flexibility in project planning, minimizing waste and optimizing inventory management.

As global demand for sustainable and practical materials rises, sueded microfiber fabric stands out as a vegan alternative that meets both aesthetic and functional needs. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider leveraging their purchasing power to establish long-term relationships with reliable suppliers who can provide high-quality products at competitive prices.

Looking ahead, the market for sueded microfiber fabric is poised for growth, driven by evolving consumer preferences and increased applications in various industries. B2B buyers are encouraged to engage with suppliers, explore product variations, and remain agile in their sourcing strategies to capitalize on emerging trends. Seize the opportunity to elevate your offerings with sueded microfiber fabric and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.